In the world of textile innovation, graphene-enhanced heating fabrics have moved from experimental labs into real-life applications for fashion, sportswear, and protective gear. Yet, many buyers and designers hesitate to invest because they are unsure about the minimum technical and purchasing requirements to make these fabrics functional and cost-effective. Without clarity, projects can stall, budgets can overrun, and expectations may be unmet.

The minimums for graphene heating fabrics are generally defined by coating thickness, graphene concentration, voltage and power input, and production order sizes. These benchmarks serve as the starting point to ensure reliable heating performance, comfort, and durability, while meeting both safety and manufacturing efficiency needs.

When you understand these thresholds, you can negotiate better with suppliers, avoid over-specification, and ensure your product meets real-world market demands. Let’s explore the details so you can plan your next graphene-enhanced fabric project with confidence.

Minimum Graphene Content for Effective Heating

In fabric heating systems, graphene content directly determines conductivity, heat output, and response speed. Too little graphene, and the fabric barely warms; too much, and it becomes stiff and costly. The sweet spot is a balance between cost and performance.

The general industry baseline is around 50 g/kg of coating paste as the minimum functional graphene concentration. At this level, fabrics begin to generate noticeable warmth while maintaining flexibility and breathability. Increasing the concentration to 100–150 g/kg often improves heating speed and peak temperature, but this also increases raw material cost.

How does graphene concentration affect performance?

Graphene's electrical conductivity makes it ideal for heating textiles. At about 50 g/kg, you can expect the fabric to reach around 40–50 °C in moderate insulation settings. When combined with proper coating techniques, the performance can rival that of thicker heating wires without sacrificing comfort. However, for high-performance sportswear or extreme cold protection, some manufacturers push the limit to 150 g/kg to achieve rapid heating even in windy outdoor conditions.

Can I blend graphene with other conductive materials?

Yes. In fact, blending graphene with silver nanoparticles or carbon nanotubes can enhance uniformity and reduce the heating response time. This is particularly effective in thin or stretch fabrics, where pure graphene coatings might crack under repeated stretching. The blend ratio depends on the product's target market and price point.

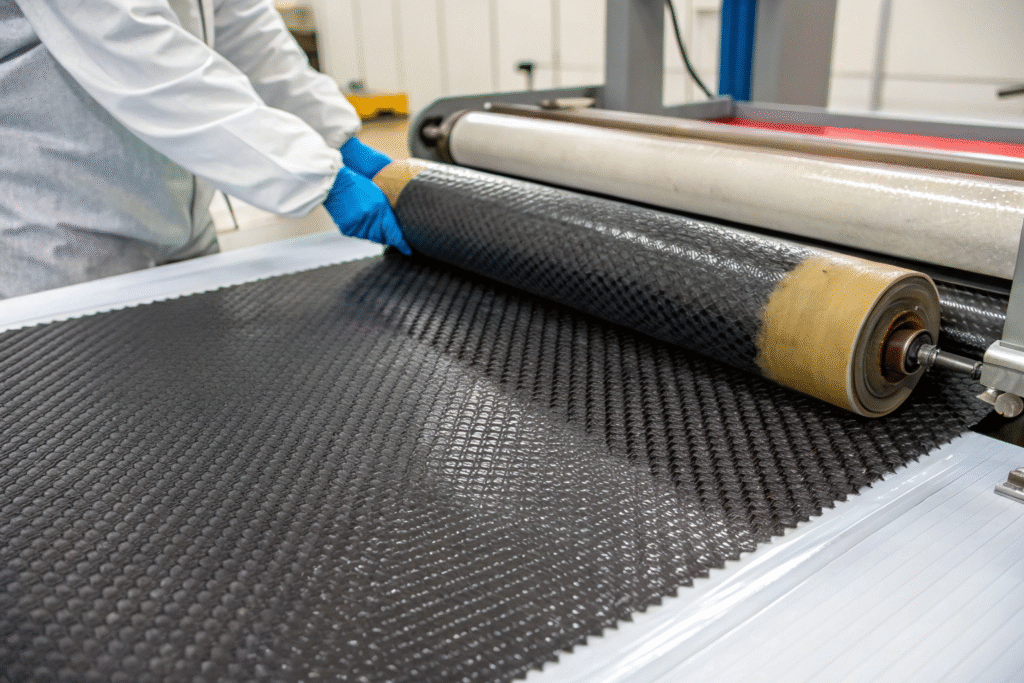

Required Coating Thickness for Optimal Warmth

Coating thickness is another critical factor in ensuring the heating effect of graphene fabrics. If the layer is too thin, the fabric won’t retain enough graphene particles to produce consistent heat. Too thick, and flexibility and comfort suffer.

Most manufacturers set the minimum coating thickness at around 0.1 mm. At this thickness, the coating can house enough graphene to achieve moderate heating without making the fabric stiff. For heavy-duty outdoor gear, thicknesses can reach 0.5 mm for better thermal insulation.

What happens if coating thickness is below 0.1 mm?

Below this threshold, the coating may lack uniform coverage, leading to cold spots and uneven heating. Tests show that at 0.05 mm, fabrics can drop in heating efficiency by more than 30%. For buyers aiming for consistent performance, sticking to 0.1 mm or above is strongly recommended. Details from published studies confirm this as the technical floor.

Is thicker always better?

Not necessarily. While thicker coatings (0.3–0.5 mm) improve heat retention and maximum surface temperature, they can reduce drape and comfort. For fashion garments, a balance is essential—especially if you are targeting premium apparel markets.

Voltage and Power Needs for Heating Fabrics

Voltage and power requirements determine both the safety and efficiency of your heating fabric. These parameters depend on graphene content, coating thickness, and garment insulation.

Laboratory results show that 30 V applied to a multi-layer graphene fabric can yield surface temperatures of ~85 °C, with ~0.12 A current draw and ~3 W power consumption. For wearable applications, target temperatures are usually lower—around 40–55 °C—for comfort and safety.

What’s the safest voltage range for wearables?

For most clothing, 5–12 V DC is preferred, as it’s safe for skin contact and can be powered by portable USB battery packs. Industrial applications may run at higher voltages, but require more robust insulation. This aligns with guidance from PMA Graphene and other leading manufacturers.

How does insulation affect power needs?

Better insulation reduces the wattage required to maintain heat. For instance, with proper lining materials, you may maintain warmth at 1–1.5 W instead of 3 W. Technical insights from Nature’s research suggest that insulation can cut power demand by over 40%.

Production and Order Minimums for Buyers

Even if you meet the technical minimums, you must also consider the purchasing and production minimums set by suppliers. These are critical for budgeting, lead times, and negotiation.

In China’s textile industry, the typical minimum order quantity (MOQ) for graphene-enhanced heating fabrics is 500–1000 meters per color or design. Smaller batches are possible but may incur higher unit costs due to setup and coating process expenses.

Can small brands negotiate lower MOQs?

Yes, especially if you work with integrated suppliers who handle weaving, coating, and finishing processes. Some factories will combine multiple small orders into a single coating run to reduce per-buyer MOQ. However, pricing flexibility depends on the market situation and raw material costs.

What are typical lead times for production?

For standard coatings and fabrics, lead times range from 3–5 weeks, depending on capacity and season. Custom blends, multiple colors, or special functional finishes can extend production by another 2–3 weeks. Planning ahead is key to avoiding delays, especially for seasonal product launches.

Conclusion

Understanding the minimums for graphene-enhanced heating fabrics—graphene content, coating thickness, voltage requirements, and production MOQs—empowers you to make smart sourcing decisions. By targeting the right technical specifications and negotiating realistic order terms, you can produce heating fabrics that balance performance, comfort, and cost.

If you are ready to explore custom graphene heating fabrics with reliable quality and on-time delivery, contact our Business Director Elaine at elaine@fumaoclothing.com. At Shanghai Fumao, we have the full capability to weave, coat, test, and ship fabrics tailored to your exact needs.