When global buyers look for the next generation of protective and functional textiles, one question rises above the rest: which fabrics can adapt their viscosity on demand to deliver higher safety without added bulk? Many in the apparel and technical textile industry feel the frustration of balancing lightweight design with protective performance. Shear-thickening fabrics, especially the programmable viscosity kind, are shaping up to be one of the most promising answers.

The latest programmable viscosity shear-thickening fabrics combine fluid science, nano-additives, and smart material engineering to create textiles that can stiffen under sudden impact while staying flexible during daily use. These new developments are transforming applications in defense, sportswear, industrial protection, and even fashion, where both comfort and safety are critical.

As someone rooted in the textile hub of Keqiao, I know how difficult it is to keep up with innovations across labs and production lines worldwide. That is why I want to walk you through the newest breakthroughs in this area. From temperature-responsive STFs to acoustic metafluids, the latest research is pushing beyond traditional protective clothing. Let us explore together how these advancements may influence sourcing decisions and inspire product development.

How Do Shear-Thickening Fabrics Work?

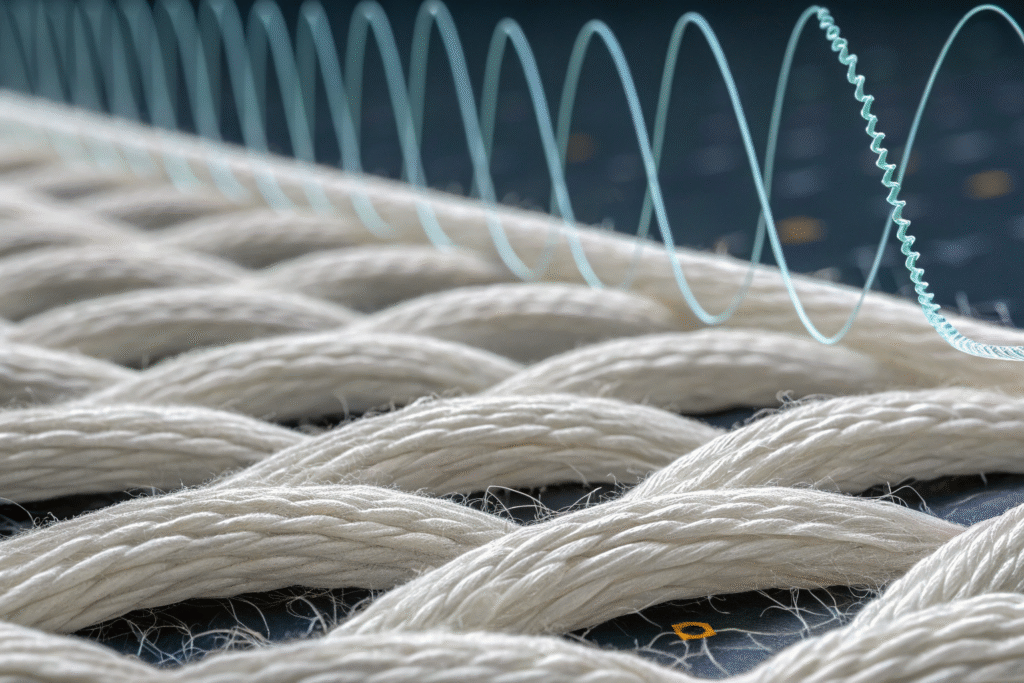

The first thing buyers often ask is how these unusual fabrics function. The principle is simple yet powerful: when impacted by sudden force, the fluid embedded in the textile thickens, making the fabric rigid and resistant to penetration.

Shear-thickening fabrics work because a specially designed fluid, usually containing silica nanoparticles, changes its viscosity under stress, instantly stiffening the fibers to absorb energy. This makes them lightweight and flexible during normal use but highly protective during impact.

In sourcing discussions, clients sometimes hesitate because the science seems too abstract. But the truth is that these materials have been tested in military, police, and industrial protection scenarios for years. What is new is how programmable versions now allow viscosity control through temperature, additives, or even acoustic signals.

What makes shear-thickening fluids different from other coatings?

Unlike traditional polyurethane coatings that add permanent stiffness (learn more here), shear-thickening fluids remain flexible until activated. They provide protection without reducing comfort, a feature increasingly demanded in sports equipment manufacturing (see details).

Are programmable fabrics more reliable in daily use?

Yes, because they reduce the trade-off between softness and toughness. Unlike static armor inserts, programmable viscosity ensures a textile reacts only when necessary. This means less fatigue for wearers in sectors like construction safety apparel (source) and more confidence in long-term wear.

What Are the Newest Breakthroughs in Programmable Viscosity?

Every year researchers publish new results that push the boundary of what fabrics can do. The latest wave focuses on programmability—fabrics that not only thicken but do so in more controlled ways.

Recent breakthroughs include double-thickening systems responsive to temperature, ultrahigh-viscosity STFs using metal-organic additives, and acoustic metafluids that can tune shear response on demand.

These innovations are making the technology attractive not only for defense but also for fashion and everyday applications where both mobility and protection matter.

What are double-thickening shear-thickening fluids?

These are systems where two-step viscosity changes happen across a temperature range. For example, UHMWPE fabrics treated with carboxyl-modified silica mixed with polyacrylic acid and CaCl₂ show peak viscosity around 1,330 Pa·s at 35 °C. This design provides consistent performance in hot or cold conditions (read study).

Can acoustic signals really program viscosity?

Yes. A concept called viscosity metafluids allows rapid oscillation of fluid states through acoustic perturbation. Researchers have demonstrated that viscosity can be shifted toward zero, infinite, or even negative states. This could lead to textiles with tunable stiffness in real time (see APS publication).

How Are These Fabrics Used in Real Applications?

Buyers are most interested in practical uses. While the science is exciting, it only matters if it leads to products that people want and need.

Programmable shear-thickening fabrics are already being applied in ballistic vests, sports gear, industrial safety clothing, and even fashion pieces designed for impact protection.

The industry is now moving from lab trials to scaled production, and that means sourcing decisions are becoming critical.

Where are these fabrics being tested today?

Military and police organizations have long tested STF-treated Kevlar fabrics (reference). More recently, sports brands have looked into them for cycling protection pads (read article).

Are there commercial fashion uses?

Yes. Designers are experimenting with STF-infused textiles in avant-garde fashion (see example), giving garments both style and protective function. This bridges the gap between protective wear and high-end apparel.

What Challenges Remain for Programmable STF Fabrics?

Like any innovation, programmable shear-thickening fabrics face hurdles before they can be fully mainstream. Buyers should understand these before making sourcing decisions.

Challenges include ensuring durability under repeated washing, balancing cost with large-scale production, and securing certification for international markets.

Despite these hurdles, global demand for protective textiles is rising, which creates opportunities for suppliers who can offer high-quality solutions.

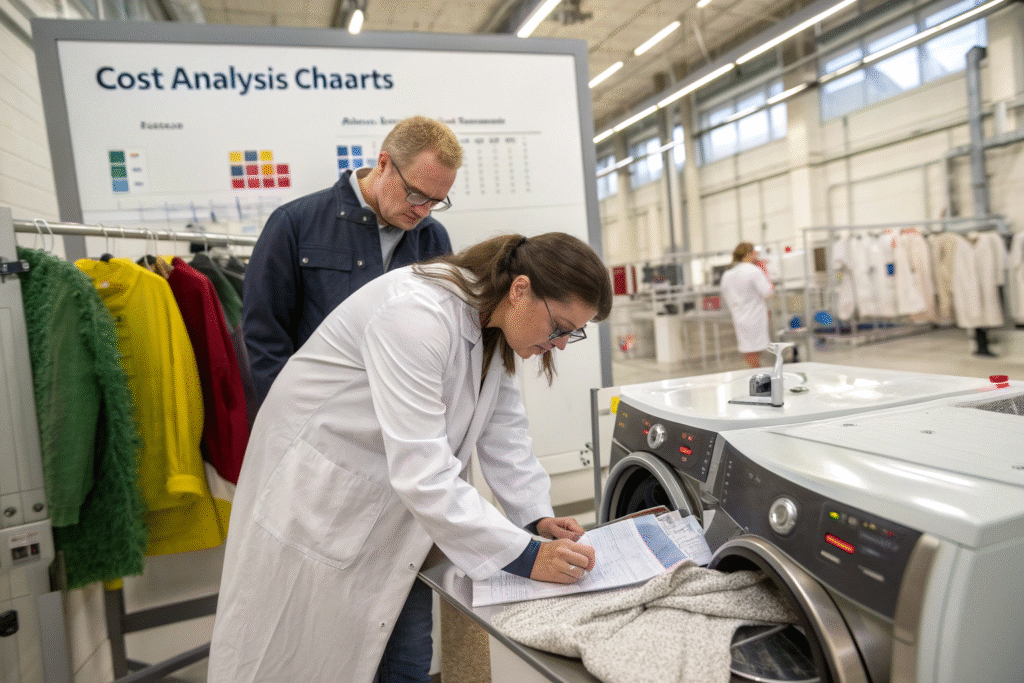

Do STF fabrics survive repeated washing cycles?

Wash durability is still a challenge. Some STF treatments lose effectiveness after 20–30 washes. Ongoing research in nano-coating techniques (learn here) aims to improve retention and lifespan.

How do costs compare with traditional protective fabrics?

STF-treated fabrics can be more expensive than traditional aramid fibers (info here). However, when performance per weight is considered, they can reduce material use and shipping costs, making them cost-effective at scale.

Conclusion

Programmable viscosity shear-thickening fabrics represent a leap forward in textile technology. They bring together lightweight comfort and high-level protection, with innovations such as double-thickening systems and acoustic metafluids opening new markets. While challenges like wash durability and cost efficiency remain, the potential is undeniable.

For buyers and sourcing managers, this is the right time to explore suppliers with strong R&D and reliable production lines. At Shanghai Fumao, we are ready to partner with you in developing custom shear-thickening and functional fabrics that meet international standards. If you are considering launching your own protective or fashion-oriented fabric line, contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can collaborate on your next order.