Have you ever been caught in the rain wearing a high-tech jacket, staying dry from the rain yet surprisingly comfortable, without that clammy, sticky feeling? This modern miracle is largely thanks to a key innovation: the breathable waterproof membrane. For brands and buyers in the outdoor, sportswear, and fashion sectors, understanding this technology is no longer a luxury—it's a necessity. It's the difference between a product that satisfies and one that truly delights the end-user. As a fabric supplier with over two decades in the heart of China's textile hub, Keqiao, we've seen this technology evolve and become a cornerstone of high-performance apparel.

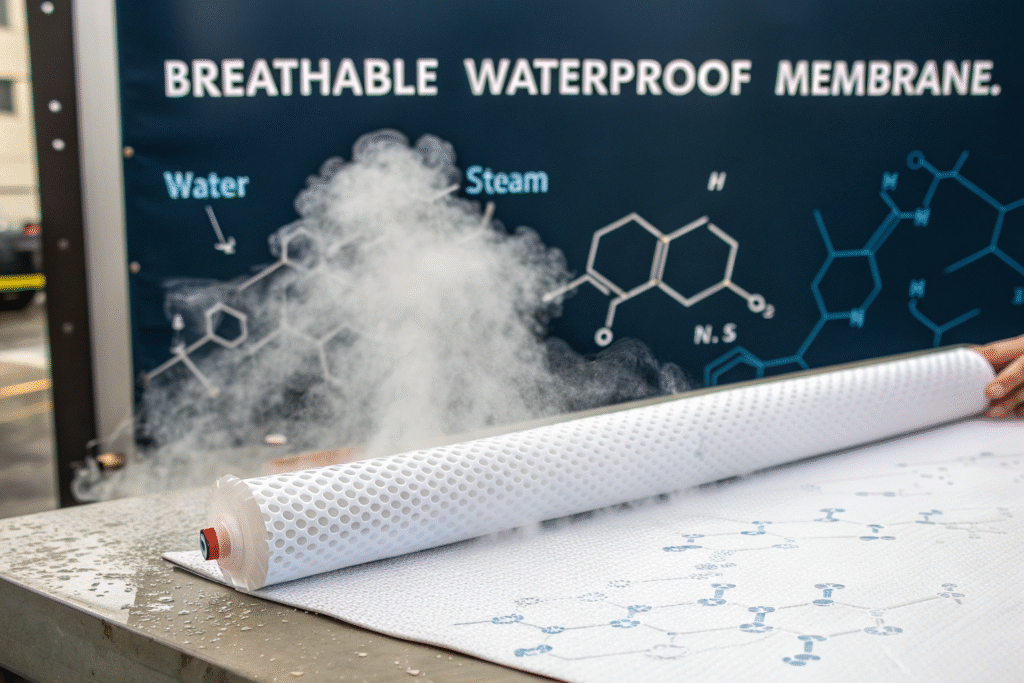

Simply put, a breathable waterproof membrane is an ultra-thin layer of material that is permanently laminated to a face fabric. Its core function is twofold: to prevent liquid water (like rain) from penetrating from the outside, while allowing water vapor (sweat) from the inside to escape. This balance is the holy grail of performance wear. The effectiveness of a membrane is measured by two key metrics: its waterproofness, often rated in millimeters (mm) of water column, and its breathability, measured in grams (g) of water vapor transmitted per square meter over 24 hours (MVTR). For anyone sourcing technical fabrics, grasping the basics of how these membranes work is the first step to making informed decisions for your collection.

This article will demystify breathable waterproof membranes. We will explore how they actually work, break down the different types available, and provide a clear framework for selecting the right membrane for your specific product line. Finally, we will look at how this technology is evolving with a focus on sustainability, a critical concern for modern brands.

How does a breathable waterproof membrane actually work?

The magic of a breathable waterproof membrane seems almost contradictory. How can a material block water yet let vapor through? The secret lies in the fundamental science of water molecules and ingenious engineering. For buyers, understanding this principle is crucial. It moves the conversation from a simple feature checklist to a deeper appreciation of product quality and performance claims. This knowledge empowers you to ask the right questions and evaluate suppliers more effectively.

The core principle relies on the size difference between a water droplet and a water vapor molecule. A drop of rainwater is massive compared to a single molecule of vapor from your sweat. Breathable waterproof membranes are engineered with pores that are smaller than liquid water droplets but larger than water vapor molecules. Think of it as a very sophisticated sieve. This micro-porous structure creates a one-way barrier: rain cannot physically pass through the tiny holes, but sweat vapor can easily diffuse outwards, keeping the wearer dry and comfortable.

What is the science behind the pore size?

The effectiveness of a micro-porous membrane hinges on precise pore size. Typically, these pores are less than 10 microns in diameter, and often as small as 0.1 microns. To put that in perspective, a water droplet is about 100 microns in size, while a water vapor molecule is roughly 0.0004 microns. This enormous size difference is the physical basis for the membrane's function. It's a purely physical mechanism, not a chemical one. This is why these membranes are so durable; their performance isn't reliant on a coating that can wear off. The most famous example of this technology is Gore-Tex, which pioneered this approach. The integrity of these pores is critical, which is why quality control during the lamination process at a certified factory is non-negotiable.

Are there other mechanisms besides micro-porous?

Yes, another important technology is the hydrophilic membrane. Unlike micro-porous membranes, hydrophilic ones have no physical pores. Instead, they are made from a solid polymer film that has a chemical affinity for water molecules. Water vapor from sweat is absorbed by the membrane on the inside, travels molecule-by-molecule through the film by diffusion, and is then released on the outside surface. It works like a sponge moving moisture. Brands like Sympatex utilize this technology. Each type has advantages; micro-porous membranes generally offer higher breathability, while hydrophilic membranes are excellent at preventing contamination from oils and detergents that could clog tiny pores.

What are the main types of waterproof breathable membranes?

Navigating the world of membranes can be confusing, with various branded names and technical specifications. However, most technologies fall into a few primary categories. Choosing the right type is a strategic decision that impacts cost, performance, durability, and the target market for your garments. A clear understanding of these options allows you to match the technology to your brand's price point and performance promises.

The two primary classifications we've already touched on are micro-porous and hydrophilic. But from a construction and sourcing perspective, membranes are also defined by how they are integrated into the fabric. The main structures are 2-Layer, 2.5-Layer, and 3-Layer laminates. Each offers a different balance of weight, packability, durability, and cost. For instance, ultra-lightweight hiking gear often uses 2.5-layer construction, while durable mountainwear relies on robust 3-layer builds.

How do 2-Layer, 3-Layer, and 2.5-Layer constructions differ?

This refers to how the membrane is assembled with the other fabric components.

- 2-Layer (2L): The membrane is laminated to the outer shell fabric. A separate, loose lining is then added inside the garment. This construction is generally more cost-effective and is common in entry-level to mid-range jackets. It offers good durability but can be slightly heavier and less packable.

- 3-Layer (3L): The membrane is sandwiched and laminated between the outer shell fabric and an inner protective scrim (a thin knitted layer). This creates a single, robust piece of fabric. 3L construction is typically lighter, more durable, and offers superior performance, but it comes at a higher cost. It's the choice for professional-grade equipment.

- 2.5-Layer (2.5L): This is a 3-layer construction where the inner lining is a very light, often printed, protective coating instead of a full fabric layer. This results in an extremely lightweight and packable garment, ideal for fast-and-light activities. The compromise can be a slight reduction in durability and next-to-skin comfort compared to 3L.

What are the pros and cons of PU, ePTFE, and TPU membranes?

| The base material of the membrane itself is another key differentiator. | Membrane Type | Pros | Cons | Common Applications |

|---|---|---|---|---|

| PU (Polyurethane) | Cost-effective, versatile, can be hydrophilic or micro-porous. | Generally lower breathability than high-end ePTFE, can be less durable over time. | Budget-friendly rainwear, fashion-oriented outerwear. | |

| ePTFE (Expanded Polytetrafluoroethylene) | Exceptionally high breathability, very durable performance. | Higher cost, can be prone to clogging from oils and contaminants without a protective layer. | High-performance outdoor apparel (e.g., Gore-Tex). | |

| TPU (Thermoplastic Polyurethane) | Good balance of cost and performance, high elasticity, and durability. | Breathability can vary widely depending on the specific formulation. | A wide range of sportswear and outdoor gear, often as an alternative to PU. |

How to choose the right membrane for your product line?

Selecting a membrane is not about finding the "best" one in absolute terms, but the most appropriate one for your specific product. A misstep here can lead to inflated costs, underperformance, or customer dissatisfaction. The choice should be a deliberate decision based on a clear understanding of your target audience's needs, the garment's intended use, and your overall cost structure. It's a key part of the value engineering process.

The decision-making process should be driven by a few critical questions. What is the primary activity the garment is designed for? High-exertion activities like ski touring demand the highest breathability, while a casual urban raincoat can prioritize cost and fashion. What is your target price point? Membrane technology significantly impacts cost. Finally, what are your sustainability goals? The industry is now offering membranes made with recycled content, like recycled TPU, which can be a strong brand differentiator.

What performance specifications should I prioritize?

You must align the technical specs with the end-use.

- Waterproof Rating (mm H₂O): For heavy rain and snow, look for a rating of 10,000mm to 20,000mm or higher. For light showers, 5,000mm may be sufficient.

- Breathability Rating (MVTR): For high-intensity activities, aim for 20,000 g/m²/24h or more. For low-output use, 10,000 g/m²/24h is often adequate.

- Durability: Consider the abrasion resistance of the entire laminate. A 3-layer construction will generally be more durable than a 2.5-layer. Ask your supplier for Martindale or Wyzenbeek test results on the finished fabric.

How do cost, sustainability, and brand value intersect?

The cheapest option is rarely the most valuable. Investing in a recognized, high-performance membrane can enhance your brand's perceived value and justify a premium price. Conversely, using a basic PU membrane allows you to hit an aggressive price point for a mass market. Today, sustainability is a powerful value driver. Partnering with a fabric supplier who offers membranes with Global Recycled Standard (GRS) certification or who uses PFAS-free DWR (Durable Water Repellent) finishes can be a significant market advantage. At our company, we help clients navigate these choices to find the optimal balance for their brand.

What is the future of sustainable waterproof breathable technology?

The future of waterproof breathable technology is inextricably linked with sustainability. The industry is acutely aware of its environmental footprint, particularly concerning PFCs (Per- and Polyfluorinated Substances) historically used in DWR treatments and the petroleum-based origins of most membranes. The next generation of membranes is focused on reducing this impact without compromising performance. For forward-thinking brands, adopting these sustainable technologies early is a powerful way to future-proof your products and resonate with an increasingly eco-conscious consumer.

Innovation is happening on multiple fronts. The development of PFAS-free DWR finishes is now mainstream, ensuring that water beads up without harmful chemicals. More profoundly, there is a push towards creating circular membranes. This includes membranes made from bio-based polymers or high-content recycled materials. Furthermore, designs for recyclability are emerging, where the different layers of the laminate can be more easily separated at the end of the garment's life.

Are there eco-friendly alternatives to traditional membranes?

Absolutely. The market is seeing rapid growth in several areas:

- Recycled Membranes: Membranes made from recycled TPU are now commercially available. These membranes significantly reduce the reliance on virgin fossil fuels.

- Bio-Based Materials: Research into membranes derived from plants and other biological sources is advancing. While not yet mainstream, they represent the cutting edge of sustainable innovation.

- End-of-Life Solutions: Technologies are being developed to make complex fabric laminates more recyclable. This "design for disassembly" approach is crucial for creating a truly circular textile economy.

How can I ensure my sourcing is future-proof?

Partner with a supplier that is invested in R&D and has a clear sustainability roadmap. Ask specific questions: Do you offer membranes with recycled content? Are your DWR finishes PFC-free? What certifications can you provide? A proactive supplier, like us with our CNAS-certified lab, will not only provide compliant fabrics but also act as a strategic partner in navigating the evolving landscape of eco-standards and consumer expectations. This partnership is key to building a resilient and responsible supply chain.

Conclusion

Understanding breathable waterproof membranes is fundamental for anyone serious about sourcing high-performance apparel. We've explored the science behind how they work, the practical differences between membrane types and constructions, and a framework for selecting the right technology for your market. Most importantly, we see that the future of this field is green, driven by innovation in recycled and sustainable materials. This knowledge empowers you to make smarter sourcing decisions, create better products, and build a stronger brand.

At Fumao Textiles International, we don't just supply fabrics; we partner with you to co-create value. Our expertise in technical textiles, backed by our integrated supply chain from weaving to finishing, allows us to guide you through these complex choices. We offer a range of waterproof breathable laminates to meet different performance and budget needs, including options aligned with modern sustainability goals. If you are looking to develop a new line of performance outerwear or upgrade your existing range, let's talk. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can bring your vision to life with quality, innovation, and reliability.

One Response

This is a really engaging explanation it makes the tech behind breathable waterproof jackets feel accessible and relevant. I like how you balance the science with real-world benefits, showing why understanding membranes matters for both brands and end-users.