The Martian surface poses one of the toughest challenges to textile science: regolith abrasion. Unlike Earth’s soil, Mars dust is rich in volcanic glass and jagged silicates that grind against fabrics like millions of tiny blades. For astronauts, equipment, and long-term habitation, using the wrong fabric means faster material degradation, higher risk of mission failure, and even threats to human safety. With my academic background and years of research in advanced textiles, I see abrasion resistance as a critical parameter that defines survival on Mars.

The strongest candidates for Mars regolith abrasion resistance are advanced fibers such as Vectran, UHMWPE, and PBI. These materials have already proven performance in aerospace and defense, combining tensile strength, stability, and wear resistance beyond conventional fabrics. Their adaptation for planetary exploration shows the future direction of high-performance fabric engineering.

Choosing fabrics for Mars is not just about strength—it is about balancing flexibility, cost, coating technology, and durability in multi-layer systems. This article will break down which fabrics excel and why they matter for both space and Earth industries.

Why Is Abrasion Resistance Critical for Mars Missions?

The microstructure of Martian regolith makes it significantly harsher than any desert dust on Earth. Its angular grains penetrate between yarns and accelerate wear. Testing with simulants has shown that fabrics without specialized resistance lose tensile strength in days rather than months.

Abrasion resistance is critical because regolith is unavoidable. Astronaut suits, gloves, habitat walls, and mechanical joints will all be exposed to constant dust storms and surface operations. Without fabrics engineered for endurance, equipment may fail prematurely, putting entire missions at risk.

What Makes Vectran a Proven Choice?

Vectran, a liquid-crystal polymer fiber, has a track record with NASA missions. It was used in airbags for Mars Pathfinder and later rovers like Spirit and Opportunity. Its advantages are thermal stability, abrasion endurance, and high tensile modulus. In fact, without Vectran, the landing cushions might not have survived sharp Martian rocks.

For more, see Vectran aerospace applications and testing data from fabric abrasion methods.

Can UHMWPE Outperform Traditional Nylon?

Ultra-High-Molecular-Weight Polyethylene (UHMWPE) fibers, branded as Dyneema or Spectra, combine exceptional toughness with low density. Compared to nylon, UHMWPE resists surface friction, minimizing wear caused by regolith rubbing. It also provides ballistic-level strength, making it ideal for lightweight structural textiles in Martian exploration.

More insights are available at UHMWPE properties and Dyneema official site.

Which Fabrics Offer Both Durability and Flexibility?

In extreme environments, durability alone is insufficient. Astronauts must bend, move, and grip tools, requiring flexible textiles that resist abrasion without sacrificing comfort.

Polybenzimidazole (PBI) excels in this dual role. It is inherently flame-resistant, chemically stable, and strong against wear. Unlike rigid composites, PBI can be tailored into fabrics that preserve mobility while ensuring structural integrity. This is why NASA has integrated PBI into astronaut suits.

Why Is PBI Used in Astronaut Suits?

PBI does not burn, melt, or lose strength under high heat or abrasion. These features make it ideal for outer protective layers. Its history in firefighter gear and military pilot uniforms highlights its ability to withstand life-threatening environments.

Learn more at PBI material science and its role in aerospace textiles.

How Does Cordura Compare?

Cordura is a high-tenacity nylon fabric widely used in military packs, footwear, and tactical uniforms. While less extreme than Vectran or PBI, it offers reliable durability and affordability, making it useful for non-critical gear in Martian missions.

More details on Cordura and military textile applications.

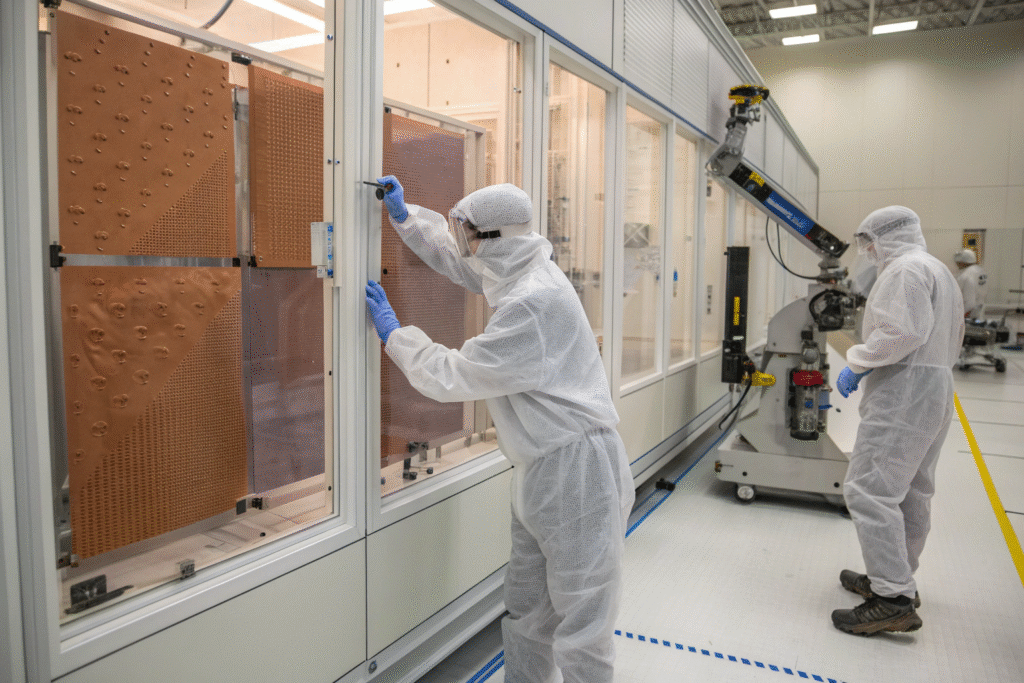

Are Coatings and Laminations Necessary?

Even the toughest fabrics degrade under regolith abrasion if left untreated. Coatings and laminations act as shields, reducing dust penetration and static charge buildup. These protective layers enhance longevity and dust repellence, extending the performance life of base fabrics.

What Role Do Waterproof and Dustproof Membranes Play?

Membranes like PTFE (Teflon) and polyurethane laminates create smooth barriers that reduce particle embedment. They also improve moisture and chemical resistance. Similar systems are found in Gore-Tex® outdoor fabrics, but for Mars, these membranes would face harsher loads.

Check Gore-Tex technology and industrial coated fabrics.

Can Hybrid Fabric Systems Provide Better Protection?

Hybrid approaches combine multiple layers, such as a Vectran outer shell laminated with UHMWPE and topped with fluoropolymer coatings. This synergy yields abrasion resistance, dust repellence, and flexibility. Space agencies are experimenting with multi-layer composites for the next generation of spacesuits.

Explore materials in space research and laminated protective fabrics.

Which Fabrics Balance Performance and Cost?

Performance is vital for survival on Mars, but material cost still matters for scalability. Ultra-premium fabrics will be prioritized for life-critical applications, while Cordura and advanced polyester blends may serve in supporting roles.

On Earth, cost-performance balance drives industrial adoption, and Mars research fabrics often trickle into consumer applications like climbing gear and protective uniforms.

Is Cost a Limiting Factor for Mars Missions?

In aerospace, cost takes a backseat to reliability. The expense of failure outweighs fabric prices, which is why agencies continue to fund premium fibers. For secondary gear, however, affordable options like Cordura help reduce the mission budget.

Check NASA material research and cost-effective textile design.

Could Commercial Applications Drive Down Costs?

If UHMWPE, PBI, and Vectran expand into consumer products, economies of scale will reduce costs. Already, UHMWPE is used in helmets, ropes, and fishing lines, bridging aerospace science with everyday life.

See Dyneema consumer uses and Cordura lifestyle applications.

Conclusion

Martian regolith is more than dust—it is a relentless abrasive threat. Fabrics that can resist it must combine abrasion endurance, flexibility, and resistance to environmental extremes. Vectran, UHMWPE, and PBI are the most promising candidates, while Cordura and hybrid coatings provide broader applications. These innovations will not only safeguard future astronauts but also shape industrial textiles on Earth.

As a fabric manufacturer with global supply capability, we are ready to help partners source and co-develop abrasion-resistant fabrics. If you are seeking to produce advanced protective textiles, please contact our Business Director Elaine at elaine@fumaoclothing.com to discuss tailored solutions for your projects.