Thermal bonded non-woven fabrics have become a staple in industries ranging from apparel to automotive. But not all thermal bonded non-wovens are made the same. If you're sourcing for technical applications, knowing the right types, structures, and properties can be the difference between consistent performance and costly defects.

Thermal bonded non-woven fabrics offer excellent dimensional stability, high tensile strength, and breathability, making them ideal for filtration, packaging, insulation, and interlining in fashion. With no chemical binders required, they’re also increasingly used in eco-conscious manufacturing.

Whether you're a fabric buyer, technical garment maker, or industrial product developer, this article helps you choose the best options for your use case. We'll explain structure types, fiber composition, sourcing standards, and compare performance against alternative bonding methods.

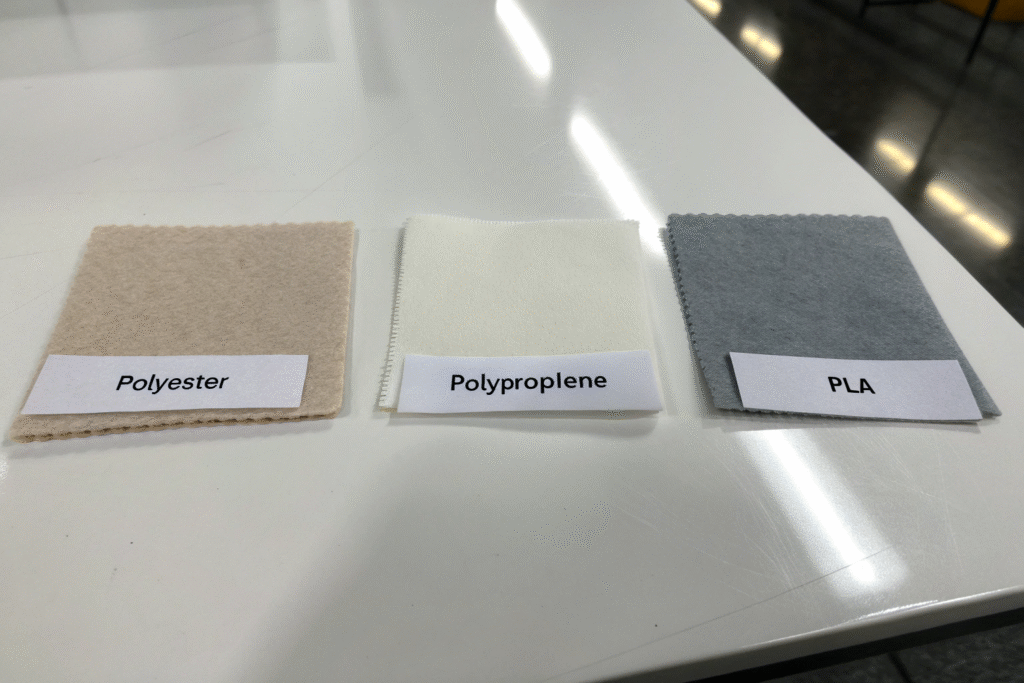

What Are Thermal Bonded Non-Woven Fabrics Made Of?

Thermal bonded non-wovens are engineered from synthetic or bio-based fibers fused under heat and pressure without chemical adhesives. The composition plays a key role in defining strength, hand feel, and functional traits.

The most common fibers for thermal bonding include polypropylene (PP), polyester (PET), and polylactic acid (PLA). Each offers distinct benefits in softness, biodegradability, or resistance to moisture.

Why Is Polypropylene a Popular Choice?

Polypropylene is a low-cost, lightweight polymer with high chemical resistance and moisture-repelling properties. It’s widely used in medical disposables and industrial filtration. Its low melting point (~165°C) makes it suitable for efficient thermal bonding.

How Does PLA Offer a Sustainable Alternative?

PLA (polylactic acid) is derived from corn or sugarcane and is fully compostable. Though it has lower durability compared to PP or PET, its biodegradability makes it attractive for green packaging and low-impact disposables.

Which Applications Benefit Most from Thermal Bonding?

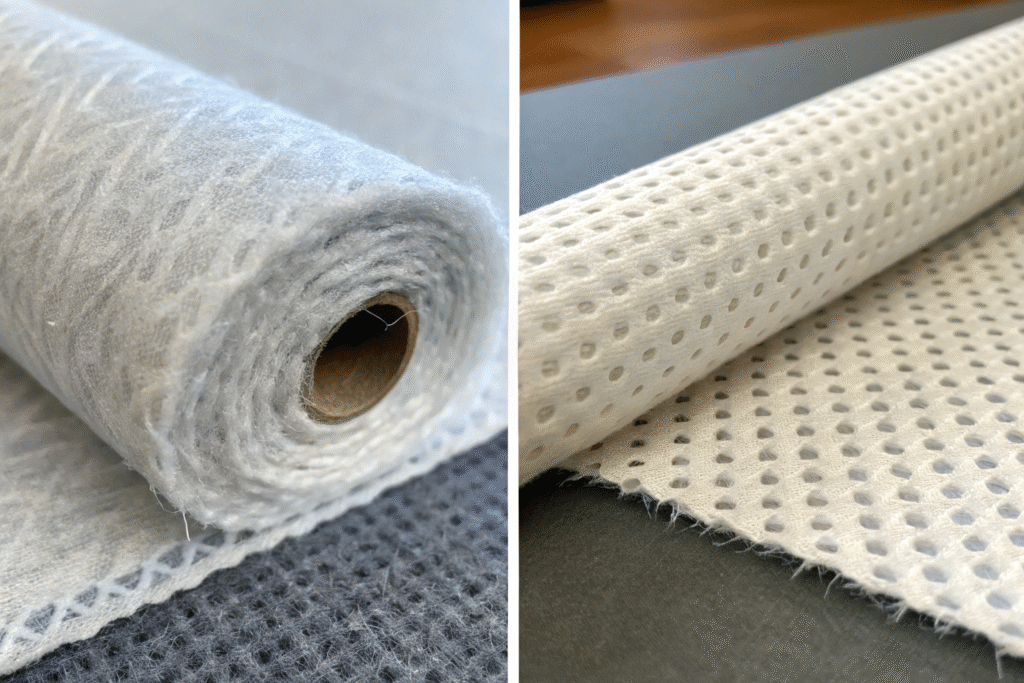

Thermal bonding creates stable, durable nonwoven fabrics ideal for applications requiring precise dimensions, high air permeability, and resistance to fraying. Its no-chemical binding method is ideal for sensitive environments.

Key applications include garment interlining, surgical masks, air filters, automotive linings, and sustainable product packaging.

What Are the Benefits in Technical Outerwear?

In outdoor gear and jackets, thermal bonded non-wovens act as lightweight insulation or structured backing. Their breathability and compression recovery help maintain warmth without bulk.

Why Are They Used in Filtration and Hygiene?

N95 respirators and industrial filters rely on thermally bonded layers for structure. Their fine pore structure ensures particle retention, and the bonding method avoids residual binder chemicals.

How Do They Compare with Needle-Punched Nonwovens?

While both are popular bonding techniques, thermal bonded nonwovens differ significantly from needle-punched ones in texture, durability, and production method.

Thermal bonding provides a cleaner finish and better dimensional stability, while needle punching offers more flexibility and volume but with a rougher surface.

Which One Offers Better Surface Smoothness?

Thermally bonded fabrics typically have a smoother and more uniform surface, making them ideal for lamination, printing, and cleanroom use. In contrast, needle-punched fabrics tend to pill or shed fibers.

Is Thermal Bonding More Efficient for Mass Production?

Yes. Thermal bonding lines offer higher throughput with consistent quality because the process is faster and continuous. However, the equipment cost is higher, and it works best with thermoplastic fibers.

What Should Buyers Look for When Sourcing These Fabrics?

Sourcing thermally bonded non-wovens requires attention to supplier capabilities, fiber origin, bonding methods, and compliance standards.

Prioritize suppliers with in-house thermal bonding lines, cleanroom certification, and experience in your specific industry. Always request data on GSM, tear strength, and thermal aging.

Which Certifications Are Most Relevant?

Depending on your industry, look for suppliers offering ISO 13485 (for medical), OEKO-TEX® (for safety), and REACH compliance (for chemical handling). These ensure safety in wearables and filtration.

What Minimum Order Quantities Should I Expect?

MOQ varies by fiber and GSM. Standard technical non-wovens often require 3,000–5,000 meters per style, but recycled or colored options might have higher thresholds. Check if your supplier can accommodate small-batch prototyping for R&D.

Conclusion

Thermal bonded non-woven fabrics provide a clean, reliable, and cost-effective solution for many technical and industrial uses. Whether you're manufacturing interlining for performance jackets or sourcing air-filter media, choosing the right fiber and bonding technique is key.

If you're ready to source premium thermal bonded non-woven materials with certified quality control and international logistics support, partner with Shanghai Fumao. We offer custom development, technical testing, and seamless delivery to your door. For project consultations or sample requests, please contact our Business Director Elaine at elaine@fumaoclothing.com.