Pilling—those pesky fabric balls that appear after wear or washing—can ruin the feel and look of even the most expensive textile. For brands shipping garments globally, poor pilling resistance leads to high return rates and negative reviews, especially in premium segments like children’s wear, sportswear, and upholstery.

This article explains the main international test methods for pilling resistance, what each measures, and how buyers can use these results to verify fabric quality before production.

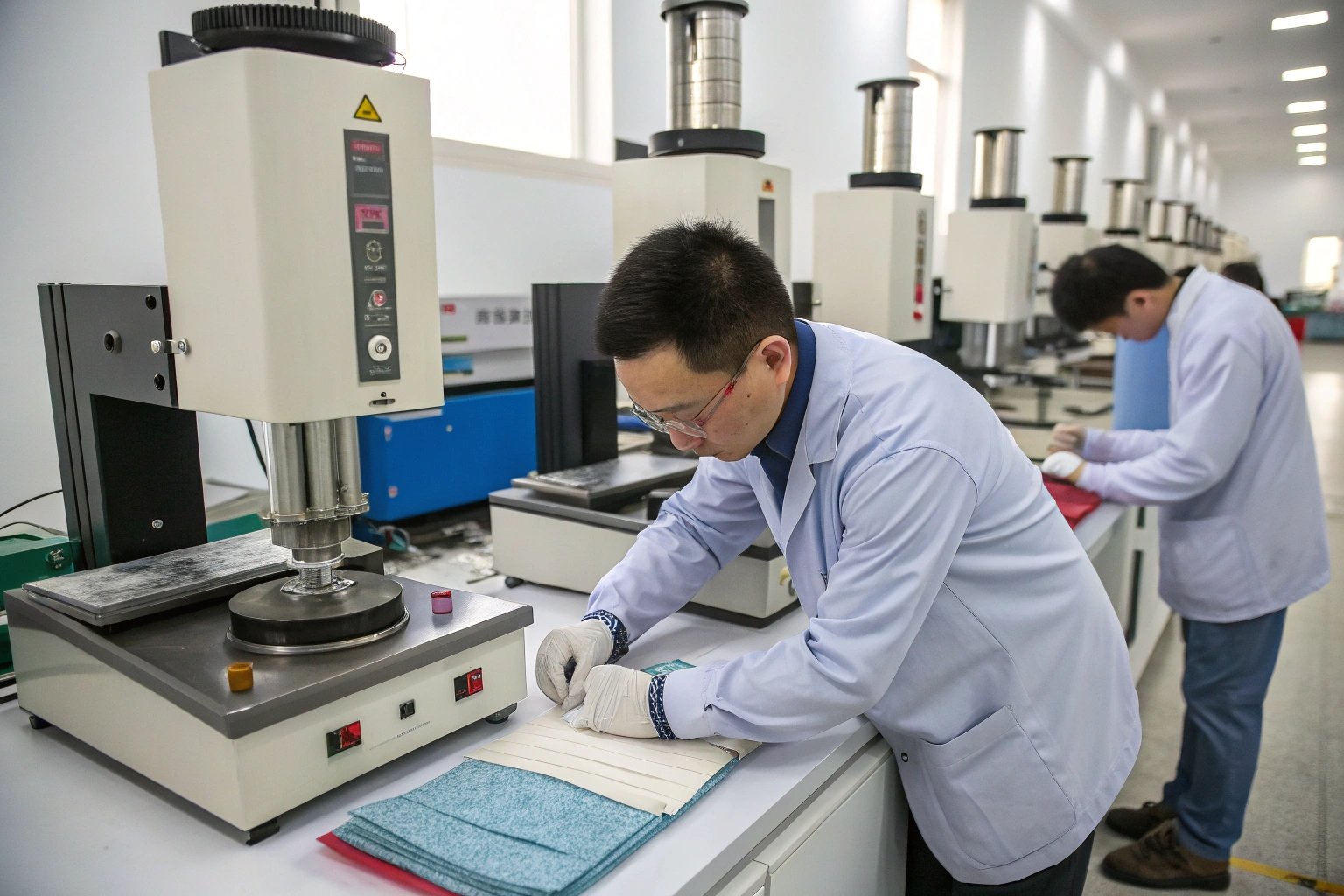

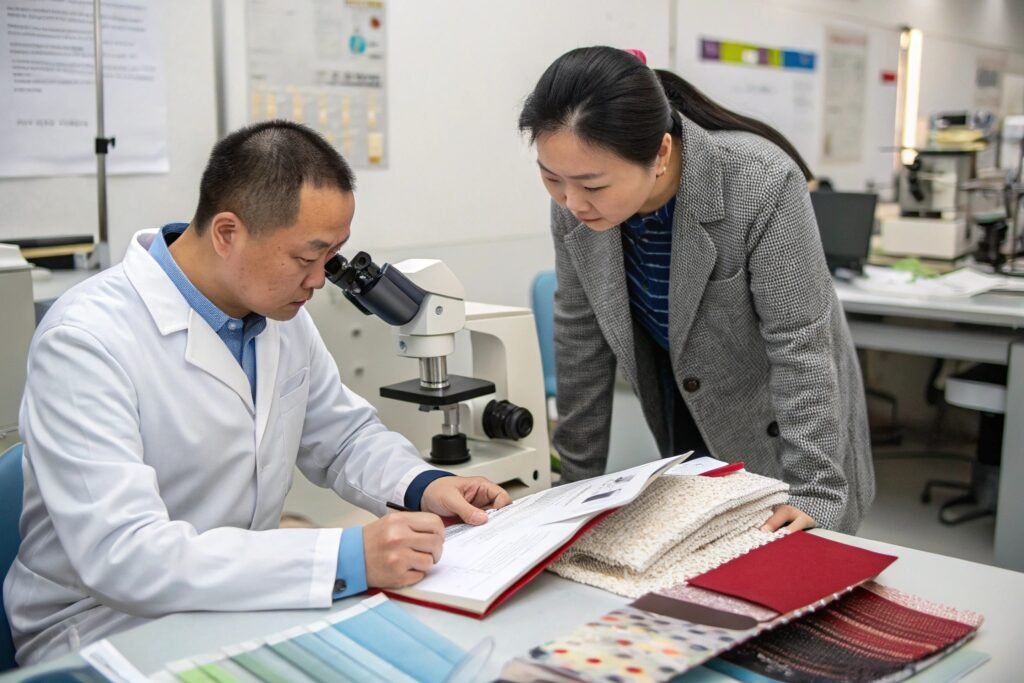

As a fabric manufacturer based in Keqiao, China, I’ll also share how we perform these tests in our CNAS-certified lab and interpret them for overseas clients.

Why Is Pilling Resistance Important for B2B Buyers?

Pilling affects a garment’s perceived quality, comfort, and longevity. For bulk apparel or upholstery orders, fabric that pills too quickly can cost brands reputation and profit.

Pilling resistance testing helps importers avoid future returns and ensures fabrics maintain a premium look after wear, wash, or abrasion.

How Does Pilling Affect Different Fabric Types?

Natural fibers like wool, cotton, and linen tend to pill differently than synthetics like polyester or viscose. Wool, for instance, can show severe pilling if not treated properly. Blends like poly-cotton may form tighter, more visible pills due to friction from both fibers reacting differently.

Knitted fabrics like jersey are especially prone to pilling due to loose structure. That’s why understanding your fabric’s composition and construction is step one before testing.

Why Should Brands Test Before Production?

Many brands skip pilling tests in favor of visual checks. But once a product reaches market, it’s too late to fix. Third-party QC inspections can only catch surface flaws, not how fabric behaves after 5 washes or repeated wear.

Conducting tests like Martindale or Random Tumble before confirming bulk avoids huge losses from customer complaints, product rework, or early inventory obsolescence.

What Is the Martindale Abrasion and Pilling Test?

The Martindale Test is one of the most globally accepted standards for both abrasion and pilling resistance, especially in Europe and Australia.

This test measures how fabric reacts to controlled rubbing under pressure, simulating wear over time. Results are graded from 1 (poor) to 5 (excellent).

How Does the Martindale Test Work?

The fabric is rubbed in a Lissajous (figure-eight) pattern against standard wool or abrasive material using weighted disks. After set cycles—often 125, 500, 2000, or 7000—the fabric is visually assessed for pilling.

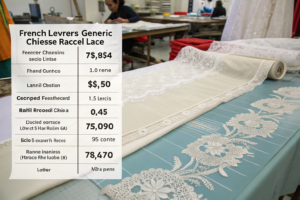

Testing is done under ISO 12945-2 or ASTM D4970, with clear scoring criteria. A grade of 4-5 is ideal for fashion, while 3 is often acceptable for budget lines.

What Are the Limitations?

Martindale is great for flat-woven fabrics, but less accurate for fleece, knits, or loose yarns. It may also under-predict wear from daily movement or washing.

Still, it’s the go-to method for apparel brands aiming to standardize global quality checks.

What Is the Random Tumble Pilling Test?

The Random Tumble test is more popular in North America and better simulates casual-use conditions—especially for soft knits and fleece garments.

This method assesses pilling by tumbling swatches inside a drum with cork or rubber paddles under specific airflow and heat for up to 60 minutes.

What Standards Apply to Random Tumble Testing?

Primarily governed by ASTM D3512, the test grades fabric from 1 (heavily pilled) to 5 (no pilling). After tumbling, swatches are compared to a standard set of photographic references for pilling severity.

This is especially useful for fleece, polyester knits, and innerwear where garments are subject to friction under low pressure.

When Should You Use Random Tumble vs. Martindale?

| Fabric Type | Preferred Test |

|---|---|

| Woven Cotton | Martindale |

| Polyester Fleece | Random Tumble |

| Cotton/Poly Blends | Both Recommended |

| Synthetic Jerseys | Random Tumble |

If unsure, we typically test with both to provide comparative scores before client approval.

What Other Pilling Tests Should Importers Know?

While Martindale and Random Tumble are most common, some niche fabrics need additional or regional test methods to evaluate true pilling performance.

Other methods include Brush Pilling (for delicate yarns), ICI Pilling Box (for high-stretch items), and Circular Track tests (for functional wear).

What Is the ICI Pilling Box Test?

The ICI Pilling Box simulates garments rubbing in real-life wash or drawer storage situations. Multiple swatches are tumbled in cork-lined boxes under specific revolutions. After 10-30 minutes, the samples are rated visually.

This test is ideal for sportswear and stretch knits that deform under Martindale or Tumble.

Are There Tests for Washed Fabrics?

Yes. BS 5811 and AATCC 124 simulate laundering-induced pilling, using actual wash/dry cycles before pilling is scored. These are critical for pre-washed jeans, enzyme-treated fleece, or brushed cottons.

In our lab, we use these methods alongside Martindale to check performance before and after washing cycles.

Conclusion

Pilling tests are more than lab rituals—they’re essential tools for ensuring product quality in global textile supply chains. Whether you’re sourcing organic cotton t-shirts or durable upholstery fabrics, knowing how Martindale, Random Tumble, and ICI tests work can protect your brand and bottom line. At Fumao, we run all major pilling tests in-house and guide clients in interpreting results to meet buyer expectations, whether for fashion, kidswear, or technical textiles.