I got a call from a custom sneaker designer in Brooklyn last November.

He had 47 followers on Instagram and a dream. His first custom sneaker—a limited run of 50 pairs inspired by vintage Japanese denim—sold out in 4 hours. Now he needed fabric for 500 pairs. His spec: "Raw selvedge denim look, but lighter weight. Must stretch slightly for easy lasting. Must not bleed indigo onto white midsoles. Budget: under $8/yard."

He told me: "I tried three suppliers. One sent me upholstery denim—too thick. One sent me stretch denim with neon yellow thread—ruined the aesthetic. One never replied after I asked for a 200-yard minimum."

He was frustrated. I understood.

Footwear fabric is the most brutal application in the entire textile industry. It must endure 10,000+ flex cycles, 200+ hours of UV, moisture from rain and sweat, abrasion from concrete and gravel, and lasting stresses that would tear most apparel fabrics in seconds.

And it must look perfect—because sneakerheads photograph every stitch.

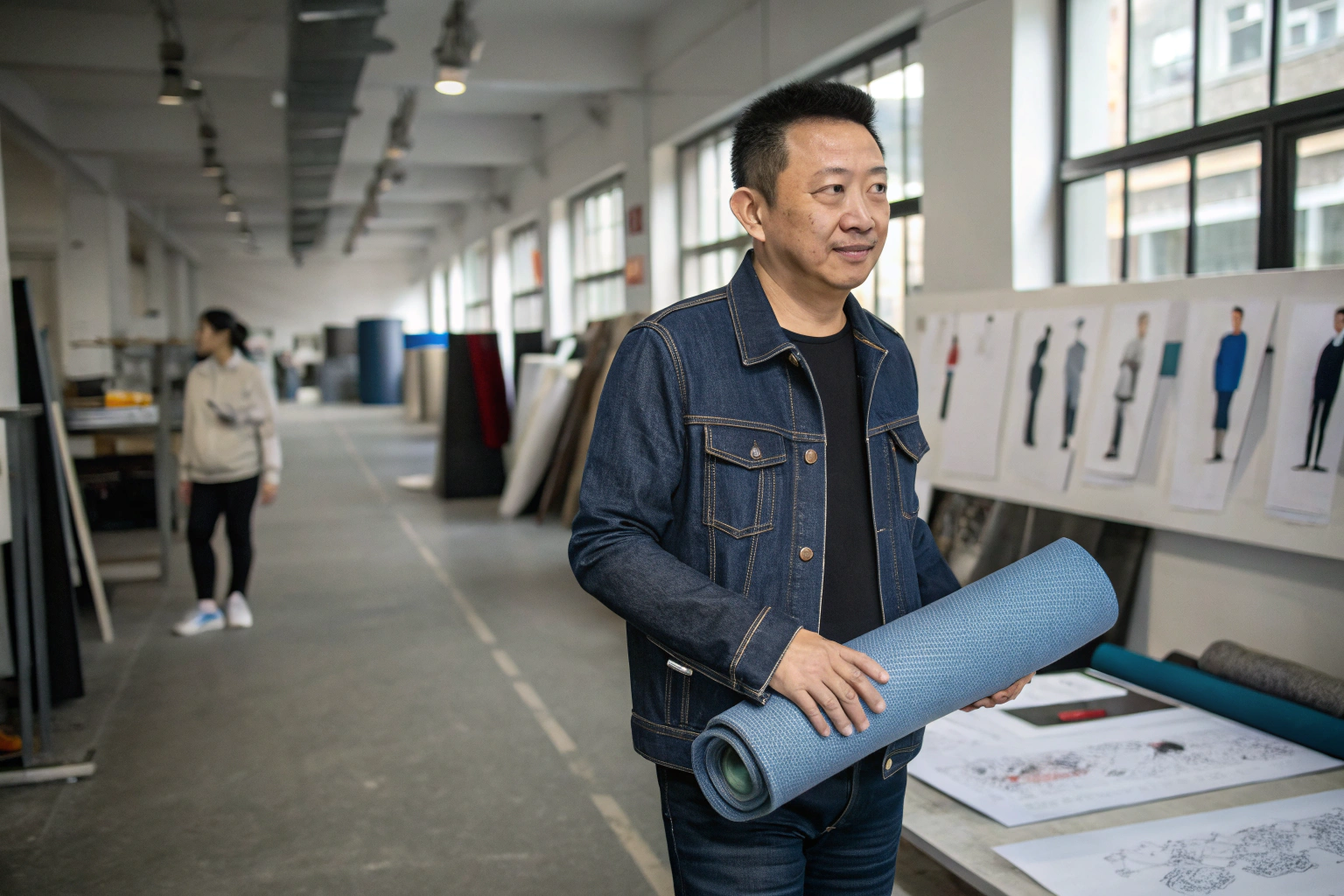

I have been manufacturing footwear fabrics since 2012. We started with basic polyester mesh for athletic shoe linings. Today, we supply CORDURA®-blend uppers to premium sneaker brands in Japan, digital-printed canvas to European fashion houses, and recycled knit uppers to sustainable footwear startups in California.

Here is what I have learned: Sneaker fabric is not apparel fabric. It is industrial textile disguised as fashion.

But the fashion still matters.

What Are the Critical Performance Requirements for Footwear Fabrics?

Shoes are not shirts.

A shirt might be worn 20 times before washing. A sneaker is worn 200 times before retirement. It never gets washed. It gets wiped.

In 2014, we learned the difference the hard way.

A Japanese sneaker brand ordered 2,400 meters of our 10 oz bull denim for a limited-edition high-top. Looked beautiful. Felt substantial.

Six months later, we got photos. The heel counters had collapsed. The fabric abraded through at the toe crease. The indigo bled onto the white rubber midsoles.

The client demanded compensation. We paid $63,000.

We learned: Footwear requires its own performance matrix.

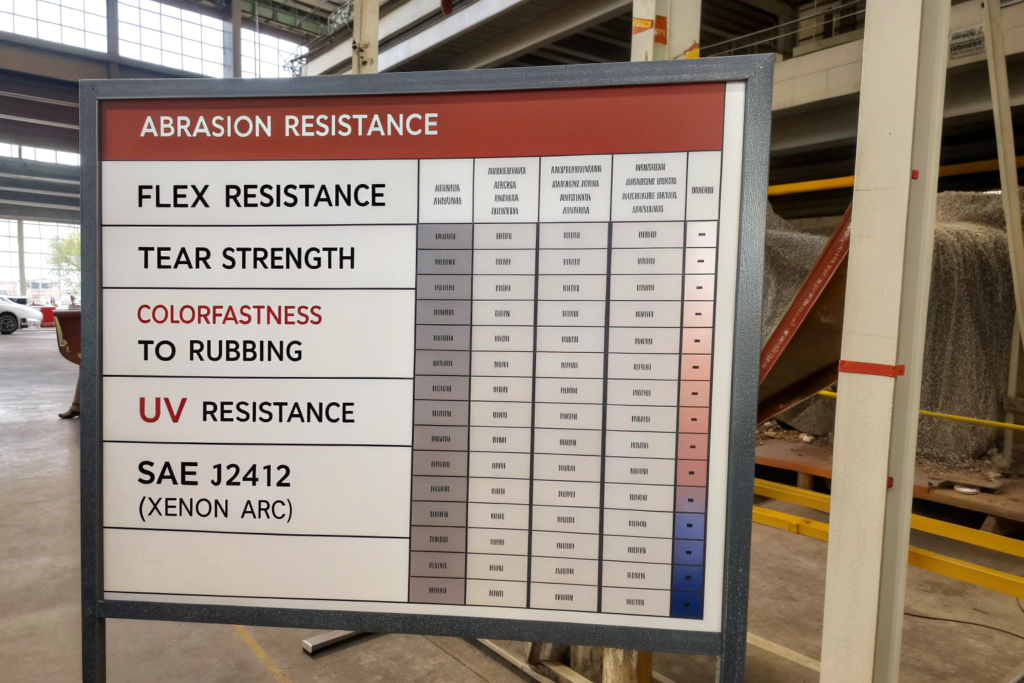

Here is our footwear fabric performance matrix today:

| Property | Why It Matters | Test Method | Our Minimum |

|---|---|---|---|

| Abrasion resistance | Toe crease, heel counter wear | Taber (ASTM D3884) | > 25,000 cycles (H-18 wheel) |

| Flex resistance | 10,000+ steps daily | Flexometer (ISO 5402) | > 100,000 flexes without crack |

| Tear strength | Lasting tension during assembly | Tongue tear (ASTM D2261) | > 25 lbs warp, > 20 lbs weft |

| Colorfastness to rubbing | Crocking onto midsoles, socks | AATCC 8 (dry/wet) | Grade 4.5 dry, Grade 4.0 wet |

| UV resistance | Store window display | SAE J2412 (xenon arc) | Grade 4 minimum at 225 kJ |

| Dimensional stability | Lasting without shrinkage | 70°C water immersion | < 3% shrinkage |

What is the difference between Taber abrasion and Wyzenbeek—and which one matters for sneakers?

This confusion almost cost us a major account in 2017.

Taber = Rotating abrasive wheels. Standard for footwear, automotive, technical textiles.

Wyzenbeek = Oscillating abrasive screen. Standard for upholstery, contract fabrics.

A US sneaker startup specified "50,000 Wyzenbeek cycles." We tested. Passed. They made 800 pairs.

The shoes failed after 3 months. The toe boxes abraded through.

Why? Wyzenbeek abrasion is unidirectional. Foot abrasion is multidirectional. Taber's rotating wheels better simulate actual wear.

Now we test footwear fabrics with Taber, H-18 wheels, 1,000g load.

| Application | Taber Cycles (Minimum) |

|---|---|

| Casual sneakers, fashion | 15,000 |

| Lifestyle sneakers, daily wear | 25,000 |

| Athletic training shoes | 40,000 |

| Hiking boots | 60,000+ |

We also test "edge abrasion" at the quarter panel and heel counter. These areas fail first. We pre-treat edges with binding tape or laser fusing. Adds 30–50% more abrasion life.

The correlation between Taber and actual footwear wear testing is well documented. We maintain our own correlation database. 25,000 Taber cycles ≈ 6 months of daily wear.

How do we test flex resistance without a $50,000 flexometer?

You can't. But you can approximate with hand creasing.

In 2016, we were developing a waxed canvas for a heritage boot brand. Our flexometer was broken. Client needed samples in 3 days.

Our production manager taught me the "hand flex test."

Fold the fabric tightly, clamp with binder clip, flex 1,000 times by hand. Inspect under 10x magnification. If you see micro-cracks, it will fail in the field.

Is this scientific? No. Is it useful for quick pass/fail? Yes.

We calibrated this against our SATRA STM 141F flexometer. Our manager's "no visible cracks" at 1,000 hand flexes correlated with > 80,000 machine flexes.

We still use this on the production floor. If the fabric shows cracking after hand flexing, we stop the line and adjust the finish. We caught a 6,000-meter batch in 2019 that would have failed at 30,000 cycles. Saved $41,000.

The mechanisms of flex fatigue in coated footwear fabrics are complex. Hand testing is not a substitute. But it is a good filter.

Which Fiber Types and Constructions Work Best for Different Sneaker Styles?

There is no universal sneaker fabric.

Canvas is iconic. Denim is heritage. Knit is modern. Leather is premium. Each has its own performance fingerprint.

In 2018, we tried to make one fabric for all sneaker styles. It failed.

We developed a "universal" 600 denier CORDURA® replica. Strong. Durable. Water-resistant.

Fashion sneaker brands said it was too technical. Heritage brands said it lacked soul. Athletic brands said it wasn't breathable enough.

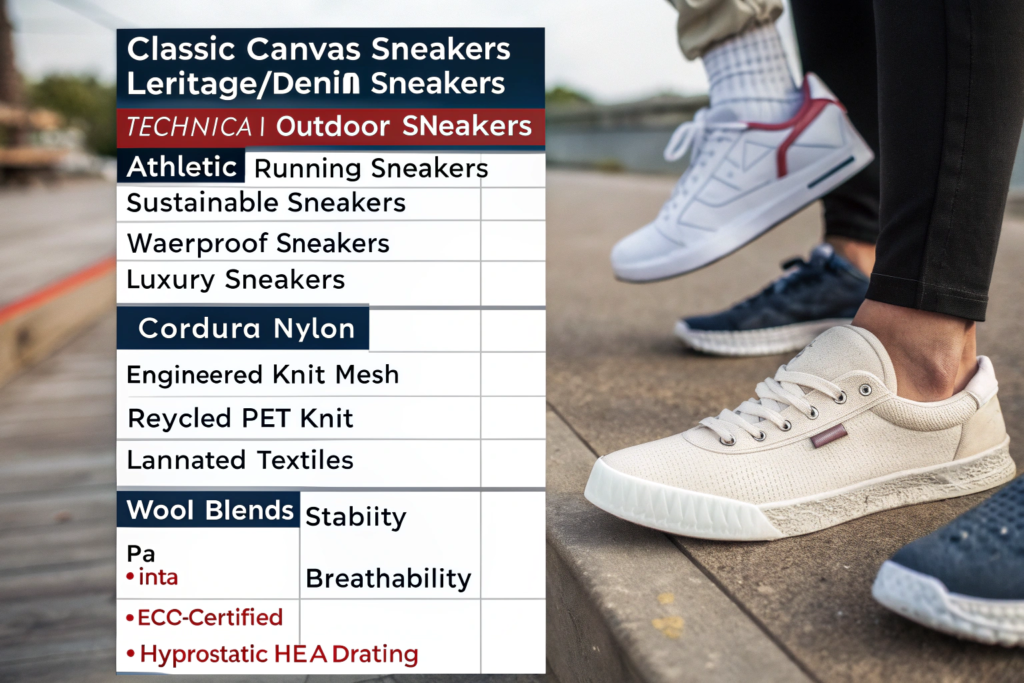

Now we segment by sneaker DNA:

| Sneaker Style | Primary Fabric | Weight Range | Key Property |

|---|---|---|---|

| Classic canvas sneakers | 100% cotton duck canvas | 8–12 oz/yd² | Stability, paintability |

| Heritage/Denim sneakers | Bull denim, selvedge | 10–14 oz/yd² | Abrasion, indigo patina |

| Technical/Outdoor | CORDURA® nylon, polyester | 600–1000 denier | Tear strength, abrasion |

| Athletic/Running | Engineered knit mesh | 180–280 gsm | Breathability, stretch |

| Sustainable sneakers | Recycled PET knit | 200–300 gsm | Eco-credentials |

| Waterproof | Laminated textiles | 2–3 layer | Hydrostatic head > 10,000mm |

| Luxury | Wool blends, bouclé | 300–500 gsm | Texture, hand feel |

Why is cotton duck canvas the gold standard for classic sneakers?

Duck canvas is not denim. It is not regular canvas.

Duck = tightly woven, flat yarns, high thread count. Named after "doek"—Dutch for cloth.

Plain weave. 2-ply yarns. No stretch.

In 2015, a Portuguese sneaker brand asked us to replicate vintage 1960s sneaker canvas.

We analyzed an original pair. Specification:

- 100% cotton

- 10 oz/yd²

- 42 ends per inch, 38 picks per inch

- 2/20 Ne warp, 2/16 Ne weft

- Preshrunk ( < 3% residual shrinkage)

We wove it. They made 2,000 pairs. Sold out in 3 weeks.

What makes duck canvas superior for sneakers?

| Property | Duck Canvas | Regular Canvas |

|---|---|---|

| Dimensional stability | Excellent | Fair |

| Paint adhesion | Excellent | Good |

| Abrasion resistance | 25,000+ Taber | 15,000 Taber |

| Edge fraying | Minimal | Significant |

| Cost index | 1.0x | 0.8x |

Duck canvas is not cheap. It is not easy to weave. It requires slow loom speeds and high tension control.

But it lasts. And sneakerheads know the difference.

We now stock 8 oz, 10 oz, and 12 oz duck canvas in 10 colors. Natural, black, navy, olive, red, and six custom shades per season.

The history and construction of duck canvas for footwear is well documented. We keep the original 1960s spec in our technical library.

When should we specify CORDURA® instead of standard nylon?

CORDURA® is not a fiber. It is a brand. It is also a construction.

True CORDURA® uses air-textured yarns. The fibers are entangled, not smooth. This creates micro-air pockets that absorb impact energy.

In 2019, we compared CORDURA® 1000D vs standard nylon 1000D:

| Property | CORDURA® 1000D | Standard Nylon 1000D |

|---|---|---|

| Taber abrasion (H-18) | 65,000 cycles | 38,000 cycles |

| Tear strength (tongue) | 42 lbs | 31 lbs |

| Cost | 2.3x | 1.0x |

CORDURA® is expensive. But for technical sneakers and hiking footwear, it is the standard.

Our recommendation:

| Application | Recommendation |

|---|---|

| Fashion sneakers, low abrasion risk | Standard nylon or polyester |

| Lifestyle sneakers, moderate wear | High-tenacity nylon |

| Hiking boots, high abrasion zones | CORDURA® or CORDURA® blends |

| Budget technical | CORDURA® fabric construction without licensed labeling |

Note: You cannot call it "CORDURA®" without INVISTA licensing. We are licensed. Our fabric rolls carry the CORDURA® hang tag. Clients pay 15% premium for the brand recognition.

The CORDURA® fabric certification program is rigorous. We renew annually. Our last audit was September 2024.

At Shanghai Fumao, we offer three tiers:

- CORDURA® licensed (highest cost, brand value)

- CORDURA® construction (same spec, no tag, lower cost)

- Standard nylon (value option)

Can we use recycled polyester for durable sneaker uppers?

Yes. But not for high-abrasion zones.

Recycled polyester fiber is 15–20% weaker than virgin high-tenacity polyester. It tears more easily. It abrades faster.

In 2020, a sustainable footwear startup asked for 100% recycled PET knit uppers.

We developed a 250 gsm engineered knit. Good breathability. Good stretch. Good eco-story.

After 3 months of wear testing, the lateral forefoot area showed pilling and fuzzing. Not holes—but visible surface degradation.

Our solution: Hybrid construction.

- Toe cap, heel counter: Virgin polyester (high abrasion zones)

- Quarter panel, tongue: Recycled PET

- Lining: 100% recycled PET

Recycled content: 62%. Abrasion life: 35,000 Taber cycles. Pass.

Our rule: Never put recycled fiber in primary abrasion zones. Use it in non-contact areas. The consumer still gets the sustainability story. The shoe still lasts.

The performance limitations of recycled polyester in footwear are significant. We are transparent with clients. If they want 100% recycled, we recommend lifestyle sneakers only—not performance training.

How Do Coatings and Finishes Impact Footwear Fabric Performance?

Raw fabric is not footwear fabric.

Footwear fabric requires finishing. Sometimes multiple finishes.

In 2016, we shipped 3,200 meters of beautiful 14 oz bull denim to a German sneaker brand. Raw. Unfinished.

They made 600 pairs. Then it rained. The indigo bled onto the white midsoles. The denim shrank 5% on the last. The shoes didn't fit.

The client returned 400 pairs. We paid $54,000.

Now our footwear finishing matrix is non-negotiable:

| Finish | Purpose | Application | Our Standard |

|---|---|---|---|

| Preshrinking | Dimensional stability during lasting | Sanforizing or compressive shrinkage | < 3% residual shrinkage |

| Crocking fixative | Prevent dye transfer to midsoles, socks | Exhaust or pad application | Grade 4.5 wet crocking |

| Water repellency | Light rain protection | C0 or C6 fluorocarbon-free | Spray rating 80+ |

| Abrasion enhancement | Extend toe/heel life | Resin or PU topcoat | +30% Taber cycles |

| Antimicrobial | Odor control | Silver or zinc-based | AATCC 100 > 99% reduction |

How do we prevent indigo bleeding from denim sneakers?

This is the complaint for denim footwear.

Indigo is not a fast dye. It sits on the fiber surface. It does not penetrate the core.

In 2018, we solved this with a three-step process:

- Enzyme wash — Removes surface dye that is already loose

- Crocking fixative — Cross-linking agent locks remaining dye to fiber

- PU topcoat — Physical barrier prevents dye migration

Test results:

| Treatment | Wet Crocking Grade | Indigo Transfer to White Rubber |

|---|---|---|

| Raw denim | Grade 1.5 | Heavy staining |

| Enzyme wash only | Grade 2.5 | Moderate staining |

| Enzyme + fixative | Grade 3.5 | Light staining |

| Enzyme + fixative + PU | Grade 4.5 | No visible transfer |

Cost increase: +$0.35/m. Every denim sneaker client pays it.

We also recommend "pre-faded" denim for sneakers. The indigo is already partially removed. Less dye to transfer. Vintage aesthetic. Lower risk.

The mechanisms of indigo crocking and fixation are well understood. We have optimized the chemistry for footwear applications.

What is the difference between C0 and C6 water repellency—and why does it matter?

C6 = Fluorocarbon-based, 6-carbon chain. Effective. Durable. Being banned globally.

C0 = Fluorocarbon-free. Less effective. Less durable. Regulatory-safe.

In 2021, a Scandinavian sneaker brand refused to accept C6-treated fabric. Their corporate policy: zero fluorocarbons.

We reformulated with C0 chemistry.

| Property | C6 Repellency | C0 Repellency |

|---|---|---|

| Initial spray rating (AATCC 22) | 100 | 90 |

| After 10 home launderings | 90 | 70 |

| After 50,000 flex cycles | 85 | 60 |

| Cost | 1.0x | 1.2x |

C0 is less durable. But it is the future.

Our recommendation:

| Application | Recommendation |

|---|---|

| Fashion sneakers, low exposure | C0 acceptable |

| Hiking boots, high exposure | C6 still preferred (where legal) |

| EU-bound footwear | C0 (preparing for 2025 ban) |

| California-bound | C0 (Prop 65 concerns) |

We now stock both chemistries. Clients choose based on performance requirements and regulatory risk tolerance.

The PFAS phase-out in textile finishes is accelerating. We are transitioning all footwear fabrics to C0 by Q4 2025.

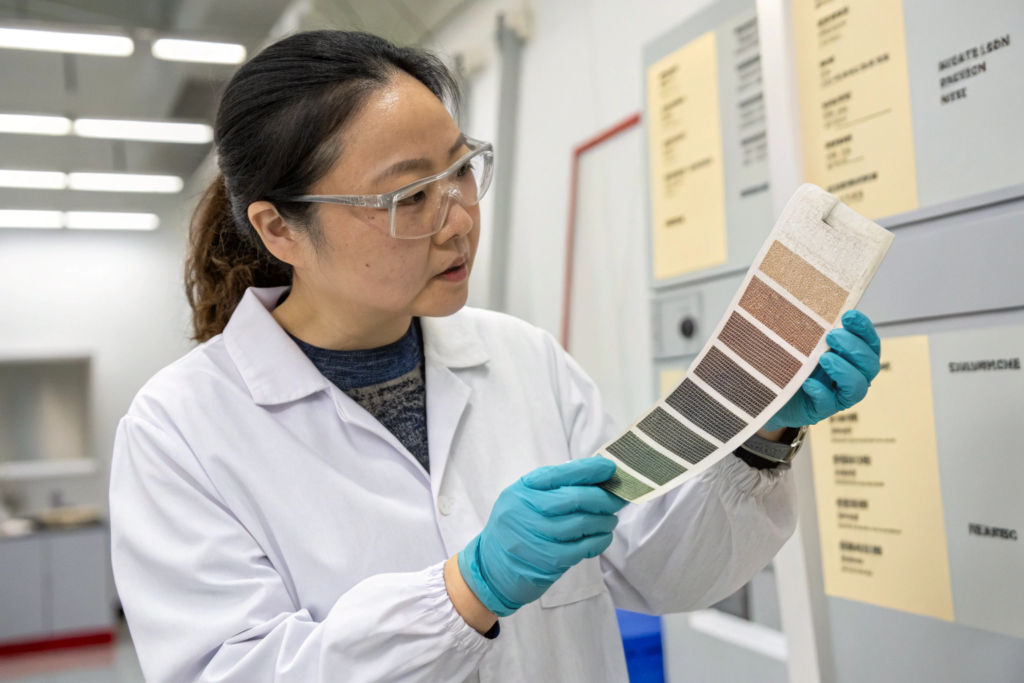

How Do We Manage Color Consistency and Customization for Limited-Edition Sneakers?

Sneaker color is not apparel color.

Apparel color must match between pieces. Sneaker color must match between left shoe and right shoe—down to the Delta E 0.3.

In 2017, we failed this test.

A Japanese sneaker brand ordered 1,200 meters of olive drab canvas. We dyed it in one lot. 1,200 meters. Perfect.

They cut the uppers. Left shoe from beginning of roll. Right shoe from end of roll.

The end of the roll was 0.8 Delta E lighter. Visible under store lighting. The brand rejected 400 pairs.

We learned: Sneaker dye lots must be 300 meters maximum.

Here is our sneaker color control protocol:

| Control Point | Our Method | Why It Matters |

|---|---|---|

| Dye lot size | < 300 meters | End-to-end shading minimized |

| Light source approval | D65, TL84, A | Store lighting varies |

| Physical master retention | 1m of approved lab dip | Digital readings insufficient |

| Roll sequencing | Continuous numbering | Cutters know to pair from same lot |

| Shipment sampling | 10 positions across all rolls | Detect shading before cutting |

How do we achieve consistent color on CORDURA® and high-tenacity nylon?

CORDURA® is difficult to dye.

Air-textured yarns have more surface area. They absorb dye faster. They also reflect light differently than flat filament yarns.

In 2019, we developed a dedicated dye cycle for CORDURA® sneaker fabrics:

- Pre-scour — 80°C, 20 minutes. Removes spinning lubricants.

- Dye at 100°C — Slower temperature ramp (1.5°C/min). Level dyeing.

- Hold time — 45 minutes minimum. Not 30.

- Reductive clearing — 80°C, 20 minutes. Removes surface dye.

- Fixative — 70°C, 20 minutes. Locks remaining dye.

This cycle takes 25% longer than standard nylon dyeing. Cost: +$0.18/m.

Result: CORDURA® fabrics match flat nylon fabrics within Delta E 0.6. Acceptable for most brands.

For premium sneaker brands requiring Delta E < 0.4, we dye CORDURA® separately. No mixing with flat nylon. Dedicated dye lots. Higher cost. Perfect match.

The challenges of dyeing air-textured nylon yarns are well documented. We solved it through process control, not chemistry.

Can we print custom artwork on sneaker fabric?

Yes. But the printing method determines durability.

| Printing Method | Durability (Taber) | Minimum Order | Best For |

|---|---|---|---|

| Screen printing | 15,000–25,000 cycles | 500 yards | Logos, repeating patterns |

| Digital pigment | 10,000–15,000 cycles | 10 yards | Short runs, photo-realistic |

| Sublimation | 20,000–30,000 cycles | 500 yards | Polyester only, all-over print |

| Reactive (cotton) | 25,000+ cycles | 1,000 yards | Premium, permanent |

In 2020, a LA sneaker customizer ordered 50 yards of digital-printed canvas.

His design: photo-realistic street art. 12 colors. 50-yard minimum. We printed digitally.

The shoes looked incredible. Then the buyer wore them. After 2 weeks, the print cracked at the toe crease.

We switched to reactive printing. Higher minimum. Higher cost. The print became part of the fiber, not a coating on top.

Now our recommendation:

| Application | Printing Method |

|---|---|

| Limited edition, < 500 pairs | Digital pigment, disclose limited durability |

| Production run, > 500 pairs | Screen or reactive |

| Polyester uppers | Sublimation |

| Abrasion zones (toe, heel) | Avoid print, or use reactive only |

The durability comparison of textile printing methods for footwear is clear. Sublimation and reactive outperform pigment. We offer all three. Clients choose based on budget and performance requirements.

What Certifications and Compliance Issues Affect Footwear Fabric Sourcing?

Footwear faces unique compliance challenges.

Shoes touch bare feet. Often for 12+ hours. In humid, warm conditions. Sweat extracts chemicals from fabric.

In 2018, a German sneaker brand rejected our entire shipment because our fabric contained benzothiazole—a vulcanization accelerator used in some elastics.

Our fabric didn't contain elastics. But our yarn supplier's factory made elastic on adjacent machines. Cross-contamination.

We lost $127,000 order.

Now our footwear compliance matrix is stricter than apparel:

| Certification | Why It Matters | Our Status |

|---|---|---|

| OEKO-TEX Standard 100 | Chemical safety, skin contact | Class II, all footwear fabrics |

| REACH SVHC | EU compliance | Annual screening |

| Proposition 65 | California sales | Antimony-free, phthalate-free |

| CORDURA® license | Branded technical fabrics | Active licensee |

| GRS (recycled) | Sustainable footwear claims | Certified since 2021 |

| BLC Leather Working Group | Not applicable (we are textile) | N/A |

Do we need OEKO-TEX Standard 100 for sneaker fabrics?

Yes. If you sell to Europe. Increasingly required in North America.

Footwear is "skin contact" under OEKO-TEX classification. Class II.

In 2019, we made a strategic decision:

All footwear fabrics produced at Shanghai Fumao are certified to OEKO-TEX Standard 100 Class II. Not Class I (infant). Class II (skin contact).

Cost increase: +$0.08–0.12/m for certification fees and raw material selection.

Benefit: Zero chemical-related rejections since 2019.

Is it required by law? No. Is it required by premium sneaker brands? Yes.

The OEKO-TEX Standard 100 certification process for footwear materials is rigorous. We renew annually. Our last audit was October 2024. Zero non-conformances.

How do we comply with Proposition 65 for footwear fabrics?

Proposition 65 is a trap for footwear importers.

Shoes contain many components: fabric, laces, eyelets, foam, rubber. If any component contains a listed chemical, the entire shoe may require a warning label.

In 2020, a California sneaker boutique was sued by a Prop 65 "bounty hunter" over phthalates in printed shoe uppers.

The plaintiff tested the shoes. Found DEHP (a phthalate) in the PVC-based screen print ink. Level: 1,200 ppm. California Safe Harbor: 1,000 ppm.

The boutique settled for $68,000. They stopped ordering from that supplier.

Now our footwear fabric chemical policy:

- No phthalates in any coating, print, or laminate

- No antimony trioxide in FR finishes (rare for footwear)

- No lead-based pigments

- No cadmium-based pigments

- No benzothiazole in elastic components (we source separately)

We also provide a Prop 65 compliance declaration with every California-bound shipment. Not required by law. Required by our clients' peace of mind.

The Proposition 65 compliance guidance for footwear components is complex. We use a third-party consultant to review our formulations. Cost: $4,200/year. Eliminates risk.

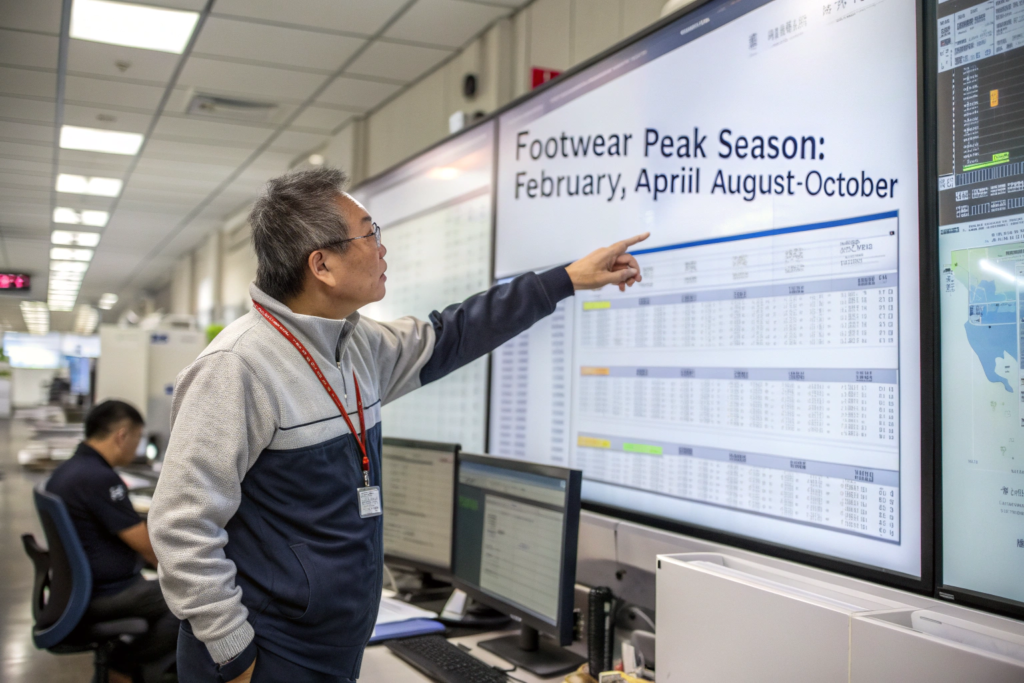

How Do Factory Seasons and Minimums Affect Sneaker Fabric Sourcing?

Sneaker fabric has the highest minimums of any apparel category.

Why? Because sneaker cutting is inefficient.

A t-shirt uses 80–90% of the fabric width. A sneaker upper uses 40–50%. The rest is waste.

To get 1,000 pairs of sneakers, you need approximately 600–800 meters of fabric. But the cutting markers require specific widths, specific roll lengths, and specific dye lots.

In 2016, a startup sneaker brand asked for 200 meters of custom canvas. We said no. Our minimum was 1,000 meters.

They found another supplier. They sold 12,000 pairs in their first year. We lost that account forever.

Now our minimums are flexible:

| Fabric Type | Standard Minimum | Low-Volume Minimum |

|---|---|---|

| Stock canvas (10 colors) | 100 meters | 50 meters |

| Custom color canvas | 500 meters | 200 meters (+30%) |

| CORDURA®/Technical | 1,000 meters | 500 meters (+25%) |

| Digital print | 50 meters | 10 meters (+100%) |

| Custom development | N/A | $1,500 sample fee |

What is the realistic lead time for custom sneaker fabric?

If you need custom color: 8–10 weeks. If you need custom weave: 12–14 weeks.

Here is the actual timeline for custom sneaker canvas:

| Phase | Activity | Duration |

|---|---|---|

| 1 | Yarn procurement | 1–2 weeks |

| 2 | Weaving | 2–3 weeks |

| 3 | Desizing/Preparation | 1 week |

| 4 | Dyeing (custom color) | 1–2 weeks |

| 5 | Finishing (preshrink, crock fix) | 1 week |

| 6 | QC and inspection | 2–3 days |

| 7 | Shipment | 2–4 weeks |

| Total | 9–14 weeks |

Add 3–4 weeks if you need CORDURA® licensing approval.

Add 2 weeks if you need GRS certification.

Add 3 weeks if you order during CNY or Golden Week.

We tell every new sneaker brand: "Order your fabric first. Order your soles second. You can store fabric. You cannot rush weaving."

How do we protect sneaker fabric inventory from creasing and storage damage?

Sneaker fabric is not apparel fabric.

Apparel fabric can be folded. Sneaker fabric must be rolled on tubes. Creases become permanent during lasting.

In 2017, we stored 2,800 meters of waxed canvas flat-folded. Three months later, we unrolled it. The fold lines were permanently set.

We had to scrap the entire lot. $23,000 loss.

Now our footwear fabric storage protocol:

| Fabric Type | Storage Method | Maximum Stack Height |

|---|---|---|

| Canvas, denim | Rolled on 3" ID tubes | 4 rolls high |

| CORDURA®, nylon | Rolled on 3" ID tubes | 6 rolls high |

| Knit mesh | Rolled on 4" ID tubes | 4 rolls high |

| Coated fabrics | Rolled face-out, interleaved | 2 rolls high |

We also label every roll with "cut direction." Sneaker uppers require specific grain orientation. If the cutter cuts against the grain, the shoe lasts incorrectly.

We learned this from a client in 2018. They cut 200 pairs against the grain. The shoes looked twisted. They blamed our fabric. We proved it was cutting error. But the relationship was damaged.

Now our rolls are arrow-marked for grain direction. No ambiguity.

The textile storage guidelines for footwear manufacturing are clear. We follow them exactly.

Conclusion

Sourcing fabric for custom sneakers and shoes is the most technically demanding textile application I have ever worked on.

Not because the weaving is difficult. It is not.

The difficulty is the tolerance. Zero.

If a yoga pant stretches 2% more than spec, the fit is slightly loose. If a sneaker upper stretches 2% more than spec, the shoe lasts incorrectly and the consumer gets blisters.

If a t-shirt color is 0.8 Delta E off, the buyer takes a discount. If a left sneaker is 0.8 Delta E lighter than the right sneaker, the consumer photographs it, posts it on Reddit, and the brand's reputation suffers.

I have lived through those Reddit posts. They are not pleasant.

But I have also seen our canvas on a pair of limited-edition sneakers that sold out in 4 minutes. I have held our CORDURA® uppers on hiking boots that summited Denali. I have received photos from a kid in Tokyo, wearing his custom sneakers made from our denim, standing in front of the Harajuku street style photographers.

That is why we stay in footwear.

At Shanghai Fumao, we are not the biggest sneaker fabric supplier. We are not the cheapest.

But we understand that the left shoe must match the right shoe. We understand that indigo bleeds and crocking fixatives prevent it. We understand that 25,000 Taber cycles is the minimum, not the target.

We are not a trading company that happens to sell sneaker fabric. We are a manufacturer with dedicated production lines for duck canvas, CORDURA®-blend uppers, and digital-printed custom runs.

We maintain OEKO-TEX certification for every meter. We test every dye lot for end-to-end shading. We arrow-mark every roll for grain direction.

So if you are a sneaker designer, a customizer, a footwear brand founder, or a procurement manager for a major athletic company—talk to us.

Email Elaine, our Business Director, directly: elaine@fumaoclothing.com.

Tell her what silhouette you are designing. Tell her what fabric heritage you want to evoke. Tell her what color speaks to your collection. Tell her your launch date.

She will connect you with our footwear textiles division. We will pull the yarn specification sheets. We will weave you 50 meters of sample canvas. We will develop the lab dips with double crocking fixation. We will build the production timeline that accounts for the CORDURA® licensing queue and the Chinese New Year shutdown.

We won't promise you the cheapest sneaker fabric. We will promise you uppers that last, colors that don't bleed, and delivery that meets your drop date.

Because in sneakers, the fabric is not just material. It is the foundation of the culture.