As a textile professional with twenty years of experience, I understand that innovation must meet practical business needs. When fabric buyers and clothing brands consider new materials like bio-based polyester, they need clear answers about performance, availability, and cost-effectiveness. This isn't just about sustainability—it's about finding reliable fabrics that work for today's fashion industry.

Bio-based polyester represents a significant shift in how we source raw materials. Instead of relying entirely on petroleum, this innovative fabric uses renewable plant sources like corn and sugarcane to create the building blocks for polyester fibers. For clothing brands and manufacturers, the scalability question is crucial: current production capabilities and supply chain infrastructure confirm that bio-based polyester can indeed meet commercial demands across multiple market segments.

Let's examine what makes this material different, how it performs in real-world applications, and why it's becoming a viable option for forward-thinking fashion businesses.

How is Bio-Based Polyester Produced?

Understanding the manufacturing process helps buyers evaluate quality and consistency. The production methodology distinguishes bio-based polyester from conventional alternatives while maintaining comparable performance standards.

Bio-based polyester utilizes biomass feedstocks—primarily industrial crops like sugarcane and corn—that undergo biochemical conversion processes. Through industrial fermentation, plant sugars transform into bio-monethylene glycol (bio-MEG), which combines with purified terephthalic acid (PTA) to form the polymer polyethylene terephthalate (PET). The resulting polymer chips undergo melt spinning and texturing processes identical to conventional polyester production, ensuring familiar handling and performance characteristics.

What distinguishes its manufacturing from conventional methods?

The fundamental difference occurs at the molecular sourcing stage. While conventional polyester begins with petroleum refining, bio-based polyester initiates with agricultural processing and biochemical conversion. This feedstock substitution reduces fossil fuel dependency while maintaining the downstream manufacturing advantages of traditional polyester production. The polymerization, spinning, weaving, and finishing stages remain consistent with established textile manufacturing protocols, enabling seamless integration into existing production facilities without significant retooling requirements.

What verification standards ensure material authenticity?

Quality-conscious buyers should prioritize suppliers who provide transparent certification documentation. Key verification mechanisms include:

- Biobased Content Certification: The USDA Certified Biobased Product program quantifies renewable carbon content through standardized testing protocols.

- Supply Chain Traceability: Systems like ISCC PLUS provide chain-of-custody verification from raw materials to finished fabric.

- Performance Validation: Reputable manufacturers supply comprehensive test reports confirming mechanical properties, colorfastness ratings, and dimensional stability metrics comparable to conventional polyester standards.

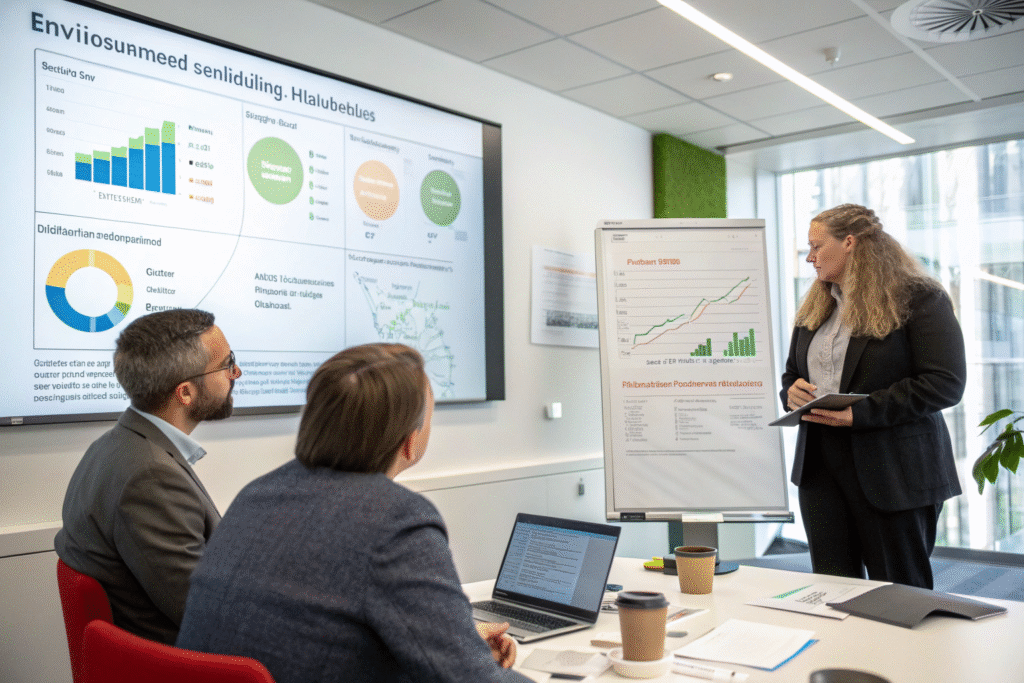

Does Bio-Based Polyester Deliver Environmental Benefits?

Sustainability claims require scientific validation. For business decision-makers, environmental considerations must align with practical performance requirements and commercial viability.

Independent life cycle assessment (LCA) studies demonstrate that bio-based polyester can reduce greenhouse gas emissions by 20-30% compared to petroleum-based equivalents. This reduction primarily occurs during the raw material phase, where renewable plant feedstocks sequester atmospheric carbon during growth. The carbon footprint advantage varies depending on agricultural practices, transportation logistics, and manufacturing efficiency, underscoring the importance of transparent supply chain documentation.

How does end-of-life management compare to alternatives?

Bio-based polyester integrates seamlessly into existing polyester recycling infrastructure, supporting circular economy initiatives through both mechanical and chemical recycling pathways. Importantly, brands should recognize that bio-based polyester is not biodegradable under normal conditions—a distinction from alternative biopolymers like polylactic acid (PLA). This compatibility with established recycling systems represents a significant advantage for brands developing comprehensive sustainability strategies.

What about resource utilization concerns?

Responsible sourcing addresses legitimate questions about agricultural land use and water resources. Industry leaders increasingly utilize non-food biomass and agricultural residues, reducing competition with food production systems. Certification programs incorporate sustainability criteria regarding water management, soil health, and ecosystem preservation, enabling buyers to select suppliers who demonstrate responsible resource stewardship throughout their supply chain.

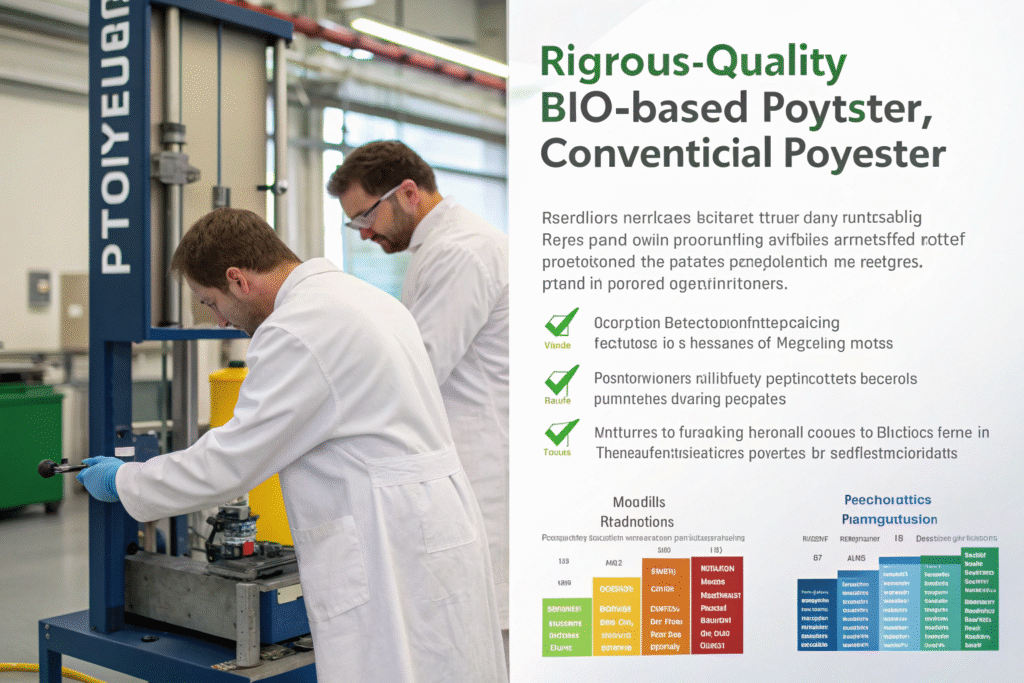

Can Bio-Based Polyester Meet Performance Expectations?

Material innovation must satisfy practical requirements. Fashion brands cannot compromise on quality, durability, or aesthetic properties when adopting sustainable alternatives.

Rigorous testing confirms that high-quality bio-based polyester matches the performance benchmarks of conventional premium polyester. Our CNAS-accredited laboratory consistently verifies that bio-based variants meet industry standards for tensile strength, abrasion resistance, and color retention. The molecular structure of the finished polymer is functionally identical to petroleum-based polyester, ensuring predictable performance across manufacturing and use phases.

How does it perform across different applications?

Bio-based polyester demonstrates remarkable versatility across product categories. For activewear and performance clothing, it readily incorporates functional finishes for moisture management, quick-drying properties, and stretch recovery. In fashion applications, it achieves the drape, luster, and texture requirements for everything flowing chiffons to structured jacquards. Blending possibilities with elastane and natural fibers further expand its application range without compromising aesthetic or functional requirements.

Is quality consistency maintained across production batches?

Vertical integration within manufacturing operations ensures consistent quality outcomes. Our controlled weaving processes and established partnerships with certified dyeing facilities maintain strict tolerances for weight, width, and color uniformity. Advanced monitoring systems track production parameters throughout manufacturing, enabling real-time adjustments that prevent batch-to-batch variation. This operational control provides the reliability that brands require for predictable production planning and consistent final products.

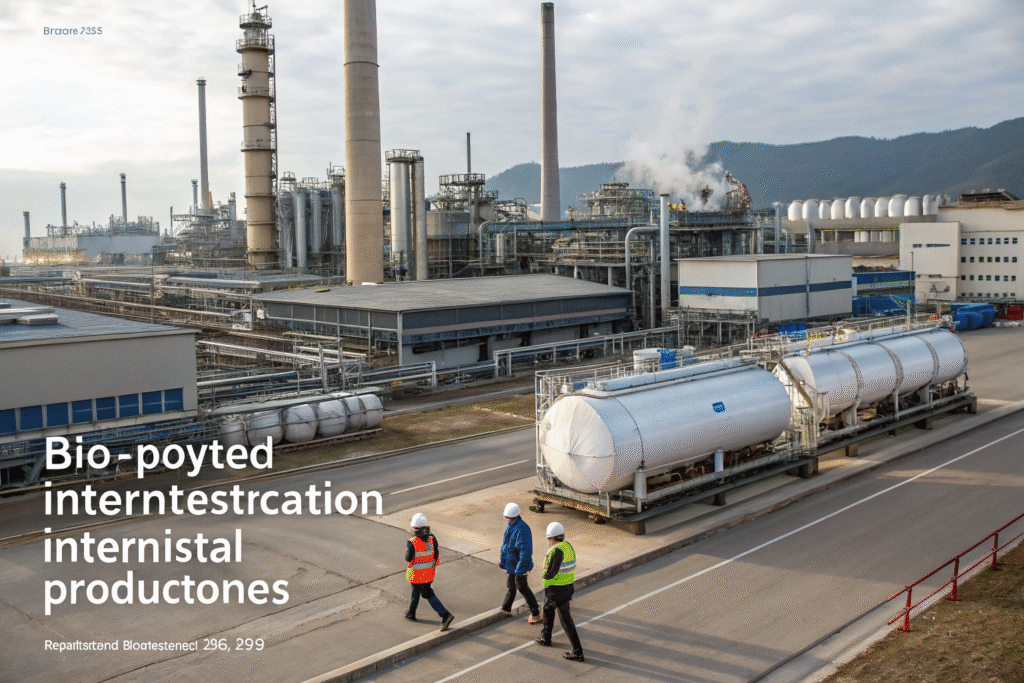

Is Commercial Scalability Achievable Today?

Business adoption requires more than technical feasibility—it demands commercial availability at viable cost structures with reliable supply chain support.

Global production capacity for bio-based polyester intermediates continues expanding, with major chemical manufacturers committing significant investment to commercial-scale production facilities. Within China's textile ecosystem, our position in the Keqiao cluster provides access to diversified raw material sources and manufacturing partnerships capable of translating these materials into finished fabrics at commercial volumes. Current production infrastructure readily accommodates orders ranging from development samples to full container quantities.

What are the current cost considerations?

Bio-based polyester typically carries a 15-30% price premium over conventional equivalents, reflecting the advanced fermentation technology required for bio-intermediate production. However, this gap continues narrowing as production efficiencies improve and manufacturing scales increase. From a timing perspective, lead times for bio-based polyester align with conventional fabric sourcing cycles, with sample development typically requiring 48 hours and bulk production following established scheduling protocols.

How do logistics and regulatory factors impact availability?

Strategic sourcing from specialized manufacturers mitigates potential supply chain complications. Bio-based polyester often qualifies for favorable tariff classifications in key markets like the United States, providing cost advantages over conventional alternatives subject to standard duty rates. Integrated logistics management handles transportation, documentation, and customs clearance, creating a streamlined supply chain from manufacturing facilities to destination markets. This comprehensive approach reduces administrative burdens while ensuring regulatory compliance.

Conclusion

Bio-based polyester represents a commercially viable pathway toward reducing the fashion industry's environmental footprint without compromising quality or performance. The material's technical characteristics align with industry requirements, while manufacturing scalability supports adoption across market segments. As production volumes increase and costs continue their downward trajectory, bio-based polyester offers a practical sustainable alternative for progressive brands.

For brands interested in exploring bio-based polyester applications, we offer comprehensive support from material selection through production. Our technical team can provide detailed specifications, swatch collections, and development samples to inform your sourcing decisions. To discuss how bio-based polyester might enhance your product offerings, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We welcome the opportunity to collaborate on your sustainable initiatives.