Walk into any fabric market in Keqiao, and you’ll hear the same question from new buyers: “Which one is better—polyester, nylon, or rayon?” It’s like asking if a hammer, a screwdriver, or a saw is the “best” tool. The answer is: it depends entirely on the job you need it to do. Choosing the wrong one can sink your product before it even launches. I’ve seen a startup invest heavily in beautiful rayon dresses for a resort collection, only to find them arriving at stores stretched and wrinkled after a long sea voyage—a classic case of material mismatch.

So, what are the key differences between polyester, nylon, and rayon? At their core, polyester is the durable, easy-care synthetic workhorse; nylon is the strong, elastic performance fiber; and rayon is the breathable, drapey semi-synthetic that mimics natural luxury. But knowing this isn’t enough. You need to understand their hidden trade-offs: how they feel against the skin, how they react to water and sweat, their environmental footprint, and their true cost in production. Your choice will dictate your product’s comfort, durability, care label, and even its marketing story.

Let’s move past the basic descriptions and break down these three giants of the textile world from a practical, production-floor perspective. By the end, you’ll know exactly which fiber to lead with for your specific application, and how to blend them for the perfect balance.

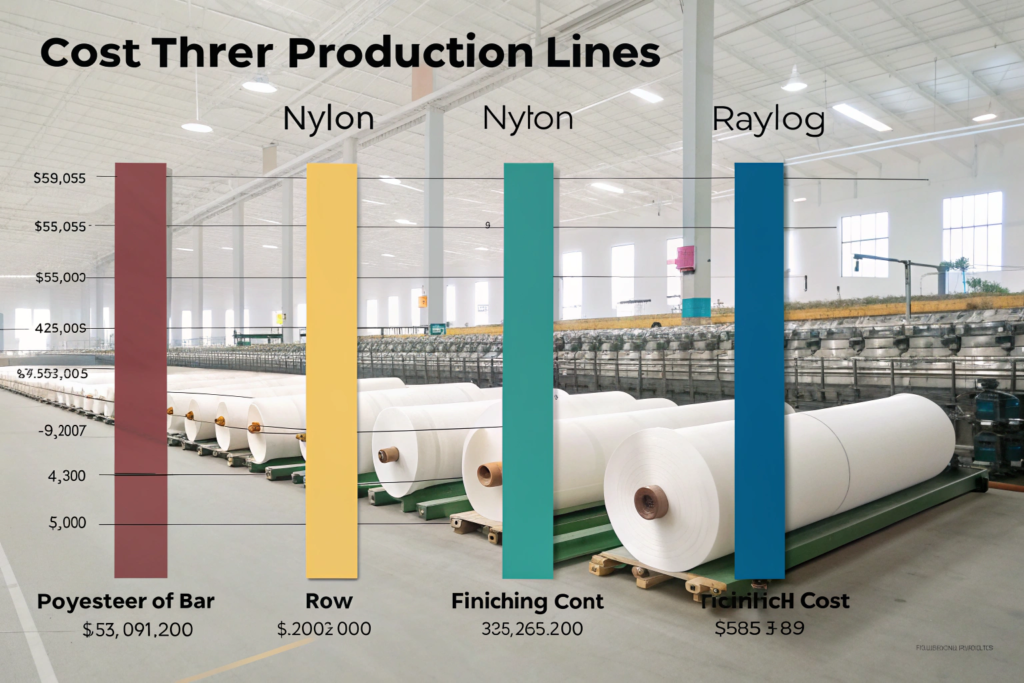

Which Fiber is Most Cost-Effective for Bulk Production?

When the production manager in our factory calculates costs for a 10,000-meter order, the fiber choice is the first line item. The “cheapest” fabric isn’t always the one with the lowest price per meter; you have to factor in yield, printing costs, and finishing. A European fast-fashion client once forced a switch from a standard polyester to a cheaper alternative to save $0.15/meter. The result? The dye uptake was inconsistent, leading to a 12% rejection rate during color inspection—wiping out the savings and delaying shipment by three weeks. True cost-effectiveness is about total value.

How do raw material and processing costs compare?

Let’s talk numbers. The price volatility here is tied to oil (for synthetics) and wood pulp (for rayon).

- Polyester: The undisputed cost champion. Its raw materials (purified terephthalic acid and ethylene glycol) are petroleum derivatives with a stable, large-scale supply. Dyeing polyester is also cheaper and faster—it uses disperse dyes at high temperatures, which are efficient and yield vibrant colors. The entire process, from chip to fabric, is highly optimized in China.

- Nylon: Generally 20-40% more expensive than polyester. Nylon chips (from caprolactam) cost more. Its dyeing is trickier—it requires acid dyes, which are more expensive and the process is more sensitive to pH and temperature control, adding cost and time.

- Rayon (Viscose): Its cost sits in a volatile middle ground. The price of dissolving wood pulp fluctuates. The chemical process to turn pulp into spin-able viscose is complex, energy and water-intensive, and involves handling chemicals like carbon disulfide. Environmental regulations in China are tightening, which is pushing costs up. However, its dyeing with reactive dyes is relatively straightforward and brilliant.

Bottom Line: For pure per-meter cost on high volume, polyester wins. But if you need the specific properties of nylon (extreme strength) or rayon (luxurious drape), you’re paying a premium for performance.

What hidden production costs should you anticipate?

The sticker price is just the beginning. Here’s where hidden costs creep in:

- Yield and Shrinkage: Rayon (especially viscose) has higher wet shrinkage than polyester or nylon. If you don’t pre-shrink it adequately, you’ll get garment size variation. This means you must buy more fabric per piece (a higher “fabric consumption”), a hidden cost many overlook.

- Finishing Requirements: Polyester and nylon often need antistatic or moisture-wicking finishes to be comfortable. Rayon often needs wrinkle-resistant or strengthening finishes to be durable. Each finish adds $0.10-$0.50 per meter.

- Printing & Color Matching: Rayon absorbs dye deeply, giving rich colors but can appear darker when wet, making color matching critical. Polyester can be prone to “barre” (subtle horizontal streaks) if the yarn isn’t uniform, which can ruin printed designs. Always order a strike-off (test print) before bulk printing. For a deeper dive, resources like the production and processing nuances of polyester fibers can be very helpful.

How Do Performance and Durability Differ in Real Use?

This is where the fibers truly separate. Imagine three identical backpacks: one polyester, one nylon, one rayon. After a year of daily use, the rayon one would be falling apart, the polyester would look almost new but might have scratched up, and the nylon would be broken in but still incredibly strong. Performance isn't an abstract spec; it's how the fabric survives the real world.

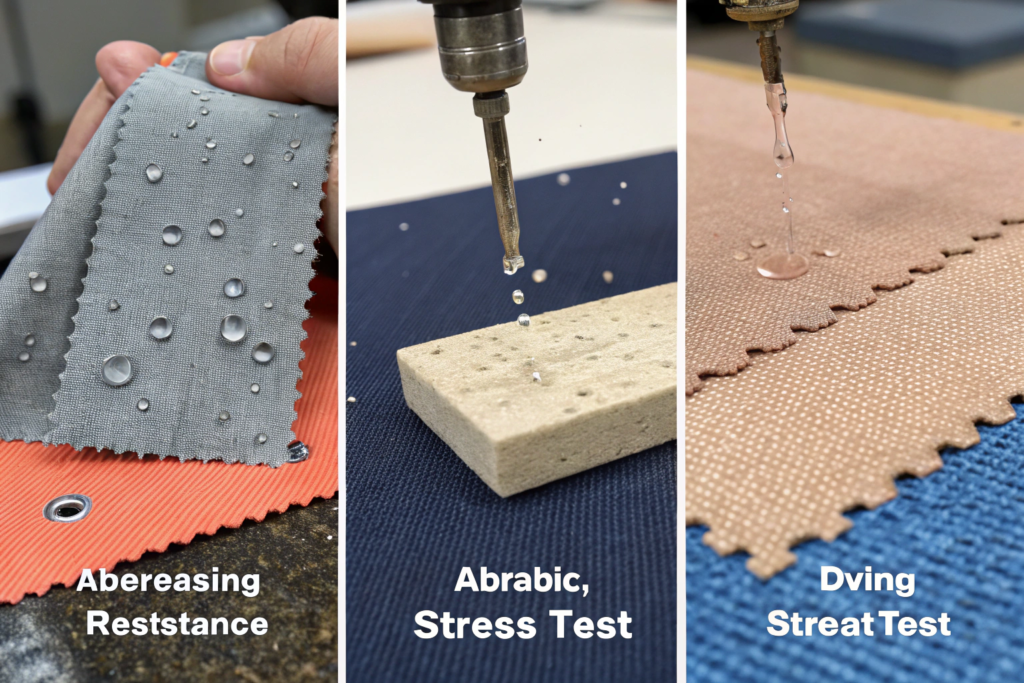

Which fiber is strongest and most abrasion-resistant?

Strength is about tenacity (force to break) and abrasion resistance (rubbing wear).

- Nylon: The heavyweight champion. It has the highest tensile strength and excellent elasticity (it can stretch and recover). This is why it’s used in seatbelts, climbing ropes, and premium luggage. Nylon 6,6 is even stronger than Nylon 6. In our tests, a 70D nylon fabric often outperforms a 100D polyester in abrasion.

- Polyester: Very strong, but stiffer and less elastic than nylon. Its strength is more dimensional—it holds its shape better under load and has superior resistance to sunlight (UV degradation) and chemicals. A polyester flag will outlast a nylon one in the sun.

- Rayon: The weakest of the three, especially when wet. Wet rayon can lose up to 50% of its strength. It has low abrasion resistance. You would never use pure rayon for anything requiring durability.

Takeaway: For activewear, bags, upholstery—anything that gets rough use—nylon is king. For outdoor furniture, curtains, or garments that need to hold a crisp shape, polyester is better. Rayon is for gentle, low-friction applications.

How do moisture management and care differ drastically?

| This is the comfort and practicality divide. | Property | Polyester | Nylon | Rayon |

|---|---|---|---|---|

| Moisture Absorbency | Very Low (<0.4%) | Low (~4%) | Very High (~13%) | |

| Drying Speed | Very Fast | Fast | Slow | |

| Wrinkle Resistance | Excellent | Very Good | Poor | |

| Heat Sensitivity | Melts at ~250°C | Melts at ~220°C | Does not melt; scorches |

- The Synthetics (Polyester/Nylon): They are hydrophobic. They wick moisture (pull it to the surface) but don’t absorb it. This is great for sweat moving away from the skin in sportswear, but can feel clammy if the fabric isn’t engineered with capillary channels. They are easy care: machine wash, tumble dry low, and they come out with few wrinkles.

- Rayon: It is hydrophilic. It absorbs moisture into the fiber, which makes it feel cool and comfortable in heat—a key reason for its use in summer blouses and linings. However, this also means it shrinks, loses strength when wet, and wrinkles terribly. It often requires dry cleaning or very gentle hand wash. Understanding the proper care and handling of rayon fabrics is essential to avoid customer returns.

What Are the Sustainability and Environmental Impacts?

You can’t have a sourcing conversation today without this. Each fiber has a very different environmental story, and the “greenest” choice is not always obvious. A client recently demanded we switch all their polyester to organic cotton for sustainability. We had to show them the life cycle analysis: for their high-turnover product, durable polyester that lasts for years and can be recycled might have a lower total impact than water-intensive cotton. It’s about the full picture.

Is recycled polyester truly a sustainable solution?

Recycled PET (rPET) is the biggest story in “green” synthetics. It diverts plastic bottles from landfills and oceans. The technology is mature, and at Shanghai Fumao, we offer a full range of rPET fabrics with GRS certification. But there are caveats:

- Downcycling: Most mechanical recycling shortens fiber length. The fabric might be slightly less strong or prone to pilling over multiple recycles. The true holy grail is chemical recycling (back to polymer chips), which is emerging but costly.

- Microplastics: Both virgin and recycled polyester shed microfibers when washed. This is a systemic issue solved by washer filters or special fabric finishes, not by recycling itself.

So, yes, rPET is a major step forward in reducing fossil extraction and waste, but it’s not a perfect, circular solution yet. It’s currently the most scalable and cost-effective “eco” option for performance fabrics.

How does rayon's "natural" origin affect its eco-profile?

This is the great paradox. Rayon comes from trees (a renewable resource), but the traditional viscose process is chemically intensive. The key issues are:

- Deforestation Risk: Not all wood pulp is from sustainably managed forests. Look for certifications like FSC (Forest Stewardship Council) or PEFC.

- Polluting Chemicals: The process uses and can release carbon disulfide and other chemicals if not managed in a closed-loop system.

The sustainable leader in this category is Lyocell (Tencel™). It uses a non-toxic solvent (NMMO) in a closed loop where over 99% of the solvent is recovered and reused. It’s more expensive but represents the future of cellulosic fibers. When sourcing rayon, always ask: “Is it viscose or lyocell? Is the pulp certified?”

When Should You Consider Blends vs. Pure Fibers?

On our factory floor, pure fibers are the exception, not the rule. Blending is where fabric engineering gets smart. It’s about combining strengths and mitigating weaknesses. A 100% rayon dress is a wrinkle nightmare. A 100% polyester shirt can feel cheap and sticky. But a 55% Polyester / 45% Rayon blend? You get the drape and comfort of rayon with the durability and easy care of polyester. It’s the secret behind countless successful products.

What are the most common and effective blends?

These classic blends have stood the test of time for a reason:

- Polyester-Cotton (or Polyester-Rayon): The king of blends. The polyester provides strength, shrink resistance, and wrinkle recovery. The cotton or rayon provides absorbency, softness, and a better hand-feel. Common ratios: 65/35, 50/50, 35/65. This is the workhorse for shirts, dresses, bed linens, and uniforms.

- Nylon-Spandex: The foundation of activewear and stretch garments. The nylon provides strength and durability, while the spandex (usually 5-20%) provides the essential stretch and recovery. You’ll find this in leggings, swimwear, and athletic jerseys.

- Wool-Nylon: Used in socks, suiting, and outerwear. The nylon dramatically increases the abrasion resistance and durability of the more delicate wool, making the fabric last much longer.

How does blending affect sourcing and production?

Blending adds a layer of complexity. You must ensure a consistent blend ratio throughout the fabric. This requires good fiber mixing at the spinning stage. Dyeing can also be trickier, as you might need to use two different types of dyes (e.g., disperse for polyester and reactive for cotton) in the same bath—a process called union dyeing. The key is to work with a supplier like Shanghai Fumao that has tight control over its spinning and dyeing partners. For a Scandinavian workwear brand last year, we developed a 70% Recycled Nylon / 30% Recycled PET blend for rugged pants. The nylon gave tear strength, the PET gave stiffness for a sharp crease, and the recycled story was a huge sell. It took four sampling rounds to perfect the union dyeing process, but the result was a best-seller.

Conclusion

Choosing between polyester, nylon, and rayon isn’t about finding the “best” fiber. It’s about matching the fiber’s inherent DNA to your product’s mission. Polyester is your go-to for cost-effective, durable, and easy-care solutions. Nylon is your champion when you need unmatched strength, elasticity, and abrasion resistance. Rayon is your answer for achieving affordable luxury, beautiful drape, and moisture-absorbent comfort. And remember, the most ingenious solutions often lie in thoughtful blends that harness the best of each world.

Let this framework guide your next fabric specification. Don’t just ask for a “polyester.” Ask for the right polyester for the job—consider its denier, filament vs. staple, weave, and finish. Your fabric choice is the foundation of your product’s success.

If you’re wrestling with these decisions for an upcoming collection and need a partner who can not only supply these fibers but also engineer the perfect fabric specification for your needs, let’s talk. At Shanghai Fumao, we live in the details of fiber performance, cost engineering, and sustainable innovation. Contact our Business Director, Elaine, to start a conversation about how we can source or develop the ideal fabric for your project. Email: elaine@fumaoclothing.com.