As a fabric supplier with over two decades in the textile industry, I've seen firsthand how color can make or break a collection. You have a vision for your line, a specific shade that will capture your brand's essence. But translating that tiny Pantone swatch into thousands of meters of perfectly consistent fabric is where the real challenge begins.

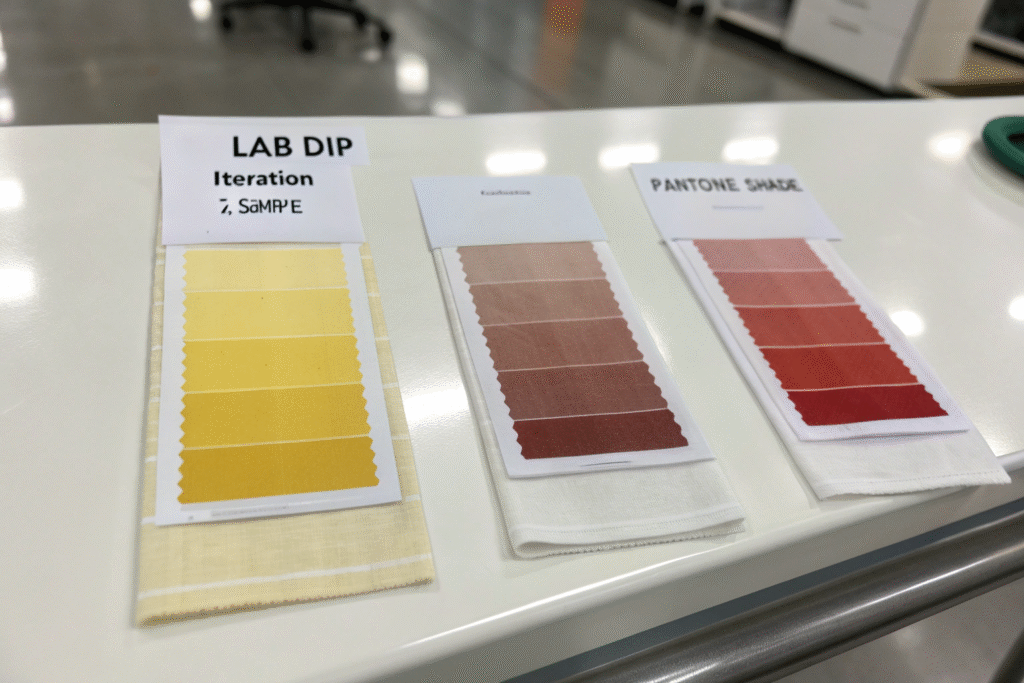

Color matching by Pantone is the standardized process of replicating a specific color from the Pantone Matching System (PMS) onto a fabric substrate. It ensures color accuracy and consistency for brands and manufacturers globally. The number of lab dips considered normal typically ranges from one to three iterations.

What is the Pantone Color Matching process?

The Pantone Color Matching process is our first and most critical step in bringing your design vision to life. It's a universal language that bridges the gap between your creative idea and the physical fabric.

The Pantone Matching System (PMS) is a standardized color reproduction system. By assigning unique codes to thousands of colors, it allows manufacturers and designers all over the world to communicate color accurately without personal interpretation.

This process is far more complex than simply pouring dye into a vat. Our technical team analyzes the Pantone code you provide. We then consider the base fabric—whether it's organic cotton, polyester, silk, or a blend.

Why is a standardized color system crucial for global supply chains?

In today's globalized market, your supply chain is often spread across continents. You might be designing in Los Angeles, sourcing fabric from us in China, and manufacturing garments in Vietnam.

A standardized system creates a single source of truth. When we send you a lab dip, we reference the Pantone code. When you approve it, you reference the same code. This clarity is vital for our quality control procedures throughout production.

How do fabric composition and dye type affect color matching?

The interaction between dye and fiber is a science. You cannot achieve a perfect color match without understanding this relationship.

| Fabric Type | Common Dye Classes Used | Key Consideration for Color Matching |

|---|---|---|

| Cotton | Reactive Dyes, Direct Dyes | Excellent for achieving bright, vibrant colors |

| Polyester | Disperse Dyes | Requires high temperature for color fixation |

| Wool | Acid Dyes | Produces rich, deep shades |

| Nylon | Acid Dyes, Disperse Dyes | Dye uptake can vary significantly |

Choosing the wrong dye type or not accounting for the fabric's properties can result in a color that is off-target or lacks fastness.

How many lab dips are typically needed?

The number of lab dips required is a common concern for our clients, as it directly impacts your development timeline. While everyone hopes for a perfect match on the first try, the reality is that textile dyeing is an iterative process.

For most standard colors on common fabrics, we achieve approval within two lab dips. The first lab dip establishes a baseline, and the second refines the shade based on your feedback.

We understand that time is of the essence, especially in fast fashion. That's why we've optimized our process for a 48-hour sample development turnaround.

What factors influence the number of lab dip iterations?

Several technical factors can add steps to the color approval process. One of the most significant is the fabric blend. A 50/50 cotton-polyester blend, for example, is more challenging to dye than a 100% cotton fabric.

Another major factor is the desired color fastness. If your end-product requires high-performance features, such as exceptional UV resistance or chlorine fastness for swimwear, the chemicals and dyes used can subtly shift the color.

How can you help speed up the lab dip approval process?

You play an active role in streamlining the color matching process. Providing a physical Pantone swatch on the correct material is always better than relying on a digital image.

When evaluating a lab dip, it's crucial to view it under a controlled light box using standardized D65 daylight simulation. When providing feedback, be as specific as possible using directional language.

What are the costs of multiple lab dips?

It's natural to wonder about the financial implications of a prolonged development phase. While we provide the initial lab dips as part of our service, multiple rounds do incur internal costs for us.

The primary "cost" of multiple lab dips for you, the client, is usually time. Each iteration can add several days to your pre-production schedule. For time-sensitive campaigns, these delays can be more critical than the direct financial cost.

There is also a broader cost to consider: the risk of proceeding with an imperfect color. Rushing the approval to save a few days can be a costly mistake.

How does the lab dip process prevent costly bulk production errors?

The lab dip is your first and best line of defense against a production disaster. Think of it as a prototype for color. It allows you to see and approve the color before we commit to massive bulk dyeing.

In bulk production, a single dye bath can involve thousands of kilograms of fabric. If the color is wrong at this stage, the financial loss is not just in the fabric itself, but also in lost production time and missed shipping schedules.

Is investing in fewer lab dips a false economy?

Some clients may be tempted to approve a "good enough" lab dip to save time. In our experience, this is almost always a false economy.

A color that is 95% there in the lab will be 100% wrong in your customer's eyes. The returns, exchanges, and damage to brand reputation far outweigh the initial time spent perfecting the shade.

How do you ensure color consistency after approval?

Getting the lab dip approved is a major milestone, but the journey isn't over. The next challenge is ensuring that every single meter of fabric matches the lab dip you signed off on.

We ensure bulk color consistency through a multi-stage QC protocol. First, the approved lab dip is used as the absolute standard. Then, we conduct inline checks during dyeing and final fabric inspection on every batch.

This scientific approach is backed by our end-to-end control. Because we manage the weaving, dyeing, and finishing in a coordinated supply chain, we eliminate variability.

What role does technology play in maintaining color accuracy?

Technology is a game-changer for color consistency. In our CNAS-accredited lab, we use spectrophotometers to measure color. This device assigns numerical values to the lab dip and each production sample.

This data tells us objectively if a batch is within your pre-agreed tolerance levels, removing all guesswork and human error from the equation.

How does your supply chain structure minimize color variation?

Our roots in the Keqiao textile cluster provide a unique advantage. Our cooperative dyeing and finishing factories are located nearby, creating a tightly integrated supply chain.

This proximity allows for constant communication and real-time adjustments. Our QC team is on-site at these partner facilities, monitoring the dyeing process from start to finish.

Conclusion

The journey from a Pantone color idea to a warehouse full of perfectly consistent fabric is a detailed and technical process. Understanding the fundamentals empowers you to make better sourcing decisions.

At Fumao Textiles, we see ourselves as an extension of your team. We leverage our 20 years of expertise and advanced testing facilities to de-risk the color development process for you.

To discuss how we can partner on your next clothing order and ensure your colors are perfectly matched, please contact our Business Director, Elaine at elaine@fumaoclothing.com.