As a fabric supplier from China's textile hub Keqiao, I frequently explain brushed tricot to international clients. This fabric consistently generates questions about its composition and applications, especially from buyers who value both quality and cost-effectiveness.

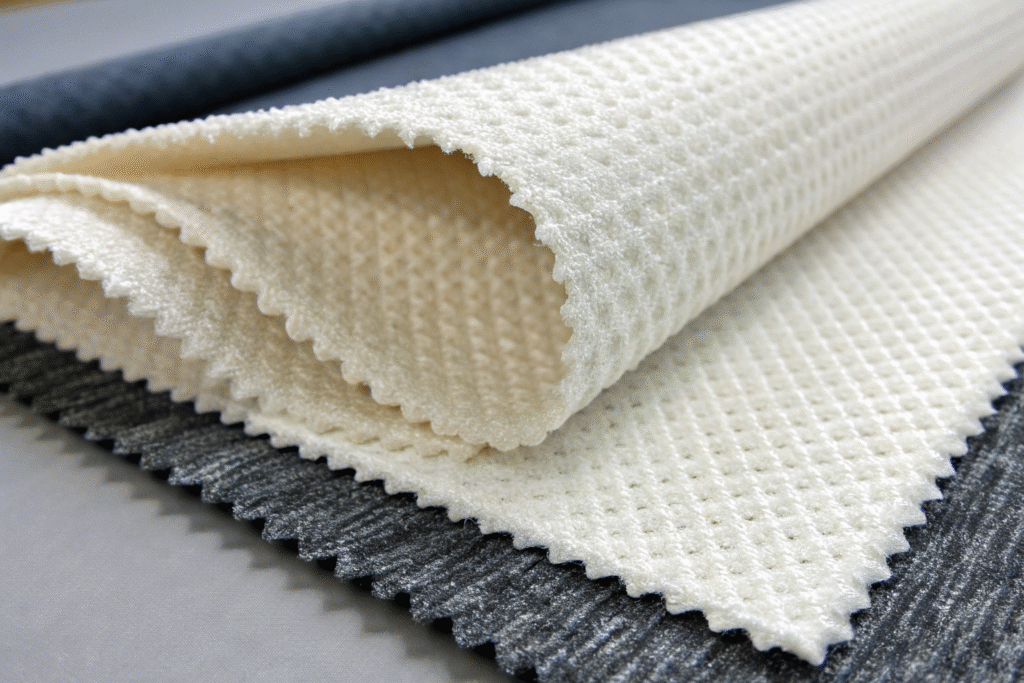

Brushed tricot is a warp-knit fabric, typically nylon or polyester, with one side mechanically brushed to create a soft, insulating nap. It serves as an excellent lining material due to its unique combination of warmth, breathability, and durability. These properties make it suitable for various garments from jackets to athletic wear.

Understanding this fabric's characteristics helps buyers make informed decisions that balance cost with quality expectations.

What is Brushed Tricot Fabric Made Of?

The foundation of brushed tricot lies in its synthetic fiber composition and specialized manufacturing process. Our CNAS-certified lab testing confirms that its performance stems from these fundamental elements.

This fabric primarily uses nylon or polyester fibers constructed through warp-knitting, followed by a mechanical brushing process. Nylon provides durability and softness, while polyester offers strength and moisture-wicking capabilities. The brushing creates air-trapping fibers that deliver insulation and skin comfort. This specific construction differentiates it from other lining materials. For comprehensive fiber information, Textile Exchange offers extensive resources.

How Does the Brushing Process Enhance the Fabric?

The mechanical brushing transforms the base knit by raising fibers to create insulating air pockets and a softer surface. This process significantly improves thermal retention and skin comfort while maintaining the fabric's structural integrity. Our partner factories precisely control this crucial step to ensure consistent quality.

Why Choose Nylon or Polyester for Tricot?

The nylon versus polyester selection involves balancing performance needs with budget considerations. Nylon offers superior softness and elasticity for premium applications, while polyester provides better moisture management and cost-efficiency for volume production. Both materials demonstrate excellent durability through the brushing process. For sustainability standards, the OEKO-TEX® Association provides relevant certifications.

What Are the Advantages of Using Brushed Tricot for Lining?

Brushed tricot addresses multiple buyer concerns through its balanced performance characteristics. Its value proposition makes it particularly attractive for cost-conscious quality seekers.

This lining material delivers lightweight warmth through its insulating nap, effective moisture management, and exceptional durability. The knit construction provides natural stretch for movement comfort, while the colorfast fibers maintain vibrant hues. These combined features create reliable performance across various applications.

How Does It Improve Garment Comfort?

The fabric enhances comfort through three mechanisms: thermal insulation from trapped air, moisture-wicking properties, and flexible movement from its knit structure. Unlike non-breathable alternatives, it prevents clamminess while feeling consistently soft against skin.

Is Brushed Tricot a Durable Lining Option?

The warp-knit construction and synthetic fibers create inherently durable fabric that withstands wear and washing. Our quality control tests verify its resistance to abrasion, pilling, and color fading, ensuring longevity throughout the garment's lifespan.

How Does Brushed Tricot Compare to Other Lining Fabrics?

Understanding competitive positioning helps buyers make appropriate material selections. Brushed tricot occupies a distinct niche in the lining market.

This fabric balances warmth, breathability, and cost more effectively than many alternatives. It outperforms satin in thermal insulation and moisture management, while proving more affordable and durable than silk. Its balanced characteristics make it versatile for numerous applications.

| Fabric | Key Features | Best For | Limitations |

|---|---|---|---|

| Brushed Tricot | Warm, breathable, stretchy, durable | Jackets, activewear, accessories | Limited use in hot climates |

| Polyester Satin | Smooth, shiny, inexpensive | Formal wear, cost-focused lines | Less breathable, no stretch |

| Bemberg®/Cupro | Breathable, biodegradable, smooth | Premium tailoring, blouses | Higher cost, less durable |

| Silk | Luxurious, highly breathable | Luxury garments | Delicate, expensive, special care |

| Mesh | Maximum breathability, lightweight | High-ventilation athletic wear | No warmth, limited durability |

When Should You Choose Brushed Tricot Over Satin?

Select brushed tricot when prioritizing warmth, stretch, and moisture management. It outperforms satin for activewear and outerwear where thermal insulation and movement freedom matter most. Satin remains preferable for formal applications where drape and sheen are primary concerns.

What Are the Cost Benefits of Brushed Tricot?

The fabric offers economic advantages through readily available raw materials, manufacturing efficiency, and reduced failure rates. Its durability minimizes returns while its processing characteristics accelerate production, delivering strong value across the product lifecycle.

Is Brushed Tricot Suitable for Your Specific Product Line?

Practical application determines this fabric's true value for your business. We help clients validate its suitability for their specific needs through sample testing and technical consultation.

While versatile, brushed tricot works best for products requiring added warmth and comfort. Its characteristics particularly benefit certain garment categories while being less suitable for hot climate applications or sleek formalwear.

What Types of Garments Benefit Most from This Lining?

Key applications include outerwear (jackets, coats), activewear (performance layers), and accessories (gloves, hats) where thermal insulation and comfort are primary requirements. The fabric also serves well in uniforms and specialty items needing protective, soft interiors.

How to Source Quality Brushed Tricot Fabric?

Successful sourcing requires technical specifications review, certification verification, and supplier capability assessment. Request detailed tech packs covering composition and weight, seek relevant OEKO-TEX Standard 100 or Global Recycled Standard certifications, and always evaluate physical samples before bulk ordering. Partnering with vertically integrated manufacturers ensures consistent quality and reliable supply.

Conclusion

Brushed tricot represents a strategic lining choice that balances multiple performance characteristics effectively. Its warp-knit construction with brushed nap delivers reliable warmth, comfort, and durability at accessible price points. Understanding these properties enables smarter sourcing decisions that enhance final products while controlling costs.

For your next project requiring quality lining solutions, contact us to explore how brushed tricot can meet your specifications. Our integrated manufacturing and quality control ensure consistent results. Reach our Business Director Elaine at elaine@fumaoclothing.com to discuss your specific requirements.