You're launching a vegan fashion line committed to ethics and sustainability, but the options are overwhelming. Cork leather? Pineapple leaf fiber? Recycled plastic? They all claim to be "the future," but which ones actually perform, scale, and meet the aesthetic demands of discerning customers? And how do you avoid the trap of simply replacing animal leather with plastic-based "vegan leather" that's just greenwashed PU?

The search for the best vegan fabrics isn't just about removing animal products; it's a three-dimensional puzzle balancing material performance, environmental impact, and commercial viability. The ideal alternative must look and feel luxurious, wear durably, have a verifiably lower ecological footprint than both animal and conventional synthetic leather, and be available at a scalable quantity and cost. This is where material science meets conscious commerce.

From our development work at Shanghai Fumao with pioneering vegan brands, we've learned that success lies in a strategic mix of established high-tech materials and emerging bio-based innovations. The key is to match the fabric's properties to the product's purpose—what works for a structured handbag will fail for a flowing dress. Let's cut through the hype and map the landscape of viable vegan fabrics.

What are the high-performance synthetic leather alternatives?

For applications demanding the look, feel, and durability of traditional leather—bags, shoes, jackets, upholstery—advanced synthetics are currently the most reliable workhorses. However, the spectrum here is vast, from cheap, polluting PVC to next-generation polymers with recycled content and improved chemistry. The goal is to move up that spectrum.

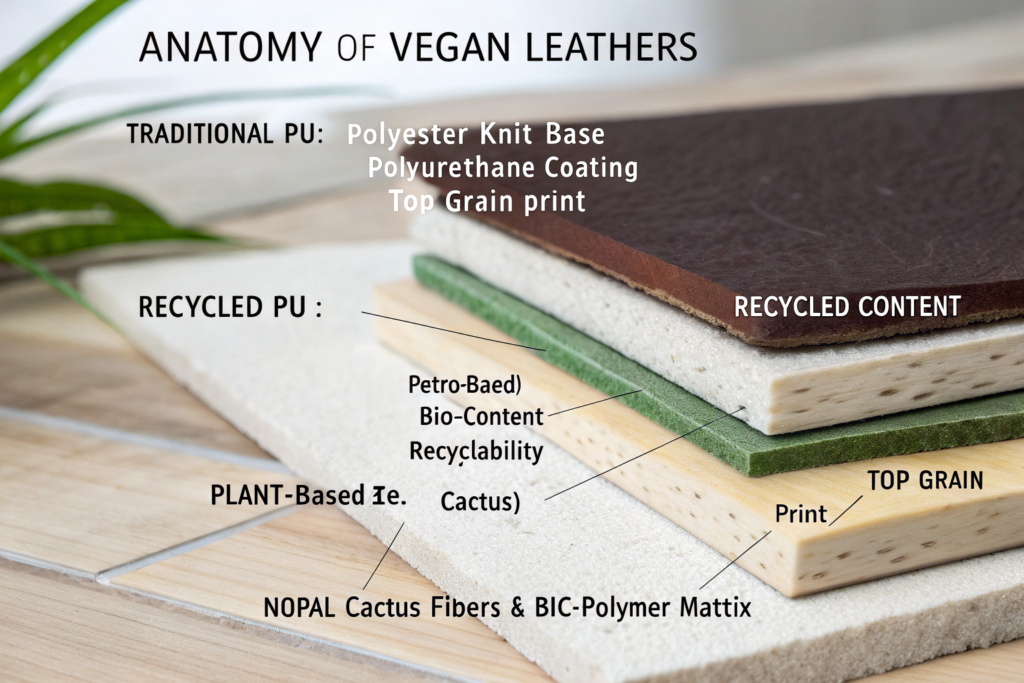

The critical divide is between polyurethane (PU) and polyvinyl chloride (PVC), with a new generation of bio-based polymers entering the fray.

How do PU, recycled PU, and bio-based polymers compare?

- Traditional PU Leather: A fabric base (usually polyester) coated with a polyurethane layer. It's more flexible, breathable, and environmentally friendly than PVC, as it doesn't require toxic plasticizers like phthalates.

- Pros: Softer hand, more realistic drape, can be made with partial bio-content (e.g., from corn), and is easier to recycle.

- Cons: Still petroleum-based at its core, and durability can vary. Lower-quality PU can crack or peel.

- Recycled PU (rPU): A significant step forward. Uses recycled polyester for the base fabric and incorporates recycled content into the PU coating where possible.

- Pros: Closes the loop on plastic waste, offers a strong sustainability story, and performance is identical to virgin PU. Can be GRS (Global Recycled Standard) certified.

- The Sourcing Key: Demand a Supplier's Declaration (Sd) or Transaction Certificate proving the recycled content. At Fumao, our rPU comes with full GRS traceability.

- Bio-Based Polymers (e.g., Pinatex®, Desserto®): These are not just coatings; they are materials grown or fermented.

- Pinatex (Piñatex®): Made from cellulose fibers extracted from pineapple leaves (a waste product). It has a unique, textured, natural aesthetic.

- Desserto®: Made from nopal cactus. Remarkably soft, with excellent durability and a more leather-like grain. It's partially biodegradable.

- Pros: Plant-based, innovative, unique storytelling.

- Cons: Higher cost, limited supply/scale, specific performance characteristics (may not be as water-resistant without a coating).

For a high-end vegan bag line, a top-tier rPU or a bio-based polymer like cactus leather offers the perfect blend of ethics, performance, and story. A fast-fashion accessory might use a standard PU, but the trend is decisively toward recycled and bio-content.

What about microsuede and ultra-fabrics?

For a soft, suede-like handfeel without the environmental burden of traditional microsuede (which can shed microplastics), the focus is on construction and fiber origin.

- Recycled Polyester Microsuede: A finely knitted or woven fabric made from recycled PET yarns, then brushed or sanded to create a velvety nap. It's durable, colorfast, and has a lower impact than virgin polyester.

- Ultra-Fabrics® (Lorica® etc.): A branded category of high-tech, breathable, synthetic microfiber materials. They are often 100% PU-based (no PVC), extremely durable, uniform, and easy to clean. Used in high-performance footwear, athletic gear, and luxury vegan accessories.

- Performance: These fabrics excel in applications where a consistent, durable, and cleanable soft surface is needed, like shoe linings, apparel accents, and upholstery.

What are the leading plant-based and innovative materials?

Beyond synthetics, a new frontier of materials is emerging from labs, farms, and waste streams. These materials are often biodegradable, have stunningly low carbon and water footprints, and offer utterly unique aesthetics. They represent the aspirational future of vegan fashion, though they often come with challenges in scale, cost, and sometimes performance.

This category is for brands wanting to lead with radical innovation and storytelling.

What are pineapple, mushroom, and apple "leathers"?

These are bio-fabricated materials, often using agricultural waste as a feedstock.

- Piñatex® (Pineapple Leaf Fiber): As mentioned, it's a non-woven mesh of pineapple leaf fibers (PALF) combined with a PLA (corn-based plastic) coating. It has a distinct, textured, almost canvas-like appearance. Best for structured items where the natural texture is a feature.

- Mushroom Leather (Mylo™, Muskin): Mycelium (mushroom root structure) is grown on a substrate into a sheet, then tanned and finished.

- Pros: Truly grown, not made, can be engineered to specific thicknesses and textures, and is compostable at end-of-life under industrial conditions.

- Cons: Still in early commercialization, very expensive, and supply is limited to a few licensed partners.

- Apple Leather / Other Fruit Waste: Made from pomace (the pulpy waste from juicing apples, grapes, etc.). The fibers are combined with polyurethane to create a durable material. Brands like AppleSkin™ market this. It's a clever upcycling story but is still a composite material (part bio, part PU).

These materials are perfect for limited-edition capsules, statement accessories, or as accent materials where their story and unique look can command a premium price.

How viable are cork, hemp, and organic cotton as alternatives?

Sometimes, the best alternative isn't a leather mimic, but a celebration of a natural fabric's own inherent properties.

- Cork "Leather": Actually thin sheets of cork oak bark, backed with a fabric (often cotton or PU) for stability. It is naturally waterproof, lightweight, anti-microbial, and has a unique visual and tactile warmth. Excellent for wallets, bags, and shoe accents. It's a 100% plant-based, renewable resource (the tree is not cut down).

- Hemp: One of the most sustainable crops on earth. Hemp canvas is incredibly strong, durable, and becomes softer with wear. It's ideal for bags, shoes, and structured jackets where a rugged, natural aesthetic is desired. It can be waxed for water resistance.

- Organic Cotton Canvas: A certified, low-impact version of the classic workhorse. For a truly soft, breathable, and biodegradable option, it's unbeatable for casual bags, sneaker uppers, and apparel.

A client creating a zero-waste travel line uses organic hemp canvas for their duffel bodies and cork for the trims and bases—a combination that is fully plant-based, durable, and tells a compelling earth-to-earth story.

How to assess the true sustainability of vegan fabrics?

"Vegan" does not automatically mean "sustainable." A PVC-based leather is technically vegan but an environmental disaster. The conscious brand must dig deeper, evaluating the full lifecycle impact—from raw material sourcing and production chemistry to end-of-life disposal. This is where certifications and hard data become your compass.

Your sourcing must include a forensic sustainability audit. It's the only way to avoid greenwashing and make truly responsible choices.

Which certifications and lifecycle metrics matter?

Look for verifications that cover different parts of the journey:

- Material Origin & Content:

- Global Recycled Standard (GRS): For any recycled content (rPET, rPU). This is non-negotiable for synthetics.

- Organic Content Standard (OCS) / GOTS: For plant-based fibers like organic cotton or hemp.

- Production Impact:

- OEKO-TEX® Standard 100: Ensures the final fabric is free from harmful chemicals—critical for any coated or dyed material.

- Bluesign®: A more holistic system that approves chemicals, processes, and materials for environmental and worker safety.

- End-of-Life:

- Biodegradability Certifications (e.g., OK compost INDUSTRIAL): For materials claiming to break down. Understand the conditions (home vs. industrial compost).

- The Data Ask: Request a Life Cycle Assessment (LCA) or carbon/water footprint data from the material producer. While not always available, it shows who is serious about measurement.

For our rPU, we provide a dossier with GRS TC, OEKO-TEX certificate, and water-based PU coating information to give clients a clear, defensible sustainability profile.

What are the pitfalls of "greenwashed" vegan materials?

Be hyper-aware of these common issues:

- The PVC Problem: Avoid it entirely. It's cheap and common in low-end "vegan leather," but its production and disposal release dioxins and phthalates.

- The "Biodegradable" Mirage: Many "biodegradable" vegan leathers are only biodegradable under specific industrial composting conditions (heat, moisture, microbes) that don't exist in landfills or oceans. They are not "throw-away" solutions.

- The Plastic Core: Most leather alternatives, even plant-based ones, still use a petroleum-based polymer (PU or PLA) coating or binder for durability and water resistance. The percentage of bio-content varies widely. Ask for the exact ratio.

- Durability vs. Disposability: The most sustainable product is one that lasts for years. A fragile, trendy vegan material that falls apart in a season is less sustainable than a durable, well-maintained animal leather item. Prioritize quality and longevity.

A resource like the Material Sustainability Index from the Higg Co. can be a valuable tool for comparative assessment, though it requires data input.

How to source and design with vegan fabrics successfully?

Integrating these materials into your collection requires adjusted expectations, specialized manufacturing partners, and clear communication with your customers. They are not drop-in replacements for cotton or cowhide; they have their own personalities and requirements.

Your success depends on treating them as new, distinct material categories and designing for their strengths, not against their limitations.

What are the key sourcing and cost considerations?

- MOQs and Lead Times: Innovative vegan materials often have higher MOQs and longer lead times than conventional fabrics. Piñatex or mushroom leather may be sourced through a licensor with set ordering windows. Plan your development timeline accordingly, sometimes 6-9 months in advance.

- Cost Realities: Premium vegan materials (rPU, cactus, mushroom) are more expensive than mid-quality animal leather, let alone cheap PU. This must be factored into your cost model and product pricing. The value is in the story and ethics, not cost-saving.

- Supplier Specialization: Source from suppliers who specialize in or have dedicated lines for sustainable/vegan materials. Their expertise is invaluable. At Fumao, we have a curated "Conscious Materials" library with pre-vetted options, simplifying this search for our clients.

How does design and manufacturing need to adapt?

- Design for the Material: Cork is great for flat panels but not for complex gathered shapes. Piñatex has a natural texture—design to highlight it, don't try to make it look like smooth calfskin.

- Pattern Making & Sewing: Some materials (like thick cork or stiff apple leather) may require specialized cutting tools, needle types, and seam allowances. Work with factories experienced in technical materials, not just soft goods.

- Care & Brand Communication: Vegan materials have specific care needs (e.g., avoid certain cleaners, don't machine wash). Clear care labels and consumer education are crucial to ensure product longevity. Use hangtags to tell the material's origin story—this is a major part of the product's value.

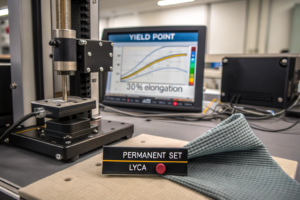

- Sample Extensively: Never skip this. Make full prototypes and test them for abrasion, color transfer, and water resistance. A vegan shoe upper must be lasted and worn; a bag must carry weight.

We worked with a bag brand transitioning to vegan materials. We facilitated a "materials workshop" where they sampled 5 different alternatives (rPU, cactus, apple, cork, recycled polyester) on small bag components. This hands-on testing was the only way they could make an informed choice on look, feel, and manufacturability.

Conclusion

Identifying the best fabrics for vegan fashion is a multifaceted quest that moves beyond simple substitution. It requires navigating a landscape where high-performance recycled synthetics like rPU offer scalable, durable solutions, while groundbreaking plant-based materials like mushroom and pineapple leather provide innovative, low-impact storytelling. Crucially, "vegan" must be scrutinized through a robust sustainability lens, demanding certifications like GRS and OEKO-TEX to avoid the pitfalls of greenwashed plastics like PVC. Finally, success hinges on adapting design and sourcing strategies to the unique properties and supply realities of these materials, ensuring they are not just ethically sourced but also commercially viable and beautifully executed.

The future of vegan fashion lies not in finding a single perfect alternative, but in building a diverse, responsible material palette that aligns performance with planetary ethics. It's a commitment to continuous improvement and transparency, from the farm or recycling bin to the finished product.

Ready to build your next collection with materials that are both cruelty-free and genuinely sustainable? At Shanghai Fumao, our Conscious Materials division is dedicated to sourcing and developing the leading edge of vegan fabrics, from certified recycled synthetics to partnerships with innovative bio-material producers. We provide the technical data, supply chain access, and production guidance you need. Contact our Business Director, Elaine, to explore our vegan material library: elaine@fumaoclothing.com.