Let’s face a messy truth. The dream of a shirt that repels coffee spills or a sofa that shrugs off wine stains feels perpetually just out of reach. We’ve had “stain-resistant” finishes for years, but they wash out, wear off, or rely on chemistry we now know is harmful. So, are self-cleaning fabrics just a marketing gimmick, or is something genuinely new happening? From inside our CNAS-certified lab in Keqiao, I can tell you: the game is changing. The old spray-on treatments are being replaced by molecular engineering and biomimicry. Today’s innovation isn’t about making a fabric resistant; it’s about making it actively repellent and even self-degrading stains, all while being safe and durable. If you’re sourcing performance fabrics, ignoring these trends means missing the next wave of consumer demand.

So, what are the key trends? They converge on three fronts: smarter chemistry, nano-structural design, and bio-integration. We’re moving beyond generic fluorocarbon-based DWR (Durable Water Repellent) finishes toward eco-friendly, cross-linking polymers that bond covalently to fibers. We’re engineering fabric surfaces at the microscopic level to mimic lotus leaves or shark skin. And we’re embedding enzymes or photocatalytic nanoparticles that break down organic matter when triggered by light or moisture. The goal is no longer just “stain release” in the wash, but “stain avoidance” and “stain elimination” in real-time. This shifts the value proposition from a convenient feature to a core performance benefit for athleisure, workwear, medical textiles, and home furnishings.

The drivers are clear: consumers want ultra-low maintenance, regulators are phasing out PFAS “forever chemicals,” and brands need durable, verifiable claims. This isn’t lab fiction anymore. I’ll walk you through the real, commercial-ready technologies that are moving from R&D papers to fabric rolls, and what you need to know to specify them for your next product line.

How Are Next-Gen Finishes Replacing Harmful PFAS Chemicals?

For decades, the king of stain and water resistance was the fluorochemical family, especially long-chain PFAS (C8). They worked incredibly well but left a toxic legacy—persisting in the environment and accumulating in our bodies. The regulatory axe has fallen. The EU’s REACH and US state laws are severely restricting their use. This created a massive innovation imperative: find something as good, but safe.

The answer is coming from two directions: shorter-chain fluorochemistry (C6) as a transitional solution, and more importantly, PFAS-free alternatives. The PFAS-free front is where the real action is. The leading contenders are silicon-based polymers, hydrocarbon-based wax emulsions, and dendrimer (branched polymer) technologies. These work by creating a dense, low-surface-energy barrier on each fiber. The key innovation is in the binding mechanism. Instead of just sitting on the fiber, new hybrid polymers form covalent bonds with cellulose or synthetic polymer chains during curing, making them remarkably durable to washing and abrasion. Think of it as grafting a protective layer onto the fiber itself, rather than painting it on.

What Makes Dendrimer and Hybrid Polymer Finishes More Durable?

The problem with old finishes was that they formed a film on the fabric surface. This film cracked, peeled, and washed away with mechanical action. Dendrimers and engineered hybrid polymers change the game through architecture and bonding.

Dendrimers are perfectly symmetrical, branched nano-sized polymers. Their 3D structure allows for an immense number of functional end-groups to attach to the fiber surface at multiple points, creating a incredibly strong and uniform shield. It’s like using a nano-Velcro with thousands of hooks instead of a weak glue.

Hybrid Polymers (e.g., silane-quat compounds) work differently. They use reactive groups that, under heat (during finishing), form permanent Si-O-C or other covalent bonds with hydroxyl groups on cotton or with synthetic polymer chains. This isn’t a coating; it’s a chemical modification of the outermost layer of the fiber. The result is outstanding wash durability.

We validated this in late 2023 with a series of tests for a German contract furniture brand. We applied a leading commercial PFAS-free hybrid polymer finish to a polyester-cotton blend upholstery fabric. After 30 home washes (equivalent to years of use), the water repellency (measured by spray test rating) dropped from 90 to 85. A traditional wax-based finish failed completely after 10 washes. This durability is what makes these new finishes commercially viable. For brands looking for PFAS-free durable water repellent technologies approved by standards like bluesign®, these are the solutions to demand from your supplier.

How Do Bio-Based and Natural Oil Finishes Perform?

This is the most exciting frontier: using nature’s own chemistry. Finishes derived from castor oil, soy oil, and tannins are being developed. They work by creating a hydrophobic layer derived from plant fatty acids. The performance is good, though not yet at the extreme level of top-tier synthetics for heavy rain, but excellent for stain repellency against water-based spills.

Their biggest advantage is a compelling sustainability story and ultimate biodegradability. The innovation lies in modifying these natural oils to improve their bonding and durability. For instance, epoxidized soybean oil can be polymerized and cross-linked to create a more robust network. A client in the sustainable kids’ wear space partnered with us in early 2024 to develop an organic cotton jersey finished with a castor-oil-based repellent. It achieved a spray test rating of 80 (good protection) and maintained it through 20 gentle washes, perfectly adequate for children’s everyday spills. The brand could market a fully bio-based, non-toxic stain-resistant garment—a powerful claim. Exploring resources on bio-based textile chemicals can provide deeper insight into this growing niche.

What Role Does Surface Engineering and Biomimicry Play?

This trend moves beyond chemistry to pure physics. Instead of changing the fabric’s chemical nature, we change its topography. By creating nano- or micro-scale structures on the fiber surface, we can physically prevent liquids from wetting the fabric. This is biomimicry at its best, copying the lotus leaf effect.

A lotus leaf isn’t chemically super-slippery; it’s covered in tiny, waxy bumps. This structure traps a layer of air, causing water droplets to bead up and roll off, picking up dirt as they go. Replicating this on fabric involves techniques like laser etching, plasma treatment, and nano-imprinting. For example, a tightly woven nylon can be treated with a low-temperature plasma that etches precise patterns at the nanometer level, then combined with a mild hydrophobic coating. The result is a dual-action barrier: physical structure plus chemical repellency.

Can “Lotus Effect” Fabrics Withstand Real-World Abrasion?

This is the critical question. A nano-pattern etched onto the surface can, in theory, be worn down by friction. The innovation here is in creating patterns that are recessed or in engineering the entire fiber, not just coating it.

One advanced approach is melt-spinning of inherently textured fibers. During polymer extrusion, additives or specific die designs create fibers with permanent, integral micro-grooves or porous structures that are inherently hydrophobic. The “structure” is inside the fiber, so it can’t be abraded away. Another method is creating a durable composite layer. For instance, bonding a thin, ultra-durable polymer film (like expanded PTFE, but PFAS-free) that has a micro-porous structure to the fabric. The film takes the abrasion, protecting the nano-structure underneath.

We’re working with a partner on a plasma technology that modifies the first 100 nanometers of the fiber polymer itself, creating a durable textured shell. Preliminary abrasion tests (Martindale test) on a polyester fabric showed the effect remained effective (>80 water repellency) after 20,000 cycles, suitable for backpack and outdoor apparel applications. The key is that the treatment isn’t an “add-on”; it’s a transformation of the surface layer of the polymer.

How Are Photocatalytic “Self-Cleaning” Treatments Evolving?

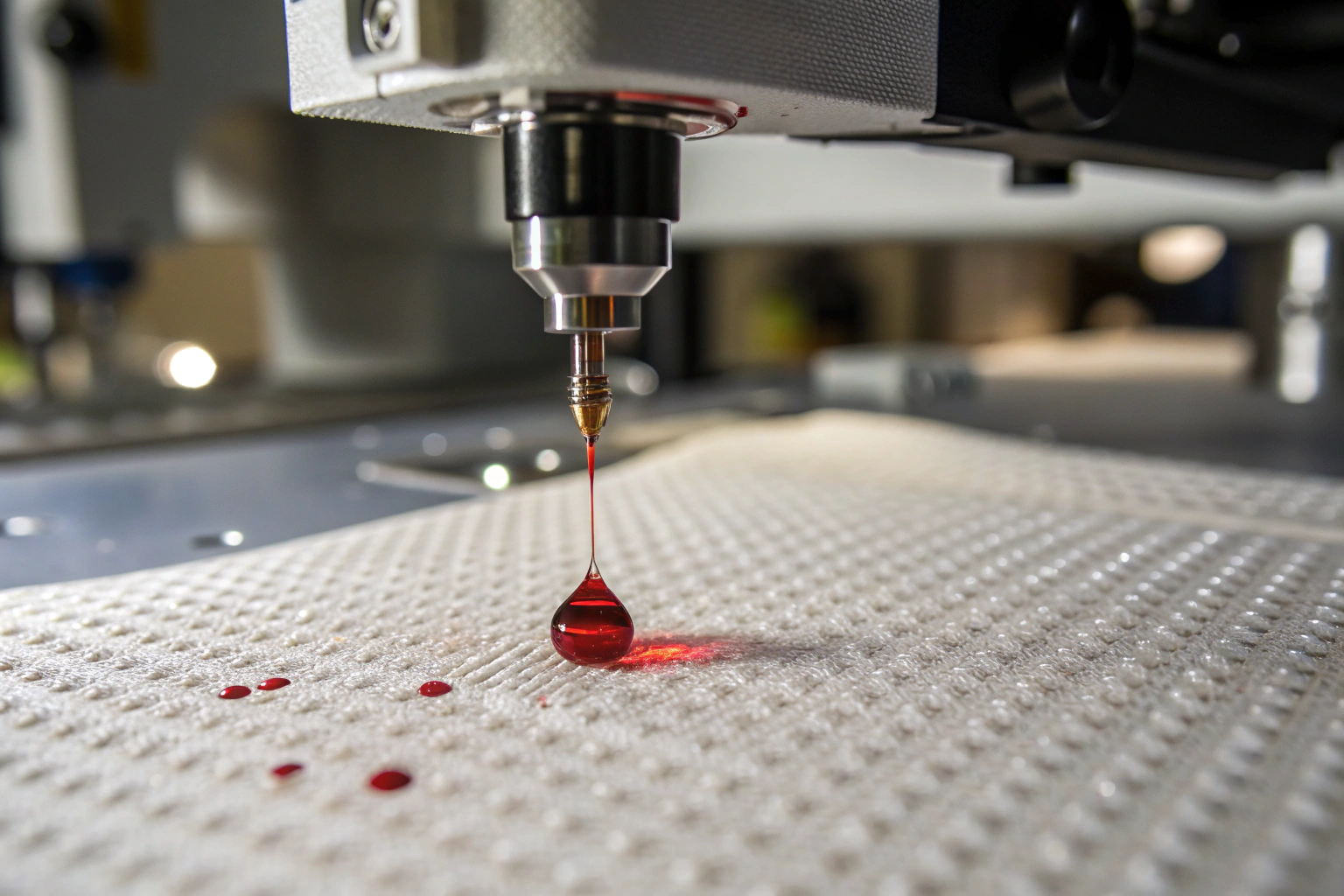

This is the holy grail: fabric that actively destroys stains. The most common agent is titanium dioxide (TiO2) nanoparticles. When exposed to ultraviolet light (sunlight), TiO2 becomes a powerful photocatalyst, producing reactive oxygen species that break down organic matter like oil, sweat, and food stains into carbon dioxide and water.

The old problem was that TiO2 needed strong UV light and could degrade the fabric itself over time. The innovations are tackling these issues:

- Doping and Sensitization: By doping TiO2 with nitrogen or combining it with other materials like graphene oxide, its photocatalytic activity is enhanced and can be triggered by visible light indoors.

- Smart Encapsulation: The nanoparticles are encapsulated in a porous silica or polymer shell. This allows the reactive species to diffuse out and attack stains while protecting the fiber polymer from degradation.

- Combination Finishes: Pairing TiO2 with a super-hydrophobic finish creates a “1-2 punch.” The hydrophobic finish repels most liquids, while the TiO2 breaks down any small organic residues that do land, preventing long-term yellowing or odor buildup.

A practical application we developed in 2023 was for a hotel chain’s curtain fabric. The curtains faced windows and were prone to dust and urban grime buildup. A finish incorporating visible-light-active TiO2 kept the curtains noticeably cleaner for longer between washes, reducing their laundry burden and chemical use. It was a functional sustainability win. For a deep dive into the scientific principles and recent research on photocatalytic textiles, academic portals are invaluable.

How is Smart Integration Creating Truly Responsive Fabrics?

The ultimate trend is moving from passive to active, from “always-on” repellency to responsive, smart systems. Imagine a fabric that is breathable and absorbent when you’re dry but instantly becomes hydrophobic when it senses sweat or rain. This is being explored through stimuli-responsive polymers.

These are materials that change their conformation or surface energy in response to a trigger like pH, temperature, or moisture. For example, a polymer with both hydrophobic and hydrophilic segments. In a dry state, the hydrophobic parts dominate the surface, repelling water. When moisture (sweat) arrives, the polymer chains reconfigure, exposing the hydrophilic parts to wick away the liquid. Once dry, it switches back. This is akin to creating a fabric with millions of tiny, automatic gates.

What Are the Commercial Applications of Moisture-Triggered Fabrics?

The most immediate application is in high-performance sportswear and military uniforms. The soldier or athlete needs a fabric that provides excellent breathability and thermal regulation during high exertion (when sweat is high) but also needs storm protection if the weather turns.

We are in the prototyping phase with a moisture-responsive membrane laminate. The membrane’s pore structure is tuned to expand in the presence of high humidity (sweat), dramatically increasing vapor transmission rate (RET). When humidity drops or liquid water hits the outside, the pores contract to a highly water-resistant state. This provides dynamic comfort that a static Gore-Tex membrane cannot match. For brands at the pinnacle of performance, this is the next benchmark. It addresses the classic “boil in the bag” feeling of traditional waterproof gear.

Can Enzymatic and Odor-Eliminating Finishes Truly “Clean” Fabrics?

Yes, and this goes beyond stain removal to odor and allergen control. The innovation is in immobilizing enzymes onto fibers. Enzymes are nature’s catalysts—incredibly efficient at breaking down specific substances. A protease enzyme breaks down protein-based stains (blood, grass). A lipase breaks down oils. An amylase tackles starches.

The challenge was keeping the enzymes active and attached through washes. New bio-conjugation techniques use linker molecules to tether enzymes to the fiber surface without denaturing them. A more advanced approach is microencapsulation: surrounding the enzyme in a tiny, durable capsule that is attached to the fiber. The capsule slowly releases the enzyme over time or ruptures under friction during wear, providing a long-lasting effect.

In 2024, we collaborated with a medical textile company on a pillowcase for allergy sufferers. We immobilized a gentle protease and an anti-microbial agent derived from chitosan onto a Tencel™ fabric. The finish was designed to break down dust mite allergens (which are protein-based) and inhibit bacterial growth, reducing nighttime allergy symptoms. Independent lab tests showed a >90% reduction in detectable allergen levels after simulated use. This is self-cleaning at a biological level, offering genuine health benefits.

What Should a Buyer Look for When Sourcing These Advanced Fabrics?

With all these exciting options, the risk of greenwashing or over-promising is high. You need to be a savvy specifier. Don’t just ask for “stain-resistant.” Be specific.

- Demand Test Data: Ask for AATCC Test Method results. Key ones are:

- AATCC 22: Water Repellency (Spray Test). Look for a score of 80+ for good, 90+ for excellent.

- AATCC 193: Oil Repellency. Crucial for food and oil-based stains.

- AATCC 130: Stain Release (how well a stain washes out).

- ISO 105-C06 or AATCC 61: Colorfastness to Washing. How many washes does the effect last? Demand data for 5, 10, 20, and 30 washes.

- Ask for Chemistry Disclosure: Require a Safety Data Sheet (SDS) and a statement on PFAS content. Certifications like OEKO-TEX STANDARD 100 and bluesign® approval are strong indicators of safety.

- Understand the Application: A heavy-duty upholstery fabric needs extreme abrasion resistance (Martindale test > 50,000 cycles). A delicate silk blouse needs a soft hand-feel. The technology must match the end-use.

- Audit the Supplier’s Capability: Do they have in-house finishing and a lab, or are they outsourcing? An integrated supplier like Shanghai Fumao controls the process from yarn to finish, ensuring consistency and allowing for custom R&D to match your exact performance matrix.

How Do You Balance Performance, Durability, and Cost?

This is the final equation. The most advanced technologies command a premium. Here’s a rough guide:

| Technology Tier | Typical Cost Add | Best For | Durability (Washes) | Key Consideration |

|---|---|---|---|---|

| Basic DWR (C6 Fluorocarbon) | Low | Budget outerwear, temporary protection | 10-20 | Regulatory risk, environmental concerns. |

| Advanced PFAS-Free Polymer | Medium | Mainstream athleisure, workwear, home textiles | 30-50+ | Excellent balance of performance and compliance. |

| Biomimetic/Nano-Structured | High | Technical outerwear, luxury performance, medical | 50+ (if integral) | Hand-feel may be affected, verify abrasion resistance. |

| Photocatalytic/Smart-Responsive | Very High | Specialty applications, high-value contract, innovation flagship products | Varies widely | Requires clear performance validation for the specific use case. |

Strategy: Use a cost-benefit analysis. For a mass-market t-shirt, an advanced PFAS-free finish might be perfect. For a flagship $500 jacket, a biomimetic or smart-responsive technology justifies the price and tells a superior story. Always test prototypes in real-world conditions.

What Are the Verification and Certification Benchmarks?

Your claims need backbone. Rely on third-party certifications, not just supplier assurances.

- For Safety: OEKO-TEX STANDARD 100, bluesign® PRODUCT, USDA BioPreferred (for bio-based content).

- For Performance: Look for suppliers whose in-house labs are CNAS or ISO 17025 accredited. This means their test results are internationally recognized.

- For Sustainability: Global Recycled Standard (GRS) if using recycled fibers, along with the finish’s eco-profile.

In our partnerships, we provide a Fabric Technology Dossier that bundles the fabric specs, SDS, test reports from our CNAS lab, and relevant certifications into one document. This transparency builds trust and de-risks your sourcing decision. It shows we stand behind the innovation.

Conclusion

The innovation in self-cleaning and stain-resistant fabrics is moving from a chemical-dependent afterthought to a sophisticated, multi-disciplinary science integrating safe chemistry, structural physics, and responsive biology. The trends are clear: ditch the PFAS, embrace biomimicry and smart materials, and demand verifiable, durable performance. This isn’t just about avoiding laundry; it’s about creating textiles that are higher-performing, longer-lasting, and inherently more sustainable by reducing water, energy, and chemical use over their lifecycle.

For forward-thinking brands, these technologies offer a powerful way to differentiate, justify premium positioning, and meet the rigorous demands of modern consumers and regulators. The key is to partner with a supplier who has the R&D depth, testing rigor, and production integration to turn these exciting concepts into reliable, commercial-grade fabrics.

If you’re looking to integrate cutting-edge, high-performance finishes into your next collection with full transparency and technical support, let’s explore the possibilities. At Shanghai Fumao, our dedicated functional finishes lab is at the forefront of these innovations, from PFAS-free repellents to photocatalytic applications. To discuss how we can engineer a fabric solution that actively protects your product and your brand’s reputation, contact our Business Director, Elaine. Reach her at: elaine@fumaoclothing.com. Let’s build fabrics that care for themselves—and for your customers.