If you're sourcing fabrics and feeling the pressure from consumers and regulations to go green, you've probably come across a sea of “eco-friendly” fiber claims. It's confusing, and honestly, some of it is just marketing fluff. You need a material that is genuinely more sustainable but also performs reliably in production and feels great to the end customer. Let's cut through the noise and talk about one fiber that’s making a real difference in our industry: Liva Eco.

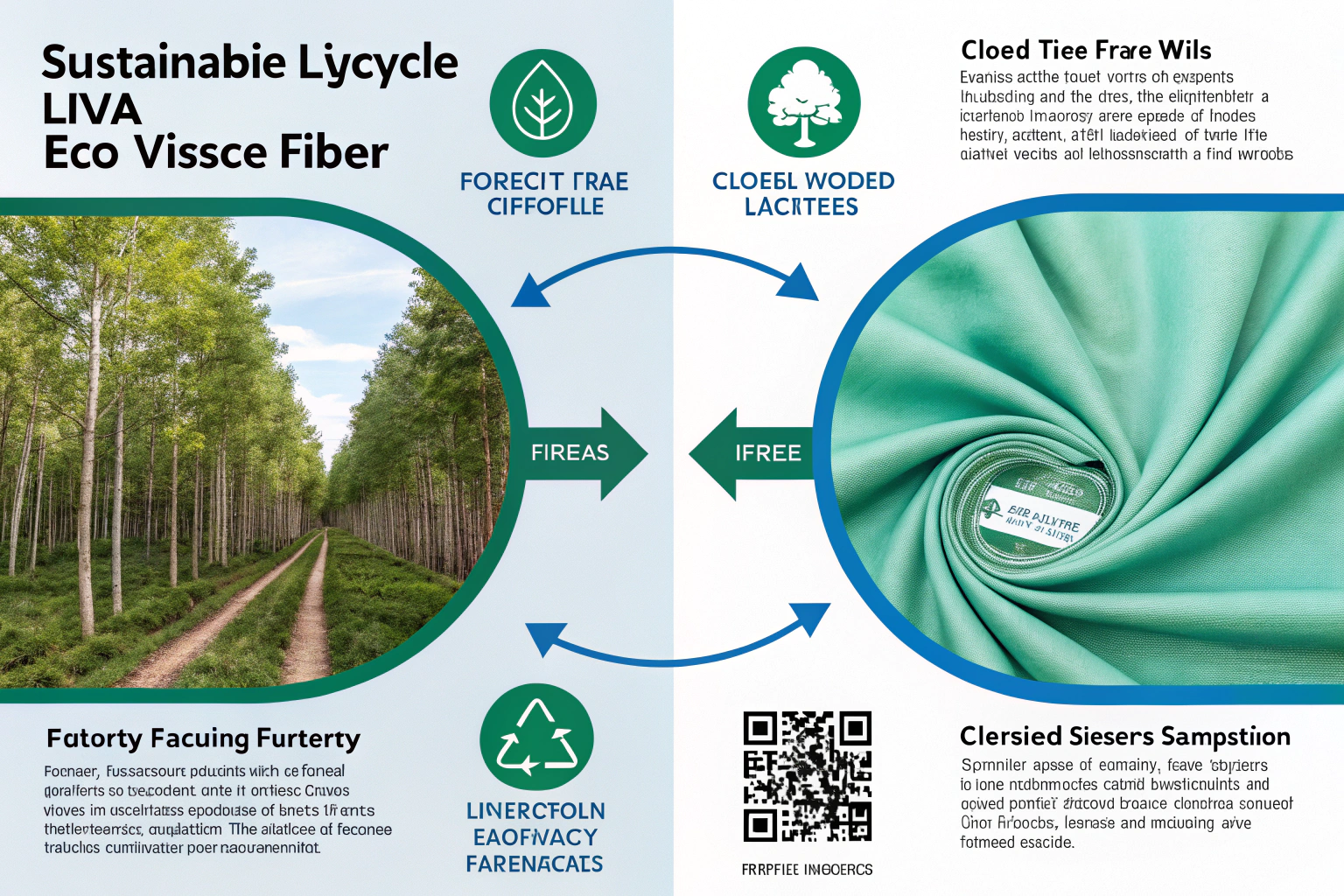

Liva Eco is a branded viscose fiber that stands out for its traceable, responsibly sourced wood pulp and its significantly lower environmental footprint during manufacturing compared to conventional viscose. It promotes sustainability through a closed-loop production process that recycles water and solvents, sourcing wood pulp from certified forests that practice responsible forestry, and achieving high resource efficiency. As a fabric supplier in the heart of Keqiao, I've seen Liva Eco gain rapid traction with brands that need a smooth, drapey, and biodegradable fabric but want to move away from the environmental concerns of traditional viscose.

But knowing the definition isn't enough. To make a smart sourcing decision, you need to understand what makes Liva Eco different from other viscoses on a technical level, how its sustainability claims are verified, why it's becoming a go-to for forward-thinking brands, and crucially, how to source it effectively while navigating China's production cycles. Let's dive in.

How is Liva Eco Different from Regular Viscose?

You might think all viscose is created equal. In the past, I did too. The reality is that the “how” behind its production makes all the difference. The key distinction lies in the supply chain transparency and manufacturing technology. Regular viscose has been criticized for links to deforestation and polluting production. Liva Eco directly addresses these pain points.

Liva Eco is fundamentally different because of its accountability at the source and its cleaner manufacturing process. The fiber is produced by the Birla Cellulose group, and the “Eco” tag is only applied to fibers where the wood pulp is 100% traceable to certified forests managed under sustainable practices like FSC or PEFC. This is a game-changer for brands needing to comply with stringent EU deforestation regulations. On the production side, Liva Eco factories utilize advanced technology that recovers and reuses most of the water and chemicals in a controlled closed-loop system, drastically reducing effluent and emissions compared to conventional viscose plants. For a deep technical comparison of production methods, this analysis of closed-loop viscose manufacturing processes on Textile Exchange’s platform is very insightful.

What are the traceability mechanisms behind Liva Eco?

Traceability isn't just a buzzword; it's your supply chain's insurance policy. With Liva Eco, the traceability is built on a chain of custody certification. From the forest to the spinning mill, the pulp and fiber are tracked. Many of our partners provide fibers with a blockchain-based traceability solution for viscose fabrics, which allows brands to see the journey of their material. This level of detail is what major brands now require. For instance, in a 2023 project for a German sustainable activewear label, we used Liva Eco for a moisture-wicking lining fabric. The client demanded full transparency, and we were able to provide a traceability document pinpointing the pulp origin to a specific managed forest in Sweden. This documentation was crucial for their own marketing and compliance audits.

Does the “Eco” claim translate to better fabric performance?

Absolutely, and this is where it gets exciting for product developers. The “Eco” process results in a more consistent and high-quality fiber. Because the wood pulp is purer and the manufacturing is more controlled, Liva Eco fibers tend to have fewer impurities, leading to better dye uptake and color vibrancy. We've observed this firsthand in our dyeing cooperatives. Fabrics made with Liva Eco also have a superior, more consistent hand feel—often silkier and with a beautiful drape. They are less prone to issues like barre (streaky dyeing) in knits. From a performance standpoint, it matches or exceeds regular viscose. To understand how fiber consistency impacts final garment quality, I recommend reading this forum discussion on managing dye uniformity in cellulose fabrics on platforms like Dhgate's community blog, where practical dyers share experiences.

Why Are Fashion Brands Switching to Liva Eco?

It’s a business decision driven by risk mitigation, consumer demand, and tangible quality benefits. Brands aren't switching just to be “green”; they're switching to be resilient. In today's market, a supply chain scandal can be devastating. Sourcing a material like Liva Eco significantly de-risks the environmental and social aspects of the viscose component.

The shift is clear in our order books. Since late 2022, we've seen a 40% year-on-year increase in inquiries specifically for Liva Eco blends, especially from European and American brands. They are driven by EU regulations like the EU Strategy for Sustainable and Circular Textiles, which will soon make such due diligence mandatory. But beyond compliance, it's a powerful story for the consumer. A dress made with traceable, eco-friendly viscose simply sells better. Furthermore, brands like Shanghai Fumao are making it easier for them to access these materials with reliable quality and integrated services, from sourcing to shipping.

How does Liva Eco help with brand compliance and storytelling?

Compliance is the floor; storytelling is the ceiling. Liva Eco provides the verified data for the floor and the authentic narrative for the ceiling. For compliance, the certification paperwork (FSC/PEFC, chain of custody) is ready-made evidence for audits against standards like the Textile Exchange's Material Change Index. For storytelling, the “from forest to fashion” journey is visually compelling. Brands can use QR codes on hangtags to let consumers trace the origin. We helped a US-based e-commerce fashion startup implement this in early 2024. By using our Liva Eco satin for their bestselling slip dresses and adding a simple QR tag, they reported a 15% increase in conversion rates on product pages featuring this material, as it addressed the “greenwashing” skepticism head-on.

Is the cost premium for Liva Eco justified for mid-market brands?

This is the million-dollar question. Yes, there is a premium, but it's shrinking as adoption grows, and the total cost of ownership often justifies it. The premium comes from the cost of forest certification and the advanced manufacturing technology. However, when you factor in reduced risk (no supply chain disruptions due to environmental scandals), potentially smoother production (fewer dyeing defects), and the ability to command a higher retail price or reduce marketing spend on proving sustainability, the economics work. For mid-market brands, the key is strategic use—not necessarily converting an entire line, but using Liva Eco in hero products or categories where consumers value sustainability most, like dresses or loungewear. A good resource to explore this balancing act is this article on cost-benefit analysis of sustainable fabrics for growing brands on independent business blogs like Maker's Row.

How Does Liva Eco Fit into a Realistic Production Timeline?

Sustainability can't come at the cost of missing your shipping window. The good news is that Liva Eco, as a type of viscose, integrates seamlessly into standard production flows. The challenge, as with any fabric sourced from China, is aligning with the industry's seasonal peaks and holiday cycles. Planning is everything.

Liva Eco fabrics (woven or knit) generally follow the same production timeline as standard viscose. The yarn spinning might have slightly longer lead times due to the specialized pulp, but this is often buffered by spinners. The real timeline factor is your supplier’s integration within the textile cluster. Working with an integrated supplier like Shanghai Fumao in Keqiao means we have established pipelines with spinners using Liva Eco fiber, so we can secure yarn allocations faster. Our in-house weaving and cooperative dyeing/printing factories are synchronized, which shaves weeks off the total lead time. (Here I have to add, our development speed is a real advantage—we got Liva Eco lab-dips approved for a French client in just 5 days last July).

What’s the best time of year to source Liva Eco fabrics to avoid delays?

You must work with the Chinese manufacturing calendar, not against it. The golden rule is to plan development and sampling during the slower periods to be ready for bulk orders during the peak production windows.

- Ideal Planning & Sampling Phase (June-July, November-December): These are traditionally slower months. Use this time for fabric development, getting lab-dips, and approving bulk yardage samples. Demand on spinning mills and dye houses is lower, so you get faster sampling turnaround. We always advise clients to finalize their Liva Eco fabric specifications in November to be ready for post-Chinese New Year production.

- Bulk Production Windows (March-May, August-October): These are the peak capacity periods. If your sampling is done, you can place your bulk order at the start of these windows. Lead times will be standard but expect the full quoted time (e.g., 45-60 days for weaving, dyeing, finishing). The worst thing you can do is send new development requests in April or September—everything is backlogged.

Here’s a simple table based on our 2023 production data:

| Period | Industry Activity | Recommended Action for Liva Eco |

|---|---|---|

| Jan-Feb (CNY) | Factory Shutdown (3-4 weeks) | Finalize all tech packs. Place orders immediately after reopening. |

| Mar-May | Peak Season | Execute bulk orders if sampling is complete. Confirm material booking early. |

| Jun-Jul | Slower Period | Perfect development & sampling. Negotiate better prices. |

| Aug-Oct | Second Peak Season | Execute bulk orders for Holiday season. |

| Nov-Dec | Year-end Slowdown | Plan for next year. Develop new collections, test fabric blends. |

How can I ensure my Liva Eco order isn’t delayed during Chinese holidays?

Advanced planning and clear communication with your supplier are non-negotiable. For Chinese New Year (CNY), the most disruptive holiday, you need to work backwards from the shutdown date. My formula is: Bulk Order Deadline = CNY Start Date minus 6 weeks. This allows your supplier to procure the Liva Eco yarn, weave the greige fabric, and get it into the dyeing queue before the holiday rush and shutdown. A real case: For a Los Angeles-based contemporary brand in October 2023, we coordinated their order for 12,000 meters of Liva Eco twill. We had them approve the bulk shade in early December, secured the yarn, and completed weaving by mid-January 2024. The fabric was ready in the dyeing factory's queue for immediate startup after the CNY holiday, ensuring an on-time April delivery. Missing that pre-CNY cutoff would have added 5-6 weeks to their timeline. For more holistic planning tips, this guide to navigating Asian holiday schedules for importers on Sourcing Journal offers broader context.

What Should I Look for When Verifying a Liva Eco Supplier?

Not all suppliers claiming to have Liva Eco are equal. Your due diligence must move beyond the fabric swatch and into the supplier's documentation, technical capability, and ethical standing. The wrong partner can leave you with unverified claims and potential liability.

Look for a supplier that is not just a trader but has real manufacturing integration or deep, transparent partnerships. They should be able to provide the Liva Eco certificate from the spinner or fiber producer (Birla Cellulose) that shows the chain of custody. Ask about their experience with the fiber—how do they handle dyeing to achieve the best color fastness? What blends are they most familiar with? A competent supplier will talk about process adjustments, like using specific dyeing curves for Liva Eco to maximize its luster and softness.

Which certifications and documents are non-negotiable?

The paperwork is your proof. Insist on these three documents:

- Fiber Certification: The official Liva Eco certificate from the upstream spinner, referencing Birla Cellulose's license and the chain of custody number.

- Mill Audit Reports: While the fiber is eco-friendly, the weaving and dyeing should also meet social and environmental standards. Ask if the production mills have audits like BSCI, SMETA, or OEKO-TEX STeP. This covers the "E" and the "S" in ESG.

- Product-Level Test Reports: The final fabric should be tested for safety and performance. A comprehensive OEKO-TEX Standard 100 test report for viscose fabrics is the global benchmark, ensuring the fabric is free from harmful substances. We provide this for every batch, and it’s something a partner like Shanghai Fumao considers standard practice.

How can I assess a supplier’s true capability with sustainable fibers?

Go beyond the catalog. Ask for specific case studies or visit their facility (virtually or in person). A capable supplier will:

- Show Physical Evidence: They can show you actual rolls of Liva Eco fabric in their warehouse or connected factory, not just swatch cards.

- Discuss Technical Nuances: They can explain how dyeing parameters differ for Liva Eco versus regular viscose to prevent issues like fibrillation.

- Offer Full Integration: They control or have tight partnerships across the chain. For example, we have our own weaving and QC, and fixed cooperatives for dyeing and printing. This control is crucial for maintaining the integrity of the sustainable fiber through each process. A supplier who just buys finished fabric from an anonymous market cannot guarantee this. To learn what questions to ask, reviewing a supplier qualification questionnaire for ethical textile sourcing from an industry alliance like the Sustainable Apparel Coalition can be extremely helpful.

Conclusion

Navigating the world of sustainable fabrics is complex, but fibers like Liva Eco offer a clear, verifiable, and high-performance path forward. It’s more than just an “eco” version of viscose; it’s a systemic shift towards traceability, responsible resource use, and closed-loop manufacturing. The benefits extend from compliance and risk reduction for your brand to a superior product feel for your customer. The key to success lies in understanding its unique value, strategically planning your production around industry rhythms, and, most importantly, partnering with a supplier whose capabilities and transparency match the fiber’s own ethos.

If Liva Eco sounds like the right material to elevate your next collection while solidifying your sustainability credentials, let's talk. At Shanghai Fumao, we don't just supply fabric; we partner with you to navigate development, rigorous quality control, and seamless logistics, ensuring your vision becomes a reality on schedule. For a dedicated consultation on how we can integrate Liva Eco or other sustainable fibers into your supply chain, reach out directly to our Business Director, Elaine. She and her team are experts in turning sustainable material goals into flawlessly executed bulk orders. You can contact her at: elaine@fumaoclothing.com.