You've finally found a fabric supplier with promising samples and a decent price. The excitement is building to launch your new line, but a nagging voice in your head asks: "What am I missing?" Placing that first bulk order with an unknown supplier is one of the biggest risks in the fashion and textile business. A single mistake in communication or assumption can lead to delayed shipments, unusable fabric, and thousands of dollars lost. How do you move from hopeful inquiry to confident partnership?

The key is to transform your initial conversation from a price negotiation into a comprehensive due diligence audit. You must ask strategic questions that uncover the supplier's true capabilities, quality systems, ethical standing, and reliability. The right questions protect you by setting clear expectations, establishing accountability, and revealing potential red flags before money changes hands. This isn't about being distrustful; it's about being professionally thorough and building a foundation for a successful, long-term supply relationship.

Simply asking about price and lead time is a rookie mistake that will cost you. You need to dive deep into their production control, testing protocols, communication workflows, and contingency plans. Based on two decades of supplying fabric and seeing where client partnerships fail, I've distilled the critical interrogation points into four categories: Capability & Capacity, Quality & Compliance, Logistics & Communication, and Risk & Relationship.

Can You Handle My Order? (Assessing Capability & Capacity)

This is the foundational question. A supplier might be excellent at making basic cotton jersey but a disaster with complex jacquards or functional coatings. You need to match their core competency with your technical requirements, and ensure they have the physical and managerial bandwidth to deliver your order on time.

Start by asking for specifics, not generalities. Instead of "Do you make knits?" ask "What is your monthly production capacity for 95% cotton 5% spandex single jersey in 220 GSM?" Request a virtual or in-person tour of their primary production facilities. A supplier with in-house weaving/knitting and fixed cooperative dyeing factories (like us at Shanghai Fumao) has far more control over timing and quality than a pure trading company that sources everything from the spot market. Ask about their current order book and lead times for similar fabrics to gauge if they are overextended. Peak season (Mar-May, Aug-Oct) can stretch lead times by 1-3 weeks, so understanding their planning is crucial.

What is your exact process from my order to shipment?

Demand a step-by-step breakdown. A transparent supplier will outline:

- Contract & Deposit: Terms and timeline.

- Raw Material Sourcing: How and when they procure yarn. Do they hold stock? This is critical—if they wait for your order to buy yarn, delays upstream will hit you.

- Production Scheduling: When your order slots into the production queue at each stage (weaving, dyeing, finishing).

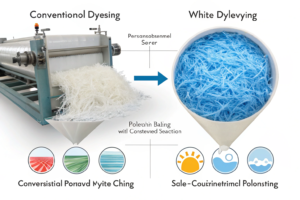

- In-Process QC: At what stages do they check quality? (It should be at greige fabric, after dyeing, and after finishing).

- Final Inspection & Shipping: Who does the final inspection, and how is shipping arranged?

This process exposes their level of integration. In 2023, a client avoided a major pitfall by asking this. The supplier's "process" involved subcontracting the entire order to an anonymous factory. My client walked away and came to us, where we showed them our integrated pipeline from our own weaving to our cooperative dyeing units, giving them a single point of control and accountability.

Can you provide references from clients with similar order profiles?

This is non-negotiable. Ask for 2-3 contacts for companies that have ordered similar fabric types, volumes, and who export to your region. A credible supplier will have ready references (with client permission). When you contact them, ask specific questions: "Were there any quality issues on the first order? How did they handle it?" and "Was the communication proactive during production?" A lack of verifiable references is a glaring red flag. Additionally, checking their profile on B2B platforms for verified transaction history and client reviews provides an additional layer of social proof.

How Do You Guarantee My Quality? (Verifying Quality & Compliance)

Quality isn't an outcome; it's a system. You need to understand the system that will prevent defects from reaching your loading dock. This goes far beyond "Our quality is good."

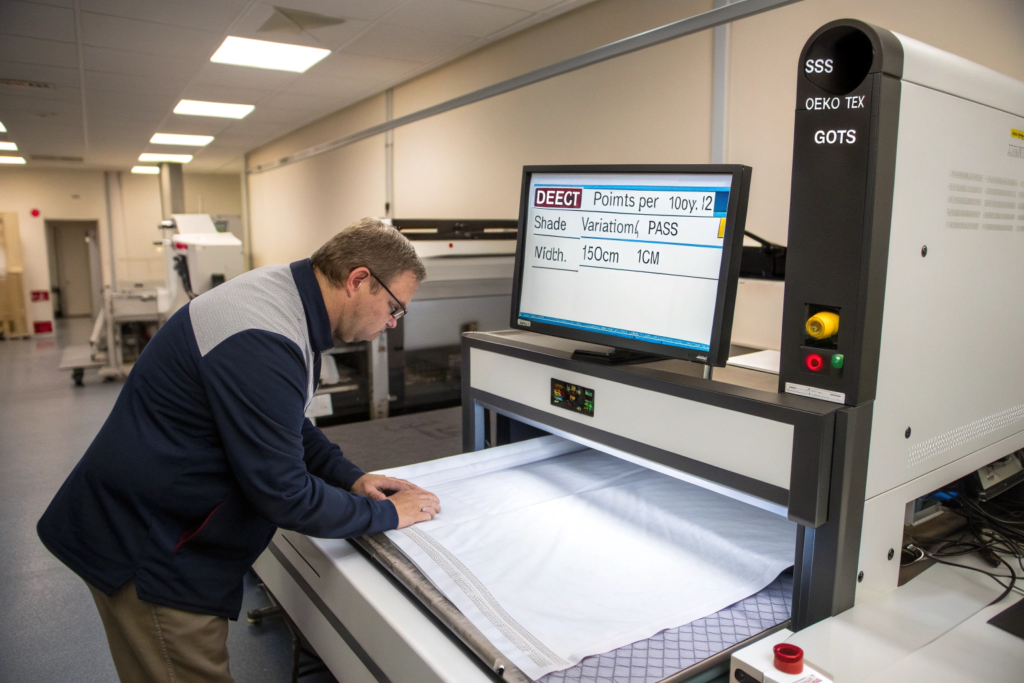

The first question should be about their in-house Quality Control (QC) team and procedures. How many QC staff? What checkpoints? Do they use standard fabric inspection machines (like 4-point or 10-point systems)? Ask for a copy of their QC report template. Secondly, drill into third-party testing. Do they test every batch? Which lab (SGS, ITS, Bureau Veritas)? Which tests? For a performance fleece, you'd want tests for pilling, colorfastness to washing & light, and composition. For children's sleepwear, you'd need flammability tests. Never assume compliance; demand the reports. A professional supplier will have this data on file. For example, we provide a unique QR code on our packing lists that links directly to the digital test report for that specific batch.

What are your tolerances for common defects and specification variances?

Get this in writing. "Good quality" is subjective; tolerances are objective. Ask:

- "What is your acceptable defect point score per 100 yards (e.g., 4-point system, max 20 points)?"

- "What is your tolerance for GSM (weight) variance? (+/- 5%? 3%?)"

- "What is your tolerance for fabric width and shrinkage?"

- "What constitutes an unacceptable color deviation from the approved lab dip?"

Their answers reveal their standards. If they hesitate or give vague answers like "we ensure it's good," be wary. A reliable supplier will state: "Our standard is ≤ 18 defect points per 100y, GSM ±3%, and shade must pass under a lightbox against the standard." This forms the basis for your right to reject non-conforming goods. Understanding the international fabric grading standards (4-point vs. 10-point system) helps you evaluate their answer.

Can I approve a pre-shipment sample (TOP sample) before bulk shipment?

The answer must be "Yes." The pre-production sample (from pilot run) and top-of-production (TOP) sample are your final safety nets. Confirm the process: Will they ship you 3-5 meters cut from the beginning of the bulk production for your final approval? Who pays for the courier? How long do you have to approve? This step caught a critical issue for one of our clients in Germany last year. Their TOP sample showed a slight knitting defect that wasn't in the development sample. We halted production, identified the machine fault, and corrected it before proceeding, saving them from a 20,000-meter defective shipment. A supplier who refuses or rushes you through TOP approval is gambling with your money.

What Happens After the Fabric is Made? (Clarifying Logistics & Communication)

The job isn't done when the fabric rolls off the line. How it gets to you, who manages it, and what it costs are decisive factors in your total landed cost and timeline. Misunderstandings here are incredibly common and expensive.

Begin with incoterms and shipping. "What is your preferred FOB port?" (e.g., Ningbo, Shanghai). "Can you handle shipping arrangements, or do I use my own forwarder?" If they handle it, get a sample freight quote breakdown. Ask about packaging standards—how is fabric rolled (on tubes?), wrapped, and palletized to prevent damage and moisture? For a US client worried about tariffs, we demonstrated how our consolidated shipping and customs documentation process could help avoid delays. Furthermore, establish the single point of contact for all communications. Is it a salesperson, a project manager, or a QC coordinator? Insist on direct access to the operational team, not just the sales agent.

What is your detailed payment schedule and terms?

Clarity here prevents conflict. A standard schedule might be: 30% deposit with order, 70% balance against copy of bill of lading. But you must ask:

- "What payment methods do you accept?" (T/T, L/C?)

- "Is the deposit refundable if you fail to meet the approved TOP sample spec?"

- "Are there any hidden fees (e.g., bank charges, inspection fees)?"

- "Can we do a smaller initial order to establish trust?"

If they demand 100% upfront for a first order, it's a major risk. Conversely, be prepared for suppliers to run a credit check on your company. It's a two-way street. Using secure payment methods through platforms that offer trade assurance programs for first-time orders can provide a safety net.

How will you communicate updates and handle problems?

Establish the protocol before there's a problem. Ask:

- "How often will I receive production updates? Weekly? With photos?"

- "If there is a delay at the dyeing factory, how quickly will you notify me?"

- "What is your process for handling a quality dispute?"

The best suppliers provide proactive, transparent communication. At Shanghai Fumao, we assign a dedicated project manager who sends weekly update reports with photos from the factory floor at key stages (yarn arrival, greige fabric, dyed fabric). This builds tremendous confidence. Ensure they are responsive across time zones—a 12-hour email response time is reasonable; 3 days is not.

What If Things Go Wrong? (Evaluating Risk & Relationship)

You're not just buying fabric; you're entering a relationship. You need to assess their commitment to problem-solving and long-term partnership. This separates transactional vendors from strategic suppliers.

Probe their business continuity and contingency plans. "What is your backup plan if your primary dyeing factory has an environmental shutdown?" (This happens). An integrated supplier with multiple fixed partners has a clear advantage. Ask about their financial stability—how long have they been in business? Can they provide a business license? While sensitive, it indicates their ability to weather raw material price fluctuations without defaulting on your order. Finally, gauge their willingness to invest in the relationship. Will they help you with value-added services like fabric development or trend forecasting for future seasons? A partner thinks beyond the current PO.

What is your policy for defective goods or shipment delays?

Get the policy in writing. Key questions:

- "If the bulk fabric fails to meet the approved TOP sample, what are the remedies? (Replacement, discount, full refund?)"

- "Who bears the cost of returning defective goods?"

- "If shipment is delayed due to your production issues, what compensation do you offer?"

A reputable supplier will have clear, fair terms. They might offer a discount for minor defects or commit to reproducing the order quickly for major failures. Vagueness is unacceptable. Understanding international trade dispute resolution mechanisms gives you a framework for these discussions.

Are you open to a small trial order first?

This is the ultimate litmus test for risk mitigation. Proposing a small trial order (even 500-1000 meters) at a slightly higher unit cost allows you to vet their entire process—communication, quality, logistics—with limited exposure. A confident, capable supplier will agree to this, seeing it as an investment in a larger future partnership. A supplier who insists on a huge MOQ for a first order with a new client is often either incapable of flexibility or sees the transaction as one-off. Your goal is to find a partner like Shanghai Fumao, where we routinely structure phased roll-outs with new clients to build mutual confidence.

Conclusion

Placing your first order with a new fabric supplier is a leap of faith, but it shouldn't be a blind jump. By systematically asking these key questions about capability, quality, logistics, and risk management, you turn uncertainty into a structured evaluation. You're not just checking boxes; you're building a transparent, accountable framework for a business relationship. The supplier's willingness and ability to provide clear, detailed answers is more revealing than any sample swatch.

The right supplier won't see your thorough questioning as a burden, but as the mark of a professional, serious partner they want to work with long-term. They will have systems, data, and references ready to share. This due diligence is your most powerful tool to prevent costly mistakes and secure a supply chain partner that helps your business grow. Ready to have this conversation with a supplier built on transparency and integration? At Shanghai Fumao, we welcome these questions because our operations are designed to pass this audit with flying colors. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start your first order process with confidence.