Every season, the buzz around "sustainable fabrics" grows louder, but for fashion brands, it's a minefield of greenwashing, confusing certifications, and unpredictable supply chains. You want to do the right thing—and meet your customers' demands—but choosing the wrong material can mean compromising on quality, blowing your budget, or facing backlash for unsubstantiated claims. The pressure is real: your choice of fabric in 2026 will define your brand's authenticity and resilience.

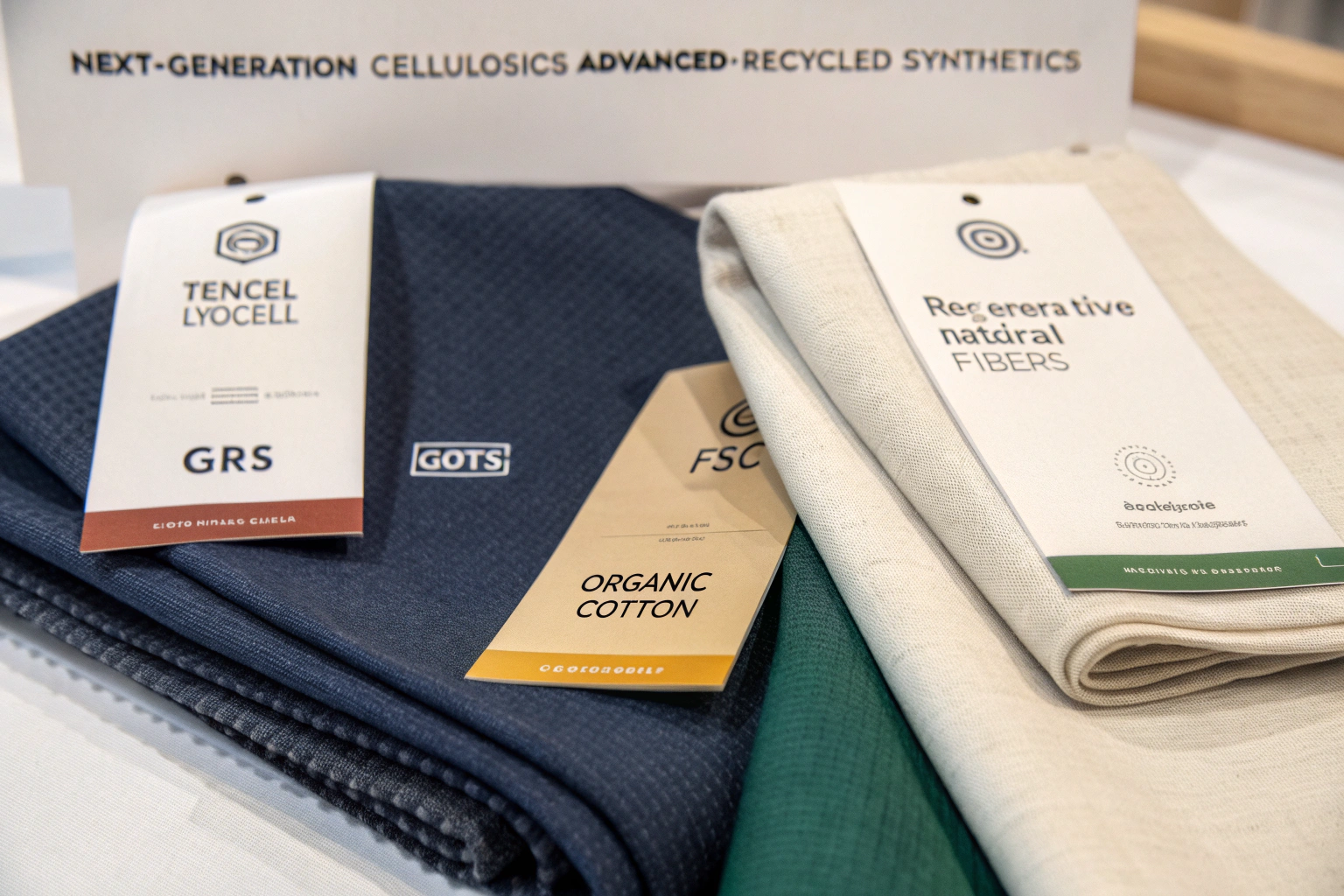

The most popular sustainable fabrics for fashion in 2026 are defined not just by their fiber origin, but by a proven balance of environmental impact, commercial viability, and circularity potential. They fall into three dominant categories: Next-Generation Cellulosics (like Tencel™ Lyocell with closed-loop processing and new blends like BAMSILK bamboo silk), Advanced Recycled Synthetics (including rPET and chemically recycled nylon with traceability), and Regenerative Natural Fibers (such as organic cotton from regenerative farms and responsible wool). Crucially, popularity in 2026 is tied to a fabric's complete, verifiable lifecycle story—from raw material sourcing to end-of-life—backed by credible certifications like GRS, GOTS, and FSC.

Forget the niche, ultra-expensive materials of yesterday. The winners in 2026 are the fabrics that have successfully scaled, offering designers the performance, aesthetics, and supply chain reliability they need, without the "sustainable premium" being prohibitive. This guide cuts through the hype to show you the materials that are moving from the margins to the mainstream, backed by real adoption data from mills like ours in Keqiao and clear trajectories for cost and innovation.

Why Are Next-Generation Cellulosics Dominating the Market?

Cellulosic fabrics—made from plant-based pulp—have been a sustainability staple for years. But in 2026, it's the next generation of these materials that are capturing market share. Why? Because they solve the historical drawbacks of their predecessors. Viscose/rayon, once criticized for its chemically intensive and polluting production, is being replaced by closed-loop lyocell processes. Meanwhile, new entrants are expanding the textural and functional palette beyond basic softness.

The leader remains Tencel™ Lyocell (and its generic counterpart, lyocell), but its dominance is now about more than just a closed-loop process. It's about versatility. Through advanced spinning and finishing, lyocell can now mimic the dry hand of linen, the drape of silk, or the robustness of a heavy twill. In Q1 2024, a Scandinavian minimalist brand we work with launched a best-selling line of tailored blazers using a 100% lyocell fabric we developed that had a crisp, wool-like structure—a far cry from the typical fluid lyocell dresses. This performance evolution, combined with its certified sustainable pedigree (often FSC-certified wood pulp), makes it a default choice for designers.

What New Blends Are Making Bamboo and Other Fibers Truly Sustainable?

Pure bamboo viscose has faced scrutiny over its processing. The innovation in 2026 is in creating responsible blends and new production methods. For instance, BAMSILK (Bamboo Silk) is a game-changer we've heavily invested in. It's not a viscose; it's a process that retains more of bamboo's natural long-filament structure, creating a fabric with a luxurious, silken luster and inherent antibacterial properties, using a more controlled chemical process. Blending it with organic cotton or recycled polyester creates fabrics with enhanced performance and a more defensible sustainability story.

Another rising star is hemp blends. Historically, pure hemp could be rough. Now, blending hemp (which requires minimal water and no pesticides) with Tencel™ or organic cotton results in fabrics that are soft, durable, and have a beautiful, natural texture. The key for any cellulosic is transparency in processing. Brands must ask for evidence of closed-loop systems or certifications like the EU Ecolabel or specific manufacturer's sustainability reports, like those from Lenzing AG for Tencel™.

How Do These Fabrics Perform in Dyeing and Finishing?

This is a critical technical point. A fabric's sustainability doesn't end at the fiber; it extends to wet processing. Next-gen cellulosics like lyocell are notoriously dye-hungry, which can lead to high water and chemical use if not managed properly. The leading mills in 2026 are addressing this head-on with:

- Low-Liquor Ratio Dyeing Machines: These use up to 50% less water and chemicals.

- Digital Printing: Applied to these fabrics, it reduces water waste by over 90% compared to conventional rotary printing.

- Pre-Colored (Dope-Dyed) Fibers: For synthetics and some cellulosics, color is added to the polymer melt or solution before the fiber is extruded, eliminating the dyeing process entirely.

When vetting a supplier, ask specifically about their dyeing partners and technologies. At Shanghai Fumao, our cooperative dyeing factories have invested in these advanced technologies, which we can track and report on for our clients—turning a potential sustainability weakness into a verified strength.

How Have Recycled Synthetics Evolved Beyond Basic rPET?

Recycled polyester (rPET) from plastic bottles is now table stakes. In 2026, popularity is shifting towards advanced recycled synthetics that address rPET's limitations: primarily, its reliance on PET bottles (which is a downstream, not circular, solution) and the quality degradation after multiple recycles.

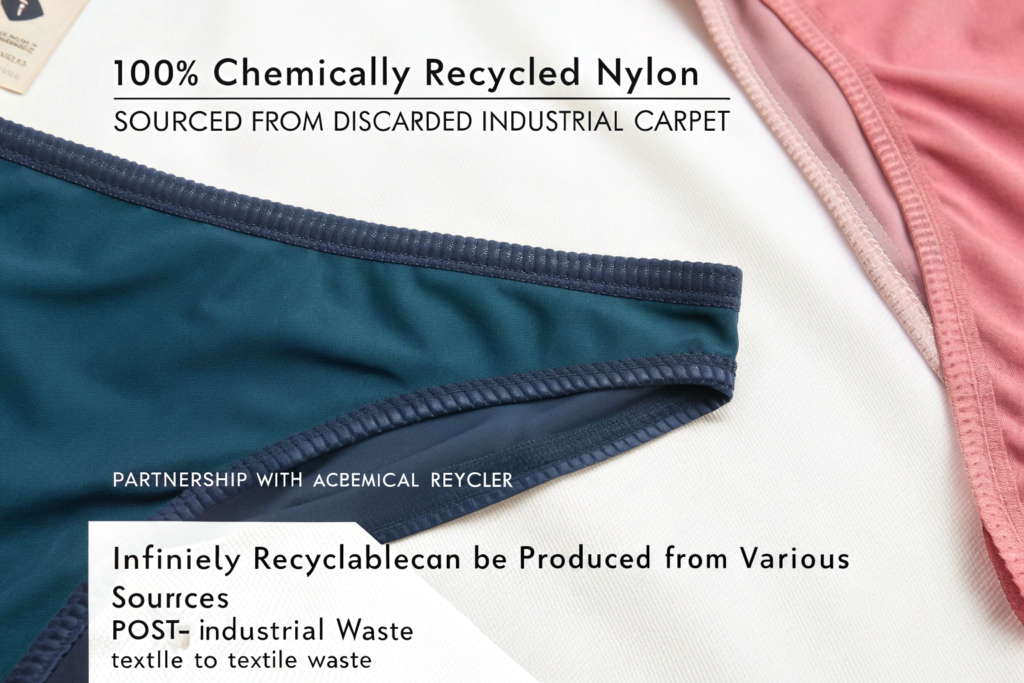

The frontier is in chemically recycled nylon and polyester. Unlike mechanical recycling (shredding and melting), chemical recycling breaks polymers down to their raw monomers, which can then be repolymerized into virgin-quality fiber. This means:

- Infinite Recyclability: The fiber doesn't degrade.

- Source Flexibility: It can use post-industrial waste, old fishing nets, or even textile-to-textile waste, creating a true circular loop.

In late 2023, we partnered with a chemical recycler to produce a batch of swimwear fabric made from 100% chemically recycled nylon sourced from discarded industrial carpet. The performance was identical to virgin nylon, but with a 60% lower carbon footprint. While still at a premium, its cost is falling rapidly.

What Does "Traceability" Really Mean for Recycled Fabrics?

In 2026, "recycled" is not enough. Brands and consumers demand proof. The gold standard is chain-of-custody certification like the Global Recycled Standard (GRS). A GRS certificate tracks the recycled content from its source, through every stage of production, to the final product. You should be able to get a transaction certificate (TC) for your order.

Beyond certification, technology is enabling new levels of transparency. Some innovators are using blockchain or digital product passports where a QR code on the fabric tag reveals the exact percentage of recycled content, its origin (e.g., "X% from post-consumer plastic bottles collected in Southeast Asia"), and the carbon footprint of its production. Asking your supplier for this level of data is becoming a standard part of the sourcing conversation. Resources like the Textile Exchange's Recycled Polyester Guidelines set the benchmark for what credible traceability looks like.

Are Recycled Synthetics Suitable for High-Performance Apparel?

Absolutely, and this is a major growth area. The myth that recycled fibers are weaker is outdated. Through advanced polymer engineering and blending, recycled synthetics are now engineered for high-stress applications.

- Recycled Nylon (rNylon): Excellent for activewear, swimwear, and outerwear due to its strength, elasticity, and abrasion resistance.

- Recycled Polyester (rPET) with Enhancements: Can be combined with moisture-wicking finishes, UV protection, or made into high-tenacity yarns for durable bags and shoes.

- Blends: Combining recycled polyester with organic cotton or Tencel™ creates hybrid fabrics that balance performance, comfort, and sustainability.

The key is to work with a supplier who understands the technical specifications required. For a recent project with a US-based outdoor brand, we developed a recycled nylon canvas with a PFC-free DWR (durable water repellent) finish that performed flawlessly in their lab tests, proving that high-performance and sustainability are no longer mutually exclusive.

Why Is "Regenerative" the New Benchmark for Natural Fibers?

Organic is no longer the pinnacle. In 2026, the most forward-thinking brands are looking to regenerative agriculture for their natural fibers. While organic farming avoids harmful inputs, regenerative farming actively improves the ecosystem—rebuilding soil organic matter, increasing biodiversity, and capturing carbon. For cotton and wool, this represents the next level of climate-positive sourcing.

Regenerative Cotton is leading this charge. It's not just about the absence of pesticides; it's about crop rotation, cover cropping, and no-till farming that can actually sequester carbon in the soil. The challenge is scale and verification. Pioneering programs, often led by NGOs or brand consortiums, are building traceable pipelines from regenerative farms to spinners. The premium is significant, but for brands building a premium, authentic story, it's a powerful investment. Following the work of organizations like the Regenerative Organic Alliance can provide pathways into this complex but rewarding sourcing area.

How Is Wool Being Reimagined Responsibly?

Wool's natural, renewable, and biodegradable properties have always given it a sustainable edge. The focus in 2026 is on ensuring holistic animal welfare and land management. Certifications like the Responsible Wool Standard (RWS) are becoming minimum requirements for brands that use wool.

Beyond certification, innovation is happening in wool blends and processing. For example:

- Wool-Tencel™ Blends: Combine wool's warmth and biodegradability with Tencel's™ smoothness and drape, creating luxurious, season-spanning fabrics.

- Recycled Wool: Using pre-consumer (factory offcuts) or post-consumer wool garments, the fiber is shredded, re-spun, and blended with virgin wool or other fibers. This dramatically reduces waste and water usage compared to virgin wool processing.

We've seen a 40% year-on-year increase in requests for RWS-certified or recycled wool blends from our European clients, indicating a clear market shift.

What About Emerging Materials: Mushroom, Algae, and Lab-Grown?

These materials generate immense buzz, but in 2026, their role is still largely specialized and supplemental rather than mainstream. Their "popularity" is in brand storytelling and pilot projects.

- Mushroom Leather (Mylo, etc.): Gaining traction for small leather goods (wallets, watch straps) and apparel accents. The limitations are scale, cost, and currently, a lack of the full performance durability of animal leather for heavy-use items.

- Algae-Based Fibers: Used in foam for shoes (like in some sneaker insoles) or as a component in yarn blends for its moisture-management properties.

- Lab-Grown Cotton/Collagen: Still in early R&D phases, far from commercial scale.

The smart approach for brands is to use these innovatively in capsule collections to drive awareness and demonstrate commitment to material innovation, while relying on the scaled, proven sustainable fabrics mentioned above for core volume. A good resource to track the commercialization of these materials is Material Innovation Initiative's public reports.

How Do You Source These Fabrics Reliably and at Scale?

Knowing what to source is only half the battle. The real challenge for brands in 2026 is sourcing these popular sustainable fabrics reliably, at a viable cost, and with undeniable proof. The market is flooded with claims, and greenwashing is rampant at the supplier level.

The most critical step is partnering with a vertically-engaged supplier who can provide documentation, not just promises. This means:

- Demand Certificates, Not Logos: For any claimed certification (GOTS, GRS, RWS, FSC), request the actual certificate PDF with a valid license number and scope that covers the production stages you're using. Verify it online.

- Audit the Supply Chain: Ask your supplier to map the journey of the fiber. Which farm or recycler? Which spinner? Can they facilitate a virtual audit? A supplier like Shanghai Fumao, with our CNAS-lab and integrated partnerships, can provide this transparency because we control and verify each link.

- Test, Don't Trust: Always conduct independent lab tests (or review the supplier's recent test reports from SGS/ITS) for composition, harmful substances (against OEKO-TEX® STANDARD 100 or REACH), and claimed performance (moisture-wicking, durability).

What Are Realistic Cost Premiums and MOQs in 2026?

The sustainability premium is shrinking but still exists. Here's a realistic snapshot for bulk orders (5,000m+) from a direct manufacturer:

| Fabric Type | Typical Premium vs. Conventional (2026) | Key Cost/MOQ Drivers |

|---|---|---|

| GOTS Organic Cotton | 15% - 25% | Cost of certified cotton lint; often similar MOQ to conventional. |

| Tencel™ Lyocell (FSC) | 20% - 35% | Pulp cost; closed-loop process investment. MOQs can be low. |

| GRS rPET (from bottles) | 5% - 15% | Recycled chip premium; well-commoditized, low MOQ. |

| Chemically Recycled Nylon | 50% - 100%+ | New technology premium; limited supply, higher MOQs. |

| Regenerative Cotton | 40% - 80%+ | Very limited supply, premium paid to farmers, high traceability cost. |

Negotiation Tip: Your leverage to reduce cost is volume commitment and long-term partnership. A supplier is more likely to offer better pricing if they see you as a strategic partner for the next 3 seasons, not a one-off buyer.

How Do You Future-Proof Your Sustainable Sourcing Strategy?

The landscape will keep evolving. To stay ahead:

- Diversify Your Portfolio: Don't bet everything on one "miracle" fiber. Build a matrix of 2-3 proven sustainable fabrics that work for your brand.

- Invest in Relationships, Not Transactions: Work closely with a technically capable supplier who is also investing in R&D. Their innovation pipeline becomes your future material pipeline.

- Educate Your Customer: Use hangtags, your website, and marketing to clearly explain why your chosen fabric is sustainable, using specific data (e.g., "saves X liters of water"). Transparency builds trust and justifies any price premium.

- Plan for Circularity from the Start: Consider how the garment will be recycled or composted at end-of-life. Mono-material fabrics (100% cotton, 100% polyester) are easier to recycle than complex blends. This is the next frontier of sustainable fashion.

Conclusion

The most popular sustainable fabrics for fashion in 2026 are those that have successfully bridged the gap between ecological idealism and commercial reality. They are no longer just niche alternatives but are becoming the new standard, driven by advancements in processing technology, rigorous certification, and a market that now demands proof alongside promise. The winners—next-gen cellulosics, advanced recycled synthetics, and regenerative naturals—offer a compelling combination of reduced environmental impact, enhanced performance, and growing accessibility.

Choosing the right fabric is a strategic decision that defines your brand's place in the future of fashion. It requires moving beyond surface-level claims to a deeper understanding of supply chains, certifications, and lifecycle impacts. By focusing on transparency, forging partnerships with credible suppliers, and committing to continuous education and improvement, you can confidently build collections that are both beautiful and responsible.

If you're ready to translate the promise of 2026's sustainable fabrics into the reality of your next collection, you need a partner with both the technical expertise and the supply chain integrity to make it happen. At Shanghai Fumao, we've invested ahead of the curve in developing and sourcing the full spectrum of credible sustainable fabrics—from our BAMSILK innovations to GRS-certified recycled polyesters. Let us help you navigate the options with clear data and reliable execution. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can source or develop the right sustainable fabric for your brand's vision and values.