If your final garment tears at the seam under minimal stress—or worse, separates after the first wear—it’s likely not due to sewing error. It's a classic case of seam slippage, a silent enemy in apparel, upholstery, and even industrial textiles. For quality-focused buyers, designers, and sourcing managers, selecting seam-slippage resistant fabrics isn’t just smart—it’s essential to brand integrity.

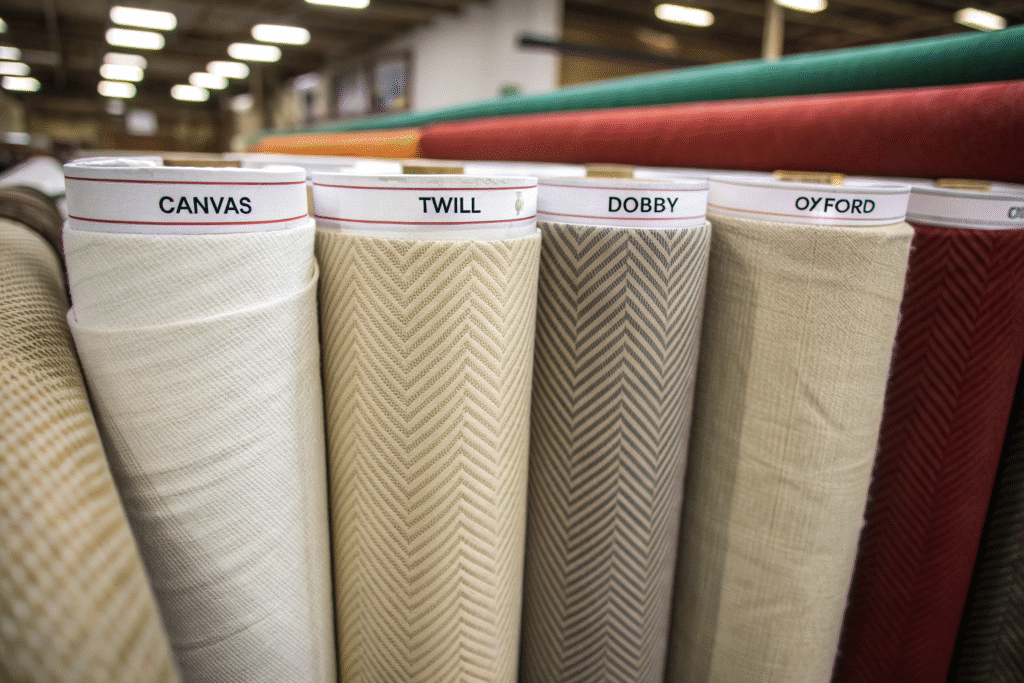

The best seam-slippage resistant fabrics include tightly woven cotton canvas, high-twist polyester twill, textured dobby weaves, and blends with a small percentage of elastane or nylon for structural resilience.

At Fumao Fabric, we test all our fabric batches for seam strength and slippage resistance before bulk delivery. In this article, I’ll walk you through which fabric types offer superior seam retention, what factors affect slippage, and how to test and source the right textiles for your application.

What Is Seam Slippage and Why Does It Happen?

Seam slippage occurs when yarns in a fabric pull away from each other at the stitched area, even when the stitching itself remains intact. It often happens in lightweight, smooth, or loosely woven fabrics, especially when the weft yarns aren’t well anchored.

This weakness is triggered by stress across the seam, garment movement, or tension in upholstery applications—leading to visible gaps, garment failure, or safety issues.

What Causes Seam Slippage?

- Low fabric density (low ends per inch)

- Slick yarns (e.g., acetate, viscose)

- Overly tight seam tension

- Inappropriate stitch type or thread thickness

- Yarn slippage due to lack of friction or twist

This makes seam slippage common in delicate satins, chiffon, rayon, and some polyester blends—especially when stitched with inappropriate techniques or used in high-movement zones like underarms or seats.

How Is Seam Slippage Measured?

Standards like ASTM D1683 or ISO 13936-2 measure the force required to open a seam by 6mm. The result is recorded in Newtons (N)—a higher number indicates better resistance.

Our testing lab in Keqiao is CNAS-accredited and routinely runs seam-slippage tests as part of our QA workflow.

Which Woven Fabrics Offer the Best Seam Strength?

Woven fabrics can be engineered for high seam resistance through weave tightness, yarn twist, and surface texture. Among the best performers are:

- Cotton duck canvas – 12oz or heavier

- Tightly woven poly-cotton twill

- High-twist dobby weaves

- Warp-faced Oxford cloth

These structures distribute stress effectively and lock yarns in place to prevent slippage at the seam.

Why Does Twill Weave Perform Well?

Twill weaves (like denim or gabardine) offer diagonal structure that allows yarns to interlace more frequently, improving friction and reducing pull-apart risk. That’s why they’re used in workwear, trousers, and military uniforms.

We’ve supplied poly-viscose twills with 4% elastane that exceed 100N in slippage tests, ideal for structured pants and school uniforms.

What About Oxford or Panama Weave?

Oxford weaves use basket-style interlacing that offers balanced structure. When woven with textured polyester or mercerized cotton, they perform well in shirts, uniforms, and home textiles.

Top brands like Dickies and Land’s End use high-density oxford cloth in garments that require long seam life.

Are Knitted or Stretch Fabrics Also Seam-Slippage Resistant?

While knits stretch more than wovens, their looped structure allows stress to be distributed more evenly—making them less prone to traditional seam slippage. However, weak edges, poor needle selection, or ultra-lightweight structures can still cause failure.

The best-performing stretch fabrics include double-knit ponte, high-GSM interlock, and elastane-infused performance jerseys.

Why Is Ponte Knit Popular in Stretch Garments?

Ponte di Roma is a double-knit structure with stable edges and smooth recovery. Its density resists both seam slippage and bagging, making it popular in women’s fashion, yoga wear, and uniforms.

We supply rayon-nylon-spandex blends (300–360 GSM) for leggings and blazers with 4-way stretch and certified seam strength above 85N.

Can Spandex or Lycra Help Reduce Slippage?

Yes—5–10% elastane blended into cotton or polyester adds recovery and friction, reducing the chance of yarn pull-out at seams. It also allows designers to use lighter base fabrics without compromising seam safety.

Leading brands like Athleta and Gymshark utilize this in performance apparel to ensure durability across repeated use.

How Can You Test Seam Resistance Before Bulk Order?

Testing is critical before you greenlight bulk yardage. Seam resistance can vary even within the same fabric type depending on finishing, yarn quality, and batch tension.

You should always request lab-tested samples stitched at standard density and checked against ASTM or ISO methods for seam integrity.

What Should Be Included in a Seam Test Report?

- Seam slippage value in Newtons (e.g., “90N @ 6mm”)

- Test standard used (ASTM D1683, ISO 13936)

- Fabric GSM and weave description

- Stitch type and density (e.g., 301 Lockstitch, 10 SPI)

At Fumao Fabric, we integrate this into every bulk inspection log with QR-traceable labels linked to the test certificate.

How to Simulate Slippage in Real-Use Conditions?

- Stitch sample garments or panels using your actual thread and seam style

- Stretch across stress points (like crotch, back seams, or sleeve caps)

- Evaluate for seam opening or yarn movement post-wash

Many buyers also run field tests or industrial wash tests to assess long-term slippage risk.

Conclusion

Seam slippage might go unnoticed during inspection, but it shows up loud and clear once your product hits the real world. Whether you're developing uniforms, formalwear, or activewear, investing in seam-slippage resistant fabrics means fewer returns, stronger reviews, and longer-lasting garments.

At Fumao Fabric, we combine advanced weaving, certified yarn blends, and CNAS-lab testing to deliver fabrics that hold their seams—batch after batch. Ready to source durable, slippage-proof textiles? Reach out to our Business Director Elaine at elaine@fumaoclothing.com and let’s strengthen your supply chain from the inside out.