As a fabric manufacturer with over twenty years of experience, I understand how crucial safety standards are for our clients, especially those importing children's products to the U.S. market. The question of fabric flammability for children's sleepwear is one of the most critical we encounter. Compliance isn't just about legal requirements—it's about protecting children and building trustworthy brands.

The U.S. Consumer Product Safety Commission (CPSC) enforces strict flammability requirements for children's sleepwear under regulations 16 CFR Part 1615 (sizes 0-6X) and 16 CFR Part 1616 (sizes 7-14). These standards protect children from burn injuries by ensuring sleepwear fabrics and garments are flame-resistant and self-extinguish if ignited. For brands sourcing children's sleepwear, partnering with a fabric supplier that deeply understands these standards is essential for compliance and market success.

Understanding the differences between 16 CFR 1610 for general apparel and the more stringent 16 CFR 1615 and 1616 can be challenging. This guide breaks down everything you need to know—from test methods to sourcing strategies—ensuring your next order is safe and compliant.

What Are the Key Differences Between 16 CFR 1610 and 1615/1616?

Many importers confuse general flammability standards with specific sleepwear requirements. This confusion can lead to non-compliant products and serious safety risks. Understanding the distinction is fundamental to your sourcing strategy.

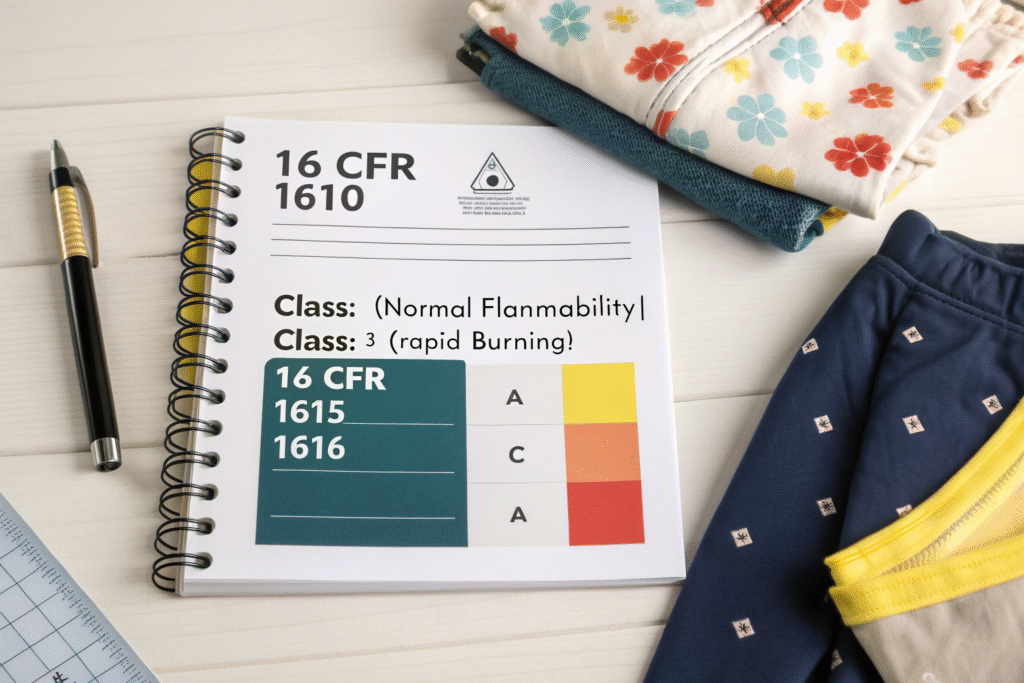

The main difference lies in intended use and protection level. 16 CFR 1610 is a general standard for most clothing textiles, classifying fabrics from Class 1 (normal flammability) to Class 3 (rapid burning). However, children's sleepwear is held to a much higher safety standard under 16 CFR 1615 and 1616. These regulations were created specifically to protect vulnerable children during sleep, when supervision is minimal and fire risks are present. They don't use the class system; instead, they require fabrics and garments to not ignite or burn beyond strict limits.

Why Is Children's Sleepwear More Strictly Regulated?

The answer lies in historical tragedies. Before the 1970s, children suffered severe burns and fatalities from sleepwear fires. The U.S. government responded with rigorous, science-backed regulations. Children are less cautious, their sleepwear is often loose-fitting (easier to catch fire), and home accidents happen quickly. These regulations limit vertical flame spread, giving caregivers extra seconds to respond. Tests for 16 CFR 1615 and 1616 are pass/fail and notoriously strict—unlike the more lenient 16 CFR 1610 classifications. Brands cannot assume a Class 1 fabric under 1610 is acceptable for sleepwear; it must be tested specifically for 1615/1616 compliance.

How Do 16 CFR 1615/1616 Test Methods Ensure Safety?

The test is a rigorous vertical flame procedure simulating real fire scenarios. A fabric specimen is suspended in a special cabinet, and a controlled flame is applied to its bottom edge. The test measures char length (destroyed fabric area) and after-flame time (how long fabric burns after flame removal). To pass, char length cannot exceed specific limits (usually 7 inches for a 10-inch specimen), and after-flame time must be brief. The entire garment—including trims and seams—must be tested in final form. This ensures every component contributes to flame resistance. At Fumao Textiles, our CNAS-accredited lab pre-tests using these methods, giving clients confidence their production will pass third-party SGS or ITS lab audits.

What Fabric Characteristics Ensure 16 CFR 1615/1616 Compliance?

Compliance isn't accidental—it results from deliberate fabric engineering and selection. The regulation is performance-based, not prescriptive: it doesn't mandate materials but requires specific performance. However, certain fabrics consistently meet these demands.

Common compliant fabrics include tight-fitting sleepwear from inherently flame-resistant materials or treated fabrics. Inherently flame-resistant fabrics include specific polyester and modacrylic blends. These synthetics melt and drip from ignition sources instead of sustaining flames. For loose-fitting sleepwear, fabrics are often treated with flame retardant (FR) chemicals during dyeing or finishing. Note that FR chemical use is regulated; brands must ensure treatments comply with other standards like CPSIA. At Fumao, we specialize in developing compliant fabrics—from soft FR-treated cottons to durable polyester blends offering safety and easy care.

Which Fiber Types Best Pass Flammability Tests?

Fibers behave differently under fire conditions. Here's a breakdown:

| Fiber Type | Performance in 16 CFR 1615/1616 | Considerations |

|---|---|---|

| 100% Cotton | Usually fails without FR treatment | Highly flammable naturally; needs chemical treatment |

| 100% Polyester | Often passes (melt-drip behavior) | Melts from flame; requires construction testing |

| Nylon | Variable performance | Can be engineered; needs careful selection |

| Modacrylic Blends | Excellent inherent resistance | Top choice for high safety without chemicals |

| Wool | Naturally flame-resistant | Less common due to cost and comfort |

Synthetics like polyester and modacrylic are popular for inherent properties. However, fabric construction matters as much as fiber content. Weight (GSM) and construction (tight weaves or knits) significantly impact flammability. Tighter weaves and heavier weights generally perform better with less air to fuel flames. Our R&D team creates optimal fiber blends and constructions meeting safety standards and design visions for comfort and style.

How Does Fabric Construction Impact Flame Resistance?

Fabric build quality is critical. Loose, fluffy pile fabrics like plush velvet are fire hazards, while tight, smooth satin weaves or compact double knits perform better. Surface characteristics matter—napped or brushed surfaces with more air pockets tend to be more flammable. This is why standards often require trims like lace or ribbons to also meet flammability criteria. During our fabric development process, we simulate and pre-test constructions—whether woven shirting for pajamas or knitted brunch cloth for loungewear—ensuring high pass probability in formal tests. This proactive approach saves clients from costly failures and delays.

How Can Importers Verify Fabric Compliance and Manage QC?

Verification is multi-stage, starting long before production and continuing to final shipment. Relying solely on supplier assurances is risky. Robust due diligence and quality control protocols are your best defense.

The gold standard is testing by CPSC-accepted, independent third-party laboratories. While in-house testing by suppliers with CNAS-accredited labs (like ours) is excellent for screening, final compliance certificates for the U.S. market must come from accepted labs like SGS, Intertek, or Bureau Veritas. The process involves submitting final production garment samples for full 16 CFR 1615/1616 testing. Importers should request and retain these test reports for each style and lot number. Additionally, comprehensive Quality Control plans are essential—including pre-shipment inspections randomly selecting production samples to check workmanship, labeling, and fabric consistency with approved samples.

What Documentation Should I Request from Fabric Suppliers?

Trustworthy suppliers provide transparent documentation trails. Key documents include:

- First-Party Test Report: From the supplier's own lab (like Fumao's CNAS lab) showing fabric passed vertical flame tests.

- Mill Certificate of Compliance (MCC): From the fabric mill affirming standard compliance.

- Third-Party Test Report: The crucial certificate from an accredited lab (e.g., Intertek) confirming garment compliance with 16 CFR 1615/1616.

- General Certificate of Conformity (GCC): Required by the Consumer Product Safety Improvement Act (CPSIA), created by importers based on third-party test reports.

Always verify reports are recent and apply to exact fabric batches and garment styles. Beware suppliers offering generic or outdated certificates.

What Are the Risks of Importing Non-Compliant Sleepwear?

Risks are severe beyond rejected shipments. U.S. Customs and Border Protection (CBP) and CPSC actively monitor imports. Non-compliant products can be detained, refused entry, and destroyed at ports—with importers bearing costs. Worse, CPSC can mandate recalls of marketed products, forcing consumer notifications and refunds—destroying brand reputation and finances. If non-compliant products cause injuries, importers face devastating lawsuits and liabilities. Partnering with a knowledgeable, compliant manufacturer isn't an expense—it's an investment in business security and longevity.

How Does Fumao Textiles Simplify Compliance for US Importers?

We know navigating U.S. safety standards from abroad is daunting. That's why we've built our service model around simplifying this process for American clients, turning regulatory challenges into seamless supply chain components.

Our approach integrates compliance from the start. During fabric development, our R&D experts guide material choices proven to comply, avoiding trial-anderror with inexperienced suppliers. Our in-house CNAS-accredited testing lab conducts rigorous pre-compliance checks on samples before official third-party testing. This "test early, test often" philosophy boosts first-pass rates and prevents costly bulk production mistakes. Our professional QC team inspects throughout production, ensuring compliant approved fabrics are used in final orders and garment-making meets standards.

Can You Help with Pre-Production Testing and Development?

Absolutely—this is a core strength. When you approach us with children's sleepwear concepts, we don't just quote prices. We start collaborative development, presenting curated compliant fabric swatches from our diverse portfolio. Once directions are chosen, we produce lab dips and submit fabric samples for in-house flammability testing. We manage entire workflows, providing data and confidence at each step. This service is invaluable for brands using eco-friendly innovations like Recycled Polyester or Tencel™ blends—we engineer these sustainable materials to meet safety standards without compromising environmental values.

What Is Your Process for Ensuring Bulk Order Compliance?

Our bulk order process is systematic and transparent for your peace of mind:

- Pre-Production Sample Approval: We send samples from bulk fabric for your verification.

- In-House Bulk Fabric Testing: We test bulk fabric rolls in our lab before cutting.

- Third-Party Testing Coordination: We facilitate submissions to your chosen third-party labs, managing logistics and communications for mandatory compliance certificates.

- Pre-Shipment Inspection: Our QC team performs final random inspections on packed cartons, checking consistency, labeling, and quality against tested samples.

This end-to-end control, combined with global logistics expertise, delivers compliant products ready for U.S. markets while navigating challenges like tariff costs and optimizing sailing schedules.

Conclusion

Understanding and adhering to 16 CFR 1615 and 1616 is non-negotiable for sourcing children's sleepwear for the American market. It's where fabric choice, testing, and quality control intersect to ensure child safety. From knowing standard differences to verifying compliance through proper documentation, a proactive, informed approach is your strongest asset. The risks of non-compliance are too great for chances.

Navigating these regulations alone is inefficient and risky. Let us be your trusted partner in China. With Fumao Textiles, you gain more than a supplier—you get experts dedicated to safe, high-quality, compliant fabrics. We handle flammability standard complexities so you can focus on designing and selling with confidence. If you're producing compliant children's sleepwear lines, contact our Business Director, Elaine. She and her team will ensure your project succeeds from concept to delivery. Email Elaine today at elaine@fumaoclothing.com to discuss your next order.