I'll never forget the panic call from a Miami swimwear brand in 2022. Their entire spring collection was delayed because the 5,000 meters of floral Raschel lace they received had a nearly invisible flaw—skipped stitches forming a subtle line that only showed under bright runway lights. By then, the fabric was already cut in their factory. The loss was six figures. This disaster didn't happen because they lacked a QC checklist; it happened because their inspection was rushed and didn't know where to look. In the lace world, beauty is in the details, and so are the most expensive defects. This guide will arm you with the professional inspector's eye, teaching you the specific defects that can ruin your lace and how to catch them before they ruin your production.

Lace fabric inspection is a systematic process of examining lace material for visual, structural, and functional flaws that affect its quality, appearance, and performance. Unlike solid fabrics, lace requires inspecting both the patterned areas and the open ground, making it a specialized skill. Common critical defects include mis-knits/dropped stitches, pattern misalignment, slubs/yarn imperfections, dye variations, and width inconsistencies. Identifying these defects early—preferably at the supplier's facility before shipment—is the single most effective way to protect your profit margin, timeline, and brand reputation.

If you think inspecting lace just means "checking if it looks pretty," you're risking your entire order. Let's move beyond the surface and learn what professionals really look for under the inspection light.

Why is Specialized Inspection Critical for Lace Compared to Other Fabrics?

Lace is an architectural fabric. Its value lies in the precise execution of a complex, often delicate, structure. A small error in the knitting, embroidery, or finishing process doesn't just create a local stain; it can compromise the structural integrity of the entire pattern repeat or cause a visible "run" like in stockings. The open, net-like construction also makes it more vulnerable to handling damage during production and transit. A snag that might be negligible on a twill becomes a glaring hole on lace.

Furthermore, lace is frequently used in high-visibility, emotionally charged applications like bridal, lingerie, and statement fashion pieces. Consumers have zero tolerance for flaws in these categories. A defect you might accept on a lining fabric will guarantee a return on a lace bodice. The inspection standard must therefore be exceptionally stringent. At Shanghai Fumao, we treat lace inspection with a different protocol than our bulk cotton fabrics, involving higher magnification, more lighting angles, and a lower Acceptable Quality Level (AQL) threshold. (Here's an inside tip: we always inspect lace at a slower meter-per-hour rate—it simply takes more time to do it right.)

What Are the Major Categories of Lace Defects?

To inspect systematically, group defects into these categories:

- Yarn & Raw Material Defects: Flaws originating from the yarn itself.

- Slubs/Thick & Thin Places: Inconsistent yarn thickness creating bumps or weak, thin areas in the lace.

- Foreign Yarn/Different Fiber: A stray yarn of a different type or color woven in by mistake.

- Yarn Barre: Subtle, repeating horizontal streaks caused by yarn lot variation, often only visible under specific light.

- Knitting/Weaving/Embroidery Defects: Flaws occurring during the fabric formation.

- Mis-knit (or Dropped Stitch): A missed loop, causing a small hole or a "run" that can propagate. The #1 defect in Raschel lace.

- Pattern Distortion/Misalignment: The design motif is crooked, stretched, or out of sync at the seams. This points directly to a digitization or machine calibration error.

- Holes or Tears: Beyond the design, these are unintended breaks in the ground mesh.

- Finishing & Dyeing Defects: Flaws introduced after the lace is made.

- Color Bleeding/Staining: Dye transferring to unintended areas.

- Shade Variation: Differences in color hue or depth across the roll or between rolls.

- Skewing/Bowing: The pattern lines are not perpendicular to the fabric's selvage, causing the design to "bend."

- Poor Hand/Excessive Stiffness: Caused by improper washing or chemical finishing.

How Do Defects Differ Between Raschel Knitted Lace and Embroidered Lace?

The origin point changes the common failure modes.

| Defect Type | More Common in Raschel/Knitted Lace | More Common in Embroidered Lace |

|---|---|---|

| Structural | Mis-knits, dropped stitches, broken warp threads. | Puckering of the base fabric, thread breaks, missing stitches in dense fill areas. |

| Pattern | Whole pattern repeat misalignment, ground mesh inconsistency. | Registration errors (embroidery not aligning with underlying pattern), jump stitches not properly trimmed. |

| Yarn/Thread | Yarn slubs, barre from warp beam inconsistencies. | Thread tension variations causing shiny/dull patches, different thread lots. |

| Finishing | Width distortion from high stretch, thermal shrinkage. | Adhesive residue from stabilizer backing, water spots from cleaning. |

Understanding this helps you focus your inspection. When checking Raschel lace from a supplier like Shanghai Fumao, our QC team spends extra time tracking the continuity of the pattern repeat across the entire width and length, as that's a core stability indicator of the warp-knit process.

What is the Step-by-Step Process for a Professional Lace Inspection?

Don't just unroll and glance. Follow a disciplined method. The industry standard uses a backlit inspection table with frames to hold the lace under consistent, moderate tension.

- Prepare the Environment: Use a clean, well-lit area. The backlight is non-negotiable—it reveals holes, thin places, and density variations that overhead light misses.

- Mount the Fabric: Secure the roll on the table and unroll 1-2 meters. Ensure the lace is flat but not over-stretched.

- Systematic Scanning: Inspectors use a "S" path pattern with their eyes, scanning section by section. They inspect both the face and back of the lace. Many defects, like floating threads on embroidered lace, are more visible on the back.

- Mark Defects: Every flaw is immediately tagged with a colored clip or sticker at the selvage. Different colors can denote different defect types (e.g., red for major, yellow for minor).

- Measure Key Parameters: Periodically check:

- Width: Measured at multiple points. Lace, especially elastic lace, can vary.

- Pattern Repeat: Verify the horizontal and vertical repeat dimensions are within tolerance (e.g., ±0.5%).

- GSM (Grams per Square Meter): Checks for consistent density.

- Grade the Roll: Using a standard like the 4-Point System, assign penalty points per defect based on its length/severity. Calculate the total points per 100 square yards/meters to determine if the roll passes or fails.

What Are the Critical "On-Light" and "Off-Light" Checks?

This is a pro technique. You must inspect lace under two lighting conditions:

- On-Light (Backlit): As described. Best for finding holes, dropped stitches, thin areas, and verifying pattern symmetry and openness.

- Off-Light (Reflected Light): Turn off the backlight and use overhead, angled light. This is crucial for spotting surface flaws like:

- Soil, oil stains, or dirt

- Shade variations (a roll that looks uniform under backlight might show color streaks in reflected light)

- Yarn barre and slubs

A case study from last year: For a Norwegian brand's organic cotton lace, we found a subtle, recurring oil stain only visible under angled morning sunlight in our warehouse. It traced back to a single guide ring on the knitting machine that needed cleaning. Neither the factory's overhead lights nor our initial backlight check had caught it.

How Do You Use the 4-Point System to Grade Lace?

The 4-Point System quantifies defects. Here’s how it works for lace:

| Size of Defect (Max Dimension) | Penalty Points |

|---|---|

| Up to 3 inches (7.5 cm) | 1 Point |

| 3-6 inches (7.5-15 cm) | 2 Points |

| 6-9 inches (15-22 cm) | 3 Points |

| Over 9 inches (Over 22 cm) | 4 Points |

Rules for Lace:

- A continuous defect (like a run) is measured by its length.

- A major defect (e.g., a large hole, misaligned pattern) is usually automatically 4 points.

- No more than 4 points can be charged for any single linear yard/meter.

- Calculation:

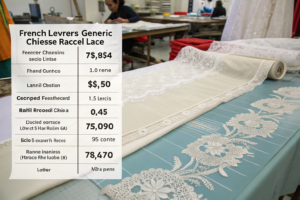

(Total Penalty Points in Roll / Total Yards in Roll) * 100 = Points per 100 Yards. - Typical Acceptance Level for Lace: For premium apparel, the threshold is often ≤ 20 points per 100 yards. For fast fashion, it might be ≤ 40. You must agree on this AQL with your supplier before production.

How Can You Set Up an Effective Inspection Protocol with Your Supplier?

Trust, but verify. Your supplier's QC is your first line of defense, but you need your own checks.

- Define the Standard in Your PO: Don't just write "good quality." Specify: "Fabric to be inspected per 4-Point System, AQL 2.5 for major defects, 4.0 for minor defects, with a maximum of 20 points per 100 yards. Inspection to be performed on a backlit table."

- Request Pre-Shipment Inspection Reports: Require your supplier to provide detailed QC reports with photos of any defects found and their locations on the roll. Shanghai Fumao provides digital reports that link defect photos to roll and meter numbers.

- Conduct a "Golden Sample" Comparison: Before bulk production, approve a perfect golden sample. During inspection of bulk goods, physically compare random sections to this sample for hand, color, pattern clarity, and weight.

- Plan for Third-Party Inspection: For large orders or new suppliers, hire a neutral third-party inspection company (like SGS, BV, or QIMA) to conduct an in-factory pre-shipment inspection. This is a cost-effective insurance policy.

What Are the Top 5 Must-Check Defects Before Approving Shipment?

Focus your final verification on these high-impact flaws:

- Pattern Repeat Misalignment at Seams: Take two pieces from the end of a roll. Align them side-by-side as if sewing a garment. Does the pattern flow perfectly? If not, reject the roll.

- Color Consistency Across Rolls: Lay out cuttings from the beginning, middle, and end of multiple production rolls under daylight-equivalent (D65) lighting. Any shade variation? This is critical for cutting multiple garments from different rolls.

- Stretch and Recovery Consistency (for elastic lace): Hand-stretch samples from different areas. Do they recover to the same length? Inconsistent recovery causes garment distortion.

- Width Stability: Measure the width every 10 meters. For a 150cm wide lace, more than ±1.5cm variation can cause cutting losses.

- Finishing Smells/Residue: Smell the fabric. Any foul chemical odor? Perform a white cloth rubbing test to check for colorfastness and finishing residue.

How Do Fabric Defects Directly Impact Your Cutting and Sewing Efficiency?

Defects aren't just a quality issue; they're a cost and timeline issue. Let's quantify it:

- Misaligned Patterns: Forces cutters to "pattern match" manually, increasing fabric waste by 5-15%. It can also slow down the cutting process by 20%.

- Width Variations: Causes misalignment in automated spreading machines, leading to shaded parts or short pieces that must be re-cut.

- Holes and Major Stains: The marker (cutting layout) must be planned to avoid them. In lace, where you can't simply "cut around" a small flaw without disrupting the pattern, a single hole can ruin an entire garment panel. We helped a Spanish brand optimize their marker after discovering a recurring defect type; by understanding its frequency, we adjusted the cutting layout, reducing their material waste from 8% to 4.5% on that order.

What Are the Corrective Actions and Responsibilities for Defective Lace?

Finding defects is only half the battle. You must have a clear protocol for what happens next.

- Immediate Communication: Send clear photos, video, and the exact roll/location data to your supplier. Use a non-conformance report (NCR) template.

- Determine Root Cause: Work with the supplier to understand why it happened. Was it a machine part? A bad yarn lot? A rushed finishing process? This prevents recurrence.

- Agree on Remedies: Options include:

- Replacement: The supplier replaces the defective meters/rolls.

- Sorting & Discount: You sort the fabric, the supplier gives a credit for the unusable portion.

- Repair: For some defects like small floats or loose threads, in-house repair is possible. (We maintain a small team for this at Shanghai Fumao for minor issues on premium laces.)

- Update Future Protocols: Incorporate the lesson into your next order's specifications. For example, if you found barre, your next PO should specify "Yarn from single lot only, with lot number certification."

How Can Digital Tools and AI Enhance Lace Inspection?

The future is automated, but human eyes are still essential. We are piloting two technologies:

- Automated Optical Inspection (AOI): Cameras scan the lace on the inspection frame in real-time, using algorithms to flag deviations from a "golden template" of the perfect pattern. It's excellent for finding repeat misalignments and consistent knitting errors.

- Blockchain-based Traceability: By scanning a QR code on the roll, you can access its full history: yarn source, production machine ID, dyeing batch, and the digital QC report. This level of supply chain transparency for textiles is becoming a demand from major EU and US brands.

While AI won't replace the need for a seasoned inspector's judgment on hand feel or complex shade matching, it eliminates human fatigue and ensures 100% surface coverage inspection. It's a powerful tool in the arsenal of a modern supplier committed to zero-defect delivery.

Conclusion

Inspecting lace fabric is a specialized discipline that demands a sharp eye, systematic methodology, and a deep understanding of how lace is made. The common defects—from dropped stitches and misaligned patterns to subtle shade variations—are not just minor annoyances; they are direct threats to your production efficiency, product integrity, and brand equity. By moving beyond a superficial check and implementing a rigorous, multi-stage inspection protocol that includes both your supplier's checks and your own verification, you transform quality control from a cost center into your most reliable brand protection strategy.

Remember, the goal is not to find someone to blame, but to build a system that prevents defects from reaching your cutting room in the first place. This requires partnership, clear communication, and investing in the right tools and time for thorough inspection.

Don't let hidden flaws unravel your next collection. Partner with a supplier whose inspection standards match your quality ambitions. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how our rigorous QC protocols, from backlit inspection to detailed reporting, can deliver flawless lace for your orders. Let's ensure every meter is perfect.