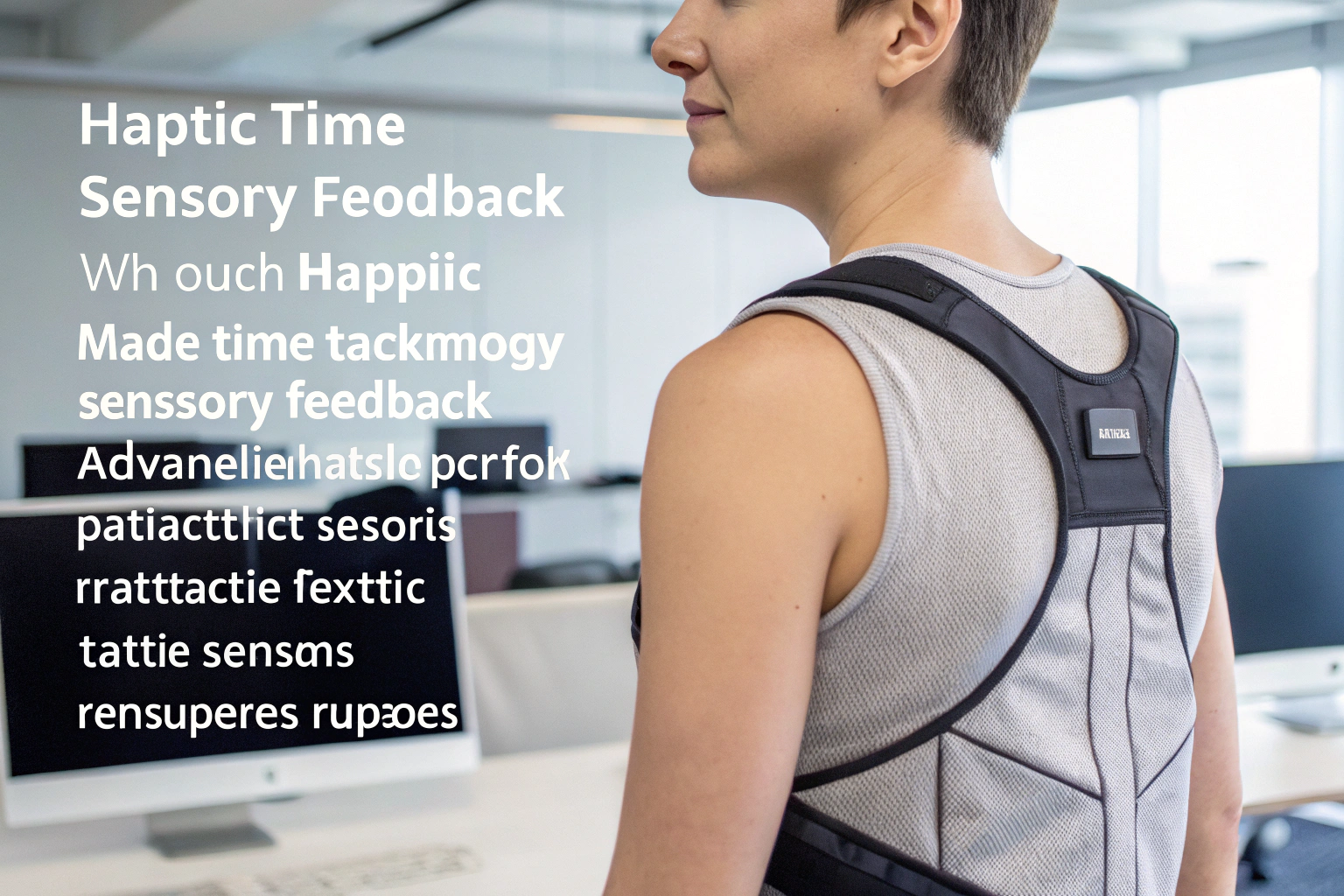

Wearable technology is no longer just about fitness trackers or smartwatches. It's entering the realm of real-time sensory feedback—transforming how we interact with devices through haptic feedback fabrics. But here lies the challenge: How do you choose a textile that’s comfortable, durable, and also responsive to vibration, pulse, or tactile stimuli?

The best fabrics for haptic feedback in wearables are those that combine comfort, flexibility, conductivity, and durability—such as conductive knits, silver-plated yarns, and elastomeric blends.

If you’re a developer, brand buyer, or tech innovator seeking to scale wearable products, understanding which fabrics support precise, stable haptic feedback will save you from poor prototypes and user dissatisfaction. This article breaks down top choices based on real-world lab performance and sourcing viability.

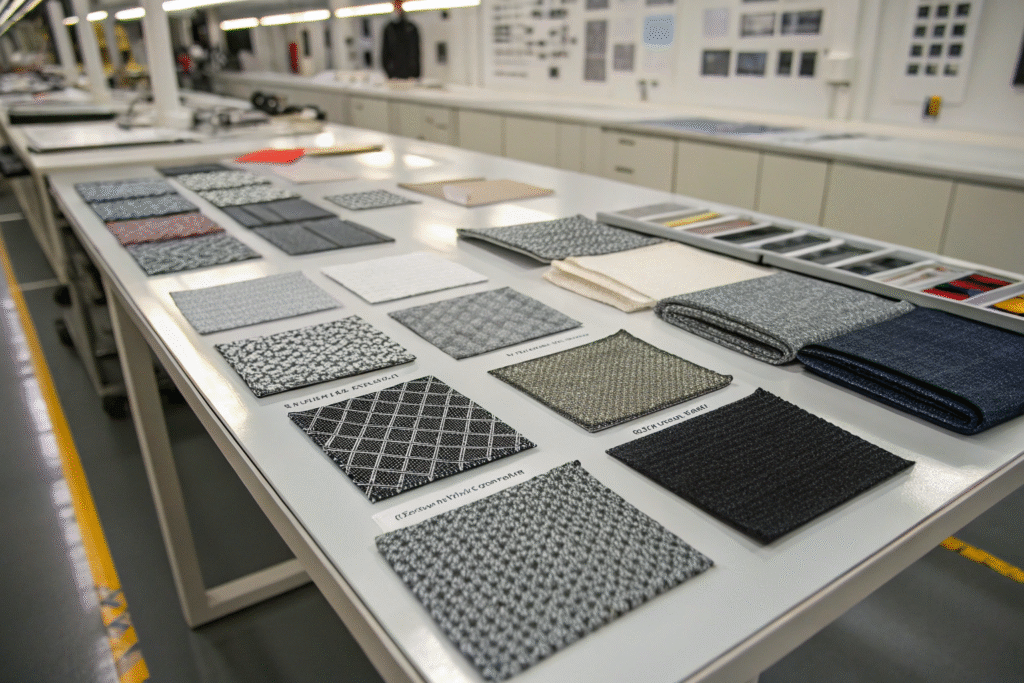

Which Fabrics Offer Optimal Conductivity for Haptic Integration?

As haptic feedback depends on electrical impulses or actuators within the fabric, conductivity becomes the #1 priority. Traditional fabrics like cotton or polyester need to be modified or blended with conductive components.

Silver-coated knits, carbon-embedded fabrics, and conductive polymers are currently the most effective materials for ensuring stable, low-resistance electrical conductivity in wearables.

What Are the Advantages of Silver-Plated Nylon or Polyester?

Silver-plated textiles are the gold standard (pun intended) when it comes to wearable conductivity. They offer excellent electrical transmission, are skin-safe, and can be knitted or woven into elastic blends.

For example, Shieldex® Silver Fabrics are widely used in health sensors and heated garments. LessEMF’s conductive fabrics are also go-to solutions for prototyping soft circuits.

Can Carbon-Based Fabrics Be Used for Soft Actuators?

Yes. Fabrics infused with carbon nanotubes or graphene are ideal for soft robotics and localized vibration feedback due to their light weight and responsiveness.

Products like Graphene Tex™ or Zorflex® are used in flexible electronic apparel, where consistent conductivity and skin-conformance are essential.

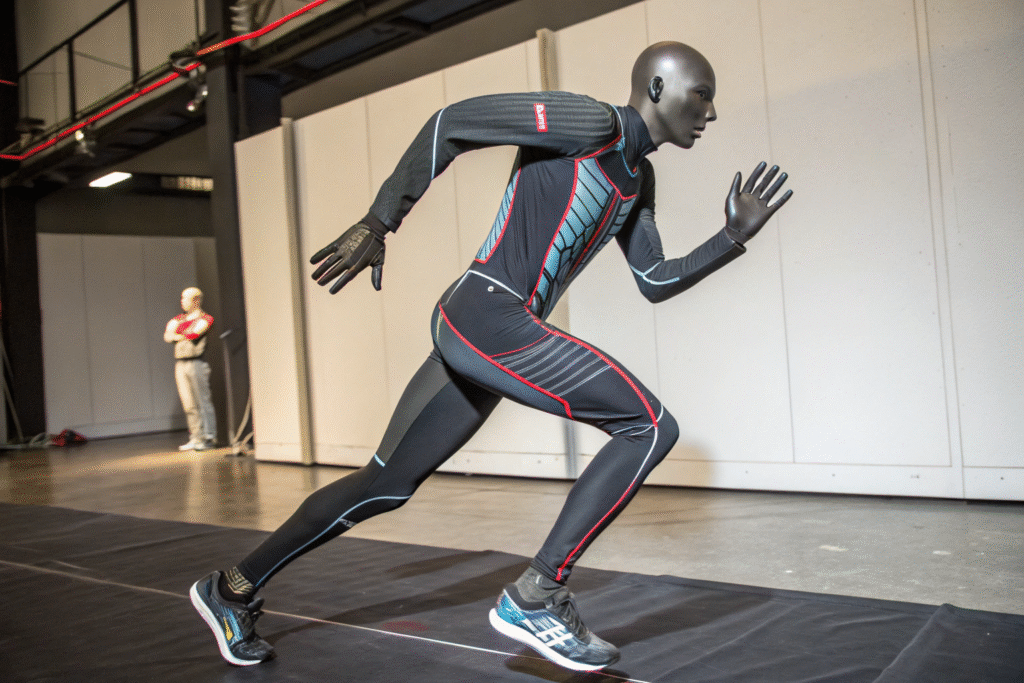

How Important Is Stretch and Drape for Comfort in Smart Fabrics?

Conductivity alone isn’t enough—especially if the fabric is stiff or bulky. For wearable haptics, the drape, stretch, and recovery of the fabric will determine user comfort and sensor alignment.

Spandex blends, warp-knit jerseys, and bi-stretch fabrics allow embedded actuators or vibration motors to remain in contact with the skin during movement.

Why Are Knitted Structures Better for Skin-Contact Haptics?

Knits naturally stretch and contour to the body, providing better tactile coupling between the actuator and the skin. Interlock knits and spacer fabrics are commonly used in gloves, shirts, and compression bands.

Check out Eeonyx’s e-textile knits or Textronics’ stretch sensors for wearable applications that require signal consistency during movement.

Can Elastomer-Coated Fabrics Improve Device Fit?

Yes. Elastomer coatings (like polyurethane or silicone-based finishes) offer moisture resistance, increased elasticity, and durable stretch recovery, ideal for wearables used in sports or healthcare.

Brands like StretchSense integrate these coatings with fiber-optic sensing for motion feedback. Also, Nanotex® provides hydrophobic performance with flexible finishes for stretchable techwear.

Which Fabrics Withstand Repeated Vibration and Washing?

The key to long-term wearable success is durability. Many conductive fabrics lose functionality after 10+ wash cycles or repetitive actuator use.

Durable haptic fabrics must resist abrasion, moisture, and mechanical fatigue—making them suitable for real-world, long-term usage.

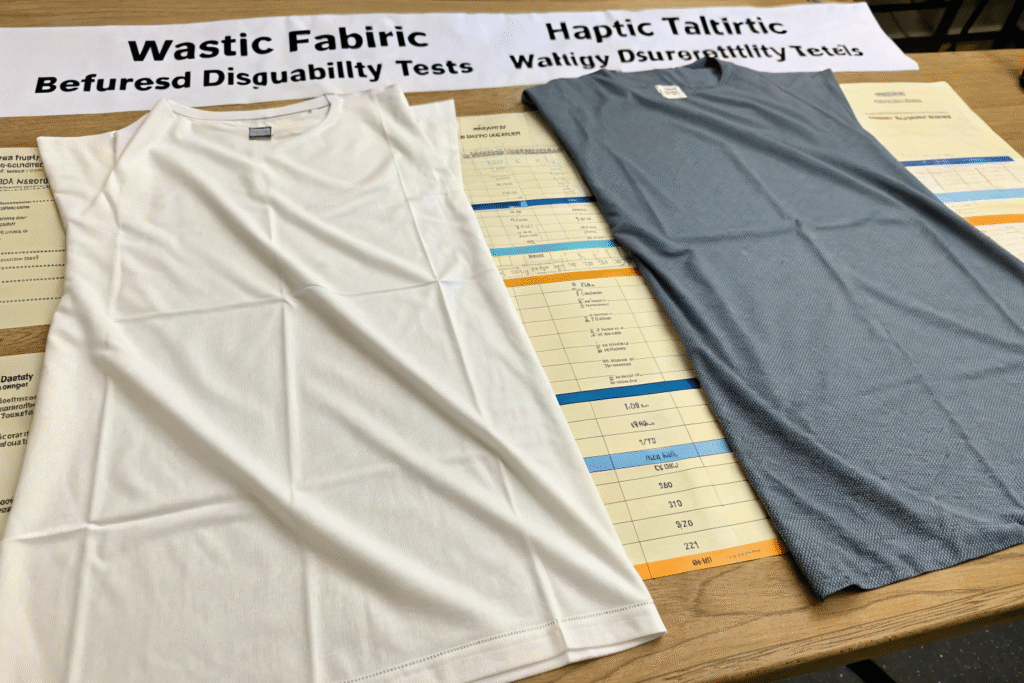

What Test Standards Apply to Haptic Fabric Durability?

Testing standards such as AATCC 135 (wash durability) and ISO 12947 (abrasion resistance) are widely used. These tests determine whether the fabric maintains conductivity and mechanical integrity over time.

You can refer to AATCC's test methods or Intertek’s textile performance services to ensure your fabric meets the necessary benchmarks.

Are There Any Coatings That Help Retain Conductivity After Washing?

Yes, encapsulation layers using TPU or PU membranes can protect conductive paths from moisture and detergent. These coatings are thin, breathable, and allow for flexible circuit protection.

Advanced materials from Bemis Associates and DowSil’s silicone encapsulants are popular in performance sportswear with integrated haptics.

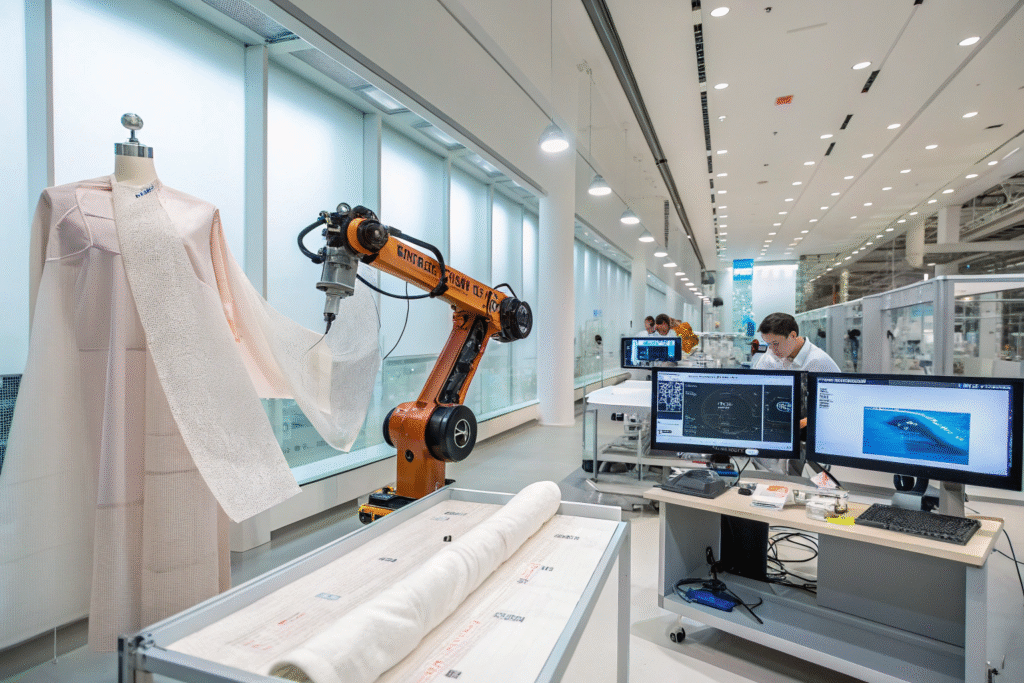

What Are Emerging Fabrics in Haptic Research and Prototypes?

While the market already has commercial-ready options, researchers are now exploring next-gen fabrics that can do more—such as changing stiffness, emitting localized feedback, or responding to gestures.

The future lies in hybrid fabrics—blending piezoelectric fibers, hydrogel sensors, and machine-learning actuated haptic zones.

What Role Does Piezoelectric Fiber Play in Future Haptics?

Piezoelectric materials generate electric signals under stress and can also deform under voltage—allowing fabrics to both sense and actuate.

Innovators like PiezoTex™ and MIT Media Lab are developing piezo-fabric interfaces that respond to body pressure or posture changes in real time.

Are AI-Powered Feedback Systems Changing Fabric Requirements?

Absolutely. AI models now optimize when and where to deliver feedback based on biometric patterns. This requires fabrics to be highly responsive and zoned, supporting localized vibration or pulse.

Check out Wearable Robotics Lab or EIT Smart Textiles for examples of real-time fabric response systems driven by haptics + AI.

Conclusion

Choosing the right fabric for haptic feedback wearables is a delicate balance between electrical conductivity, flexibility, comfort, and long-term durability. From silver-coated nylon to AI-responsive smart textiles, innovation in this field is moving fast—but the key remains practical sourcing and reliable lab performance.

At Fumao Fabric, we stay ahead by working with leading textile researchers and sourcing partners to develop wearable-grade fabrics for global buyers. Whether you're building a new line of smart gloves, vests, or posture belts, we can assist with custom sampling, durability testing, and ISO-standardized production. For collaboration, reach out to our Business Director Elaine at elaine@fumaoclothing.com—let’s bring haptic textiles to life.

203 Responses

This is the correct blog for anyone who wants to find out about this topic. You notice so much its virtually arduous to argue with you (not that I really would need…HaHa). You undoubtedly put a brand new spin on a topic thats been written about for years. Great stuff, just nice!

code promo melbet du jour telecharger melbet apk

site web 1win gratuit 1win telecharger

Производим пластиковые https://zavod-dimax.ru окна и выполняем профессиональную установку. Качественные материалы, точные размеры, быстрый монтаж и гарантийное обслуживание для комфорта и уюта в помещении.

Жалюзи от производителя https://balkon-pavilion.ru изготовление, продажа и профессиональная установка. Большой выбор дизайнов, точные размеры, надёжная фурнитура и комфортный сервис для квартир и офисов.

Изделия из пластмасс https://ftk-plastik.ru собственного производства. Продажа оптом и в розницу, широкий ассортимент, надёжные материалы и стабильные сроки. Выполняем заказы любой сложности по техническому заданию клиента.

Производство оборудования https://repaircom.ru с предварительной разработкой и адаптацией под требования клиента. Качественные материалы, точные расчёты, соблюдение сроков и техническая поддержка.

Торговая мебель https://woodmarket-for-business.ru от производителя для бизнеса. Витрины, стеллажи, островные конструкции и кассовые модули. Индивидуальный подход, надёжные материалы и практичные решения для продаж.

Szukasz kasyna? polskie kasyno w Polsce: wybor najlepszych stron do gry. Licencjonowane platformy, popularne sloty i kasyna na zywo, wygodne metody platnosci, uczciwe warunki i aktualne oferty.

Grasz w kasynie? Kasyno pl w Polsce to najlepsze miejsca do gry w latach 2025–2026. Zaufane strony, sloty i gry na zywo, przejrzyste warunki, wygodne wplaty i wyplaty.

Ищешь блины для штанки? резиновые блины для штанги для эффективных силовых тренировок. Чугунные и резиновые диски, разные веса, долговечность и удобство использования. Решение для новичков и опытных спортсменов.

Производим торговую мебель https://woodmarket-for-business.ru для розничного бизнеса и сетевых магазинов. Функциональные конструкции, современный дизайн, точные размеры и полный цикл работ — от проекта до готового решения.

Оборудование для отопления https://thermostock.ru и водоснабжения: котлы, циркуляционные насосы, радиаторы, мембранные баки и комплектующие от ведущих производителей. Что вы получаете: сертифицированные товары, прозрачные цены, оперативную обработку заказа. Создайте комфортный микроклимат в доме — выбирайте профессионалов!

Нужен памятник? заказать памятник в уфе — гранитные и мраморные изделия. Индивидуальные проекты, точная обработка камня, оформление и монтаж. Надёжное качество и внимательное отношение к деталям.

Нужен памятник? памятник уфа — гранитные и мраморные изделия. Индивидуальные проекты, точная обработка камня, оформление и монтаж. Надёжное качество и внимательное отношение к деталям.

Нужно авто? покупка автомобиля через аукцион поиск, проверка, оформление и доставка авто из разных стран. Прозрачные условия, помощь на всех этапах и сопровождение сделки до получения автомобиля.

дизайн квадратной студии авторское курирование

Нужен памятник? заказать памятник в уфе — гранитные и мраморные изделия. Индивидуальные проекты, точная обработка камня, оформление и монтаж. Надёжное качество и внимательное отношение к деталям.

Нужен проектор? https://projector24.ru/ большой выбор моделей для дома, офиса и бизнеса. Проекторы для кино, презентаций и обучения, официальная гарантия, консультации специалистов, гарантия качества и удобные условия покупки.

Do you need repairs? Home services Philadelphia professional help for apartments and private homes. Plumbing, electrical, minor and medium-sized repairs, finishing work, and equipment installation. High-quality, accurate, and on-time services.

Проблемы с авто? автоэлектрик фольксваген спб диагностика, ремонт электрооборудования, блоков управления, освещения и систем запуска. Опыт, современное оборудование и точное определение неисправностей.

Celebrity World Care https://celebrityworldcare.com интернет-магазин профессиональной медицинской и натуральной косметики для ухода за кожей при ихтиозе, дерматитах, псориазе и других дерматологических состояниях. Сертифицированные средства с мочевиной, без отдушек и парабенов. Доставка по России.

купить 1 комнатную квартиру жк светский лес сочи застройщик

химчистка обуви недорого отдать обувь в химчистку

Модульные дома https://modulndom.ru под ключ: быстрый монтаж, продуманные планировки и высокое качество сборки. Подходят для круглогодичного проживания, отличаются энергоэффективностью, надежностью и возможностью расширения.

Медсправка для замены водительских прав https://med-spravki-msk.ru

Специализированный коррекционно-речевой https://neyroangel.ru детский сад для детей с особенностями развития в Москве. Беремся за самые тяжелые случаи, от которых отказываются другие. Нейропсихолог, логопед, запуск речи. Государственная лицензия: Л035-01298-77/01604531 от 09.12.24

Рэмси Диагностика: https://remsi-med.ru Сеть высокотехнологичных диагностических центров (МРТ, КТ). Точные исследования на оборудовании экспертного класса и качественная расшифровка снимков.

Детский Доктор: https://kidsmedic.ru Специализированный медицинский центр для детей. Квалифицированная помощь педиатров и узких специалистов для здоровья вашего ребенка с первых дней жизни.

Полесская ЦРБ: https://polesskcrb.ru Официальный портал центральной районной больницы Калининградской области. Информация об услугах, расписание врачей и важные новости здравоохранения для жителей региона.

обзор проекторов интернет-магазин проекторов

АрсМед: https://arsmedclinic.ru Многопрофильная клиника, предлагающая широкий выбор медицинских услуг от диагностики до лечения. Современный подход и комфортные условия для пациентов всех возрастов.

Играешь в казино? upx простой вход, удобная регистрация и доступ ко всем возможностям платформы. Стабильная работа, адаптация под разные устройства и комфортный пользовательский опыт.

Любишь азарт? up-x играть онлайн в популярные игры и режимы. Быстрый вход, удобная регистрация, стабильная работа платформы, понятный интерфейс и комфортные условия для игры в любое время на компьютере и мобильных устройствах.

Любишь азарт? up x казино играть онлайн легко и удобно. Быстрый доступ к аккаунту, понятная навигация, корректная работа на любых устройствах и комфортный формат для пользователей.

Play online puzzles https://developers.googleblog.com/21-websites-and-apps-to-make-your-2021-better/ anytime and train your logic and attention skills. Classic and themed puzzles, various sizes, simple gameplay, and comfortable play on computers and mobile devices.

люстра потолочная деревянная люстра

мужские костюмы спб купить недорогой классический мужской костюм

Электромонтажные работы https://electric-top.ru в Москве и области. Круглосуточный выезд электриков. Гарантия на работу. Аварийный электрик.

коррозия у авто? антикор сервис в СПб эффективная защита от влаги, соли и реагентов. Комплексная обработка кузова и днища, качественные составы и надёжный результат для новых и подержанных авто.

Коррозия на авто? антикоррозийная обработка цена мы используем передовые шведские материалы Mercasol и Noxudol для качественной защиты днища и скрытых полостей кузова. На все работы предоставляется гарантия сроком 8 лет, а цены остаются доступными благодаря прямым поставкам материалов от производителя.

Планируете мероприятие? мероприятия с нейросетями уникальные интерактивные форматы с нейросетями для бизнеса. Мы разрабатываем корпоративные мероприятия под ключ — будь то тимбилдинги, обучающие мастер?классы или иные активности с ИИ, — с учётом ваших целей. Работаем в Москве, Санкт?Петербурге и регионах. AI?Event специализируется на организации корпоративных мероприятий с применением технологий искусственного интеллекта.

Украшения для пирсинга https://piercing-opt.ru купить оптом украшения для пирсинга. Напрямую от производителя, выгодные цены, доставка. Отличное качество.

Ищешь сокращатель сылок? https://l1l.kz надежный сокращатель ссылок в Казахстане, рекомендуем заглянуть на сайт, где весь функционал доступен бесплатно и без регистрации

Противопожарные двери https://bastion52.ru купить для защиты помещений от огня и дыма. Большой выбор моделей, классы огнестойкости EI30, EI60, EI90, качественная фурнитура и соответствие действующим стандартам.

Нужны цветы? доставка цветов закажите цветы с доставкой на дом или в офис. Большой выбор букетов, свежие цветы, стильное оформление и точная доставка. Подойдёт для праздников, сюрпризов и важных событий.

O’zbekiston uchun https://uzresearch.uz iqtisodiyot, moliya, ijtimoiy jarayonlar, bozorlar va mintaqaviy rivojlanish kabi asosiy sohalarda tadqiqotlar olib boradigan analitik platforma. Strukturaviy ma’lumotlar va professional tahlil.

Savdo va biznes https://infinitytrade.uz uchun xalqaro platforma. Bozor tahlili, xalqaro savdo, eksport va import, logistika, moliya va biznes yangiliklari. Tadbirkorlar va kompaniyalar uchun foydali materiallar, sharhlar va ma’lumotlar.

Ijtimoiy rivojlanish https://ijtimoiy.uz va jamoat hayoti uchun portal. Yangiliklar, tahlillar, tashabbuslar, loyihalar va ekspert fikrlari. Ijtimoiy jarayonlar, fuqarolik ishtiroki, ta’lim va jamiyatni rivojlantirish bo’yicha materiallar.

Foydali maslahatlar https://grillades.uz va g’oyalar bilan panjara va barbekyu haqida loyiha. Retseptlar, panjara qilish texnikasi va jihozlar va aksessuarlarni tanlash. Mukammal ta’m va muvaffaqiyatli ochiq havoda uchrashuvlar uchun hamma narsa.

Qurilish materiallari https://emtb.uz turar-joy va sanoat qurilishi uchun beton va temir-beton. Poydevorlar, pollar va inshootlar uchun ishonchli yechimlar, standartlarga muvofiqlik, izchil sifat va loyihaga xos yetkazib berish.

Ijtimoiy jarayonlar https://qqatx.uz va jamiyat taraqqiyoti bo’yicha onlayn axborot platformasi. Tegishli materiallar, tahliliy sharhlar, tadqiqotlar va murakkab mavzularning tushuntirishlari aniq va tuzilgan formatda.

Любишь азарт? зеркало комета казино современные слоты, live-форматы, понятные правила и удобный доступ с ПК и смартфонов. Играйте онлайн в удобное время.

Лучшее казино up x официальный играйте в слоты и live-казино без лишних сложностей. Простой вход, удобный интерфейс, стабильная платформа и широкий выбор игр для отдыха и развлечения.

Играешь в казино? ап икс казино Слоты, рулетка, покер и live-дилеры, простой интерфейс, стабильная работа сайта и возможность играть онлайн без сложных настроек.

Лучшее казино up x казино играйте в слоты и live-казино без лишних сложностей. Простой вход, удобный интерфейс, стабильная платформа и широкий выбор игр для отдыха и развлечения.

Играешь в казино? t.me Слоты, рулетка, покер и live-дилеры, простой интерфейс, стабильная работа сайта и возможность играть онлайн без сложных настроек.

Spiele jetzt Beliebte Online Slots wie Columbus Deluxe und erlebe das aufregende Ambiente eines virtuellen Casinos. Von klassischen Tischspielen bis hin zu modernen Spielautomaten ist fur jeden Geschmack etwas dabei. Genie?e die bequemen Spielmoglichkeiten von zu Hause aus und entdecke die Welt des Glucksspiels online.

Русские подарки и сувениры купить в широком ассортименте. Классические и современные изделия, национальные символы, качественные материалы и оригинальные идеи для памятных и душевных подарков.

Нужно казино? up x официальный современные игры, простой вход, понятный интерфейс и стабильная работа платформы. Играйте с компьютера и мобильных устройств в любое время без лишних сложностей.

магазин ремней ремни.рф оригинальные модели из натуральной кожи для мужчин и женщин. Классические и современные дизайны, высокое качество материалов, аккуратная фурнитура и удобный выбор для любого стиля.

Самые качественные блины для штанги под заказ широкий выбор весов и форматов. Надёжные материалы, удобная посадка на гриф, долговечное покрытие. Подходят для фитнеса, пауэрлифтинга и регулярных тренировок.

Нужна топливная карта? топливные карты для юридических лиц удобный контроль расходов на ГСМ, безналичная оплата топлива, отчетность для бухгалтерии и снижение затрат автопарка. Подключение по договору, выгодные условия для бизнеса.

Хочешь контролировать ГСМ https://bts-oil.ru экономия на топливе, контроль заправок, детальная аналитика и закрывающие документы. Решение для компаний с собственным или арендованным автопарком.

Топливный контроль топливные карты для юр лиц эффективное решение для бизнеса с транспортом. Безналичная заправка, учет топлива, детальные отчеты и удобное управление расходами по каждому автомобилю.

Контроль топлива https://ztm74.ru удобный способ учета и оплаты топлива без наличных. Контроль заправок, лимиты по авто и водителям, отчетность для бухгалтерии и снижение затрат на содержание автопарка.

Топливные карты для юр лиц https://mazdacenter.ru контроль топлива, прозрачная отчетность, удобство для бухгалтерии и безопасность расчетов. Экономия времени и средств при управлении корпоративным транспортом.

Онлайн-казино Mostbet — слоты, настольные игры и live-дилеры в одном аккаунте. Удобные депозиты, оперативный вывод средств, бонусные предложения и игра с любого устройства.

Learn More: https://telegra.ph/modele-xg–utiliser-les-stats-avancees-pour-gagner-01-14

Today’s highlights are here: over here

A sports portal https://sbs-sport.com.az/ with breaking news, statistics, and expert commentary. Match schedules, transfers, interviews, and competition results are available in real time.

Live match sporx com az results, the latest sports news, transfers, and today’s TV schedule. Live updates, key events, and all sports information in one portal.

Учишься в МТИ? экзамены мти помощь: консультации, разъяснение сложных тем, подготовка к тестированию и экзаменам. Удобный формат, быстрые ответы и поддержка на всех этапах обучения.

Zinedine Zidane zidan.com.az/ biography, football career, achievements, and coaching successes. Details on his matches, titles, the French national team, and his time at the top clubs in world football.

Нужна курсовая? купить курсовую Подготовка работ по заданию, методическим указаниям и теме преподавателя. Сроки, правки и сопровождение до сдачи включены.

Авиабилеты по низким ценам https://tutvot.com посуточная аренда квартир, вакансии без опыта работы и займы онлайн. Актуальные предложения, простой поиск и удобный выбор решений для путешествий, работы и финансов.

Нужен тепловизор? тепловизоры купить в санкт петербрурге для судов, лодок, кораблей, яхт и катеров от производителя: доступные цены, подтверждённое качество и официальная гарантия. Мы оперативно доставляем заказы по всей территории России и стран СНГ. Наши представительства работают в Санкт?Петербурге, Москве и Севастополе — выбирайте удобный пункт выдачи и получайте заказ в минимальные сроки.

заклепка вытяжная 3.2 заклепки вытяжные

Переходите сюда на ссылка на маркетплейс кракен официальная с ежедневной проверкой

Нужна топлевная крата? https://oilguru.ru: заправка на сетевых АЗС, единый счет, прозрачный учет топлива и онлайн-контроль расходов. Удобное решение для компаний с собственным автопарком.

Русские подарки купить в интернет-магазине Москвы: сувениры, ремесленные изделия и подарочные наборы с национальным колоритом. Идеальные решения для праздников, гостей и корпоративных подарков.

Today’s Top Stories: modern, luxury wedding photography in the heart of miami

По дому cleaninglviv.top зручно

ДВС и КПП https://vavtomotor.ru автозапчасти для автомобилей с гарантией и проверенным состоянием. В наличии двигатели и коробки передач для популярных марок, подбор по VIN, быстрая доставка и выгодные цены.

All the Details: https://www.upguard.com/instant-security-score/report?c=cite-architecture.org

дизайн деревянного дома дизайн коттеджа

Do you do music? music sub plans for children and aspiring musicians. Educational materials, activities, and creative coloring pages to develop ear training, rhythm, and an interest in music.

накрутка лайков инстаграми накрутка подписчиков инстаграм

дизайн маленькой квартиры 2 х комнатная дизайн

Лучшие и безопасные подземные противопожарные резервуары эффективное решение для систем пожарной безопасности. Проектирование, производство и монтаж резервуаров для хранения воды в соответствии с требованиями нормативов.

Слив курсов ЕГЭ физика https://courses-ege.ru

Подземные резервуары гост https://underground-reservoirs.ru

Лучшее казино https://download-vavada.ru слоты, настольные игры и live-казино онлайн. Простая навигация, стабильная работа платформы и доступ к играм в любое время без установки дополнительных программ.

Играешь в казино? https://freespinsbonus.ru бесплатные вращения в слотах, бонусы для новых игроков и действующие акции. Актуальные бонусы и предложения онлайн-казино.

полотенцесушитель маргроид купить полотенцесушитель

Фриспины бесплатно фриспины без депозита бесплатные вращения в онлайн-казино без пополнения счета. Актуальные предложения, условия получения и список казино с бонусами для новых игроков.

События в мире сайт сми события дня и аналитика. Актуальная информация о России и мире с постоянными обновлениями.

Тренды в строительстве заборов https://otoplenie-expert.com/stroitelstvo/trendy-v-stroitelstve-zaborov-dlya-dachi-v-2026-godu-sovety-po-vyboru-i-ustanovke.html для дачи в 2026 году: популярные материалы, современные конструкции и практичные решения. Советы по выбору забора и правильной установке с учетом бюджета и участка.

Отвод воды от фундамента https://totalarch.com/kak-pravilno-otvesti-vodu-ot-fundamenta-livnevka-svoimi-rukami-i-glavnye-zabluzhdeniya какие системы дренажа использовать, как правильно сделать отмостку и избежать подтопления. Пошаговые рекомендации для частного дома и дачи.

Trying to figure out the right approach? Look for providers with responsive support and transparent pricing—those factors help you buy tiktok views safely every time.

Халява в казино фриспины за регистрацию Бесплатные вращения в популярных слотах, актуальные акции и подробные условия использования.

косметология красоты косметология москва цены

привітання з днем ангела романа своїми словами

Общество экспертов России по недропользованию – профессиональная платформа для подтверждения статуса и компетенций специалистов по экспертизе недр. Платформа позволяет найти эксперта по профилям ТПИ, нефть и газ, геология и ГРР – и снизить риски при согласовании отчётов и отчётов в тендерах, ОЭРН и министерство природных ресурсов

Казино Кактус онлайн подходит для тех кто ценит скорость и бонусы. Регистрация не занимает много времени. Вход доступен круглосуточно. Заходи и начинай играть: cactus казино зеркало

накрутка подписчиков в тг накрутка подписчиков твич

Казино Куш онлайн это быстрый доступ к азартным играм. Регистрация и вход максимально простые. Бонусы доступны сразу. Попробуй уже сегодня: казино куш вход

Занимаешься спортом? https://bliny-trenirovochnye.ru диски для пауэрлифтинга, бодибилдинга и фитнеса. Прочные покрытия, стандартные размеры и широкий выбор весов.

Мы предлагаем комплексные решения по оснащению складов паллетными системами хранения. Фронтальные и глубинные стеллажи проектируются с учетом интенсивности грузооборота и характеристик паллет. Производство осуществляется под заказ. Готовые системы легко масштабируются при расширении склада: https://www.met-izdeliya.com/

Осваиваешь арбитраж? https://corsairmedia.ru поможет разобраться в инструментах, выбрать первую партнерку и избежать типичных ошибок новичков. Подробные обзоры от практиков: плюсы, минусы и реальные цифры заработка без воды.

Лучшее онлайн казино? https://pokerinfo.ru/download/index.html онлайн-покер, турниры и кэш-игры для игроков разного уровня. Удобный интерфейс, доступ с ПК и мобильных устройств, регулярные события и акции.

Нужен стим аккаунт? tgram.link доступ к библиотеке игр по выгодной цене. Совместное использование, подробные условия, инструкции по входу и рекомендации для комфортной игры.

Кент казино подойдёт тем, кто ищет удобное онлайн казино без лишних сложностей. Платформа предлагает понятный формат и стабильную работу. Такой подход ценят многие игроки: kent casino зеркало

Авторский блог https://blogger-tolstoy.ru о продвижении в Телеграм. Свежие гайды, проверенные стратегии и полезные советы по раскрутке каналов, чатов и ботов. Подробно о том, как увеличить аудиторию, повысить вовлеченность и эффективно монетизировать проекты в мессенджере Telegram.

хирургия косметология услуги косметологии

Погрузитесь в мир кино https://zonefilm.media с нашим онлайн-кинотеатром! Здесь каждый найдет фильмы для себя: от захватывающих блокбастеров и трогательных драм до мультфильмов для всей семьи. Удобный интерфейс, возможность смотреть онлайн на любом устройстве и постоянно обновляемая библиотека! Присоединяйтесь и наслаждайтесь!

Нужен сувенир или подарок? корпоративные подарки оптом для компаний и мероприятий. Бизнес-сувениры, подарочные наборы и рекламная продукция с персонализацией и доставкой.

Casino 7k предоставляет доступ к азартным развлечениям в удобном онлайн формате. Платформа адаптирована под разные экраны. Это позволяет играть как с компьютера, так и с телефона. Удобство остается неизменным – 7k casino зеркало на сегодня

Лучшие подарки и сувениры брендированная лента для бейджа нанесение логотипа, подарочные наборы, промо-продукция и деловые аксессуары для мероприятий и компаний.

Нужна бытовая химия? профессиональная бытовая химия моющие и чистящие средства, порошки и гели. Удобный заказ онлайн, акции и доставка по городу и регионам.

Бытовая химия с доставкой магазин бытовой химии средства для уборки, стирки и ухода за домом. Широкий ассортимент, доступные цены и удобная оплата.

UEFA Champions League sampiyonlar ligi matches, results, and live scores. See the schedule, standings, and draw for Europe’s premier club competition.

Free online games 1001 com az for your phone and computer. Easy navigation, quick start, and a variety of genres with no downloads required.

Turkish Super League super-lig com az standings, match results, and live online scores. Game schedule and up-to-date team statistics.

В нашем журнале мы объединяем полезные статьи о детях, красоте и здоровье, чтобы каждая читательница могла найти что то важное для себя. Мы работаем для вашего комфорта и вдохновения. Узнайте больше по ссылке https://universewomen.ru/

Московские шоурумы активно работают с молодыми дизайнерами, открывая новые имена в индустрии моды. Это делает ассортимент свежим и нестандартным. Подробности по ссылке https://ros.listbb.ru/viewtopic.php?f=2&t=7222

Медицинский сайт https://nogostop.ru об анатомии, патологиях и способах лечения. Симптомы, профилактика, современные препараты и рекомендации врачей в доступной форме.

Свежие новости https://plometei.ru России и мира — оперативные публикации, экспертные обзоры и важные события. Будьте в курсе главных изменений в стране и за рубежом.

Информационный портал https://diok.ru о событиях в мире, экономике, науке, автомобильной индустрии и обществе. Аналитика, обзоры и ключевые тенденции.

Шоурумы Москвы предлагают удобный формат записи через социальные сети или мессенджеры, что делает взаимодействие с брендом быстрым и простым. Современные технологии дополняют персональный сервис. Узнать больше можно по ссылке: http://domovou.3nx.ru/viewtopic.php?p=24574#24574

дизайн интерьера угловой дизайн проект интерьера

Мировые новости https://m-stroganov.ru о технологиях и криптовалютах, здоровье и происшествиях, путешествиях и туризме. Свежие публикации и экспертные обзоры каждый день.

Хочешь продать недвижимость? срочно продать квартиру в Москве экспертная оценка, подготовка к продаже, юридическая проверка и сопровождение на всех этапах сделки.

Choosing the right game provider is crucial for success. Onlyplay stands out with its crypto-native flexibility and a diverse portfolio featuring titles like Chicken Plinko and Cricket Crash: onlyplay

Все самое интересное новостной портал с лентой последних событий, аналитикой и комментариями экспертов. Оперативные публикации и аналитика каждый день.

Новый Apple iPhone 17 купить уже в продаже в Санкт?Петербурге! В интернет?магазине i4you вас ждёт широкий выбор оригинальных устройств Apple по выгодным ценам. На каждый смартфон действует официальная гарантия от производителя сроком от года — вы можете быть уверены в качестве и долговечности покупки.

Сервисный центр Miele в Москве работает оперативно и принимает заявки ежедневно. При срочных неисправностях мастер выезжает в кратчайшие сроки. Тщательная проверка после ремонта гарантирует стабильную и безопасную работу техники. Узнать подробнее можете по ссылке: https://mieleservis.ru/

Интересует бьюти индустрия? вакансии косметолога вакансии косметолога, массажиста, мастера маникюра, шугаринга, ресниц, бровиста, колориста и администратора салона красоты. Курсы для бьюти мастеров, онлайн обучение и сертификаты.

jeton promo

Реклама на будке газели https://oklejka-transporta.ru

https://goodtech.com.ua/

https://karolinka.com.ua/

https://itcent.com.ua/

Охраны труда для бизнеса охрана труда дистанционно аудит системы безопасности, обучение персонала, разработка локальных актов и внедрение стандартов. Помогаем минимизировать риски и избежать штрафов.

Проблемы с зубами? стоматологический центр профилактика, лечение, протезирование и эстетическая стоматология. Забота о здоровье зубов с применением передовых методик.

A reliable construction company Costa Blanca — from site selection to delivery of the finished home. Experience, modern materials, and quality control. We manage every detail of turnkey construction, from initial architectural drawings to final interior finishes.

Professional сonstruction Moraira: architecture, engineering systems, and finishing. We work with local regulations and regional specifics in mind. We handle permitting and material procurement so you can enjoy the creative process without the stress of management.

Охраны труда для бизнеса центр охраны труда аудит системы безопасности, обучение персонала, разработка локальных актов и внедрение стандартов. Помогаем минимизировать риски и избежать штрафов.

Нужен фулфилмент? https://mp-full.ru — хранение, сборка заказов, возвраты и учет остатков. Работаем по стандартам площадок и соблюдаем сроки поставок.

Запчасти для сельхозтехники https://selkhozdom.ru и спецтехники МТЗ, МАЗ, Амкодор — оригинальные и аналоговые детали в наличии. Двигатели, трансмиссия, гидравлика, ходовая часть с быстрой доставкой и гарантией качества.

Оформления медицинских справок https://med-official2.info справки для трудоустройства, водительские, в бассейн и учебные заведения. Купить справку онлайн быстро

Медицинская справка https://086y-spr.info 086у в Москве по доступной цене — официальное оформление для поступления в вуз или колледж.

Медицинские справки https://norma-spravok2.info по доступной цене — официальное оформление. Быстрая запись, прозрачная стоимость и выдача документа установленного образца.

Оформление медицинских https://spr-goroda2.info справок в Москве недорого консультации специалистов и выдача официальных документов. Соблюдение стандартов и минимальные сроки получения.

Медицинские справки https://medit-norma1.info в Москве с прозрачной ценой — анализы и выдача официального документа без лишних ожиданий. Удобная запись, прозрачные цены и быстрое получение документа установленного образца.

Медицинская справка https://sp-dom1.ru с доставкой — официальное оформление. Удобная запись, прозрачные цены и получение документа курьером.

Получение медицинской https://gira-spravki2.ru справки с доставкой после официального оформления. Комфортная запись, минимальные сроки и законная выдача документа.

https://digital-world.com.ua/

Справка 29н https://forma-029.ru в Москве с доставкой — без прохождение обязательного медосмотра в клинике. Отправка готового документа по указанному адресу.

Медицинские справки https://meduno.info и анализы в Москве — официально и удобно. Сеть из 10 клиник, оперативный прием специалистов и оформление документов по действующим стандартам.

https://pohod.com.ua/

https://mylikari.com.ua/

Купить квартиру недорого https://spb-novostroyki-gid.ru актуальные предложения на первичном и вторичном рынке. Подбор вариантов по бюджету, помощь в ипотеке и полное юридическое сопровождение сделки.

Орби казино https://orby-casino.com/ онлайн-платформа с широким выбором слотов, настольных игр и бонусных предложений. Узнайте об акциях, турнирах и возможностях для комфортного игрового досуга.

Онлайн казино Орби https://orby-casino.net/ большой выбор слотов, бонусы для новых и постоянных игроков, регулярные турниры с призами.

Чудові бонуси казино — депозитні бонуси, бездепозитні бонуси та Турнір з призами. Обзори пропозицій і правила участі.

https://agrotis.com.ua/

Найпопулярніша платформа казіно онлайн – популярні слоти, бонуси та турніри з призами. Огляди гри та правила участі в акціях.

Грайте в слоти ігрові автомати — популярні ігрові автомати, джекпоти та спеціальні пропозиції. Огляди гри та можливості для комфортного харчування.

https://g-smile.com.ua/

Квартиры в новостройках https://domik-vspb.ru от застройщика — студии, однокомнатные и семейные варианты. Сопровождение сделки и прозрачные условия покупки.

Найкращі казино ігри – безліч ігрових автоматів, правил, бонусів покерів і. Огляди, новинки спеціальні

pravdahub.com.ua/karta-pereiaslava/

Un’accogliente pasticceria https://www.pasticceriabonati.it con fragranti prodotti da forno, classici dolci italiani e torte natalizie personalizzate. Ingredienti naturali e attenzione a ogni dettaglio.

порно бесплатно

трансы кончают

групповое порно

старые проститутки

проститутки телеграмм

https://infobanks.com.ua/

русский секс

Металлический кованый факел купить с доставкой — прочная конструкция, эстетичный внешний вид и устойчивость к погодным условиям.

https://eu-apteka.com.ua/

https://vodkat.top/

красивое порно

Хочешь восстановить мрамор? https://conceptstone.ru устранение трещин, пятен и потертостей. Современные технологии шлифовки и кристаллизации для идеального результата.

проститутки екатеринбург

секс кино

Carbon credits https://offset8capital.com and natural capital – climate projects, ESG analytics and transparent emission compensation mechanisms with long-term impact.

https://womanworld.com.ua/

Свежие новости SEO https://seovestnik.ru и IT-индустрии — алгоритмы, ранжирование, веб-разработка, кибербезопасность и цифровые инструменты для бизнеса.

заказать проститутку

секс скрытая камера

Центр строительства бассейнов https://atlapool.ru

порно член

проститутки постарше

секс анал

Читать расширенную версию: https://parfumabc.ru/

порно дочь

Нужны казино бонусы? https://kazinopromokod.ru — бонусы за регистрацию и пополнение счета. Обзоры предложений и подробные правила использования кодов.

Онлайн покер pokerok — турниры с крупными гарантиями, кеш-игры и специальные предложения для игроков. Обзоры форматов и условий участия.

порно измена

скачать порно