Air pollution is not just an outdoor challenge; it seeps into our homes, offices, and even the clothes we wear. Buyers and innovators across the global textile industry are looking for solutions that combine sustainability with performance. Photocatalytic textiles—fabrics that can purify the air by breaking down harmful pollutants—have emerged as one of the most promising advancements. Yet, many buyers still wonder: which are the latest technologies in this space and how can they apply to their sourcing strategy?

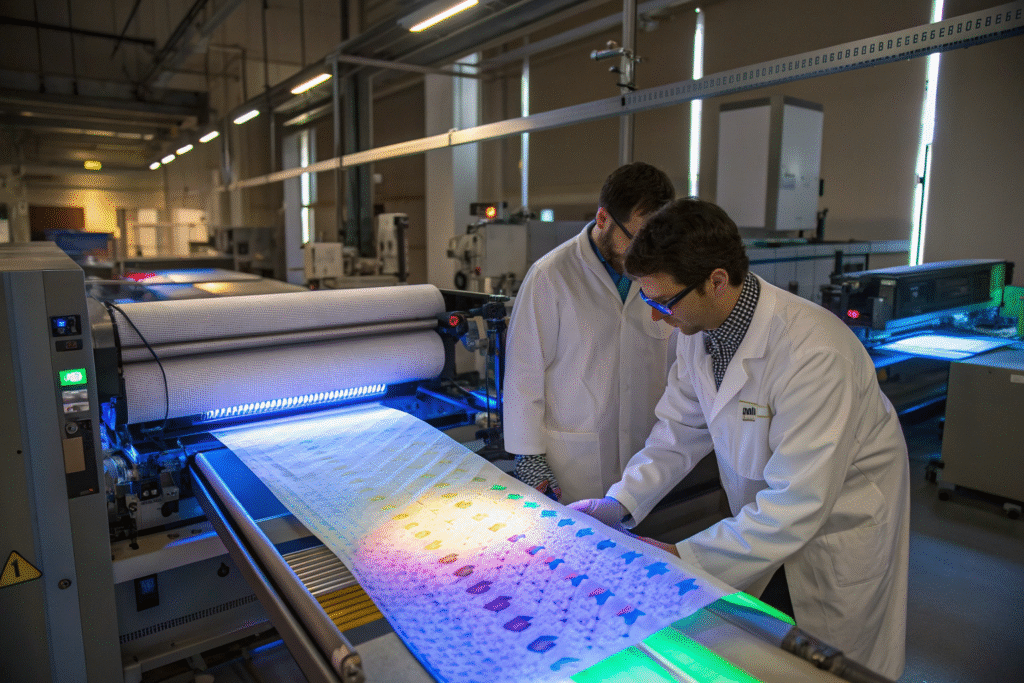

The newest photocatalytic air-purifying textiles use nano-engineered finishes and coatings to break down pollutants under light, offering both functionality and durability without compromising comfort or design. From home textiles to wearable fashion, these innovations are expanding into real commercial use.

As a textile manufacturer rooted in Keqiao, I see firsthand how these technologies are transforming fabrics from passive materials into active protectors of our environment. Let’s explore the key trends and what they mean for global buyers.

How Does Photocatalytic Fabric Technology Work?

Air pollution feels like an unsolvable issue, especially when smog, volatile organic compounds (VOCs), and odors invade our living and working spaces. Traditional fabrics do nothing to address these problems, leaving buyers frustrated with limited solutions.

Photocatalytic fabrics are treated with advanced mineral-based finishes such as titanium dioxide (TiO₂), which, when exposed to light, trigger chemical reactions that break down harmful airborne particles like NOx gases and VOCs. This technology can be applied to cotton, polyester, viscose, and even blended fabrics, creating textiles that actively purify air in real time.

What Makes TiO₂-Based Textiles Effective?

The effectiveness lies in the nano-coatings. For example, Archroma’s Perapret® AIR liq uses a patented core–shell structure that not only cleans the air but also prevents fiber degradation, a common drawback of early photocatalytic finishes. Similar research in ScienceDirect shows that cotton composites enhanced with visible-light responsive nanoparticles can achieve strong air-purifying performance while retaining softness.

Can This Be Applied in Everyday Fabrics?

Yes. Current trials are scaling photocatalytic technology into curtains, wall coverings, car interiors, and even outdoor fashion wear. Researchers at MDPI highlight how luminous textiles integrated with photocatalytic coatings can purify enclosed air on a pilot scale, offering future-ready applications.

What Are the Latest Market Innovations?

Global buyers want more than lab-scale experiments. They need real, durable, and market-ready products. Fortunately, recent breakthroughs are bridging this gap.

The latest photocatalytic textiles include advanced mineral-based coatings, cotton composites, luminous textiles, and wearable air-purifying fashion. Each innovation offers unique applications in both consumer and industrial markets.

Why Is Perapret® AIR liq Leading the Market?

Archroma’s solution has become the first commercially ready system. According to Textile World, it works under both daylight and artificial light, making it suitable for urban homes and transport systems. Its durability and compatibility with different fiber types give it a competitive edge.

What About Wearable Air-Purifying Fashion?

Beyond interiors, designers are experimenting with “Atmospheric Fashion.” Clothing treated with photocatalytic finishes acts like a moving air filter. A case covered by SustainablyU shows how garments can degrade pollutants like NOx gases in city streets, adding value for eco-conscious consumers.

How Do Photocatalytic Textiles Benefit Buyers?

Fabric buyers often prioritize price and production speed, but when quality and innovation align with sustainability, the decision becomes strategic. Photocatalytic fabrics provide clear benefits across industries.

Buyers gain access to eco-friendly, functional textiles that help reduce indoor and outdoor pollution while complying with global environmental standards.

Why Should Large Fashion Brands Care?

Sustainability is no longer optional. Brands like ZARA and H&M are already sourcing eco-certified fabrics. With photocatalytic textiles, they can move beyond recycled fibers and offer fabrics that actively improve air quality. Studies from SpringerLink show how Au-TiO₂ catalysts can extend photocatalysis into visible light ranges, further boosting effectiveness in real-life applications.

Can This Technology Reduce Tariff Risks?

Yes. For U.S. and European buyers, importing value-added textiles like photocatalytic fabrics can justify higher price points and differentiate their supply chain. Moreover, sustainable textiles often enjoy better tariff negotiations, trade show visibility, and premium branding compared to generic fabrics, as seen in industry updates from Easytec.

What Is the Future of Photocatalytic Fabrics?

The industry is moving fast, and fabrics are evolving from passive materials to active tools for health and sustainability.

Future developments will expand beyond TiO₂, exploring new nanomaterials, biodegradable composites, and even AI-enhanced fabric R&D to optimize performance.

Will This Reach Mass Production Soon?

Absolutely. Pilot-scale luminous textiles are already in testing. With the support of certifications like SGS and CNAS, photocatalytic fabrics can soon enter mainstream markets. Reports from MDPI confirm the scaling feasibility of such coatings.

How Can Buyers Prepare?

Forward-thinking buyers should begin partnering with suppliers that already invest in innovation. Exploring cooperative developments with textile hubs like Keqiao ensures early access to functional fabrics. Market reviews on ScienceDirect suggest that strategic sourcing in photocatalytic textiles will provide competitive differentiation for years to come.

Conclusion

Photocatalytic air-purifying textiles are no longer just a laboratory experiment; they are becoming a real solution for fashion, interiors, and industrial applications. From Archroma’s Perapret® AIR liq to wearable air-cleaning fashion, these fabrics represent a powerful step forward in sustainability and functionality. Buyers who adopt early will benefit from stronger branding, eco-certifications, and long-term cost advantages.

At Shanghai Fumao, we are committed to developing and supplying these innovations to global clients. If you are ready to co-create fabrics that not only look good but also clean the air we breathe, reach out to our Business Director Elaine at elaine@fumaoclothing.com to begin your project today.