In electronics manufacturing, static electricity poses a constant threat to sensitive components. I've witnessed how electrostatic discharge (ESD) causes costly damage and product recalls. This isn't theoretical—it's a daily operational risk that demands effective solutions.

Antistatic ESD fabric safely dissipates electrostatic charges through conductive materials like carbon yarn, which creates a safe pathway for static electricity to flow away from sensitive components. This controlled dissipation protects expensive circuitry and ensures workplace safety where static electricity is prevalent.

What are the common types of ESD fabrics?

Choosing the right ESD fabric requires understanding the available options and their specific applications. From my twenty years in textiles, I've learned that improper selection can compromise protection as much as having no safeguards at all.

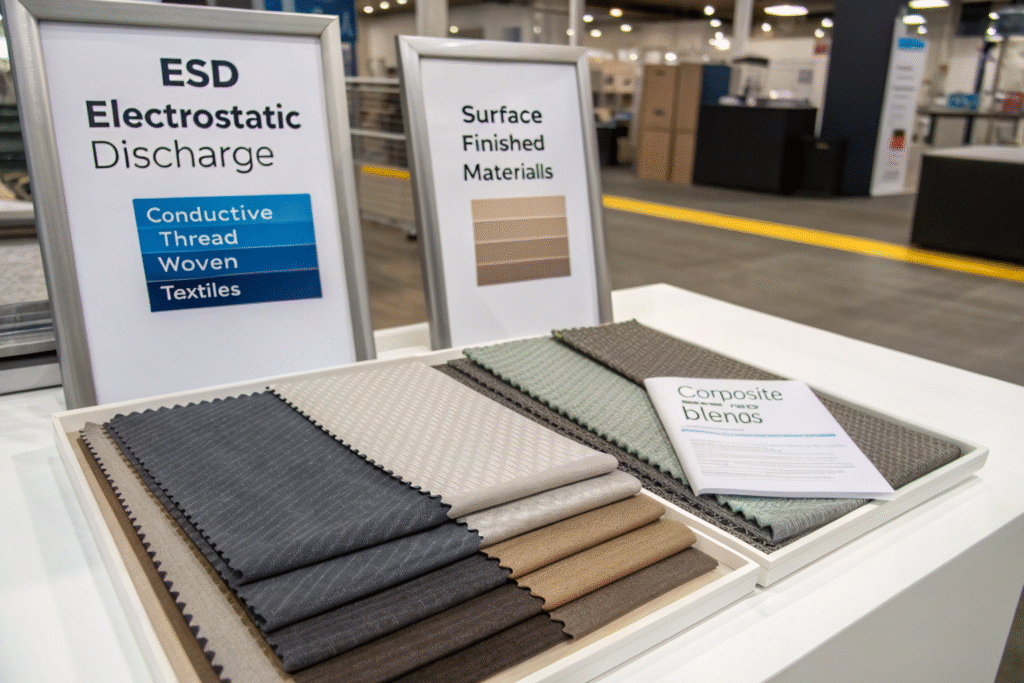

The primary ESD fabric categories include conductive-thread woven textiles, surface-finished materials, and composite blends. Each type balances protection with practical considerations like wearability and cost-effectiveness. While surface-treated fabrics may suffice for low-risk environments, high-tech laboratories handling microchips require robust woven solutions with reliable conductive networks.

How do carbon fiber blended fabrics work?

Carbon fiber blends integrate conductive filaments directly into base yarns during spinning, creating permanent conductive networks throughout the textile structure. Unlike temporary coatings, this embedded approach ensures lasting antistatic protection throughout the garment's lifespan.

These carbon fibers function as microscopic wiring within the fabric, providing low-resistance pathways for static charges to travel toward grounding points like wrist straps or conductive flooring. Our ISO 3801 compliant testing verifies optimal blend ratios for consistent performance, while meeting sustainable textile standards through durable construction.

What makes stainless steel fiber fabrics unique?

Stainless steel fabrics incorporate fine metallic filaments that provide superior conductivity and durability. These materials excel in high-wear environments requiring both static dissipation and electromagnetic shielding effectiveness.

The stainless steel fibers create a Faraday cage effect, intercepting and redistributing external electrostatic fields before they reach protected components. Though slightly heavier than carbon alternatives, these fabrics withstand repeated industrial laundering while maintaining performance verified by ASTM D257 testing standards and compliant with OSHA electrical safety requirements.

Why is carbon yarn so effective for static control?

Carbon yarn's exceptional performance stems from its inherent electrical conductivity, functioning as an electron highway that distributes charges evenly rather than allowing dangerous accumulation. This fundamental property makes it reliably effective regardless of environmental humidity levels.

In our CNAS-certified laboratory, we consistently verify that carbon yarn fabrics maintain surface resistivity between 10^5 and 10^9 ohms per square—the optimal range for safe static dissipation without creating electrical hazards.

How does carbon's conductivity mechanism work?

Carbon conductivity works by providing preferential pathways for electrical charges, allowing static to distribute evenly across the fiber network rather than accumulating to dangerous levels. This distribution prevents voltage from reaching the thousands of volts needed to create damaging sparks.

The continuous carbon fiber network enables instantaneous charge transfer to grounding points, offering real-time protection verified through advanced textile performance testing. This reliability explains why major electronics manufacturers insist on SGS-verified ESD protection.

What durability advantages does carbon yarn offer?

Embedded carbon fibers provide permanent static protection that withstands abrasion, industrial laundering, and chemical exposure. This integrated approach ensures the antistatic properties remain effective throughout the product's lifespan, unlike surface treatments that degrade over time.

The longevity translates to significant cost savings through reduced replacement frequency. Carbon fibers maintain fabric breathability and comfort while surviving rigorous ISO 5077 shrinkage and ISO 12945-2 abrasion testing, ensuring performance in demanding environments.

How is ESD fabric reliability verified?

Trustworthy ESD protection requires rigorous, independent verification through standardized testing protocols. Every fabric batch undergoes comprehensive evaluation in our CNAS-accredited lab before approval, simulating real-world conditions to validate long-term performance.

What does surface resistivity testing determine?

Surface resistivity testing measures a material's resistance to electrical current flow across its surface, serving as the primary classification metric for ESD fabrics. Using standardized electrode probes, we apply known voltages and measure resulting currents to determine dissipation capability.

Results measured in ohms per square (Ω/□) indicate whether fabrics fall within the optimal 10^5 to 10^9 Ω/□ range for effective static control. Our adherence to ASTM D257 standards ensures compliance with international ESD Association requirements for sensitive environments.

How do charge decay tests validate performance?

Charge decay testing measures how quickly fabrics neutralize applied static charges, directly simulating real-world conditions where movement generates electricity. This dynamic assessment involves inducing high voltages (typically 5000V) and recording dissipation times to specific thresholds.

Shorter decay times indicate superior ESD performance in practical applications. Following ISO 18080-4 protocols, this testing confirms fabrics will perform effectively in actual working environments, not just controlled laboratory conditions.

What defines a reliable ESD fabric supplier?

Selecting an ESD fabric supplier requires evaluating technical expertise, quality infrastructure, and partnership commitment beyond basic pricing. A qualified partner should demonstrate transparent certifications, controlled manufacturing processes, and innovative R&D capabilities.

Why is integrated quality control essential?

Comprehensive quality management from raw materials to finished products prevents defects and ensures consistent performance. Our vertically integrated model—including weaving factories and cooperative finishing partners—enforces uniform standards throughout production.

Dedicated quality teams conducting pre-production, in-process, and final inspections guarantee that every shipped meter meets specified requirements. This control methodology maintains ISO 9001 quality management integrity while ensuring client confidence in product reliability.

How does agile development benefit clients?

Rapid prototyping and custom development capabilities distinguish true partners from basic suppliers. Our 48-hour sample development cycle accelerates client time-to-market by quickly addressing specific requirements like color matching or performance enhancements.

Leveraging Keqiao's localized supply chain enables material sourcing and sample production at speeds unavailable to companies without regional expertise. This responsiveness, combined with expertise in global logistics management, ensures seamless delivery from our facility to client destinations.

Conclusion

Antistatic ESD fabric represents essential protection rather than optional precaution in electronics and sensitive equipment environments. Carbon yarn integration provides durable, effective static dissipation through continuous conductive networks that prevent charge accumulation and component damage.

The complete solution emerges through partnership with suppliers demonstrating technical expertise, verified quality control, and responsive development capabilities. For those seeking reliable ESD fabrics for protective workwear or technical applications, contact Business Director Elaine at elaine@fumaoclothing.com to discuss manufacturing solutions built on quality and innovation foundations.