You're designing a bridal gown, a delicate lingerie set, or a statement sleeve for a blouse, and lace feels like the perfect choice. But then you're confronted with a dizzying array: Chantilly, Guipure, Leavers, Embroidered, Raschel... and the prices vary wildly. How do you navigate this world of intricate patterns and technical jargon to find the lace that won't unravel your budget, your timeline, or your design vision? Let's demystify lace and build a framework for choosing it with confidence.

Lace fabric is an openwork textile characterized by patterns of holes and solid areas, created by looping, twisting, or knitting threads together. It is not woven on a standard loom. Choosing the right type for your design hinges on answering four key questions: What is the desired aesthetic and hand feel (e.g., soft/draping vs. stiff/structural)? What is the production method and its implications for cost and lead time (e.g., Leavers lace vs. Raschel lace)? What are the performance and care requirements (e.g., durability, stretch, washability)? And finally, what is the compatibility with your manufacturing process (e.g., how will it be cut, sewn, and finished)?

Understanding lace is about decoding its language—from the romance of its history to the practicality of its production. As a supplier in the heart of Keqiao's textile cluster, we work with designers globally who often start with a beautiful image but need guidance on the technical and commercial realities behind it. This guide will equip you to make an informed choice that balances beauty, function, and feasibility.

What Exactly Defines a Fabric as "Lace"?

At its core, lace is defined by its construction, not its fiber content or pattern. It's a textile built from a ground of nothing, where the pattern and the net background are created simultaneously. This distinguishes it from embroidered fabrics, where a pattern is stitched onto a pre-existing woven ground like tulle or organza.

True lace is created through one of three primary methods: Bobbin Lace (handmade, interlacing threads on a pillow with pins), Needle Lace (handmade, using a needle and thread to create stitches over a drawn pattern), and Machine Lace (the vast majority of modern lace, produced on specialized looms like Leavers, Raschel, or embroidery machines). The common thread is the creation of both the design and the open ground in one process. This results in a fabric that is often delicate, with a distinctive "right" and "wrong" side, and requires special handling. For a deep dive into heritage techniques, resources like the history and identification of handmade lace types from textile museums offer fascinating insights.

How do the main machine production methods differ?

This is crucial for cost, lead time, and design capability.

- Leavers Lace: The "Rolls-Royce" of machine lace. Produced on ancient, complex Jacquard looms (originally from Nottingham, many now in China). It produces the highest quality, most intricate laces with incredible detail, often using fine cotton, silk, or linen threads. It is expensive, has high MOQs, and long lead times (12-16 weeks). Ideal for luxury apparel.

- Raschel Lace: Made on a Raschel warp knitting machine. It's faster and more cost-effective than Leavers. Raschel lace often has a slight stretch (due to the use of nylon or polyester with lycra), is less detailed, and can sometimes have a more synthetic feel. It's the workhorse for lingerie, stretch garments, and mainstream fashion. Lead times can be 4-6 weeks.

- Embroidery/Embroidered Lace: This is technically not true lace, but a vital category. A pattern is embroidered (with Schiffli or multi-head machines) onto a temporary soluble or tear-away backing. Once the backing is removed, a lace-like fabric remains. It allows for incredible design freedom and no MOQ on the base fabric, but the process can be costly per meter. Great for appliqués and unique designs.

What are the key structural components to look for in a lace sample?

Train your eye to see beyond the pattern:

- Ground/Net (Réseau): The background mesh. Is it a fine hexagonal net (tulle), a hexagonal net with picots (little loops), or a more irregular baroque ground? The ground determines the drape and opacity.

- Pattern (Motif): The solid design elements. Are they outlined with a thicker, shiny thread (cordé)? This is a sign of quality, adding definition and preventing fraying.

- Selvage: The finished edges. A good lace will have a stable, non-curling selvage for easier cutting and sewing.

- Hand Feel & Drape: Crush it in your hand. Does it spring back? Does it drape softly or hold its shape? This tells you about the fiber and construction.

A client in 2023 wanted a "soft lace" for a flowy dress but selected a stiff Guipure. We sent them a comparable Raschel lace with a soft nylon ground, which achieved their desired drape at a third of the cost. Understanding how to evaluate lace quality and composition for garment production saved their project.

How to Match Lace Aesthetic and Drape to Your Design Vision?

Your design intent should dictate your lace selection from the very beginning. Is the lace the star of the show as an overlay, or a subtle accent? Does the garment need to flow or stand proud?

Categorize laces by their inherent character:

- Soft & Draping: Chantilly Lace (fine, floral patterns on a lightweight net, often with a scalloped edge), Schiffli Embroidered Lace on tulle. Ideal for skirts, veils, and flowing sleeves.

- Stiff & Structural: Guipure (or Venetian) Lace has no net ground; motifs are joined by bars or plaits, creating a heavy, sculptural fabric. Perfect for collars, cuffs, bodices, and structured accessories.

- Stretchy & Functional: Raschel Lace with lycra content. Essential for lingerie, bodysuits, and any close-fitting garment requiring comfort and movement.

- Romantic & Detailed: Leavers Lace with intricate, dense patterns. Used in high-end bridal and evening wear.

Create a physical mood board with swatches. The way light passes through a lace—or doesn't—will fundamentally alter your design. For a wedding dress designer in Paris, we curated a selection of 10 laces based on her "ethereal but not sheer" brief, focusing on laces with dense floral motifs on a fine tulle ground to provide coverage with a light effect.

When should I choose embroidered lace over true machine lace?

Choose embroidered lace when:

- Design Uniqueness is Paramount: You have a custom, detailed artwork that doesn't repeat. Embroidery machines can stitch any digital file.

- You're Working with Small Quantities: MOQ can be as low as the fabric for one garment, as you pay for the embroidery process, not for weaving thousands of meters of a pattern.

- You Need a Specific Base Fabric: You can embroider onto virtually any base—silk organza for luxury, cotton voile for softness, stretch mesh for fit.

The trade-off is cost per meter and potentially a less "integrated" feel than true lace, as the design sits on top of the base. It's also critical to specify the stability and wash compatibility of the embroidery backing fabric with your supplier to ensure the final product performs as expected.

How does color and fiber content influence the final look?

This is where samples are non-negotiable.

- Fiber: Nylon/Polyester laces are affordable, durable, and colorfast but can have a synthetic sheen. Cotton laces have a matte, natural feel but may wrinkle and shrink. Silk laces are the ultimate in luxury—draping beautifully with a subtle luster—but are delicate and very expensive.

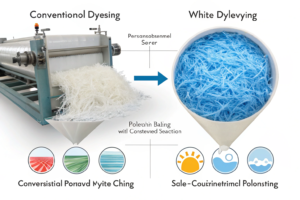

- Color: Ivory versus white can make or break a bridal design. Always order strike-offs (small dye lots) for custom colors. Remember, a colored lace pattern on a contrasting nude or black base (common in lingerie) creates a very different visual effect than an all-over dyed lace. For consistent results, work with suppliers who understand color management for lace dyeing and finishing, as the different fibers in a lace (e.g., polyester cordé on a nylon ground) can take dye differently.

What Are the Practical Considerations for Sourcing and Manufacturing?

The most beautiful lace is useless if it frays uncontrollably on the cutting table or shrinks 10% in the first wash. You must engineer your design for production from the outset.

Start with care and performance. Request test reports for colorfastness (to washing, light, perspiration) and shrinkage. Pre-wash or steam your samples to see how they behave. For stretch laces, check the recovery rate—does it snap back or bag out? Next, consider cutting and sewing. Fine laces may require stabilizers, laser cutting for precision, or specialized techniques like seaming with a French seam or a lace appliqué method to prevent fraying and maintain aesthetics. The cost of working with lace isn't just in the fabric; it's in the skilled labor to handle it.

What questions should I ask my supplier about MOQ, lead time, and sampling?

Be brutally specific:

- For MOQ: "Is this a stock lace or custom? What is the minimum order per color and per design?" For Leavers, it could be 500-1000 meters per design. For Raschel from stock, it could be 100 meters per color.

- For Lead Time: "What is the current production lead time from order confirmation to shipment?" Factor in sampling time (3-4 weeks for a custom sample). Remember the Chinese New Year shutdown can add 4-6 weeks.

- For Sampling: "What is the cost and timeline for a development sample (lab dip) and a bulk yardage sample?" A good supplier like Shanghai Fumao will guide you through this. For a new client in Australia, we produced a 5-meter custom embroidered lace sample within 2 weeks to secure their 8,000-meter annual order—they needed to test it in their production first.

Always confirm if the quoted price includes standard testing and shipping (FOB terms). Understanding how to negotiate MOQ and lead times with lace suppliers in China requires clear communication about your long-term potential.

How do I handle common lace imperfections and production challenges?

Anticipate and plan for them:

- Fraying: Use sealants (e.g., Fray Check) on cut edges or design seam allowances that are enclosed.

- Shifting during sewing: Use plenty of fine pins, basting stitches, or temporary spray adhesive.

- Sheerness: Plan for lining or underlining. The lace itself is often just the decorative layer.

- Pattern Matching: This is a skilled, fabric-intensive task. Discuss with your factory and supplier if the lace pattern has a clear repeat that needs to be matched at seams. This can increase fabric consumption by 15-30%.

Including a percentage for waste and defect allowance (often 5-10% for lace) in your fabric order is standard practice to cover these challenges.

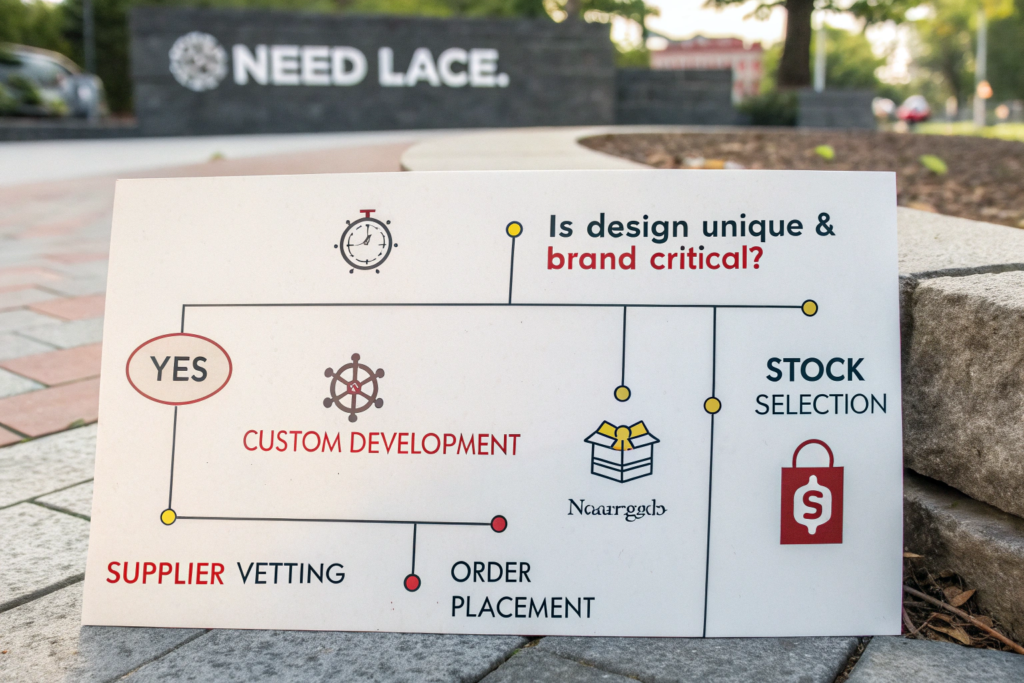

How to Source Lace Effectively: Stock vs. Custom Development?

This is the final, strategic decision. Do you buy from a stock collection or invest in custom development? Your budget, timeline, and design uniqueness will dictate the answer.

Stock Lace is pre-designed and produced, sitting in a supplier's warehouse. Advantages: Immediate availability, lower cost (amortized over many buyers), low MOQ, and you can see and feel the actual bulk fabric. Disadvantage: Lack of exclusivity; other brands may use the same lace. Custom Lace is designed by you and produced solely for you. Advantages: Complete exclusivity and design control. Disadvantages: High development cost (sample fees), very high MOQ, long lead time (3-6 months), and you commit to bulk before seeing the final result.

What is the step-by-step process for developing a custom lace?

If you choose the custom route, prepare for a partnership:

- Design Brief: Provide clear artwork (vector files are best) and specify desired fiber, width, weight, and ground type.

- Sample Development: The supplier will create a paper pattern (punch cards for Leavers) or digital file and produce a small sample (30-50cm). This can cost $200-$800.

- Sample Approval & Revisions: You review, request changes (which may incur further fees), and finally approve.

- Bulk Production Deposit: Pay typically 30-50% to commence bulk production.

- Bulk Production & TOP Sample: The supplier produces the order and sends you a Top-of-Production (TOP) sample cut from the bulk for final sign-off.

- Final Payment & Shipment: Upon your TOP approval, you pay the balance, and the goods are shipped.

This process requires trust. Work with a supplier who provides clear updates at each stage. We manage this for clients by sending photographic updates from the loom and dye house.

How can I find a reliable lace supplier?

Look beyond Alibaba listings.

- Specialization: Seek suppliers who list lace as a core category, not one of 100 products. Being in a cluster like Keqiao is a major advantage.

- Communication: They should ask you detailed questions about application, weight, and stretch.

- Transparency: They should readily explain the difference between their Raschel and Leavers laces and provide test reports.

- Sample Policy: They should be able to provide small cut samples (1 meter) of stock laces for a reasonable fee.

Attending specialized fabric fairs is invaluable. Once you find a good supplier, treat them as a strategic partner. A reliable partner like Shanghai Fumao doesn't just sell lace; we advise on its optimal use, connect you with compatible manufacturers, and help troubleshoot production issues.

Conclusion

Choosing the right lace is a beautiful alchemy of art and science. It begins with a clear vision for your design's aesthetic and function, which then guides you through the practical maze of production methods, fiber choices, and sourcing strategies. Whether you select a soft, draping Chantilly for a romantic gown or a stiff, architectural Guipure for a structured piece, understanding the "why" behind each type empowers you to make decisions that enhance your design and ensure its manufacturability.

Remember, the most successful lace applications result from early collaboration—between designer, supplier, and manufacturer. By asking the right questions, demanding physical samples, and planning for the unique challenges of working with lace, you transform a potential sourcing headache into a signature element of your collection. If you're ready to explore the world of lace with a partner who provides both beauty and brains, let's connect. At Shanghai Fumao, our expertise spans from the finest Leavers looms to innovative embroidered laces, and we are dedicated to helping you find the perfect match for your vision. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to begin your lace journey.