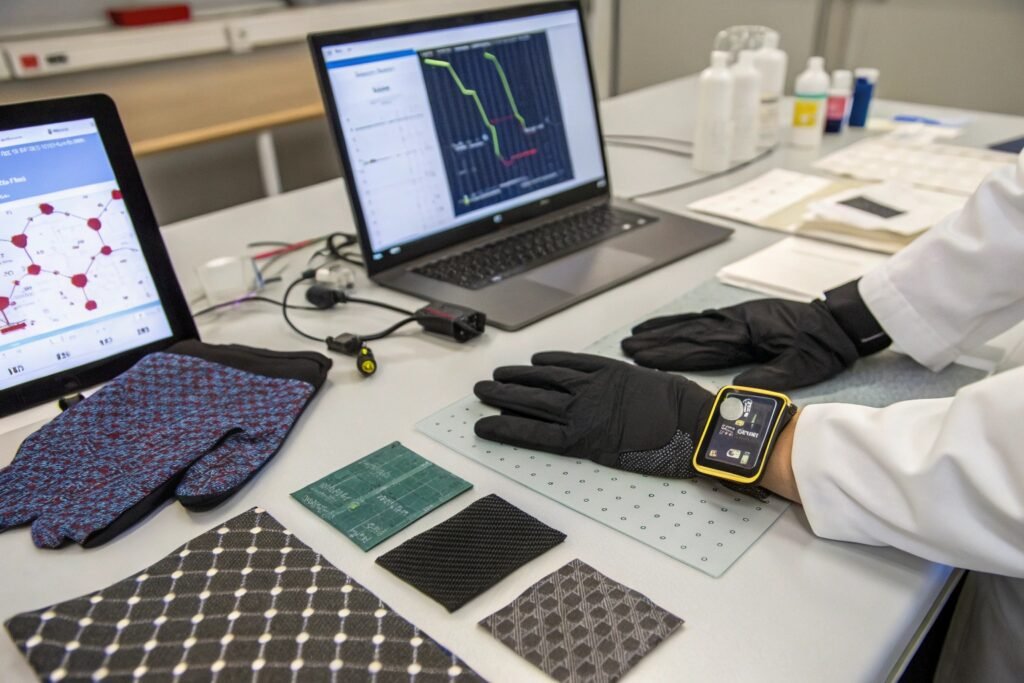

As wearable technology evolves, the demand for smart textiles—especially conductive fabrics—continues to rise. Whether you're designing fitness trackers, posture-correcting garments, or heating apparel, the fabric must do more than cover the body—it must transmit data, electricity, or signals.

Conductive fabrics for wearable tech include silver-coated textiles, carbon-infused knits, copper mesh, graphene-enhanced weaves, and conductive polymers. Each option serves different use cases from biosensing to power delivery.

At Fumao Fabric, we support R&D teams and startup brands in the U.S. and Europe with innovative textile development. Whether you're building a limited prototype or scaling a tech-integrated fashion line, here's a breakdown of the top options in conductive textiles today.

Which Metal-Based Conductive Fabrics Are Most Popular?

Metal-based conductive fabrics are among the most widely used due to their reliable conductivity and flexibility. They're ideal for powering circuits and creating capacitive sensors in clothing.

Silver-coated nylon, stainless steel yarns, and copper-plated meshes offer low resistance and high conductivity, making them the go-to choice for commercial wearable electronics.

What Makes Silver-Coated Fabrics So Effective?

Silver-coated textiles are widely favored because silver is highly conductive, antimicrobial, and corrosion-resistant. They're created by depositing microscopic silver particles on a base like nylon or polyester. This makes the fabric soft, washable, and capable of integrating with circuits.

Our lab partners in Keqiao often use silver-coated yarns in EMI shielding applications, as well as biosensing garments where skin-safe, consistent conductivity is critical.

How Are Copper Meshes Used in Smart Clothing?

Copper-infused fabrics are another strong option, especially for grounding, e-textiles, or heating pads. While slightly stiffer than silver, copper fabrics are more cost-effective and can be laminated onto garments or stitched into panels.

At Fumao, we've worked with performance gear brands embedding thin copper mesh into base layers for thermal regulation and power distribution in cold-weather wearables.

Are Carbon-Based Fabrics Suitable for Soft Sensors?

Carbon-based conductive fabrics are lightweight, flexible, and ideal for garments requiring soft sensors. They're less conductive than metals but offer better comfort and wash durability.

Carbon-infused fabrics are perfect for flexible strain sensors, ECG monitoring, and capacitive touch zones in apparel because they conform easily to body movement.

How Are Carbon-Infused Fabrics Made?

These textiles use carbon black or carbon nanotubes embedded into polymer bases or blended into yarns. The result is a fabric that retains stretch while conducting small signals—ideal for biometric monitoring.

We often recommend carbon blends for e-textile electrodes in healthcare garments or yoga tops with posture tracking.

Can They Be Used in Daily Washable Garments?

Yes—with limitations. Carbon-based fabrics are more wash-resistant than metal ones, but over time, conductivity may degrade. We apply encapsulation layers or PU coatings to extend lifespan. Clients in fitness and wellness sectors often request wash tests per AATCC 135 protocols to validate performance over 30+ cycles.

What Role Do Graphene and Nanotechnology Fabrics Play?

Graphene and other nanomaterial fabrics represent the cutting-edge of conductive textiles. They’re still in early commercial stages but show strong promise for sensors and flexible electronics.

Graphene-coated fabrics and nanocomposites offer ultrathin conductivity, stretch, and thermal regulation—ideal for futuristic wearables integrating motion tracking or display control.

How Is Graphene Applied to Textiles?

Graphene can be applied through dip-coating, inkjet printing, or extrusion into polymer yarns. It creates a highly conductive, transparent, and ultra-light layer that bonds to cotton, polyester, or even wool.

We collaborate with specialty finishing labs that apply graphene inks to knitwear for enhanced conductivity and infrared thermal control.

Are Graphene Textiles Ready for Mass Production?

Not quite—but we're getting close. While the price of graphene is falling, the consistency of application and conductivity varies by method. Most graphene textiles are used in high-value applications like biomedical sensors or energy harvesting.

We recommend graphene for short-run, high-tech garments or premium R&D collections—not yet for mass-market production unless price drops further.

How to Evaluate and Source Conductive Fabrics Effectively?

Sourcing conductive fabrics isn’t just about electrical performance—it’s about softness, stretch, washability, and integration. Many technical textiles fail because of poor handfeel or lack of consistency in bulk.

When sourcing conductive fabric, evaluate resistance levels (Ohm/m), GSM, flexibility, stretch recovery, wash tests, and certifications like RoHS or OEKO-TEX®.

What Resistance Levels Should You Look For?

It depends on the application. For power delivery or LED circuits, resistance should be under 1 Ohm/m. For soft sensors, higher resistance (5–100 Ohm/m) is acceptable. We provide real-time resistance testing data with each lot and help clients interpret specs based on end-use.

Our CNAS-certified lab in Zhejiang performs precision conductivity and durability tests with results traceable via QR codes on each production roll.

What’s the MOQ and Lead Time for Tech Fabrics?

Due to the technical setup and material cost, the MOQ for conductive fabrics typically starts around 100 meters per item. Lead times vary by complexity—stock silver knits can ship in 7 days, while custom graphene coatings may take 21–30 days.

We support startups and product developers with sample swatches, A4 testing sheets, and co-development of smart garment prototypes using conductive textiles.

Conclusion

The future of wearable technology is being woven—literally. Conductive fabrics open doors for smarter clothing, health monitoring, heated gear, and gesture-controlled accessories. But selecting the right material requires balancing electrical specs with textile comfort and processability.

At Fumao Fabric, we work directly with innovation labs, designers, and hardware developers to deliver conductive textiles that function in the real world—not just the lab. If you're exploring wearables, let us help you build fabrics that connect performance with reliability.