Whether you’re building a music studio, outfitting a corporate conference room, or creating a high-end home theater, acoustic performance starts with surface materials. And when it comes to acoustic panels, fabric isn’t just decorative—it’s functional.

If you're seeking optimal noise absorption and aesthetic versatility, choosing the right fabric is critical to ensure your acoustic panels perform to their full potential.

In this article, we’ll break down the most effective sound-absorbing fabrics, what tests matter (like NRC and ASTM C423), how fabric construction affects acoustic transparency, and where to source materials that meet both acoustic and design standards.

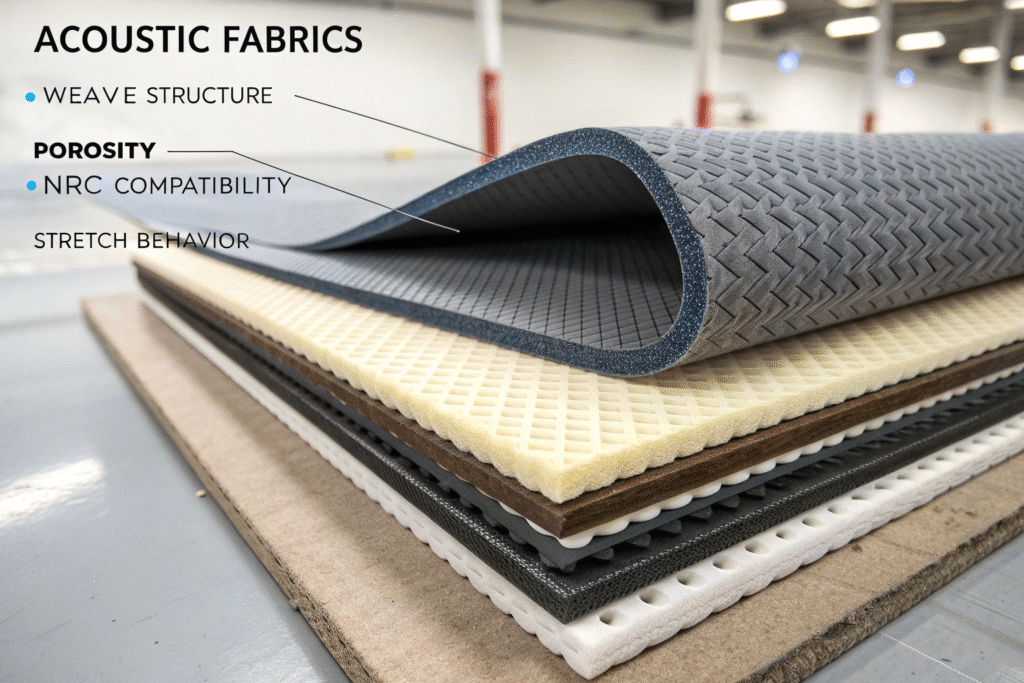

What Fabric Properties Affect Acoustic Panel Performance?

Acoustic panels work by absorbing or diffusing sound waves—especially mid and high frequencies. The fabric covering plays a big role in how sound interacts with the panel’s core material (usually fiberglass or mineral wool).

For maximum noise reduction, the ideal fabric must be acoustically transparent, breathable, non-reflective, and stretchable enough to wrap tightly over the insulation layer.

Why Does Breathability Matter in Acoustic Fabrics?

If the fabric is too dense or tightly woven, sound waves bounce off it—reducing absorption. Fabrics with open weaves or micro-perforations allow sound to pass through and get absorbed by the acoustic core.

According to ATS Acoustics, the Noise Reduction Coefficient (NRC) of a panel can drop by 0.2–0.4 if covered in the wrong fabric. That means your 0.90-rated panel might perform closer to 0.55 just because of a poor textile choice.

Look for fabrics that score well in ASTM C423 (sound absorption) and ASTM E84 (fire resistance). At Fumao Fabric, we test all acoustic materials in our CNAS-certified lab under these standards.

What Fabric Constructions Work Best for Panels?

- Woven Polyester (open-weave): Ideal for breathability + durability

- Non-woven Felt: Soft, dense texture with moderate absorption

- Wool Blends: Naturally breathable, great for luxury applications

- Suede/Microsuede: Smooth, light-absorbing surfaces (beware tight weaves)

- Knit Stretch: Great for curved panels and seamless tension wrapping

See Guilford of Maine’s acoustic collection for industry-standard references.

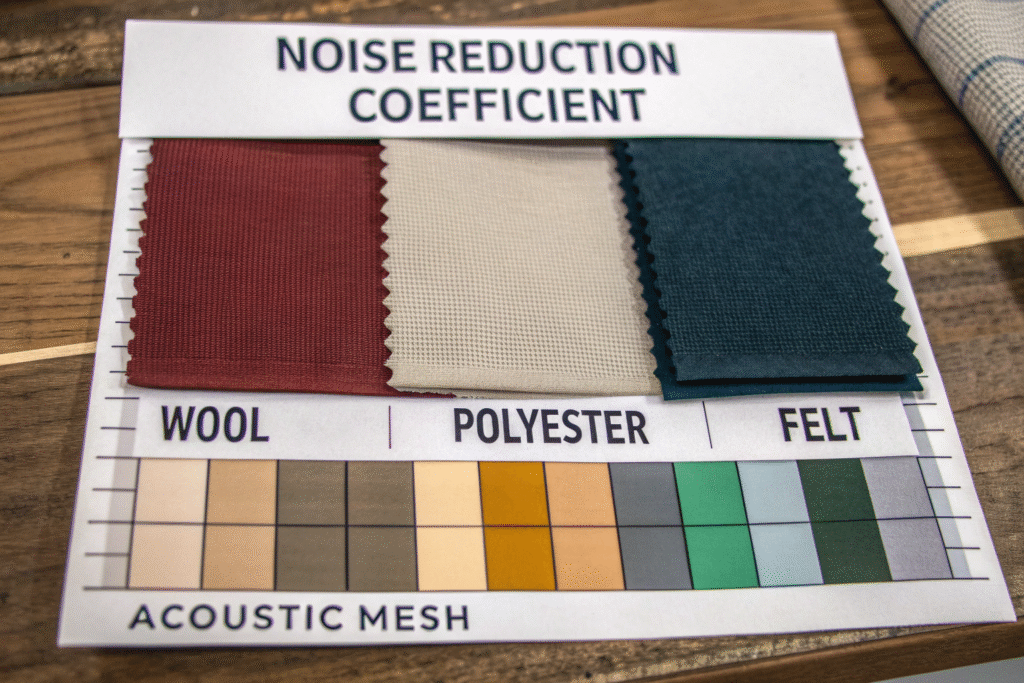

Which Fabrics Have the Best NRC Ratings for Acoustic Use?

While fabrics themselves don’t carry NRC ratings, they influence the overall panel’s performance. That said, some materials have been independently tested as “acoustically transparent” when layered over standard cores.

For high-performance panels, acousticians recommend open-weave polyester, 100% wool, and acoustically-rated stretch knits.

What Is the NRC and Why Does It Matter?

NRC (Noise Reduction Coefficient) measures how well a material absorbs sound. It ranges from 0.00 (total reflection) to 1.00 (total absorption). For fabric-wrapped acoustic panels, the NRC is usually determined with the full assembly tested per ASTM C423.

When choosing fabrics, go for those used in tested assemblies that achieve NRC ≥ 0.85. You can also request lab test data from suppliers like Acoustical Surfaces.

Top Fabric Choices with High Acoustic Performance

| Fabric Type | Common GSM | Recommended Use | Key Benefit |

|---|---|---|---|

| Open-Weave Polyester | 160–280gsm | Studio, conference panels | NRC-optimized breathability |

| Wool Serge | 300–400gsm | Luxury interiors | Moisture + thermal balance |

| Polyester Felt | 200–300gsm | Wall panels, partitions | Texture + absorption |

| Acoustical Knit | 180–260gsm | Curved/rounded panels | Stretch fit, seamless look |

Fumao Fabric offers custom-dyed acoustic fabrics with real-time QR-linked NRC and GSM test data for your QC team.

Where Can You Source Certified Acoustic Fabrics in Bulk?

Many fabric suppliers label products as “sound absorbing,” but very few provide lab-backed test reports, consistent quality, or scalable MOQ terms for real projects.

China’s Keqiao district, where we’re based, has become a trusted global source for affordable, tested acoustic fabrics—delivering to contractors, OEM builders, and architects worldwide.

Does Fumao Fabric Offer Acoustic Panel Solutions?

Yes. At Fumao Fabric, we supply more than 40+ acoustic-friendly textiles, including:

- Open-weave polyester with OEKO-TEX + flame-retardant coatings

- PET felt made from recycled bottles (rPET)

- Wool/polyester blends with low-pilling and UV protection

- Printed acoustic fabrics for design-forward commercial spaces

We also offer pre-laminated options for clients manufacturing panels at scale, and our fabrics are ISO 11612 fire-tested—ready for public space use (theaters, hotels, schools).

Explore alternatives at Carnegie Acoustical to compare textures and tests, or contact us for free swatch books.

What Are the MOQ and Lead Times?

For standard acoustic polyester, our MOQ starts at 300 meters per color, with lead times around 10–12 days. For flame-retardant or printed options, it’s 500–800 meters, with 20–25 days delivery.

Need urgent delivery for a build-out? We support air freight panel fabric shipments with vacuum packing to reduce shipping volume and cost.

Are There Sustainable Options for Acoustic Panel Fabrics?

Sustainability now matters just as much as sound absorption. More designers are looking for eco-certified, recycled, or even biodegradable fabrics for acoustic builds—especially in LEED-certified spaces.

rPET felts, organic wools, and closed-loop polyester weaves are among the most viable green acoustic panel options today.

What Certifications Should You Look For?

- GRS (Global Recycled Standard) for rPET/polyester

- OEKO-TEX 100 for toxin-free processing

- ISO 14001 for environmentally managed production

- EN ISO 11612 / ASTM E84 for flame-retardant performance

We offer QR-tracked batches for all certified fabrics, so your customers (or inspectors) can trace fiber origin, chemical use, and environmental impact.

Best Eco-Friendly Acoustic Fabrics

- Recycled PET Felt (2–12mm) – panels, baffles, partitions

- Organic Wool Melton – high-end offices, boutique hotels

- Jute-Polyester Blends – rustic/biophilic design spaces

- Biodegradable Poly Knits – event builds, short-term use

For inspiration, check out BuzziSpace’s acoustic felt solutions which mirror many of our felt-based acoustic offerings at more affordable factory-direct pricing.

Conclusion

The fabric you choose can make or break the effectiveness of your acoustic panels. It’s not just about color or texture—it’s about porosity, stretch, breathability, flame safety, and compliance with global acoustic standards.

At Fumao Fabric, we specialize in sound-optimized textiles that combine function with design. From breathable polyesters to sustainable PET felts and luxurious wool blends, we offer ready-to-ship and custom-developed acoustic fabrics—fully tested and globally compliant.

Want expert help sourcing fabric for your next acoustic project? Contact our Business Director Elaine at elaine@fumaoclothing.com to receive swatches, test reports, or factory-supported pricing today.