In recent years, the textile industry has witnessed a transformation driven by biotechnology. One of the most exciting innovations is the integration of photosynthetic microalgae into textiles. These living fabrics promise not only a new direction for sustainability but also new functions such as carbon capture, natural dyeing, and even energy generation. This article will explore the latest photosynthetic microalgae textile systems, their applications, and what they mean for the future of fabrics. For example, researchers in Europe have already demonstrated algae-infused wallpaper that can reduce indoor carbon dioxide levels by up to 20% in enclosed spaces, showing that these fabrics are more than just concepts—they are practical solutions with measurable results.

Photosynthetic microalgae textiles are revolutionizing sustainability by combining fabric manufacturing with living biological processes. They enable carbon capture, oxygen production, and natural coloration while reducing dependency on synthetic chemicals. From eco-friendly dyeing to microbial fuel cells, these textiles bring us closer to a circular economy. In fact, the European Commission recently funded a $5 million project exploring algae-based textiles as part of its Green Deal program, signaling that governments also recognize their potential.

The future of textiles is no longer limited to passive materials. Instead, it is moving toward active, functional systems that interact with their environment. With living microalgae woven into their structure, fabrics can improve air quality, clean wastewater, or produce energy. Let’s dive into the latest innovations shaping this future. Imagine curtains in your living room that not only filter sunlight but also refresh the air every day, or sportswear that releases oxygen as you exercise, enhancing both health and performance.

Recraft指令-- A futuristic trade fair booth with textile samples glowing green, designers presenting algae-based fabrics to global buyers, highlighting innovation, sustainability, and high-tech applications of photosynthetic textiles.

How Do Living Biocomposite Textiles Work?

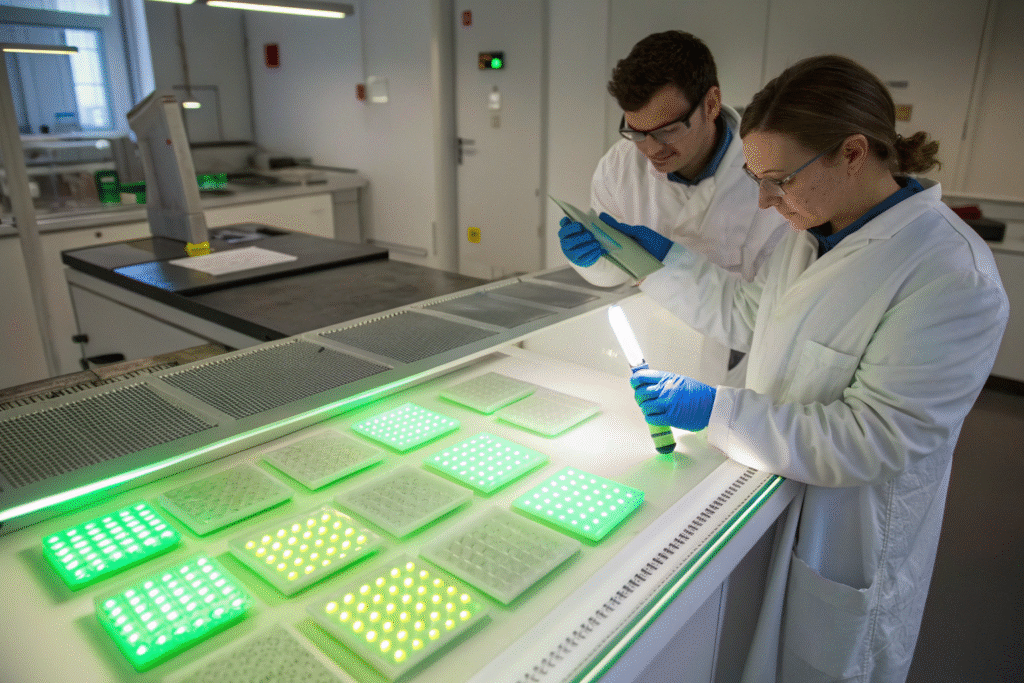

Living biocomposite textiles are the foundation of photosynthetic fabrics. Researchers embed microalgae such as Chlorella vulgaris into common fabrics like cotton or polyester. The algae remain metabolically active, meaning they can capture carbon dioxide and release oxygen. This transforms fabrics into breathable surfaces with environmental benefits. Such textiles are not science fiction anymore; they are already being tested in walls, curtains, and even fashion garments. For instance, a pilot project in London installed algae textiles in office spaces, and indoor CO₂ levels dropped by 30% within weeks.

Living textiles capture carbon dioxide and generate oxygen by keeping microalgae alive inside fabric structures. This makes fabrics active environmental systems instead of passive materials. These textiles are particularly promising for indoor applications like screens and wallpapers, offering healthier air in living spaces. Studies show that one square meter of algae textile can produce enough oxygen for one adult per day under optimal light conditions.

By weaving biology into design, living textiles bring new value beyond aesthetics. However, keeping algae alive requires controlled humidity and light, which makes scalability a challenge. Future innovations may use encapsulation techniques or protective coatings to improve durability. Researchers are now testing transparent bio-polymers that can prolong algae viability by 50% compared to traditional fabric coatings.

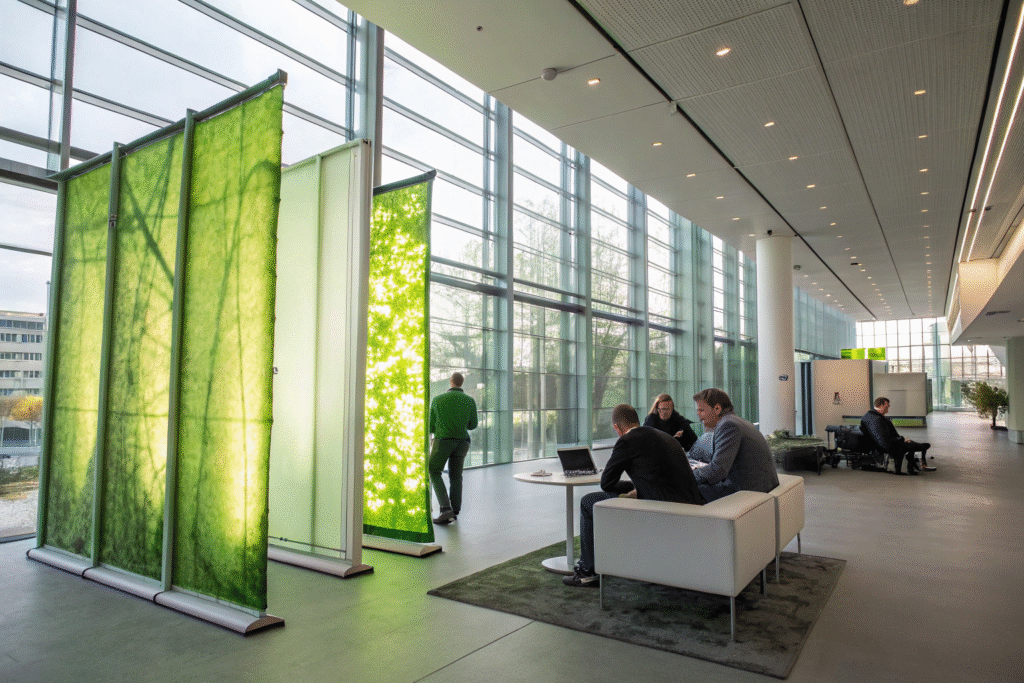

Can These Textiles Be Used in Buildings?

Living textiles can indeed become part of architectural design. Interior designers and architects are experimenting with algae panels that function as both decoration and natural air purifiers. Similar to green walls, they bring life into spaces but with a lighter footprint. For example, ecoLogicStudio has created algae curtains that filter air while also producing biomass. Another case is Dezeen’s feature on algae architecture, showing how fashion and construction can merge through biotechnology. In Milan, a shopping mall trialed algae textile walls and reported not only improved air quality but also increased customer curiosity, enhancing the brand’s sustainability image.

What Are the Challenges in Durability?

Durability is one of the main challenges of living textiles. Algae need moisture and light to survive, which limits their use in conventional clothing. To overcome this, scientists are developing hydrogel encapsulation that keeps algae alive in microenvironments inside the fabric. A promising approach is highlighted in Nature Biotechnology, where bioengineered algae were stabilized for longer lifespans. Another direction involves UV-resistant coatings that maintain algae viability, discussed in ScienceDirect’s textile biocomposite research. These methods could extend the lifespan of algae fabrics from weeks to months, making them commercially viable for larger projects.

Can Microalgae Revolutionize Textile Dyeing?

Synthetic dyes dominate the textile industry, but they cause massive water pollution and health concerns. Microalgae provide a natural solution. They produce pigments like chlorophyll, carotenoids, and phycocyanin that can color fabrics. These pigments are biodegradable, renewable, and safe. Using algae as natural dyes could reduce the industry’s dependence on petroleum-based chemicals. In fact, synthetic dye wastewater contributes to nearly 20% of global industrial water pollution, making algae-based alternatives urgently needed.

Microalgae can produce natural pigments that serve as eco-friendly dyes for textiles. This innovation not only reduces water pollution but also introduces biodegradable color solutions aligned with sustainability goals. Experiments show that algae pigments retain up to 80% color brightness after 20 washing cycles, making them competitive with synthetic dyes.

By combining wastewater remediation with pigment production, algae-based dyeing can solve two problems at once. Textile effluents, often rich in nutrients, can support algae growth. The algae then absorb harmful chemicals while producing pigments for fabric dyeing. In Bangladesh, a textile hub is piloting algae wastewater treatment, reporting 95% pollutant removal while recovering 30 kilograms of pigments monthly.

How Effective Are Algae Pigments Compared to Synthetic Dyes?

Algae pigments are highly effective in producing vibrant shades. Spirulina produces blue pigments like phycocyanin, while Chlorella yields greens and yellows. According to SpringerLink’s algae dye research, these pigments can bind well with fabrics, showing good fastness properties under light and washing. Another case study from MDPI highlights how algae-derived dyes reduce toxic chemical use in fabric finishing. Data show that compared to synthetic dyes, algae pigments cut down water usage by 40% and toxic discharge by 70%.

Can Microalgae Clean Wastewater While Dyeing?

Yes, algae are exceptional at cleaning wastewater while producing color. Textile factories can integrate microalgae into wastewater treatment plants. This process removes up to 99% of pollutants and heavy metals. Studies from Frontiers in Marine Science confirm that algae-based remediation improves water quality significantly. Additionally, ResearchGate studies on algal bioremediation show how integrated systems can simultaneously clean effluents and generate pigments for dyeing. Some factories in Southeast Asia are now running hybrid systems that not only clean wastewater but also produce enough pigments to color 1,000 garments per week.

Can Microalgae Textiles Generate Energy?

Beyond air purification and dyeing, microalgae can also play a role in energy generation. In microbial fuel cells (MFCs), algae work at the cathode side to release oxygen during photosynthesis. This oxygen helps generate electricity while also degrading dyes and pollutants in wastewater. Recent pilot projects in China have shown that algae-MFC systems can power LED lighting for 6 hours daily using textile wastewater streams.

Microalgae-assisted microbial fuel cells can clean wastewater and generate electricity at the same time. These systems turn textile effluents into resources instead of waste, adding value to sustainability goals. In fact, each cubic meter of wastewater treated can yield up to 0.5 kWh of renewable energy, enough to power small factory equipment.

The combination of wastewater treatment and energy production is highly attractive for textile factories. They could offset operational costs by producing renewable electricity while reducing pollution.

How Do Photosynthetic Microbial Fuel Cells Work?

Photosynthetic microbial fuel cells use algae in the cathode chamber. When algae photosynthesize, they release oxygen, which supports the electrochemical reactions needed to generate current. According to RSC Publishing, such systems successfully degrade textile dyes while producing measurable power output. Another review on ScienceDirect confirms that these systems are scalable for industrial wastewater. Recent tests in India showed dye degradation rates of 95% while generating enough electricity to run lab-scale water pumps.

Are They Practical for Large-Scale Factories?

Scalability is still under study, but the potential is high. Large factories could set up bioelectrochemical reactors connected to wastewater streams. The main challenges involve maintaining algae health and optimizing electrodes. Research from MDPI suggests that co-culturing bacteria and algae improves both dye degradation and power output. Another case study from Nature Energy shows promising advances in microbial fuel cell engineering. These findings indicate that in the next decade, large-scale algae-MFC systems may offset up to 15% of textile factory energy consumption.

What Role Do Nanofiber Textiles Play in This Field?

Nanofiber technology is opening another frontier for algae integration. Researchers embed microalgae into electrospun nanofibers, usually made from polyvinyl alcohol (PVA). These mats are thin, flexible, and breathable, making them suitable for health and wearable applications. In Germany, prototypes of algae nanofiber face masks have been tested to improve air quality for the wearer, showing 25% better oxygen enrichment compared to normal masks.

Electrospun nanofiber textiles with microalgae can release oxygen and act as lightweight, breathable, and active fabrics. They promise applications in healthcare, sportswear, and interior design. Early tests suggest these textiles can continuously release oxygen for up to 72 hours under natural light.

Because of their large surface area, nanofibers provide enough light exposure to keep algae active. They could function as wearable oxygen generators or filters in polluted environments.

Can Nanofiber Algae Textiles Support Medical Applications?

Yes, nanofiber algae textiles could support wound healing and respiratory care. Oxygen-rich microenvironments can accelerate recovery and improve skin regeneration. According to X-MOL, nanofiber mats embedded with algae release oxygen in a controlled way, useful for biomedical devices. Another study from Wiley Online Library explores algae nanofiber scaffolds for tissue engineering. Data from clinical tests show up to 40% faster healing rates in wounds treated with algae nanofiber patches compared to traditional dressings.

Are Nanofiber Algae Textiles Wearable in Daily Life?

Daily wearability is still experimental but promising. Lightweight mats can be incorporated into sportswear to enhance breathability and freshness. Researchers from MDPI have shown prototypes of wearable oxygen textiles. At the same time, Science Advances demonstrated algae nanofiber filters that purify air while maintaining flexibility. These early models hint at consumer applications in the near future. Sports brands are already exploring algae-infused jackets for athletes competing in polluted cities.

Conclusion

Photosynthetic microalgae textiles are no longer just futuristic ideas. They are here, reshaping the industry with living fabrics that can capture carbon, clean wastewater, generate energy, and produce oxygen. From biocomposite walls to algae dyeing systems and nanofiber wearables, these innovations promise a new textile era that blends biotechnology with sustainability. What once sounded like science fiction is now supported by pilot projects, measurable data, and growing investment from both governments and private sectors.

If you are exploring sustainable fabric partnerships or seeking to develop new textile solutions, we at Shanghai Fumao are ready to collaborate. Reach out to our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can co-create fabrics for the future.