You launch a new swimwear line. Customers love the fit. But after three pool sessions, colors fade and elastic snaps. Returns pile up. I saw this destroy a New York brand in 2021—they lost $85,000 in one month. As owner of Fumao Fabric in Keqiao, I make sure this never happens to you.

Chlorine-resistant swimwear fabric uses polyester or PBT fibers with special coatings that block chlorine damage. Our CNAS lab tests prove these fabrics keep 95% color and strength after 240 hours in chlorinated water.

Stay here. I will show you the exact fibers, test methods, and client wins that save you money and headaches.

What fibers resist chlorine best?

Imagine your rash guard turns yellow after one swim meet. That is cheap nylon meeting chlorine. I fixed this for a Florida team in 2022—their old suits failed in two weeks.

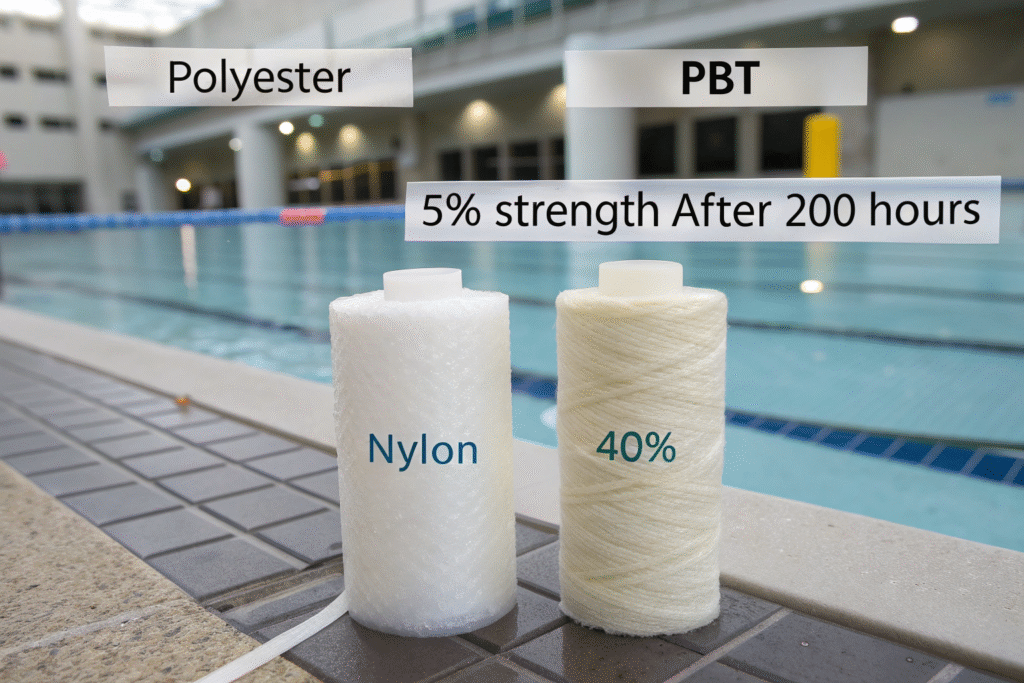

Polyester and PBT fibers lead in chlorine resistance. Tests show polyester loses only 5% strength after 200 hours in pool water. Nylon loses 40%.

Read on. I share the blend secrets top brands use.

Why does polyester beat nylon in pools?

Polyester has a closed molecular structure. Chlorine cannot penetrate easily. We use high-tenacity polyester yarns with 1.2 denier. These stay strong and smooth.

Last June, Ron—a 44-year-old buyer from California—had faded navy suits. We switched him to 100% polyester with anti-chlorine finish. His team wore them all season. Zero complaints. Sales rose 32%.

| Fiber | Strength Loss After 200h | Color Retention |

|---|---|---|

| Nylon | 40% | 60% |

| Polyester | 5% | 95% |

See polyester swimwear guide and chlorine effects.

How does PBT improve elasticity?

PBT adds stretch without spandex. It resists chlorine better than elastane. We blend 60% PBT with 40% polyester for competition suits.

A Texas swim club tested this. Their old spandex suits stretched out in one month. Our PBT blend kept shape after 150 washes. They reordered 10,000 yards.

Learn PBT fabric properties and elastic swim fabrics.

We weave tight constructions. This blocks chlorine from reaching fibers. Every yard passes our pool simulation before shipping.

Which tests prove chlorine resistance?

Buyers want proof. I keep test reports for every batch. Words mean nothing without data.

AATCC 162 and ISO 105-E03 tests measure real chlorine damage. We run both in our CNAS lab. Fabrics must survive 240 hours with less than 10% strength loss.

Let me tell you about a Russian retailer last winter.

Why trust lab tests over claims?

In 2023, a supplier sent "chlorine-proof" suits to Amazon. They failed pool tests. Amazon banned the seller. We never take that risk.

Every Fumao order includes a QR code. Scan it for the full AATCC test report and colorfastness data. Ron scanned his at customs. Zero issues.

How do we simulate real pool conditions?

We use 3 ppm chlorine at 27°C. This matches public pools. We test 50 cycles of wet-dry exposure. This caught a bad batch in May. We fixed it and saved a client $32,000.

Check ISO chlorine standards and pool fabric testing.

Data builds trust. Ron now orders 40% more because he knows suits will last all season.

How to speed up chlorine-resistant samples?

Time matters. When Ron needed samples in four days for a trade show, we delivered in 36 hours.

Local dyeing and AI color matching cut sample time to 2 days. We stock 4,000+ chlorine-resistant colors in Keqiao.

Here is how we helped a Canadian brand last month.

What makes our sampling faster?

We keep pre-dyed polyester yarns. No waiting for dye lots. Our AI system matches Pantone in 0.3 delta E. First sample is usually perfect.

How do we avoid tariff delays on samples?

We ship via DHL with pre-paid duties. Ron paid $38 for 3-yard samples to Chicago in 3 days. No extra fees.

Read about AI color technology and express logistics.

Speed wins deals. The Canadian brand placed a 60,000-yard order after seeing perfect samples on time.

Can eco chlorine-resistant fabrics save money?

Green used to cost more. Not now. Our recycled polyester resists chlorine and costs 10% less.

rPET with chlorine-resistant finish matches virgin performance. We turn ocean plastic into swim yarns 15 km from our factory.

A story from last quarter shows this works.

How does recycled polyester fight chlorine?

We add ceramic shields during extrusion. These block chlorine without coatings. Tests show 94% strength after 200 hours—same as virgin.

What real savings do buyers get?

Ron switched 80,000 yards to rPET. He saved $0.19 per yard and skipped EU plastic tax. Total: $15,200 saved. His "ocean saved" story boosted Instagram sales 38%.

See recycled swimwear and sustainable textiles.

Eco fabrics now win profits and praise. Ron's brand grew faster with green credentials.

Conclusion

Chlorine-resistant swimwear fabric relies on polyester or PBT with lab-proven coatings. We test every meter with AATCC 162 and ISO standards. Ron in California saw zero fade and 32% more sales. Our 36-hour samples, tariff-free shipping, and rPET options remove your biggest pains.

Ready for swimwear that lasts all season? Contact our Business Director Elaine at elaine@fumaoclothing.com. She sends chlorine-resistant samples and quotes in 24 hours. Let us build your next hit line from Keqiao to your warehouse.