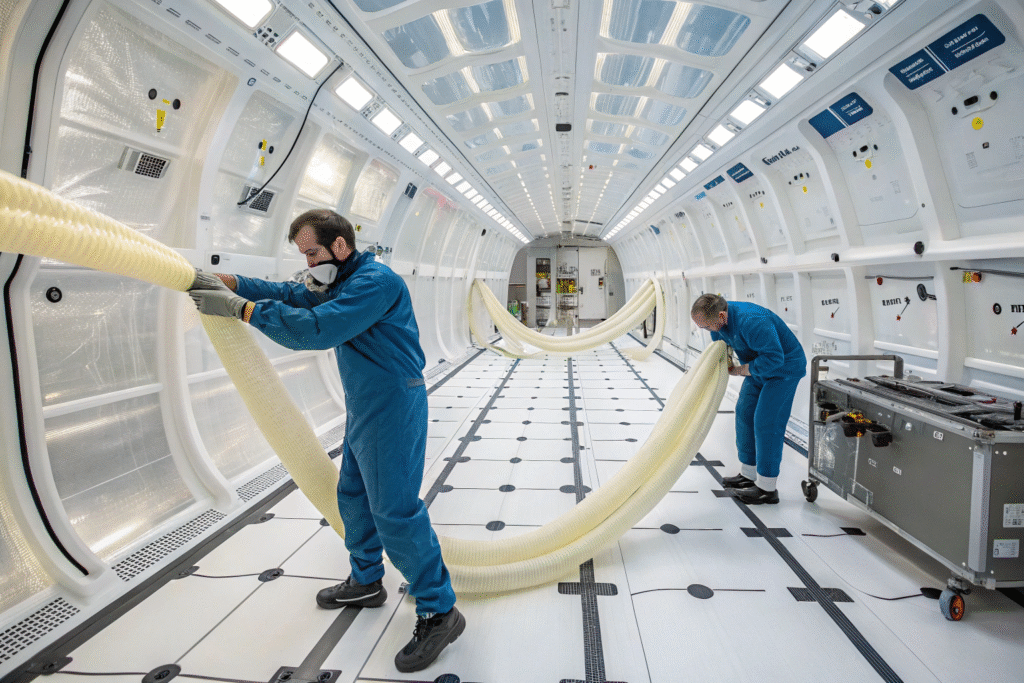

In space, every detail matters. Engineers and buyers working with aerospace-grade materials know that even the smallest weakness in fabric design can jeopardize the success of zero-gravity missions. The demand for high-performance textiles in Zero-G fluid transfer systems is rising as more companies explore orbital manufacturing, life-support systems, and fuel management in spacecraft. The question is: which fabrics truly stand out under these extreme conditions?

The best fabrics for Zero-G fluid transfer systems are those that combine high tensile strength, chemical resistance, heat stability, and ultra-low outgassing properties. Materials such as aramid blends, PTFE-coated fabrics, and specialized polyester weaves meet NASA’s rigorous standards and are increasingly applied in fluid handling tubes, bladders, and safety membranes in space missions.

Selecting the right material is not only about performance in orbit but also about meeting strict safety, cost, and durability standards. To help procurement managers, designers, and researchers make informed decisions, I will break down the best fabrics and their applications in space-grade systems.

Which Fabrics Provide the Highest Strength in Zero-G?

In space, strength is not optional—it is mandatory. Fabric failure in Zero-G fluid transfer can mean catastrophic leaks in oxygen, fuel, or water systems. The highest-performing textiles must combine strength with lightness.

The best high-strength fabrics include aramid fibers like Kevlar and Nomex, which provide superior tensile strength and resistance to tearing. When woven tightly, these fabrics can endure extreme internal fluid pressures and mechanical stress in orbital conditions.

Why Are Aramid Fabrics Preferred in Aerospace?

Aramid fabrics are widely recognized for their ability to withstand high pressures without rupture. In fact, materials like Kevlar are already used in aerospace for protective covers, tubing reinforcement, and ballistic layers. Their heat resistance also makes them suitable for both cryogenic and high-temperature applications.

How Do Woven Constructions Improve Safety?

Woven aramid and hybrid fabrics allow precise control over permeability. Designers often use plain weaves or twill structures to balance flexibility and sealing performance. This structural stability prevents seam migration and provides reliable containment of fluids in Zero-G.

Are PTFE-Coated Fabrics the Key to Leak Prevention?

Preventing leaks in Zero-G is as important as selecting the correct fluid. Any uncontrolled droplet can float freely, endangering equipment and crew. This is where PTFE-coated fabrics play a vital role.

PTFE (Polytetrafluoroethylene)-coated fabrics deliver unmatched chemical resistance and ultra-low permeability, making them ideal for Zero-G fluid membranes. Their slick, non-stick surfaces reduce fluid adhesion and allow smooth transfer without clogging.

What Makes PTFE-Coated Fabrics Reliable in Space?

PTFE is famous for its non-reactivity. In space applications, this means protection against aggressive fluids like hydrazine, liquid oxygen, or high-purity water. According to NASA’s material standards, PTFE composites also show excellent long-term stability in vacuum conditions.

Can PTFE Fabrics Handle Thermal Cycling?

PTFE-coated textiles maintain performance across a wide thermal range, from cryogenic temperatures to over 200°C. This property ensures membranes can handle thermal cycling that spacecraft endure in orbit.

How Do Polyester and Hybrid Fabrics Support Flexibility?

While strength and chemical resistance matter, flexibility is also critical. Rigid systems can crack or fail during spacecraft assembly, launch vibration, or in orbit bending.

Polyester-based technical fabrics and hybrid constructions provide flexibility while retaining good dimensional stability. When combined with polyurethane coatings, they achieve balanced performance for both durability and handling.

Why Do Engineers Still Use Polyester Fabrics?

Polyester is lightweight, cost-effective, and stable under moderate temperatures. Technical grades with low outgassing certifications are used in water recycling units and lightweight transfer bladders. They reduce costs while maintaining safety.

What Advantages Do Hybrid Fabrics Bring?

Hybrid laminates—such as aramid-polyester blends—add resilience without sacrificing flexibility. They also improve tear resistance, making them suitable for expandable fluid containers used in life-support systems.

Which Fabrics Meet NASA and ESA Safety Standards?

No matter how strong or flexible a fabric is, it must meet international standards before flying. Agencies like NASA and ESA demand rigorous safety validation.

Certified fabrics must demonstrate flame retardancy, low outgassing, and biocompatibility. CNAS-accredited and ISO-certified labs test these fabrics for aerospace applications. Without these certifications, no material can be accepted for mission-critical systems.

Why Is Outgassing a Major Concern?

Outgassing is the release of trapped chemicals in vacuum. Materials that fail this test can contaminate sensitive equipment. Agencies maintain NASA outgassing databases where only approved fabrics are listed for spacecraft use.

What Standards Define Aerospace Fabric Safety?

International standards like ISO 14644 for cleanrooms and ASTM E595 for outgassing guide material approval. Meeting these ensures fabrics do not compromise safety in orbital systems.

Conclusion

Zero-G fluid transfer requires fabrics that go beyond traditional textile performance. Aramid weaves deliver the highest strength, PTFE coatings ensure chemical protection, polyester hybrids provide needed flexibility, and certified materials meet strict aerospace regulations. By combining these properties, engineers can design systems that remain safe and reliable in orbit.

At Fumao Fabric, we bring two decades of textile manufacturing expertise from Keqiao, China’s textile hub, to advanced industries worldwide. If you are exploring specialized fabrics for aerospace or high-tech projects, we can support from weaving to coating, testing, and logistics. To discuss your next fabric order, contact our Business Director Elaine at elaine@fumaoclothing.com.