I was in a meeting with a product developer from a Seattle-based outdoor brand in February 2023. She had a problem. Their bestselling windbreaker used a 40D nylon ripstop that was perfect—lightweight, packable, $3.20 per yard. But the mill in Taiwan that supplied that specific nylon had stopped producing it. No warning. No transition plan. She had 12,000 jackets to manufacture for the fall season and no fabric. She pulled four competitor samples from her bag: Patagonia Houdini, Arc'teryx Squamish, The North Face Flight Series, and a no-name Amazon special that sold for $29. "Tell me what these are made of and if you can make it," she said.

I picked up the Patagonia sample first. It felt impossibly thin, almost like tissue paper. I knew it was a 10D nylon ripstop, probably solution-dyed, with a PFC-free DWR. The Arc'teryx sample was heavier—a 20D mechanical stretch nylon with a matte finish and excellent hand feel. The Amazon jacket was a 75D polyester taffeta, coated with a generic PU backer, stiff and noisy. I told her: "We can't make the Patagonia fabric here. The 10D weaving requires specialized air-jet looms we don't have. But we can make the Arc'teryx spec, and we can make it for 30% less than your Taiwanese supplier." She placed a trial order for 2,000 meters that afternoon.

Lightweight outerwear is the most technically demanding category of apparel fabrics. It must be thin enough to stuff into a pocket, strong enough to resist tearing, waterproof or water-resistant enough to shed rain, and breathable enough to prevent the wearer from drowning in their own sweat. It must also, increasingly, be made without the forever chemicals that have dominated this category for 50 years. This article is not a general overview. It is a deep dive into the specific deniers, weaves, finishes, and membranes that actually work for windbreakers, rain shells, and ultralight packables. I will give you the real specifications we use to engineer these fabrics for clients ranging from emerging DTC brands to publicly traded outdoor conglomerates.

What Denier and Weave Construction Should You Choose for Ultralight Performance?

Let me start with the most misunderstood specification in outerwear: denier. Denier (D) is the weight in grams of 9,000 meters of yarn. Lower denier = finer yarn = lighter fabric. Higher denier = thicker yarn = heavier, generally stronger fabric.

But here is the trap: denier alone does not determine durability. A 10D fabric with a high tenacity yarn and a tight ripstop grid can outperform a 20D commodity nylon in tear strength. Conversely, a 40D fabric with a loose plain weave and low twist yarn can tear like wet tissue paper.

The three primary constructions for lightweight outerwear are:

1. Ripstop. This is the gold standard for ultralight shells. The weave incorporates a reinforcing grid of heavier yarns at regular intervals (typically 3mm to 8mm squares). When a tear initiates, it hits the grid and stops. A 10D ripstop with a 20D grid can achieve tear strength of 15N+ (ISO 13937), which is adequate for most non-technical use. Without the grid, a 10D plain weave might tear at 5N.

2. Plain weave. Simple over-under construction. Used for budget windbreakers and lined garments. Lighter weight, lower cost, but significantly lower tear resistance. We recommend plain weave only for wind shells under 40g/m² where packability is the sole priority and the garment will not see abrasion.

3. Mechanical stretch weave. This uses textured or air-jet yarns that have natural elasticity. The fabric stretches approximately 10-20% in both directions. This is not spandex; it is constructional stretch. It recovers well and improves comfort during movement. This is what Arc'teryx uses in the Squamish series. It is more expensive to weave and requires specialized finishing.

4. Taslanized nylon. This is a process that blows air into flat filament yarns, creating a textured, cotton-like hand feel. It is heavier (typically 50D+) and less packable, but it is quieter, softer, and has better drape. Used in casual windbreakers and soft shell jackets.

Our recommendation matrix:

-

Ultralight, packable, high performance: 10D to 20D nylon 6,6 ripstop with high tenacity yarns. Minimum tear strength 12N. Weight 30-45 g/m².

-

All-around performance, durability focus: 30D to 40D nylon 6 or nylon 6,6 ripstop. Weight 55-70 g/m². This is the sweet spot for most outdoor brands.

-

Casual, lifestyle, urban: 50D to 75D taslanized polyester or nylon. Weight 80-110 g/m². Less technical, more fashion-oriented.

-

Budget, entry-level: 75D polyester taffeta with acrylic or PU coating. Weight 90-120 g/m². Acceptable for occasional use, poor breathability.

In 2024, we developed a 20D mechanical stretch nylon ripstop for a Japanese outdoor brand that required 40% stretch in the weft and 15% stretch in the warp. This required custom texturing of the nylon yarn and a specific heat-setting profile in the finishing stenter. The first trial failed—stretch was only 22%. We increased the overfeed and reduced the heat-set temperature by 8°C. The second trial passed. The client ordered 48,000 meters. The ISO 13934-1 standard for tensile strength and elongation is the benchmark for measuring these properties, and we use it to validate every stretch shell development.

What is the difference between nylon 6 and nylon 6,6 for outerwear?

This is a frequent point of confusion, and suppliers often substitute one for the other without disclosure. They are not equivalent.

Nylon 6,6 has higher melting point, higher tensile strength, better abrasion resistance, and better chemical resistance than nylon 6. It is also more expensive and requires different processing conditions. For ultralight outerwear where maximum strength-to-weight ratio is required, nylon 6,6 is superior.

Nylon 6 has better dyeability, better光泽, and is more forgiving in weaving and finishing. It is adequate for most medium-weight applications. It is also significantly cheaper—approximately 15-20% lower raw material cost.

How to tell the difference: You cannot visually distinguish finished fabric. You must request the fiber supplier certification or perform differential scanning calorimetry (DSC) testing. Nylon 6,6 has a melting point of 255°C; nylon 6 melts at 220°C. We run DSC on every incoming lot of nylon yarn designated for high-performance outerwear clients. In 2023, we caught a supplier substitution: the yarn was labeled 6,6 but tested as 6. We rejected the lot and requalified the supplier.

Patagonia's Houdini fabric uses proprietary nylon 6,6 yarns. The Arc'teryx Squamish uses a nylon 6,6 variant. The North Face uses both depending on the specific model and price point. If your brand claims "high performance," you should specify nylon 6,6 and verify it.

Is polyester ever a better choice than nylon for windbreakers?

Yes, for specific use cases.

Polyester has lower wet strength than nylon. When nylon gets wet, it loses approximately 10-15% of its tensile strength. Polyester loses almost none. For rainwear in persistent wet conditions, polyester can be more dimensionally stable.

Polyester has better UV resistance. Nylon degrades in sunlight; it weakens and yellows. Polyester is inherently UV-stabilized. For shells that will be used in high-altitude or high-UV environments, polyester is superior.

Polyester is less expensive and more available in recycled form. GRS-certified recycled polyester is widely available and performs similarly to virgin polyester. GRS-certified recycled nylon is available but scarce and expensive.

Polyester has a different hand feel—generally crisper, less 'buttery' than nylon. Some consumers prefer this.

Nylon has superior abrasion resistance and tear strength at equivalent denier. For ultralight shells that need to survive backpack strap abrasion, nylon is the better choice.

Our approach: We recommend nylon for technical, high-performance, ultralight shells. We recommend polyester for lifestyle, casual, and eco-focused collections where recycled content is prioritized and the absolute strength-to-weight ratio is less critical.

We offer a GRS-certified recycled polyester ripstop in 30D and 50D weights that has been widely adopted by European streetwear brands. It does not have the same hand feel as premium Japanese nylon, but it costs 25% less and carries a credible sustainability story. The Textile Exchange's guide to recycled polyester and nylon provides comparative environmental impact data that helps brands make this trade-off decision.

How Do You Specify Water Resistance Without PFAS?

This is the single biggest disruption in the outerwear industry since Gore-Tex. PFAS (per- and polyfluoroalkyl substances), also known as PFCs, are the chemicals that have made water-repellent jackets work for 50 years. They are also persistent environmental toxins. They are being regulated out of existence.

The EU is proposing a near-total ban on PFAS under REACH. Several US states have already restricted them. Major brands (Patagonia, Houdini, Vaude, others) have committed to PFC-free DWR by 2025. The technology exists, but it is not a drop-in replacement.

Conventional C6 and C8 DWR (fluorocarbon-based) create a low-surface-energy barrier that causes water to bead and roll off. They are extremely effective, durable, and relatively inexpensive. They are also toxic and persistent.

PFC-free DWR alternatives fall into three categories:

-

Hydrocarbon-based (paraffin waxes). Low durability, poor performance on synthetic fibers, but fully biodegradable. Suitable for limited-use garments.

-

Silicone-based. Excellent water beading, good durability, but difficult to apply evenly and can interfere with garment taping and lamination. Also problematic for printability and recoatability.

-

Dendrimer/polymer technologies. These create a structured surface that mimics the lotus effect. The best current technology. Rudolf Group's BIONIC-FINISH® ECO, OrganoClick's Bioproof, and Schoeller's ecorepel are leading examples. Durability is approaching conventional C6, but still inferior. Requires higher application temperature and longer curing time.

Here is the reality: There is currently no PFC-free DWR that matches the performance of C6 DWR on the spray test (AATCC 22) after 20 home launderings. The best PFC-free formulations start at 100 (ISO 5) initially and drop to 70-80 after 20 washes. C6 DWR maintains 80-90 after 20 washes.

What we tell clients: If your customer expects their jacket to shed heavy rain for five years, PFC-free DWR will disappoint them today. If your customer expects their jacket to handle light showers for one to two seasons, PFC-free DWR is acceptable. You must manage expectations through labelling and marketing.

We have qualified two PFC-free DWR formulations on our finishing range: one from Rudolf and one from a domestic Chinese supplier who reverse-engineered the Rudolf chemistry at 60% of the cost. The domestic version performs adequately on initial spray test (90-95) but drops to 70 after 10 washes. We disclose this to clients and let them choose based on their price point and sustainability targets. The OEKO-TEX ECO PASSPORT certification helps verify that PFC-free chemicals are genuinely non-fluorinated and not simply masked fluorinated compounds.

What is the difference between 'water resistant' and 'waterproof' in fabric specifications?

This is not a marketing distinction; it is a quantifiable engineering specification. Water resistance is measured by the spray test (AATCC 22, ISO 4920). A rating of 100 (ISO 5) means water beads and rolls off perfectly. A rating of 50 means the fabric surface is completely wetted. This test measures surface repellency, not penetration.

Waterproofness is measured by hydrostatic head (ISO 811, AATCC 127). A column of water is pressurized against the fabric. The height of water (in millimeters) at which the fabric leaks is the hydrostatic head. A rating of 1,500mm means the fabric can withstand the pressure of a 1.5-meter column of water. General rainwear requires 1,500-3,000mm. High-performance storm shells require 10,000-20,000mm.

Critical point: A fabric can have excellent spray rating (surface beading) but zero waterproofness (water penetrates under pressure). This is typical of DWR-coated woven shells without a membrane. Conversely, a fabric can have excellent hydrostatic head but poor spray rating if the DWR is worn off. This is typical of older Gore-Tex garments.

For lightweight windbreakers, most consumers expect water resistance, not waterproofness. They want to walk in light rain without wetting out, but they do not expect to sit in a downpour for an hour. A 40D ripstop with a good PFC-free DWR and no membrane will typically have a hydrostatic head of 300-500mm. This is adequate for light showers. If you claim 'waterproof' on this fabric, you are misleading the customer and inviting returns.

We specify hydrostatic head testing on any fabric destined for rainwear claims. For a recent Scandinavian client, we developed a 30D nylon ripstop with a proprietary PU membrane laminate achieving 8,000mm hydrostatic head while maintaining 70 g/m² total weight. This is the current state of the art for lightweight waterproof breathable fabrics. The ISO 811:2018 standard is the definitive method for hydrostatic head measurement, and we include this data on all technical outerwear spec sheets.

Can I achieve durable water repellency without a high-temperature cure?

This is a practical problem for brands sourcing from factories without specialized finishing equipment. High-performance PFC-free DWRs require curing at 160-170°C for 60-90 seconds. Many garment factories and small-scale finishers do not have stenters capable of these temperatures. They apply the DWR, cure at 140°C, and wonder why the performance is poor.

The solution: If you are committed to PFC-free DWR, you must either:

- Source from a mill with appropriate finishing equipment, or

- Accept lower initial performance and durability, or

- Use fluorinated DWR.

We have invested in high-temperature stenters specifically for this reason. We can cure at 170°C with ±1.5°C tolerance across 2.2-meter width. This is not common in Keqiao. Most finishing plants cap at 150°C. If your brand requires genuine PFC-free performance, you must audit your supplier's finishing line or work with a specialist.

What Breathability Standards Matter for Active Use?

Breathability is the most oversimplified and misrepresented performance attribute in outerwear. A supplier claims 'breathable'. The buyer assumes this means the wearer will not sweat. The reality is far more complex.

Breathability in coated and laminated fabrics is measured by moisture vapor transmission rate (MVTR) . Common test methods:

-

ASTM E96 (Upright Cup) : Water vapor passes through fabric into a controlled environment. Results in g/m²/24hr. Inexpensive, widely available, but poorly correlates with wearer comfort.

-

ISO 11092 (Sweating Guarded Hotplate) : Measures Ret (evaporative resistance). Lower Ret = more breathable. This is the most physiologically relevant test. Ret < 6 is very breathable; Ret > 20 is non-breathable.

-

JIS L 1099 (Calcium Chloride method) : Common in Asia. Produces very high numbers that are not comparable to ASTM or ISO.

Here is the uncomfortable truth: Most lightweight windbreaker fabrics without membranes have extremely high breathability (Ret < 3). They are essentially windproof but not waterproof. Adding a waterproof PU membrane increases waterproofness dramatically but also increases Ret to 15-25. Adding a high-end ePTFE membrane (Gore-Tex, etc.) achieves Ret 6-10 with high waterproofness.

For lightweight, non-technical windbreakers, we do not recommend waterproof membranes. The trade-off in breathability, weight, and cost is not justified for urban use. A 30D ripstop with a high-quality PFC-free DWR and no membrane provides:

- Weight: 60 g/m²

- Water resistance: Spray rating 90-100

- Waterproofness: 400mm hydrostatic head

- Breathability: Ret < 3

- Cost: $2.80-$3.50/meter

For technical rain shells, a 2.5-layer laminate is the current standard. A 20D nylon face fabric, a microporous PU membrane, and a protective scrim or printed pattern. Weight: 80-100 g/m². Waterproofness: 8,000-15,000mm. Breathability: Ret 12-18. Cost: $6.00-$9.00/meter.

For high-performance alpine shells, 3-layer laminates with ePTFE or high-end PU membranes. Weight: 120-180 g/m². Waterproofness: 20,000mm+. Breathability: Ret < 10. Cost: $15.00-$25.00/meter.

We offer a 2.5-layer PU laminate developed in partnership with a Taiwanese membrane supplier. It achieves 10,000mm hydrostatic head and Ret 14 at 95 g/m². It is not Gore-Tex, but it costs 60% less. For a Canadian lifestyle brand, we adapted this laminate with a solution-dyed recycled polyester face. Their fall 2024 collection uses this fabric across 18 SKUs. The ISO 11092:2014 standard is the benchmark for thermal and water vapor resistance, and we require this data for any fabric marketed as 'high breathability'.

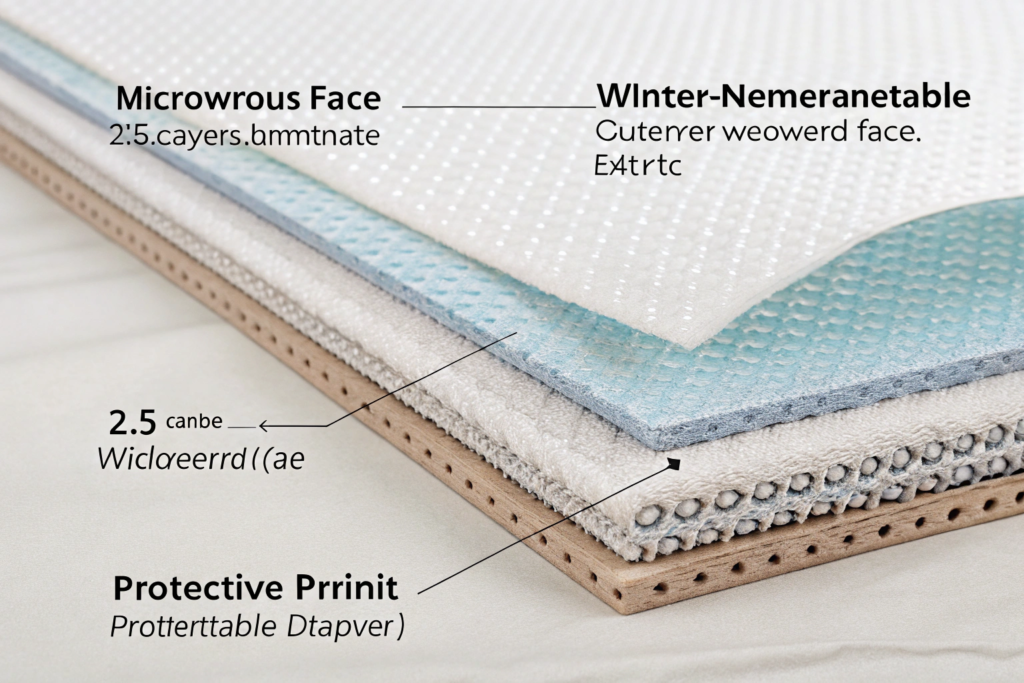

What is '2 layer', '2.5 layer', and '3 layer' construction?

This terminology confuses many buyers. Let me clarify with the actual engineering.

2-layer: Face fabric + membrane. The membrane is exposed on the back and must be protected by a separate lining. Used in rain jackets with mesh or taffeta liners. Heavier, bulkier, but more durable because the lining absorbs abrasion. Typical weight: 150-250 g/m².

2.5-layer: Face fabric + membrane + a thin protective layer (usually a printed pattern or a very lightweight scrim). No separate lining. The protective layer allows the jacket to be worn against skin or base layers without the membrane sticking or degrading. This is the standard for ultralight rain shells. Typical weight: 80-120 g/m².

3-layer: Face fabric + membrane + knitted or woven backer. All layers are permanently laminated. Most durable, best next-to-skin feel, highest cost. Used for alpine and professional use. Typical weight: 120-200 g/m².

We recommend: For most outdoor consumers, 2.5-layer is the optimal balance of weight, packability, and durability. For lifestyle brands seeking a premium feel, 3-layer is increasingly popular despite the higher cost.

Is 'breathable' the same as 'air permeable'?

No. This is a critical distinction. Air permeability (ASTM D737, ISO 9237) measures the flow of air through the fabric. A windbreaker must have low air permeability; otherwise, it does not block wind. Typical target: < 5 cfm (cubic feet per minute) or < 25 L/m²/s.

Breathability (MVTR, Ret) measures the transport of water vapor. This is a different physical mechanism. A fabric can be completely windproof (0 cfm) and still highly breathable. This is the ideal.

When a buyer asks for 'breathable windbreaker fabric', they want low air permeability and low Ret. This is technically challenging. Most waterproof membranes achieve low air permeability (they are windproof) but have moderate to high Ret. The solution is often a microporous coating or hydrophilic non-porous membrane that allows vapor diffusion while blocking convective air flow.

We have developed a 40D polyester taslan with a microporous acrylic coating that achieves air permeability < 3 cfm and Ret < 8. It is not fully waterproof (1,500mm hydrostatic head), but it is highly wind resistant and reasonably breathable. Several Chinese domestic outdoor brands use this construction for spring/autumn soft shells. The ASTM D737 standard is the reference for air permeability, and we include this data on all wind-resistant fabric spec sheets.

What Certifications and Testing Are Essential for Outdoor Fabrics?

Outerwear fabrics face more rigorous testing than most apparel categories. The combination of technical performance claims and harsh use environments creates significant liability. If a jacket is marketed as 'waterproof' and leaks, the brand faces returns, negative reviews, and potential regulatory action for deceptive advertising.

Essential tests for lightweight outerwear:

1. Hydrostatic head (ISO 811) . Required for any waterproof claim. Minimum 1,500mm for 'water resistant', 5,000mm+ for 'waterproof'. We test every production roll for waterproof laminates.

2. Spray rating (AATCC 22) . Required for DWR performance. Initial rating and after 5, 10, 20 washes. We provide wash durability curves for all DWR-treated fabrics.

3. Tear strength (ISO 13937) . Critical for ultralight fabrics. Minimum 10N for 10D fabrics, 15N+ for 20D+. We reject any fabric that tears below spec.

4. Pilling resistance (ISO 12945) . Lightweight synthetics can pill badly under backpack strap abrasion. We require minimum Grade 4 for outerwear face fabrics.

5. Lightfastness (ISO 105-B02) . For outdoor use, minimum 4.0 (blue wool scale). Many solution-dyed fabrics achieve 5.0+.

6. Dimensional stability (ISO 5077) . After washing and drying, maximum 3% shrinkage. Tighter is better.

7. Seam slippage (ISO 13936) . For woven shells, maximum 3mm at 120N. Seams must hold under load.

Optional but recommended:

8. Bursting strength (ISO 13938) . For knitted shells and stretch wovens. Simulates knee and elbow pressure.

9. Abrasion resistance (Martindale, Wyzenbeek) . For high-wear areas. Not always relevant for ultralight shells.

10. CLO value / thermal resistance (ISO 11092) . For insulated or wind-resistant garments.

Certifications:

bluesign® APPROVED. This is the gold standard for chemical management in outdoor textiles. It restricts harmful substances at the input stage, not just the output stage. A bluesign certified fabric is safer for workers, consumers, and the environment. We have 47 bluesign certified fabrics in our outerwear collection. The certification process is rigorous and expensive, but it is increasingly required by European outdoor brands.

Oeko-Tex Standard 100. More common, less stringent than bluesign. Acceptable for many lifestyle applications.

GRS (Global Recycled Standard). For recycled polyester and nylon shells. Essential for sustainability claims.

GOTS. For organic cotton shells (rare in high-performance outerwear but used in lifestyle segments).

In 2023, a German outdoor brand audited our facility for bluesign compliance. They spent three days reviewing our chemical inventory, wastewater treatment, and worker safety protocols. We passed. They now source approximately 1.2 million meters annually from us. The bluesign system website has a searchable database of certified partners, and we encourage any brand serious about sustainability to verify their suppliers there.

What is 'solution dyed' fabric and why does it matter for outerwear?

Solution dyeing, also called dope dyeing or spun dyeing, adds pigment to the polymer melt before the fiber is extruded. This is fundamentally different from piece dyeing (dyeing the finished fabric) or yarn dyeing.

Advantages for outerwear:

-

Excellent colorfastness. The pigment is throughout the fiber, not just on the surface. Lightfastness ratings of 5.0+ are routine. Fading is minimal even after years of UV exposure.

-

No water, no effluent. Piece dyeing consumes 30-60 liters of water per kilogram of fabric. Solution dyeing consumes almost zero. The carbon footprint is significantly lower.

-

Lot-to-lot color consistency. No dye lot variation. Critical for brands that reorder the same color annually.

-

Dye lot free. You can order 500 meters today and 5,000 meters next year, and the color will match perfectly.

Disadvantages:

-

Minimum order quantities. We require 3,000-5,000 kg per color for solution-dyed yarn production. This is 15,000-25,000 meters of lightweight shell fabric. Not suitable for small brands.

-

Limited color range. Specialty pigments are required. Fluorescents, neons, and certain bright shades are difficult or impossible.

-

Longer lead time. Custom colors require 8-10 weeks for yarn production and qualification.

-

Higher cost. Approximately 15-25% premium over piece-dyed equivalent for virgin polymer. The gap narrows for recycled polymer.

We offer a solution-dyed recycled polyester ripstop collection in 30D and 50D weights. Standard colors: black, navy, dark green, burgundy, charcoal. Custom colors available with 5,000kg MOQ. This collection is popular with European outdoor brands targeting zero liquid discharge and circular economy goals. The Textile Exchange's guide to preferred dyeing methods provides comparative environmental data on solution dyeing vs. conventional methods.

How do I verify that a 'windproof' fabric actually stops wind?

The test is air permeability (ASTM D737, ISO 9237). A fabric is considered windproof if air permeability is less than 5 cfm (cubic feet per minute) or less than 25 L/m²/s at 100 Pa pressure differential.

Some suppliers claim 'windproof' based on subjective hand feel. This is meaningless. We have tested 180gsm fleece that feels solid but has air permeability of 200 cfm. It is a wind tunnel.

We include air permeability data on every outerwear fabric spec sheet. For a recent Italian sportswear client, we developed a 40D polyester microfiber suede with a laminated PU membrane that achieved 0 cfm—completely windproof. The client marketed this as 'gale force tested'. We provided the test report to support the claim.

If your supplier cannot provide an air permeability test report, your fabric is not certified windproof.

Conclusion

Lightweight outerwear is not a category for generalist suppliers. The tolerances are tight, the performance requirements are unforgiving, and the regulatory landscape is shifting beneath our feet. A 10D ripstop that tears at 8N is not acceptable. A DWR that fails after two washes is not acceptable. A waterproof claim without hydrostatic head data is not acceptable.

At Shanghai Fumao, we have invested specifically in the equipment, yarn supply partnerships, and testing infrastructure required to serve this demanding category. We do not offer 'lightweight outerwear' as an afterthought to our bedding sheeting business. It is a dedicated product group with dedicated technical sales staff. We maintain inventory of high-tenacity nylon 6,6 yarns. We have qualified PFC-free DWR formulations. We run hydrostatic head and air permeability testing in-house on every production lot.

If you are developing a windbreaker, a rain shell, or an ultralight packable jacket, I invite you to challenge us. Send us your target weight, your target hydrostatic head, your sustainability requirements. We will send you a specification with test data, not marketing language. We will tell you if your requirements are achievable, and if they are not, we will tell you what is.

Contact Elaine, our Business Director, to discuss your outerwear fabric project. Elaine manages our technical textiles division and has personally overseen the development of over 200 outerwear fabrics for brands in North America, Europe, and Asia. Elaine's email is: elaine@fumaoclothing.com. Tell her what weather you need to block.