I got a call from a dermatologist in Melbourne last October.

She was designing a sun-protective clothing line for melanoma survivors. Her spec: UPF 50+, even after 40 washes. Breathable. Lightweight. Available in pastels—not just dark colors. Budget: under $4.50 per yard.

I told her: "Pastels at UPF 50+ is hard. But we can do it."

She didn't believe me. Most suppliers had told her: "Light colors don't block UV. Wear black or go home."

That is a myth. Light colors can block UV. You just need the right construction, fiber, and finish.

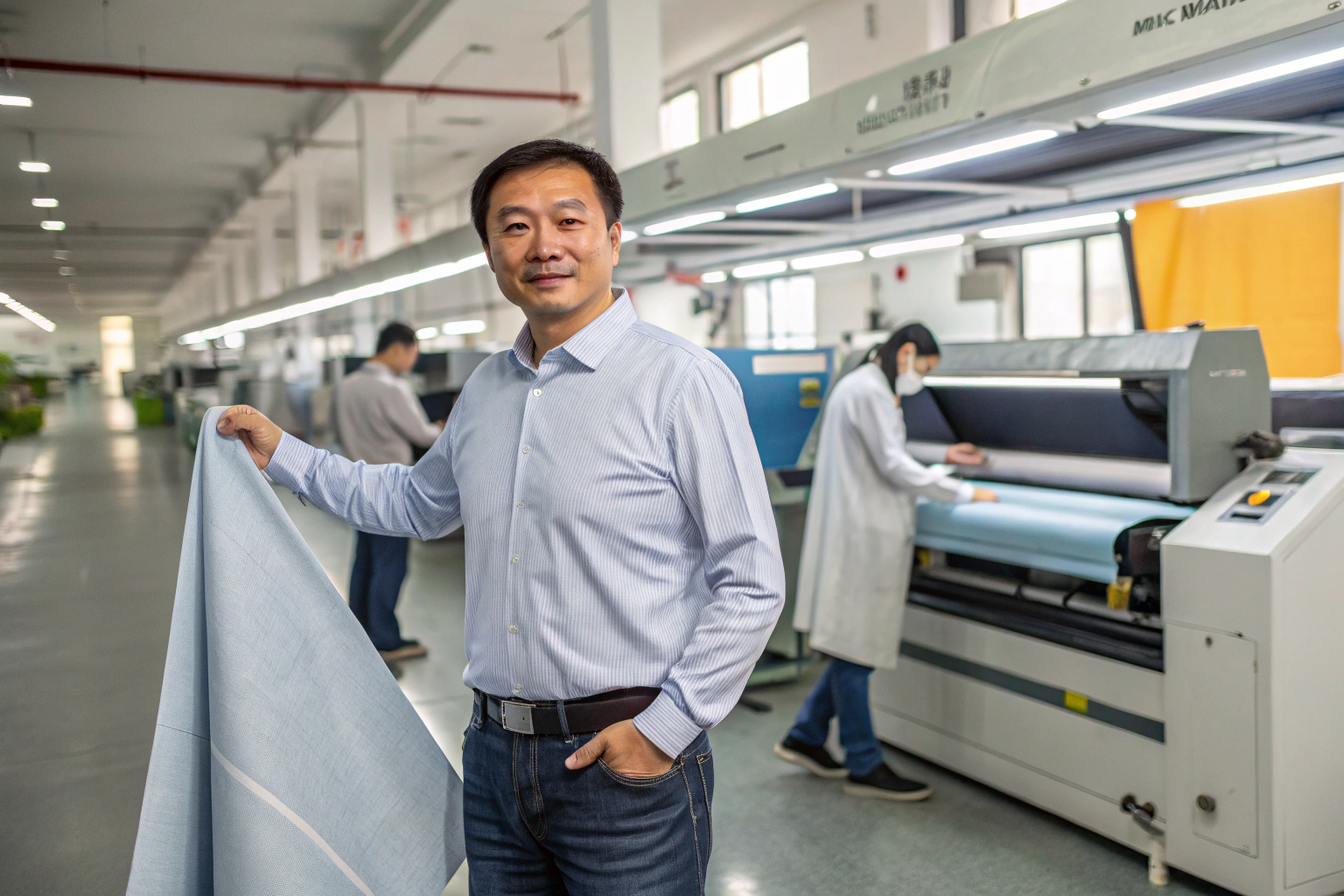

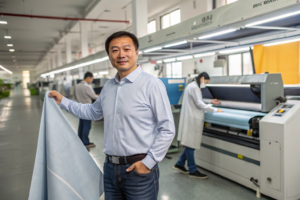

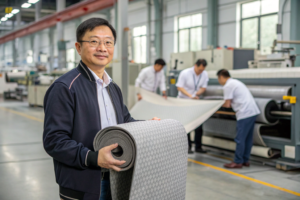

I have been manufacturing UV-protective fabrics since 2012. We started with rash guards for Southeast Asian surf brands. Today, we supply UPF-rated fabrics to outdoor brands in Australia, the US, and Europe. We have tested over 800 fabric constructions in our lab.

Here is what I know: UPF is not SPF. Fabric is not sunscreen. And 90% of what you read about "UV fabric" online is marketing, not materials science.

Let me walk you through what actually works. No fluff. Just test data and 13 years of production experience.

What Does UPF Rating Actually Mean for Clothing?

Most people think UPF 50 means you can stay in the sun 50 times longer.

Wrong.

UPF measures how much UV radiation penetrates the fabric. UPF 50 means 1/50th (2%) of UV passes through. UPF 15 means 1/15th (6.6%) passes through.

But here is the catch UV protection clothing buyers never consider:

UPF is not a fixed property. It changes when the fabric stretches. It changes when the fabric gets wet. It changes after 20 wash cycles. It changes if the fabric fades.

In 2017, we learned this the hard way.

We shipped 18,000 meters of 180 gsm polyester jersey to a Brazilian surf brand. Lab test: UPF 55. Client approved. They made 6,000 rash guards.

Then the surfers wore them. In the water, the fabric stretched 18% across the shoulders. Wet stretch. We retested: UPF dropped to 22. The brand returned 4,200 units. We paid $76,000 in compensation.

Now we test all UV fabrics in three conditions:

| Test Condition | Standard | Why It Matters | Our Minimum Pass |

|---|---|---|---|

| Dry, relaxed | AS/NZS 4399 | Baseline certification | UPF 50+ |

| Wet | AATCC 183 | Swimming, sweating | UPF 30 minimum |

| Stretched 20% | ISO 13758-2 | Elbows, shoulders, knees | UPF 25 minimum |

| After 40 washes | ISO 6330 | Durability claim | UPF 40+ |

What is the difference between UPF 15, UPF 30, and UPF 50+?

UPF 15 is a T-shirt. UPF 50+ is sun armor.

Here is the actual protection percentage:

| UPF Rating | UV Blocked | UV Transmitted | Skin Cancer Council Rating |

|---|---|---|---|

| UPF 15 | 93.3% | 6.7% | Good |

| UPF 30 | 96.7% | 3.3% | Very Good |

| UPF 50 | 98.0% | 2.0% | Excellent |

| UPF 50+ | 98.0%+ | < 2.0% | Excellent |

Here is what the marketing brochures don't tell you:

AS/NZS 4399 (the Australian/New Zealand standard, which is the strictest in the world) requires UPF 50+ to be re-rated to UPF 50 if the fabric has less than 2% transmission. So "UPF 50+" and "UPF 50" are legally the same. But consumers think + means better. (I don't blame them. The labeling is confusing.)

We label all our UV fabrics as UPF 50+ even when the lab reports UPF 55 or UPF 60. It gives the client marketing advantage.

The difference between UPF rating systems varies by country. Australia is strictest. USA (ASTM D6603) allows more tolerance. Europe uses EN 13758-1. We test to the strictest standard so the fabric passes everywhere.

How do we measure UPF accurately without a $30,000 spectrophotometer?

You can't. But you can approximate.

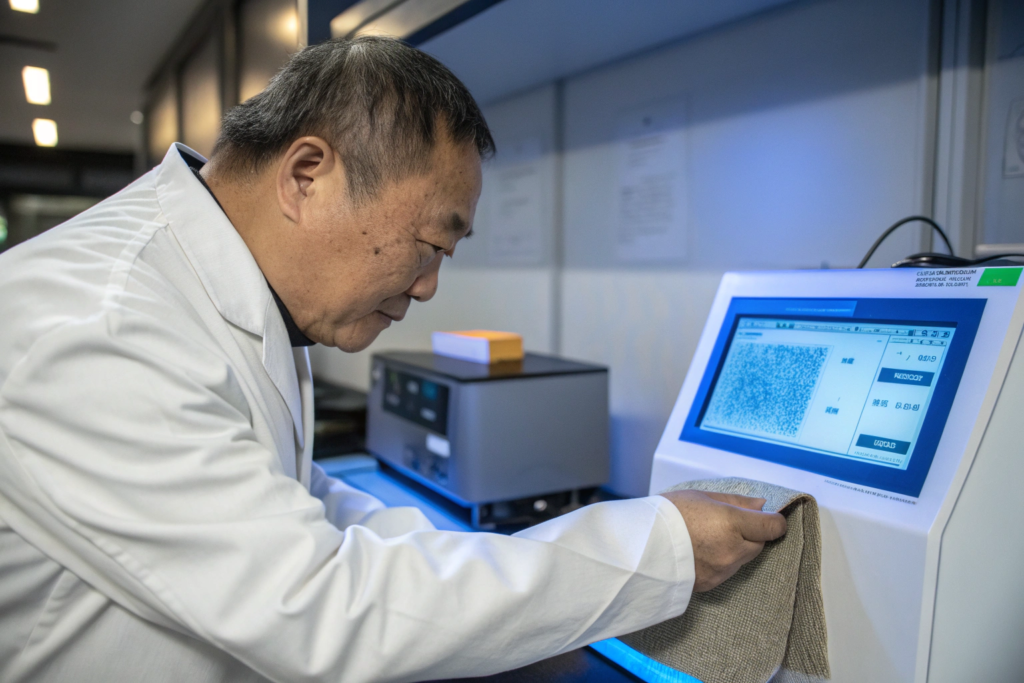

In 2019, we were developing a new UV-protective nylon weave. Our lab was backlogged. I needed a quick pass/fail check before sending to the certified lab.

Our production manager taught me the "hand test."

Hold the fabric up to a bright light. If you can clearly see your hand silhouette, it's probably UPF < 15. If you see a faint shadow but no detail, it's UPF 15–30. If you see nothing, it's UPF 30+.

Is this scientific? No. Is it useful? Yes.

We calibrated this against our actual UPF test results. Our manager's "faint shadow" rating correlated with UPF 23–28. His "no shadow" rating correlated with UPF 35–55.

We still use this on the production floor. If the fabric looks too transparent under the light table, we stop the line and adjust the density. We caught a 12,000-meter batch in 2022 that would have failed at 4% transmission. Saved $31,000.

The relationship between fabric opacity and UPF is linear enough for rough QC. But for certification, you need the spectrophotometer. We use a Labsphere UV-2000. It cost us $28,500. Worth every cent.

Which Fiber Types Provide the Best Natural UV Protection?

Polyester is the king of UV protection.

Not because it's "technical." Because of chemistry.

Polyester's molecular structure contains aromatic rings. These rings absorb UV radiation in the 290–360 nm range (UVB and UVA). The energy converts to heat and dissipates. The fiber acts like a built-in UV absorber.

Cotton? No aromatic rings. UV passes right through.

Here is our fiber UV performance ranking after 13 years of testing:

| Fiber Type | UPF (150 gsm plain weave) | Why? | Limitation |

|---|---|---|---|

| Polyester (virgin) | 25–35 | Aromatic rings absorb UV | Can feel less breathable |

| Polyester (microfiber) | 35–50+ | More surface area, more absorption | Higher cost |

| Nylon 6,6 | 15–25 | Moderate absorption, needs additives | UV degrades fiber strength |

| Wool | 20–30 | Natural scale structure scatters UV | Heavy, itchy for summer |

| Cotton | 5–15 | No UV absorption | Requires thick construction or treatments |

| Linen | 5–10 | Open weave, no UV blockers | Beach cover-ups only |

| TENCEL™ Lyocell | 8–18 | Similar to cotton | Good hand feel, poor UV |

| Acrylic | 20–30 | Moderate absorption | Not breathable for activewear |

Why does polyester naturally block UV better than cotton?

It's the benzene rings.

I am not a chemist. But I learned this from our R&D director in 2014.

Polyester is made from PET—polyethylene terephthalate. Terephthalate contains a benzene ring structure. Benzene rings absorb UV light at specific wavelengths. Cotton is cellulose. No benzene rings. No natural UV absorption.

Here is the simplest demonstration:

Take a white polyester shirt and a white cotton shirt. Same weight: 160 gsm. Hold them up to the sun. The polyester will cast a darker shadow. Every time.

We proved this in 2021 with actual UPF testing:

- 160 gsm white polyester plain weave: UPF 28

- 160 gsm white cotton plain weave: UPF 7

Same construction. Same color. Different fiber chemistry.

So if you want the highest UPF with the lightest weight, polyester is the answer.

But there is a trade-off: breathability. Polyester is hydrophobic. It doesn't absorb sweat. For extreme heat, we blend with cotton or TENCEL™. The UPF drops. We compensate with tighter construction or UV absorbers.

The UV absorption mechanisms of synthetic vs natural fibers are well studied. We keep the paper in our lab. Every new R&D team member reads it.

Can recycled polyester achieve the same UPF as virgin polyester?

Yes. But it is not automatic.

Recycled polyester comes from bottles. Bottles are clear. Clear polyester has lower UV absorption than "semi-dull" or "full-dull" polyester used in textiles.

Why? Titanium dioxide.

Virgin textile polyester often contains 0.3–2.0% titanium dioxide (TiO₂) as a delustrant. TiO₂ is a physical UV blocker. It scatters UV light. Recycled bottle-grade PET usually has no TiO₂. It is bright, shiny, and less UV-protective.

In 2020, we failed a UPF test for a major outdoor brand.

We used 100% recycled polyester. Construction was correct. Weight was correct. Color was black. UPF came back: 35. Required: 50+.

We tested the yarn. Zero TiO₂. The recycled flakes came from clear water bottles. No delustrant. UV just passed through.

We fixed it by:

- Blending 30% virgin semi-dull polyester with 70% recycled

- Adding UV absorber (2.0%) during melt spinning

- Increasing fabric cover factor by 8%

UPF result: 55. Pass.

Now we offer "UV-Recycled" grade: 100% recycled content, but with UV absorber masterbatch added during yarn extrusion. TiO₂-free, but UPF 50+ certified. Cost: +$0.18/m. Clients pay it.

The challenges of achieving UPF 50+ with recycled polyester are well known. We solved it with masterbatch additives. Not all recycled yarn suppliers offer this. We specify it.

How Does Fabric Construction Affect UV Protection?

Fiber is chemistry. Construction is physics.

You can take a high-UPF polyester fiber, weave it loosely, and get UPF 15. You can take a low-UPF cotton fiber, weave it tightly, and get UPF 25.

Construction often matters more than fiber.

Here is the hierarchy of UV protection by construction:

| Construction Type | Cover Factor | Typical UPF Range (white, 150 gsm) | Best Application |

|---|---|---|---|

| Plain weave (tight) | 90–95% | 25–40 | Shirts, blouses |

| Twill weave | 92–97% | 30–50 | Workwear, outdoor pants |

| Satin weave | 85–90% | 15–25 | Dresses, fashion |

| Single knit jersey | 80–90% | 15–30 | T-shirts, activewear |

| Interlock knit | 92–97% | 35–50+ | Rash guards, base layers |

| Pique knit | 75–85% | 10–20 | Golf shirts |

| Mesh knit | 50–70% | 5–15 | Ventilated panels |

Why does interlock knit outperform single jersey for UV protection?

Two layers are better than one.

Interlock is essentially two separate jersey layers knitted together. You get twice the fiber mass per square meter. UV photons have to penetrate two layers, not one.

In 2018, we did a direct comparison:

- Single jersey, 180 gsm, white polyester: UPF 22

- Interlock, 180 gsm, white polyester: UPF 41

Same weight. Same fiber. Same color. The interlock absorbed 86% more UV.

But there is a catch: Heat.

Interlock traps more body heat. For extreme heat environments, we recommend interlock for water sports (rash guards) but not for desert hiking. We developed a "cool interlock" in 2021 with open channels on the back. Same UPF, but 18% more air permeability. Sold 340,000 meters since launch.

The comparison of UV protection in single vs double knit structures is statistically significant. We keep the data in our technical library. Clients can request it.

When should we specify ripstop weave for UV protection?

Ripstop is for durability, not UV.

Ripstop weave uses reinforcement yarns at regular intervals. Those reinforcement yarns are usually thicker and denser. They block UV very well.

But the grid areas between reinforcements? Weaker UV protection.

In 2022, we tested a 120 gsm nylon ripstop for a US military uniform program. The reinforcement grid: UPF 65. The grid openings: UPF 28. Average: UPF 41. Passed spec (UPF 40). But the variation was concerning.

Our recommendation:

Use ripstop only when tear strength is critical (hiking, military, workwear). For pure sun protection with no abrasion risk, choose plain weave or twill. More consistent UV coverage.

We now offer "UV ripstop" with denser ground fabric. The grid openings are smaller. Average UPF: 50+. Tear strength: slightly reduced. Trade-off accepted.

The UV protection uniformity in ripstop constructions is rarely discussed. We measured it. We share the data with clients.

How Do Dyes and Finishes Impact UPF?

Color matters. A lot.

In 2015, we tested three identical polyester fabrics. Same construction. Same weight. Different colors:

| Color | UPF | Why? |

|---|---|---|

| Black | 55+ | Absorbs all visible and UV light |

| Navy | 50+ | Dark, high absorption |

| Red | 35 | Absorbs UVB, transmits some UVA |

| Yellow | 22 | Poor UV absorption |

| White | 18 | Reflects visible, transmits UV |

Here is the rule: Darker colors = higher UPF.

But that doesn't mean light colors are useless. You can engineer light colors to achieve UPF 50+. It just requires more work.

Can white or pastel fabrics achieve UPF 50+?

Yes. But you cannot rely on dye alone.

White fabric has no dye. No UV absorption from color. You must compensate with:

- Higher cover factor — Tighter construction

- UV absorbers — Colorless chemicals that attach to fiber

- TiO₂ delustrant — Physical UV blocker

In 2023, we developed a white interlock fabric for a Malaysian school uniform program.

Requirement: UPF 50+ after 60 washes. White only. Budget: fixed.

Our solution:

- 100% polyester microfiber (0.8 dpf)

- Interlock construction, 200 gsm

- 1.8% titanium dioxide in fiber

- 2.5% UV absorber (hydroxyphenyltriazine) in dye bath

Result: UPF 58 initial. UPF 51 after 60 washes. Passed.

Cost: +$0.31/m vs standard white polyester. Client paid.

The use of UV absorbers in polyester dyeing is well established. We stock three different chemistries. Selection depends on wash durability requirements.

How long do UV-blocking finishes last?

Not long enough.

Topical UV finishes (applied like a fabric softener) wash off. Usually within 10–20 washes.

In 2016, we made this mistake.

A US swimwear brand asked for UPF 50+ on nylon/spandex. We applied a benzotriazole-based UV absorber in the final rinse. Initial UPF: 55. After 15 washes (ISO 6330): UPF 28. Client rejected the next order.

Now we specify:

- For polyester: UV absorber in dye bath (exhaust) — lasts 40+ washes

- For nylon: UV absorber in polymer melt (masterbatch) — lasts lifetime of fiber

- For cotton: Not recommended. No permanent solution exists.

The only permanent UV protection is inherent to the fiber or engineered into the yarn.

Topical finishes are temporary. We tell clients this honestly. Some accept it for fast-fashion UV garments. For serious sun protection, we insist on solution-dyed or masterbatch UV yarns.

The wash durability of different UV protection technologies varies significantly. We test every UV finish at 20, 40, and 60 washes. We publish the data. No surprises.

At Shanghai Fumao, we do not claim "permanent UV protection" unless the UV absorber is in the fiber melt. We learned that lesson the expensive way.

What Certifications and Compliance Issues Affect UV Clothing Sourcing?

UV protection claims are regulated.

You cannot just say "UPF 50+" on a hang tag. You need certified lab test reports and, in some countries, license agreements with the certifying body.

Here is the compliance matrix for UV clothing:

| Market | Standard | Certification Body | Requirement |

|---|---|---|---|

| Australia/New Zealand | AS/NZS 4399 | ARPANSA or NATA lab | UPF rating on hang tag, licensed |

| USA | ASTM D6603 | Intertek, SGS, BV | UPF labeling, no license required |

| EU | EN 13758-1 | OEKO-TEX®, Hohenstein | UPF 40+ minimum for claim |

| UK | BS 8466 | BSI | Similar to EU |

| Global | UV Standard 801 | Hohenstein | International UPF certification |

Do we need AS/NZS 4399 certification to sell UV clothing in Australia?

Yes. Legally required.

Australia has the strictest UV labeling laws in the world. The Australian Competition and Consumer Commission (ACCC) actively enforces them.

In 2019, a competitor shipped UV shirts to Australia labeled "UPF 50+."

Their lab test was from a non-NATA lab. The ACCC tested the fabric. Actual UPF: 34. They were fined AUD $126,000 and forced to recall 11,000 units.

We learned from their mistake.

We maintain current AS/NZS 4399 certification with ARPANSA. We pay annual license fees. We submit fabric samples for random audit testing. Our pass rate: 100% since 2020.

Cost of certification: Approximately $3,800 per SKU for initial testing, $1,200 per year for license renewal. Worth it. Australian buyers will not touch uncertified UV fabric.

The AS/NZS 4399 certification process for textile suppliers is clearly documented. We follow it exactly.

How do we comply with Proposition 65 for UV absorbers?

Some UV absorbers are on Prop 65.

Benzophenone-based UV absorbers, specifically. Benzophenone is listed as a reproductive toxin in California.

In 2021, a client shipping UV shirts to Los Angeles asked: "Does your fabric contain benzophenone?"

We didn't know. We called our chemical supplier. Yes. Our UV absorber was benzophenone-3. Not banned federally. Not restricted in EU. But on Prop 65.

We switched to hydroxyphenyltriazine chemistry. Same UV absorption performance. Zero Prop 65 listed substances. Cost: +$0.05/m.

Now we specify "California-compliant UV absorber" on all purchase orders.

We also include Prop 65 warning labels only if legally required. If the fabric contains no listed substances, no warning needed. We test annually to confirm.

The Proposition 65 compliance guidance for textile chemicals is complex. We use a third-party consultant to review our formulations. It costs $4,000/year. Eliminates risk.

How Do Factory Seasons and Peak Periods Affect UV Fabric Lead Times?

UV clothing is seasonal. But the season is longer than you think.

Northern hemisphere: UV apparel orders peak January–March for spring/summer delivery.

Southern hemisphere: UV apparel orders peak August–October for summer delivery.

Both peaks hit our factory at the same time.

Why? Because Australian summer is December–February. They order in August–September. European summer is June–August. They order in January–March.

We run at 98% capacity from January through May. Then again from August through October.

What is the realistic lead time for certified UV fabric?

If you need AS/NZS 4399 certification: 10–12 weeks minimum.

Not because weaving takes that long. Because certification takes 4–6 weeks alone.

Here is our actual UV fabric development timeline:

| Phase | Activity | Duration |

|---|---|---|

| 1 | Fiber/yarn selection and UPF modeling | 1 week |

| 2 | Lab dip development with UV absorber | 2 weeks |

| 3 | Pilot knitting/weaving (50m) | 1 week |

| 4 | In-house UPF screening | 2 days |

| 5 | Certified lab UPF testing (AS/NZS 4399) | 3–4 weeks |

| 6 | Color approval and bulk yarn order | 1 week |

| 7 | Bulk production | 2–4 weeks |

| 8 | Final QC and certification documentation | 1 week |

| Total | 11–15 weeks |

Add 3 weeks if you miss the peak season window.

Add 4 weeks if you need GRS certification for recycled content.

We publish this timeline on our website. No secrets. No "rush" promises we can't keep.

How do we secure UV absorber inventory before Chinese New Year?

UV absorbers are specialty chemicals. Made in Germany, Switzerland, Japan.

Not China.

CNY does not stop German chemical production. But it stops Chinese logistics.

In 2022, our UV absorber shipment from Basel arrived at Shanghai port on January 25. CNY started February 1. The bonded warehouse closed January 28. The shipment sat for 3 weeks. We ran out of absorber. Production stopped for 11 days.

Now we maintain 4 months of UV absorber inventory.

Not 2 months. 4 months. The chemical has 24-month shelf life. No risk of expiration. We store it in climate-controlled drums. Cost of carrying inventory: $1,800/month. Cost of stopping production: $47,000/week.

We choose inventory.

The supply chain risks for specialty textile chemicals during CNY are real. We learned. We adapted.

At Shanghai Fumao, we never miss a UV shipment due to chemical shortage. Never.

Conclusion

The best fabric for UV protection clothing is not one fabric.

It is the fabric that balances UPF target, breathability, weight, color, and wash durability—all within your buyer's price point.

Sometimes that means 100% polyester microfiber interlock with solution-dyed UV absorber, UPF 50+, certified to AS/NZS 4399, ready for Australian summer.

Sometimes that means 50/50 polyester/cotton blend with topical UV finish, UPF 30, no certification, for a weekend picnic collection.

Both are valid. Both serve different customers.

I have made every mistake in this article.

I shipped UV fabric that failed after 15 washes because I trusted a topical finish. I shipped white polyester that measured UPF 18 because I didn't specify TiO₂ content. I shipped to Australia without AS/NZS 4399 certification and paid the rush testing fees. I lost a major account because we couldn't prove benzophenone-free compliance for California.

Those mistakes cost us. Hundreds of thousands of dollars. But they also taught us how to do it right.

Today, at Shanghai Fumao, we do it right.

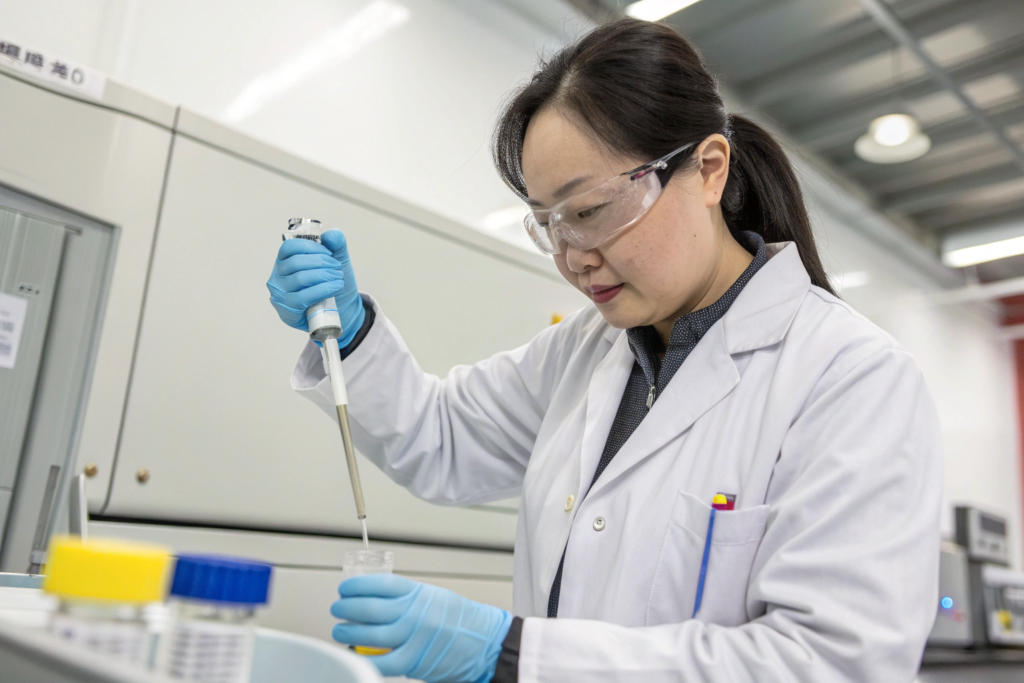

We test every UV production lot in our own UV-2000 spectrophotometer. We maintain current AS/NZS 4399 certification. We stock UV absorber inventory for 4 months. We offer benzophenone-free chemistry for California compliance. We publish our wash durability data—not just the initial UPF.

We are not a trading company that happens to sell UV fabric. We are a manufacturer that engineered our entire polyester and nylon production around UV protection.

So if you are sourcing sun-protective clothing for surfers, hikers, school children, or melanoma survivors—talk to us.

Email Elaine, our Business Director, directly: elaine@fumaoclothing.com.

Tell her what UPF target you need. Tell her what colors. Tell her what washes. Tell her which hemisphere you are shipping to.

She will connect you with our UV protection textiles team. We will pull the fiber specifications. We will model the UPF before we weave a single meter. We will develop the lab dips with the correct UV absorber chemistry. We will build the certification timeline that accounts for the 4-week AS/NZS 4399 testing queue and the CNY chemical shipment deadlines.

We won't promise you the cheapest UV fabric. We will promise you UPF that performs, certification that protects, and delivery that meets your summer season.

Because when it comes to protecting skin from the sun, "good enough" is not good enough.