Activewear isn’t just about looking fit—it’s about feeling ready. As sportswear becomes part of our daily lives, functional textiles are leading innovation in both performance and sustainability. But for sourcing experts and brand builders like Ron, trends aren’t about hype—they’re about what fabrics can do. It’s function first.

Today’s sportswear fabric trends revolve around performance innovation, sustainability, and hybrid lifestyle demands.

From sweat-activated cooling to stretch fabrics made from ocean plastic, functional textiles now serve athletes, commuters, and fashion brands alike. At Fumao, we work with global buyers to develop trend-aligned materials that don’t just follow the curve—they set it. Let’s explore what’s shaping the next generation of sportswear fabrics.

Performance meets innovation—and now both are certified, breathable, and surprisingly green.

What Performance Features Are in High Demand for Sportswear?

Athletes demand more from their gear. Comfort and performance aren’t optional—they’re expectations.

Moisture-wicking, quick-dry, stretch, UV protection, and anti-odor are top features dominating sportswear textile demand in 2025.

Modern synthetic blends like polyamide-elastane and recycled polyester-spandex are engineered to handle dynamic movement, body temperature changes, and outdoor exposure. Add nanotechnology or antimicrobial treatments, and fabrics do more than ever before.

Why Is Moisture Management Still King?

Sweat isn’t going away. Fabrics that pull moisture from the skin and dry quickly improve comfort, reduce chafing, and enhance athletic focus. We supply mesh-backed double knits and bird’s-eye textures to optimize evaporation without losing softness.

Are Anti-Odor and Bacteria Control a New Standard?

Yes. Silver-ion or zinc-based finishes neutralize odor-causing bacteria. Natural fiber blends like bamboo viscose also inhibit microbes naturally. These fabrics are favored for yoga wear, base layers, and warm-weather sportswear.

How Is Sustainability Influencing Functional Fabric Design?

Today’s sportswear buyers don’t just want high performance—they want it sustainably.

Recycled synthetics (like rPET), biodegradable polyesters, and organic fiber hybrids are redefining eco-friendly performance wear.

Buyers now ask for traceable supply chains, GRS certification, and even cradle-to-cradle life cycle plans. We develop yarns from ocean-bound plastics and blend them with TENCEL™ or bamboo for softness, stretch, and sustainability.

What Are the Most Popular Sustainable Materials?

- rPET (recycled polyester): made from post-consumer bottles

- Bio-nylon: petroleum-free with same stretch and strength

- Bamboo viscose: fast-growing, soft, antibacterial

- TENCEL™: breathable, biodegradable, and EU-certified

We offer GRS-certified options in jersey, interlock, and mesh textures, with MOQ as low as 500m.

Can Sustainable Fabrics Perform Like Synthetics?

Yes—with the right structure and finishes. For example, we develop recycled poly interlocks with 4-way stretch, UV resistance, and 250GSM weight stability—ideal for leggings and compression gear.

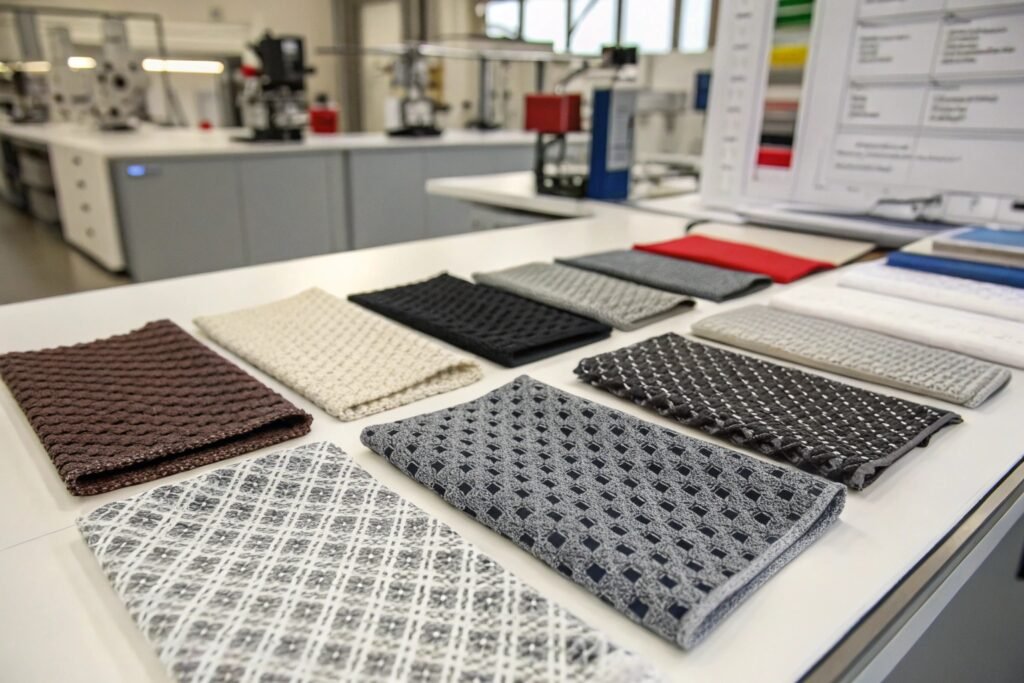

What Fabric Structures and Knits Are Leading the Market?

The secret to function isn’t just fiber—it’s structure. Knit design influences stretch, breathability, and muscle support.

Spacer knits, warp knits, and engineered mesh structures are dominating performance sportswear development.

These fabrics offer compression, airflow, and body-mapped elasticity. Brands now request zoned support knits, combining breathable and reinforced areas in a single fabric. Jacquard textures are also used for style-function fusion.

What Is Spacer Fabric and Why Is It Trending?

Spacer knits use double-knit layers with filaments in between, creating air channels. They provide lightweight insulation and cushion, ideal for jackets or padded leggings. They're also used in breathable bras and footwear.

How Do Warp Knits Improve Durability?

Warp knits like tricot and Raschel don’t ladder or curl, making them strong and shape-retentive. We use warp-knitted nylon blends for sports bras, compression sleeves, and outer shells that resist abrasion.

Are Smart or Responsive Sportswear Fabrics Becoming Real?

Smart fabrics are no longer sci-fi. They’re scaling.

Thermoregulatory knits, color-shifting prints, and conductive yarns are entering commercial sportswear slowly—but steadily.

These “responsive textiles” adjust to sweat, heat, or motion. We’ve prototyped fabrics that cool when sweat hits the surface, as well as yarns that change color with heat for smart fashion appeal. Smart blends are particularly hot in cycling, gym, and outdoor training wear.

What’s Ready Now vs. What’s Experimental?

- Ready now: Cooling yarns, thermoregulating knits, reflective coatings

- Experimental: Conductive yarns for fitness data, self-healing fibers

At Fumao, we partner with tech labs to explore yarn-level innovation for future-ready garments that go beyond stretch.

Will Smart Fabrics Affect MOQ and Cost?

Yes. These materials often require small-batch development and testing. But we offer pre-stocked sensor fabrics and fast prototyping support, especially for startup brands entering the wearable space.

Conclusion

Functional sportswear textiles are advancing fast—blending science, comfort, and sustainability into every thread. From quick-dry meshes to smart cooling yarns, buyers now demand both performance and planet-friendly value. As one of China’s leading fabric innovators, Fumao is at the frontline of this textile evolution. We help brands translate trends into action by delivering R&D-backed, lab-tested functional fabrics with real commercial scalability. Whether you're developing activewear for yoga, marathon, or lifestyle crossover, we’ve got you covered—one roll at a time.