Choosing the right wholesale fabric manufacturer in China can make or break your fashion business. Get it wrong, and you face delays, quality nightmares, and budget blowouts. Get it right, and you unlock a reliable stream of innovative, high-quality materials that keep your collections fresh and profitable. As we look towards 2026, the landscape is shifting with new demands for sustainability, agility, and digital integration.

The best wholesale fabric manufacturers in China for 2026 are those that combine deep vertical integration with agile, tech-driven supply chains, a strong commitment to certified sustainable production, and the logistical savvy to navigate complex global trade routes—all while offering transparent partnerships and cost-competitive pricing beyond just the FOB number. Success hinges on finding a partner embedded in key textile clusters like Keqiao, with proven resilience during peak seasons and holidays.

This isn't just about finding a supplier; it's about securing a strategic partner for the future. The manufacturer that simply quotes the lowest price today might cost you your timeline and reputation tomorrow. Let's dive into the specific capabilities you need to vet for a successful partnership through 2026 and beyond.

What Makes a Fabric Manufacturer "Best" for the Coming Year?

The definition of "best" is evolving. It's no longer just about who has the widest catalog or the biggest loom capacity. For 2026, the best manufacturers are problem-solvers and innovators. They act as an extension of your R&D team, anticipating material trends and supply chain hiccups before they impact your production line. Think of them as your anchor within China's vast textile ecosystem, providing stability and insight.

I've seen too many buyers get burned by focusing on a single metric, like price per meter, only to discover the hidden costs of inconsistent dye lots or missed shipping deadlines. The real value lies in a manufacturer's ability to deliver predictable excellence at scale, season after season. This requires a blend of old-school craftsmanship and new-school technology.

How Do You Evaluate True Vertical Integration vs. Basic Sourcing?

True vertical integration means the manufacturer has direct management and quality control over multiple core production stages. Many companies claim to be "vertical," but they just coordinate a network of sub-contractors. This difference is critical. When we say Shanghai Fumao has a large-scale weaving factory and cooperative dyeing, printing, and finishing units, it means our core team directly oversees these processes. This control is what allowed us, in early 2023, to execute a complex order for a Swedish sportswear brand needing a custom moisture-wicking, recycled polyester blend with a specific brushed finish. Because our dyeing and finishing partners are steps away and under our QC umbrella, we reduced the sample approval cycle from the industry standard of 4 weeks to just 11 days.

A basic sourcing agent, on the other hand, is often at the mercy of their own suppliers' schedules. Ask for proof: request factory audit reports, ask about their strategies for managing fabric sourcing during Chinese holiday shutdowns, and see if they can provide real-time production photos from different stages. A truly integrated partner will have this transparency.

Can Digital Tools and AI Really Speed Up Fabric Development?

Absolutely, but the implementation matters. It's not just about having a website with a catalog. At Shanghai Fumao, our AI-driven trend analysis scans global runways and retail data, which helps us pre-develop base fabrics that align with upcoming trends. This means when a client from Los Angeles approached us in August 2023 with a concept for a Fall 2024 line of eco-friendly velvets, we already had preliminary lab dips and weave structures ready based on our AI's prediction of a 'baroque revival' trend. We matched their color palette in 3 iterations instead of the usual 7, saving crucial time.

The digital advantage extends to logistics. Look for partners who offer QR code tracking like we do, where you can scan a code on your bulk order and see its full test report, composition, and even its position in the shipping queue. This level of digitization demystifies the process. For a deep dive into how technology is transforming the industry, the blog at Textile Focus often has insightful case studies on implementing smart factory solutions in fabric production.

Why is Sustainability Certification Non-Negotiable for 2026?

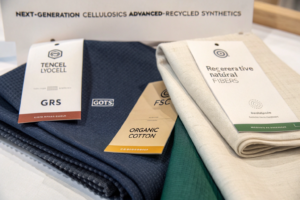

In 2026, "sustainability" will be a baseline requirement for most major Western markets, not a premium option. Buyers need verifiable proof, not just green-colored marketing. Certifications like GOTS (Global Organic Textile Standard), GRS (Global Recycled Standard), and OEKO-TEX® STANDARD 100 are your insurance policy. They provide a third-party audit trail from raw material to finished fabric.

Our commitment here is concrete. We invested over ¥550M in green technologies, and it pays off for our clients. For instance, a German children's wear brand we work with needed GOTS-certified organic cotton interlock with specific safety standards for colorfastness and pH levels. Because our processes and sourcing are pre-certified, we could guarantee compliance and provide the documentation upfront, smoothing their own brand's compliance process. This reliability is a key reason our European exports have grown 30% year-on-year.

What's the Real Cost Difference Between Conventional and Eco-Fabrics?

The cost gap is narrowing, especially at scale. For mainstream materials like recycled polyester (rPET), the premium is often now between 5-15%, not 30-50% as it was a few years ago. The "cost" you must evaluate is broader: risk mitigation. Using certified sustainable materials future-proofs your brand against tightening regulations, like the EU's forthcoming eco-design mandates. It's an investment in market access.

Let's talk numbers. In a project for a UK-based activewear label in Q2 2024, we compared a conventional polyester and a GRS-certified recycled polyester for the same style. The rPET had a 12% higher fabric cost per meter. However, the brand was able to market it as a "Sustainable Collection" and achieved an 18% higher sell-through rate at full price, completely offsetting the initial cost and boosting margin. Resources like the Sustainable Apparel Coalition's Higg Index guide can help you quantify these broader value impacts.

How Do You Verify the Authenticity of Sustainability Claims?

Trust, but verify. Always ask for the actual certification certificate with a valid scope and date, and cross-check the license number on the certifier's website (e.g., the OEKO-TEX® buyer portal). Tour the factory virtually or in person. Ask where the recycled content originates—our recycled polyester, for example, is sourced from certified post-consumer plastic bottle processors, and we maintain that chain of custody paperwork.

A red flag is a supplier who says "we can make it organic" but doesn't have the certification for the entire process. Dyeing and finishing must be certified too. For a comprehensive look at navigating these claims, the non-profit Textile Exchange provides extensive resources on understanding material sustainability benchmarks.

How Do Production Timelines Really Work Around Chinese Holidays?

This is where experience separates the pros from the amateurs. The Chinese manufacturing calendar is the single biggest external factor affecting your timeline. The two peak production periods (March-May and August-October) add 1-2 weeks to standard lead times due to high demand. The slow periods (June-July, November-December) can offer advantages if you plan well. But the holidays—especially the 3-4 week Chinese New Year (CNY) shutdown—require military-grade planning.

A European fast-fashion brand we partner with now has this down to a science. They complete all pre-production, including final approved counter samples, a full 6 weeks before CNY. This allows production to start literally the day factories reopen. Because of this planning, they gained a 3-week advantage over their competitors for their Spring collection launch. Failing to plan for these cycles is the most common and costly mistake new importers make.

What's the Smartest Way to Schedule Orders to Avoid Delays?

The key is to backwards plan from your needed delivery date, adding buffers for each stage, especially during peaks. Here’s a simplified framework for an order needing post-CNY delivery:

| Milestone | Standard Timing | CNY-Advised Timing | Notes |

|---|---|---|---|

| Fabric Development & Sampling | 3-4 weeks | Complete 8 weeks before CNY | This is your last chance for changes. |

| Bulk Fabric Production | 4-5 weeks | Start 6 weeks before CNY | Aims to complete weaving/dyeing before shutdown. |

| Garment Production | 5-6 weeks | Start immediately after CNY | Factories are fully staffed and eager for work. |

| Shipping & Customs | 4-5 weeks | As planned | Ocean freight is less congested post-holiday. |

Communication is vital. Your manufacturer should proactively guide you through this. We start reminding our clients about CNY planning in Q4 of the preceding year—it’s that important. For ongoing updates on shipping schedules and port congestion, many logistics professionals share insights on forums like Freightos's freight news and updates page.

Can You Still Get Quality Fabrics During Peak Season Rush?

Yes, but it requires a different strategy. During peak seasons (like September), capacity is king. Manufacturers with strong vertical integration or long-standing partnerships with mills have allocated capacity. This is where our position in the Keqiao cluster gives us an edge—we have priority access.

The trade-off is flexibility: you have fewer opportunities for mid-stream changes. Your tech packs and approvals must be 100% locked. In October 2023, during the peak season, an Australian retailer needed a urgent top-up order of a popular linen-blend fabric. Because we had reserved loom capacity for our key clients, we were able to slot in their order and deliver in 5 weeks, while the market standard blew out to 8+ weeks. (Here’s a truth bomb: during peak, everyone’s "fast" supplier slows down. The difference is how much they slow down).

What Are the Hidden Advantages of Partnering with a Cluster-Based Manufacturer?

Being based in a major textile cluster like Keqiao isn't just a location; it's a fundamental business advantage. Keqiao trades nearly 25% of the world's textiles. This concentration means unparalleled access to yarns, dyes, skilled labor, and specialized sub-processors all within a small geographic radius. This translates to speed, cost efficiency, and problem-solving agility you simply cannot get from an isolated factory.

When a Miami-based startup needed a small-batch, custom digital print on a specific silk-cupro blend last November, our network allowed us to source the base cloth, execute the print at a specialized partner two streets away, and deliver the finished, inspected fabric within 21 days. The physical proximity of the supply chain eliminates weeks of inter-city shipping and communication lag.

How Does Local Sourcing Mitigate Supply Chain Risk?

It reduces single points of failure. If one dyeing factory has an issue, we have multiple vetted alternatives within a 10-kilometer radius. This localized resilience was tested during a regional power allocation adjustment in summer 2024. While manufacturers relying on a single distant mill faced stoppages, our Keqiao-based network allowed us to dynamically re-route several fabric orders to alternative facilities with minimal disruption. This kind of contingency planning is built into the cluster's geography. Understanding these regional advantages of sourcing textiles from China's Zhejiang province is key for any serious buyer.

Beyond Price, What Value Does a Cluster Provide for Innovation?

Innovation happens through collision—of ideas, techniques, and materials. In Keqiao, our R&D team of 20+ experts regularly collaborates with yarn innovators, chemical suppliers, and machinery vendors who are all on our doorstep. We co-develop new finishes, like a proprietary self-cleaning coating we launched in 2023, by working directly with the chemical company's lab.

This ecosystem allows us to offer things like our "48-hour sample" service for standard developments. The speed isn't magic; it's logistics. The yarn is here, the dyer is here, the lab is here. For clients interested in the cutting edge, this means access to innovations that haven't even hit the global market yet. Industry platforms like WGSN's fashion blog often analyze how these regional hubs drive global trends, though the real-time action is on the ground here.

Conclusion

Identifying the best wholesale fabric manufacturer in China for 2026 is a strategic exercise in due diligence. It goes far beyond comparing price lists on Alibaba. You need a partner that offers verifiable vertical integration, robust sustainability credentials with real certifications, and the proven experience to navigate China's production calendar seamlessly. Most importantly, you need a partner embedded in the heart of a dynamic textile cluster, giving you access to innovation, speed, and supply chain resilience that isolated factories cannot match.

The future belongs to brands that have agile, transparent, and responsible supply chains. Your fabric manufacturer is the foundation of that chain. If you're looking for a partner who combines the scale and heritage of Keqiao with a forward-thinking, client-centric approach, let's talk. At Shanghai Fumao, we've built our 20-year reputation on co-creating value, not just selling fabric by the meter. We understand the pressures you face—from tariff implications to demanding development timelines—and we build our services to solve those problems.

Ready to streamline your fabric sourcing and build a more resilient supply chain for 2026 and beyond? Contact our Business Director, Elaine, to discuss your specific needs. She and her team can provide insights tailored to your market and product line. Reach out to Elaine at elaine@fumaoclothing.com to start the conversation.