As an experienced fabric supplier, I frequently help clients balance cost, quality, and sustainability goals. For businesses sourcing fabrics for the US market—especially those concerned with tariffs, speed, and environmental impact—one fabric technology consistently delivers: dope-dyed polyester. This isn't just another textile option; it represents a fundamental improvement in manufacturing efficiency and sustainability.

Dope-dyed polyester is created by adding color pigments directly to the liquid polymer before fibers are formed. This process integration results in fabrics with exceptional color retention and significantly reduced environmental impact compared to conventionally dyed alternatives. For brands, this means durable, vibrant products with a compelling sustainability narrative.

Understanding both the technical advantages and practical benefits of dope-dyed polyester is essential for making informed sourcing decisions. This article examines its manufacturing process, explores its measurable benefits, and demonstrates why it represents a strategic choice for forward-thinking brands.

What Advantages Does Dope-Dyed Polyester Offer?

Modern brands require fabrics that deliver both performance characteristics and sustainability credentials. Dope-dyed polyester addresses these requirements through its unique manufacturing methodology, providing benefits that directly impact product quality and brand positioning.

How Does It Achieve Superior Colorfastness?

Dope-dyed polyester demonstrates exceptional colorfastness properties due to its manufacturing process. Since colorants are integrated at the polymer stage, they become molecularly bonded within the fiber structure. This intrinsic coloration provides outstanding resistance to fading from washing, UV exposure, and chemical exposure. Unlike surface-dyed fabrics where color sits on the fiber exterior, dope-dyed colors remain vibrant throughout the product lifecycle, making them ideal for applications requiring long-term color retention.

What Environmental Benefits Does It Provide?

The environmental advantages are substantial and measurable. Traditional dyeing processes consume significant water resources for dye application and subsequent rinsing. Dope-dyeing technology eliminates aqueous dyeing altogether, reducing water consumption by approximately 60% compared to conventional methods. This process also lowers energy consumption and reduces chemical usage, contributing to a substantially improved environmental footprint. For brands committed to sustainable manufacturing, this represents a tangible improvement in resource efficiency.

How Is Dope-Dyed Fabric Manufactured?

The manufacturing process represents a paradigm shift in textile coloration, integrating color application at the most fundamental stage of fiber production rather than as a subsequent processing step.

What Constitutes the Solution Dyeing Process?

The solution dyeing process begins with creating a liquid polymer matrix. Precisely measured color pigments or masterbatches are introduced and homogenized within this liquid medium. This colored solution is then extruded through spinnerets to form continuous filaments, with coloration permanently locked into the fiber structure during solidification. This method contrasts with conventional approaches where previously formed, uncolored yarns undergo separate dyeing processes. Our CNAS-certified laboratory ensures rigorous quality control throughout this manufacturing sequence.

What Factors Determine Color Durability?

Color durability derives from the pigment distribution within the fiber cross-section. Since colorants permeate the entire fiber structure, they resist removal through abrasion, laundering, or environmental exposure. The comparative performance data illustrates this advantage:

| Performance Metric | Dope-Dyed Polyester | Conventionally Dyed Polyester |

|---|---|---|

| Wash Fastness | Excellent | Good to Very Good |

| Light Fastness | Excellent | Good |

| Crocking Resistance | Excellent | Good |

This inherent durability ensures product appearance retention, reducing returns and enhancing customer satisfaction—particularly important for technical textiles requiring consistent performance.

Why Does Dope-Dyed Polyester Make Business Sense?

Fabric selection involves strategic business considerations beyond mere material specifications. Dope-dyed polyester offers operational advantages that strengthen supply chain resilience, protect profit margins, and support brand development objectives.

How Does It Impact Total Cost Considerations?

While raw material costs may be marginally higher, total cost of ownership often proves advantageous. The integrated coloration process eliminates multiple downstream processing stages, reducing energy, water, and chemical consumption. This manufacturing efficiency also enables accelerated production timelines, while color consistency minimizes waste from shade variation. The net result includes predictable costing, reduced lead times, and enhanced supply chain efficiency—all contributing to improved financial performance.

How Does It Support Brand Development?

Sustainability has evolved from niche concern to mainstream consumer expectation. Dope-dyed polyester provides authentic, verifiable environmental credentials that support brand storytelling. The significant reductions in water consumption, energy usage, and chemical applications resonate with environmentally conscious consumers and align with corporate responsibility initiatives. Partnering with suppliers who prioritize innovations like dope-dyeing demonstrates commitment to sustainable development goals, strengthening brand positioning in competitive markets.

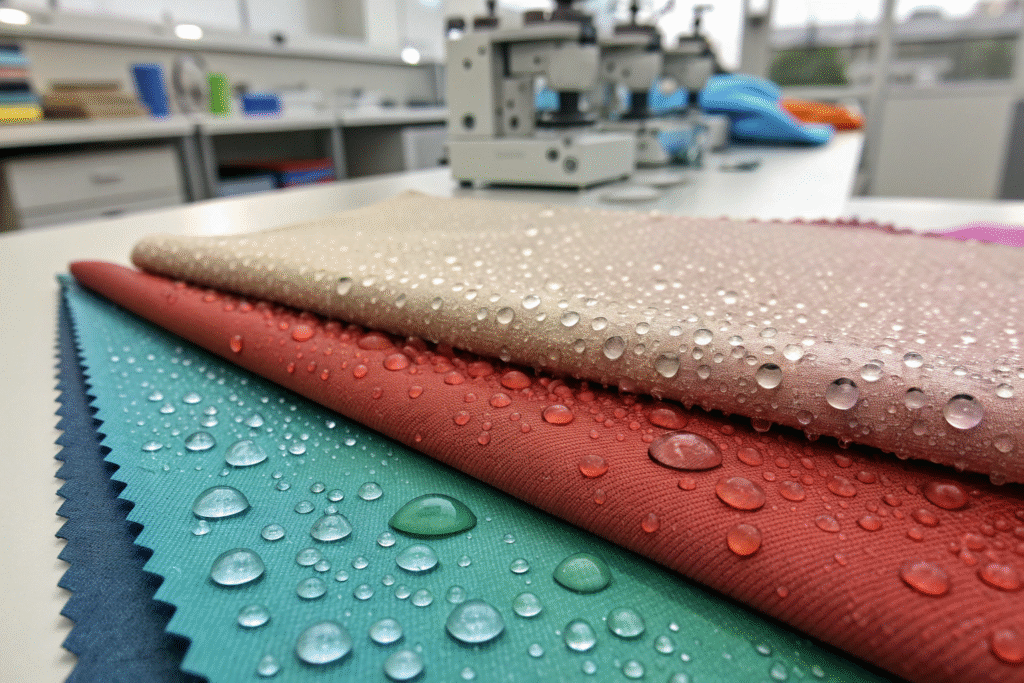

Is Dope-Dyed Fabric Appropriate for Your Applications?

Understanding application suitability is essential for material selection. Dope-dyed polyester's performance characteristics make it appropriate for diverse product categories requiring color consistency and durability.

What Applications Demonstrate Its Advantages?

Dope-dyed polyester delivers exceptional performance across multiple categories:

- Activewear and Sportswear: Superior resistance to perspiration and repeated laundering

- Outdoor and Technical Gear: Excellent UV stability for applications requiring sun exposure resistance

- Uniform Programs: Maintenance of professional appearance through industrial laundering cycles

- Automotive Interiors: Resistance to fading from sunlight and thermal exposure

- Home Furnishings: Color retention for draperies, upholstery, and other sun-exposed applications

Our comprehensive product range includes numerous dope-dyed options engineered for these specific applications.

What Practical Considerations Should Be Evaluated?

While offering significant advantages, dope-dyed polyester presents specific operational considerations. Minimum order quantities typically exceed those for piece-dyed fabrics since coloration occurs during fiber manufacturing. Lead times for new color development may also be extended due to masterbatch preparation requirements. However, for established colors and production-scale quantities, the performance and sustainability benefits typically outweigh these considerations. Our technical development team assists clients in navigating these parameters to optimize sourcing strategies.

Conclusion

Dope-dyed polyester represents a significant advancement in textile manufacturing, combining exceptional color performance, verified sustainability benefits, and operational efficiencies. From its integrated manufacturing process to its demonstrated performance in finished products, it addresses the complex requirements of contemporary brands: quality assurance, supply chain efficiency, environmental responsibility, and value optimization.

For businesses seeking a reliable partner for dope-dyed polyester sourcing and product development, our integrated manufacturing capabilities—from fiber processing to finished fabric—ensure consistent quality and reliable delivery. To explore how these innovative fabrics can enhance your product offerings, please contact our Business Director, Elaine, at elaine@fumaoclothing.com for further consultation.