Electromagnetic interference (EMI) can be a silent but significant disruptor in our increasingly connected world. As someone who has worked for decades in fabric production, I have seen how EMI shielding fabrics have evolved from niche industrial uses to becoming essential in tech apparel. Whether you are designing clothing for military personnel, engineers, or wearable device users, choosing the right EMI shielding fabric can make all the difference in safety, performance, and comfort.

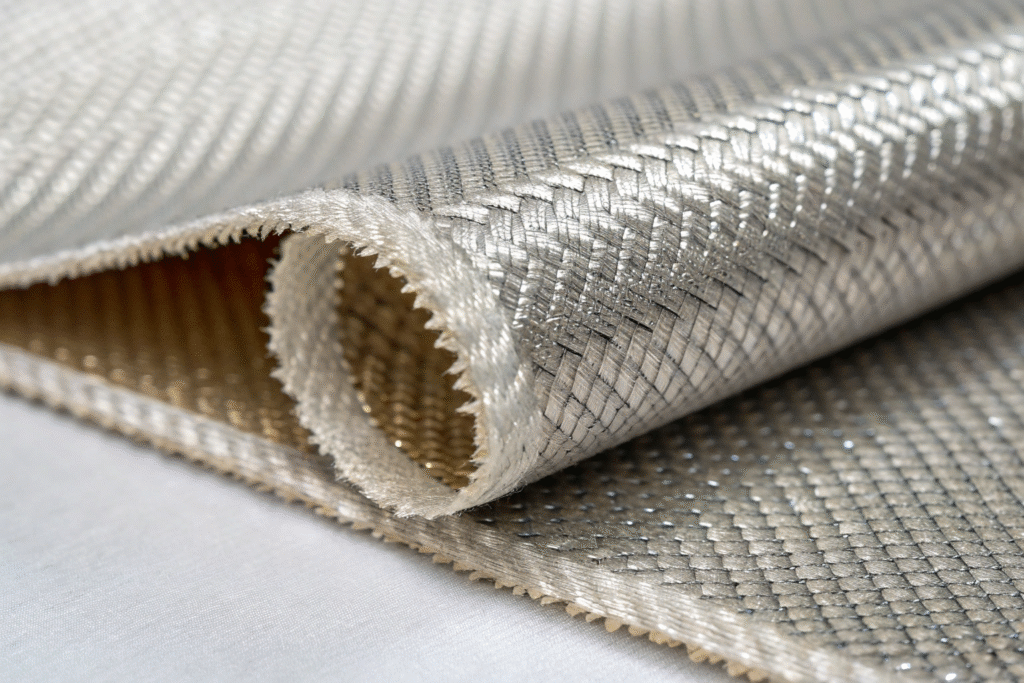

EMI shielding fabrics are designed to block or attenuate electromagnetic radiation, protecting sensitive electronics and human health. These fabrics often incorporate conductive fibers like silver, copper, or stainless steel, and are engineered for durability, flexibility, and consistent shielding effectiveness. In this article, I will guide you through how these fabrics work, the top materials to consider, how to select the right option for your needs, and how to care for garments made with them.

With my background in Fumao Fabric’s integrated supply chain in Keqiao, I will also share how we customize EMI shielding solutions for international clients, ensuring compliance with global standards while offering efficient sampling, production, and logistics.

How Does EMI Shielding Fabric Work?

Electromagnetic interference occurs when external electromagnetic fields disrupt the normal function of electronics. In tech apparel, EMI shielding fabrics work by creating a conductive barrier that reflects or absorbs electromagnetic waves before they can pass through to the protected area. This is achieved by integrating conductive materials into the textile’s structure.

The conductive grid acts as a Faraday cage, which is a principle that has been applied for over a century in protecting electronics. The fabrics used in garments are designed to maintain flexibility and breathability while offering effective shielding—often measured in decibels (dB) of attenuation.

What Makes Conductive Fibers Block EMI?

Conductive fibers, such as silver-coated nylon, copper polyester blends, or stainless steel yarns, have a unique ability to carry electric current along their surface. This creates a path for the electromagnetic energy to be dissipated or reflected, preventing it from reaching sensitive components.

In my experience, the weave density, fiber thickness, and coating quality are all factors that determine the shielding performance. A high-density plain weave with uniform coating tends to deliver higher attenuation without sacrificing fabric flexibility.

How Are EMI Shielding Fabrics Tested?

Testing follows international standards such as MIL-STD-285 and IEEE-299. Fabrics are placed between a transmitter and a receiver, and their shielding effectiveness is measured over a range of frequencies. At Fumao, we run tests in CNAS-certified labs, ensuring that each meter meets SGS and ITS requirements before shipment.

Top EMI Shielding Materials for Clothing

Different materials offer different trade-offs between performance, durability, cost, and comfort. For apparel, flexibility and wearability are just as important as shielding.

Why Is Silver-Coated Nylon So Popular?

Silver-coated nylon fabric offers a combination of excellent conductivity, antimicrobial properties, and softness. It is widely used in medical wearables, military uniforms, and anti-radiation maternity clothing. The silver coating provides stable performance even after multiple washes, though it comes at a higher cost.

I have worked with clients who needed both EMI shielding and antibacterial properties—silver-coated nylon checked both boxes, making it a premium choice for high-end tech apparel.

What About Copper-Polyester Blends?

Copper polyester blends are known for their balance between cost and performance. Copper is highly conductive, and when combined with polyester, it results in fabrics that are durable, flexible, and more affordable than silver options. However, copper is more prone to oxidation, which can affect long-term performance unless treated with protective coatings.

At Fumao, we often recommend copper blends for industrial uniforms and consumer wearable covers where cost-effectiveness is a priority.

Choosing the Right EMI Fabric for Your Needs

Selecting the best EMI shielding fabric depends on your specific application, environmental conditions, and budget.

How to Match Fabric to Application?

If you are making medical tech apparel, opt for silver-coated nylon or stainless steel blends for durability and biocompatibility. For outdoor workwear in high-EMI environments, copper-polyester blends or stainless steel fabrics provide ruggedness.

You can refer to this EMI shielding fabric buyer’s guide for comparison charts of attenuation performance versus comfort.

What Role Does Certification Play in Selection?

Always look for fabrics tested under IEEE or MIL standards and certified by recognized labs like SGS or Intertek. At Fumao, our CNAS lab testing ensures compliance with both EU and U.S. regulations, giving our clients peace of mind before their garments reach the market.

Caring for EMI Shielding Garments

Proper care extends the life and performance of EMI shielding apparel.

Can You Machine Wash EMI Shielding Fabrics?

While some fabrics like silver-coated nylon can withstand gentle machine washing, others, especially copper-based, benefit from hand washing to prevent oxidation. Always use mild detergents without bleach, and avoid wringing to preserve the conductive structure.

How to Store EMI Shielding Garments Safely?

Store garments in a cool, dry place, ideally in anti-static bags or breathable covers to prevent dust and moisture accumulation. For long-term storage, sealing in moisture-resistant packaging can further extend the garment’s effective lifespan.

Conclusion

EMI shielding fabrics are not just about blocking interference—they are about enabling safe, functional, and durable tech apparel. By understanding how they work, comparing material options, selecting the right fabric for the job, and caring for your garments, you can ensure your tech apparel delivers consistent performance.

At Fumao Fabric, we combine Keqiao’s textile expertise, advanced R&D, and a global logistics network to supply EMI shielding fabrics that meet the strictest standards. If you are ready to develop your own tech apparel with reliable EMI protection, contact our Business Director Elaine at: elaine@fumaoclothing.com to discuss your project today.