Soft robotics is transforming industries from healthcare to manufacturing, and the fabrics used in these systems are just as critical as the mechanics. The right textile can determine how flexible, durable, and functional a soft robot will be. Over my 20 years in the textile industry, I’ve seen how innovation in materials directly influences the efficiency of these next-generation machines.

The best fabrics for soft robotics combine elasticity, durability, and custom functionality—whether that’s conductivity for sensors, resistance to wear, or sustainability for eco-conscious design. From advanced coated weaves to high-performance knits, choosing the right fabric can make or break a project.

As a manufacturer rooted in Keqiao’s global textile hub, we’ve developed and sourced fabrics that meet the strict demands of engineers and designers. Let’s break down the options and what makes them work for your project.

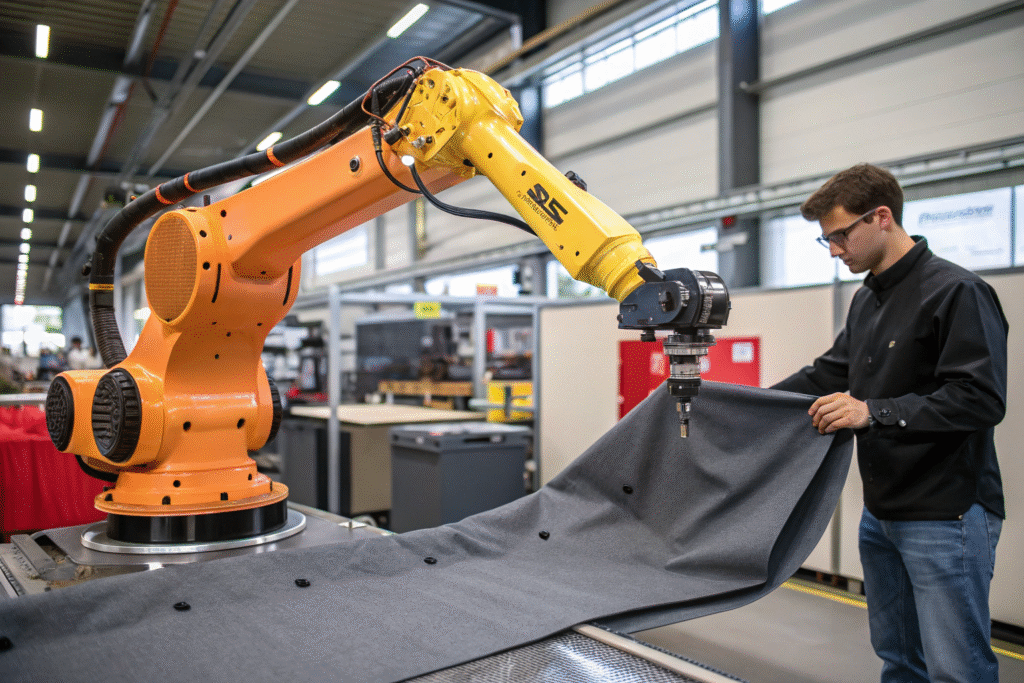

High-Elasticity Fabrics for Flexible Movement

High-elasticity fabrics are the backbone of soft robotic designs that require dynamic movement. These fabrics must stretch and recover repeatedly without losing their structural integrity.

Spandex blends, warp-knitted elastane fabrics, and high-tech polyester knits are excellent for movement-intensive robotic applications, delivering both strength and resilience. They mimic natural muscle movements, making them ideal for wearable robotics and assistive devices.

How Do Stretch Fabrics Improve Robotic Efficiency?

Stretch fabrics reduce mechanical resistance, allowing actuators to move more freely. Spandex-based textiles and warp-knit structures are designed to return to their original form even after extreme extension. This means a robotic glove can grip with precision without strain on the motors.

Why Are Recovery Rates Critical in Fabric Selection?

The recovery rate of a fabric—how fast and fully it returns to its shape—directly affects response time in robotics. Materials like Lycra blends not only offer high recovery but also maintain performance over thousands of cycles, ensuring operational consistency.

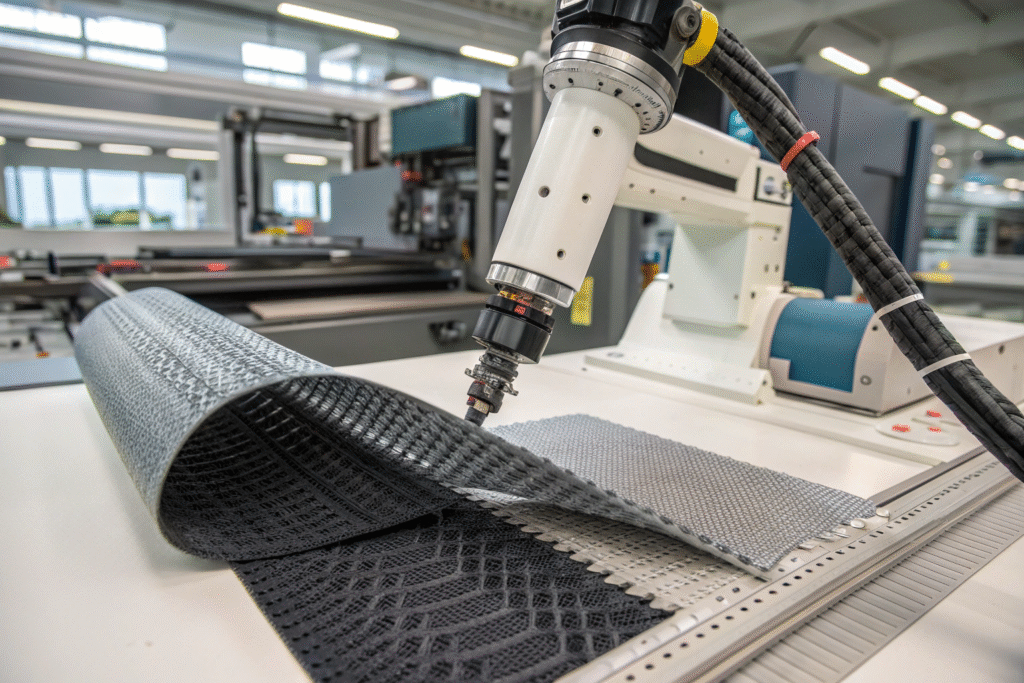

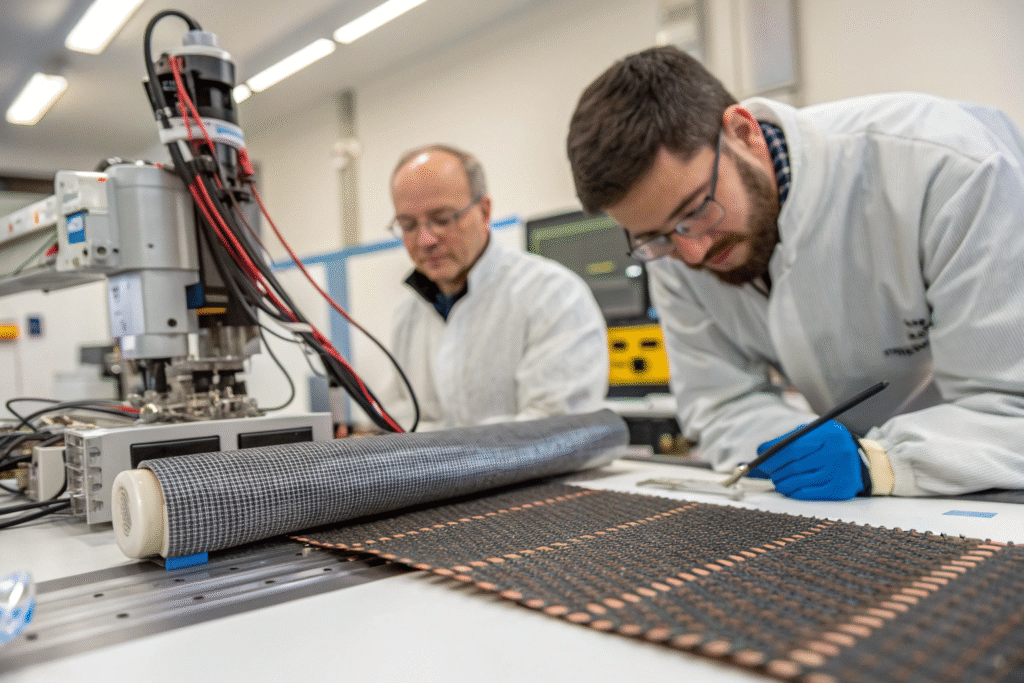

Conductive and Sensor-Integrated Textiles

In soft robotics, fabrics often need to do more than move—they need to sense. Conductive textiles allow robots to detect pressure, temperature, or even chemical changes.

Silver-coated nylon, graphene-infused polyester, and carbon-based knits are leaders in sensor integration for soft robotics. They enable real-time feedback without adding bulk or compromising flexibility.

How Do Conductive Fibers Work in Soft Robotics?

Conductive fabrics embed metals or conductive polymers into fibers, creating a textile that can transmit electrical signals. Silver-coated nylon is lightweight, corrosion-resistant, and ideal for medical robotics where hygiene is crucial.

Can Sensor Fabrics Replace Traditional Wiring?

Yes, in many cases. Integrated conductive textiles eliminate rigid wiring, making designs lighter and safer. Solutions like graphene-based fabrics can function as both structure and circuit, reducing complexity in assembly.

Durable Coated Fabrics for Wear Resistance

Soft robots that operate in industrial or outdoor environments require protection against friction, punctures, and environmental damage.

Polyurethane-coated nylons, thermoplastic polyurethane (TPU) laminates, and silicone-coated glass fabrics offer exceptional durability without sacrificing flexibility. These are essential for applications like agricultural robotics and rescue devices.

How Do Coatings Affect Fabric Performance?

Coatings create a protective barrier, making fabrics resistant to abrasion and moisture while also improving tear strength. TPU-coated textiles can handle repeated flexing without cracking, extending service life.

Are Heavy Coatings a Problem for Soft Robotics?

Weight and stiffness can be a concern, but modern silicone-coated fabrics balance toughness with supple movement, enabling protective coverage without hindering mobility.

Eco-Friendly Fabrics for Sustainable Robotics

Sustainability is becoming a priority in robotics just as in fashion and manufacturing. Choosing eco-friendly fabrics can help companies align with environmental goals while maintaining performance.

Recycled polyester, organic cotton, and bio-based elastane deliver both sustainability and technical performance for soft robotics. These materials reduce carbon footprint without sacrificing innovation.

Can Recycled Fabrics Compete with Virgin Synthetics?

Yes, advances in recycled PET now match the durability and elasticity of virgin fibers. They also offer marketing advantages for companies committed to green tech.

Are There Biodegradable Options for Robotics?

Biodegradable fabrics like Tencel and hemp blends can serve in short-term or disposable robotics, especially in medical or agricultural contexts where disposal and environmental impact are concerns.

Conclusion

Selecting the right fabric for soft robotics is a balance between performance, durability, and sustainability. From high-elasticity textiles that mimic muscle function to conductive fabrics that integrate sensing technology, each choice impacts the efficiency and longevity of your robotic systems. Coated fabrics protect in harsh conditions, while eco-friendly options help you meet sustainability goals without compromise.

If you’re ready to develop a custom fabric solution for your soft robotics project, our team at Shanghai Fumao can help. Contact our Business Director Elaine at elaine@fumaoclothing.com to start your production journey today.