You're responsible for outfitting a team of electricians or industrial workers. The safety catalogues are filled with options claiming "FR protection," but prices vary wildly. How do you know which fabric will genuinely protect against an arc flash or flash fire—and which might fail catastrophically? The difference isn't just in the label; it's in the molecular structure of the fibers and the rigor of the certifications behind them.

Flame Retardant (FR) fabrics are engineered textiles specifically designed to resist ignition, self-extinguish rapidly, and provide crucial thermal insulation to protect the wearer from burn injuries. They are a calculated defense system, not a magical force field. The "right" FR fabric is a precise match between its engineered performance and the quantifiable thermal hazard (measured in calories/cm²) present in a specific work environment.

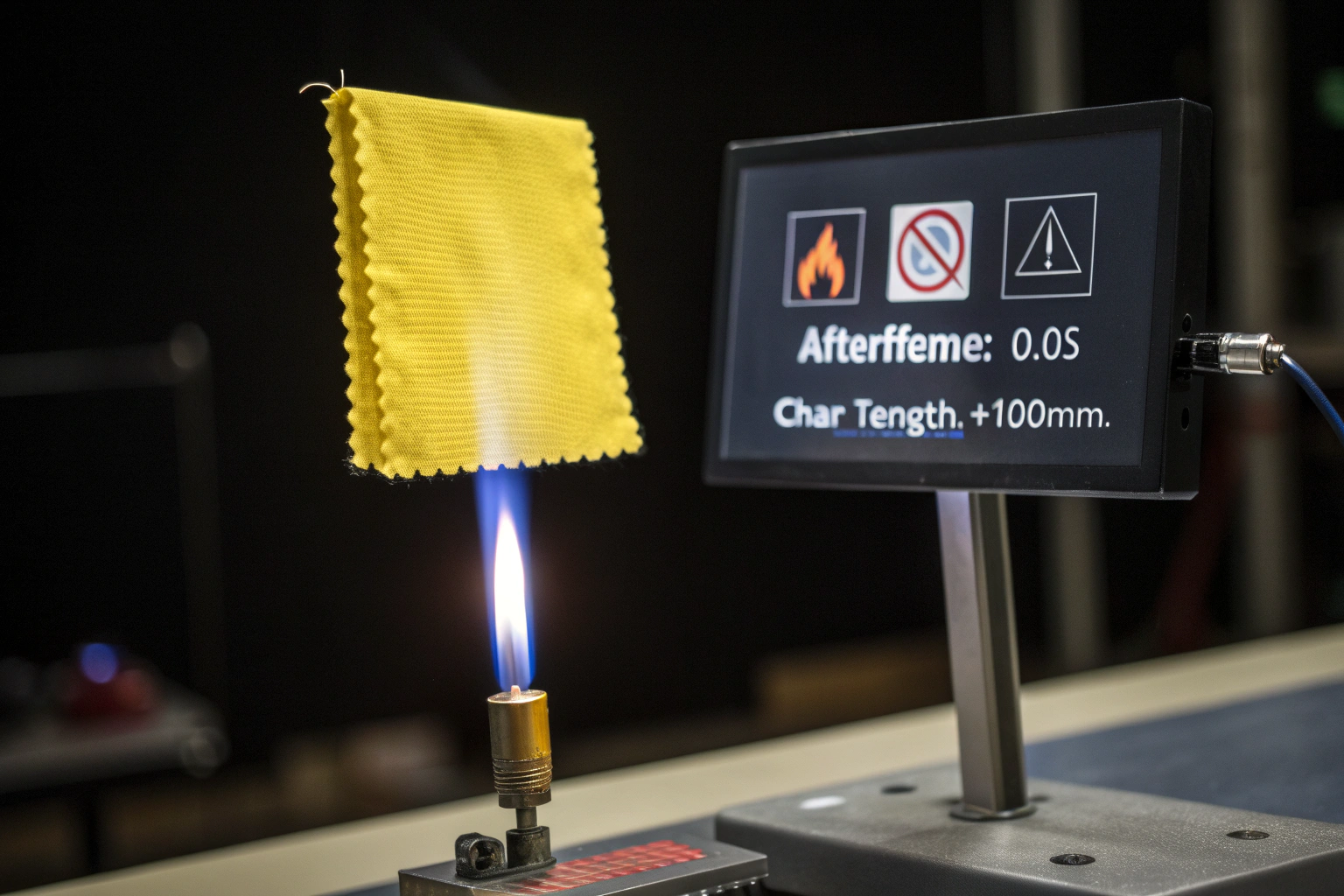

In our Keqiao lab, we subject FR fabrics to simulated arc flashes and open flames daily. The gap between marketing claims and genuine, certifiable performance can be life-threatening. Let's cut through the jargon and build a framework for understanding, specifying, and sourcing FR fabrics that truly meet the standard of care.

What are the different types of FR fabrics?

The world of FR divides into two distinct technological philosophies: Treated (or "Finished") and Inherent (or "Permanent"). This is the single most important distinction you must understand, as it dictates the fabric's lifespan, maintenance, cost basis, and fundamental reliability under stress. One is a coat of armor painted on; the other is forged from hardened steel.

Choosing based on price alone between these categories is not just poor economics—it's a fundamental safety miscalculation. The application environment dictates the technology.

How do treated (finished) FR fabrics work?

Treated FR begins life as a conventional, flammable fabric—typically a cotton or cotton-blend. Its flame resistance is a chemical finish applied post-production, like a protective coating.

- Mechanism: When exposed to heat, these chemicals react. Some release non-flammable gases to smother the flame, others cause the fabric to char and swell, forming an insulating barrier that protects the underlying material. Common modern chemistries are phosphorous-based.

- The Reality Check: The protection is durable, not permanent. It can be diminished by abrasive wear, repeated industrial laundering (especially with harsh chemicals), UV exposure, and sweat. Its performance has a defined service life that must be managed.

- The Sweet Spot: These fabrics are cost-effective and excellent for environments with a defined, lower-risk thermal hazard or where garments are treated as consumables. Think general industrial workwear where the primary risk is brief, incidental contact with a small flame, not a sustained flash fire.

A classic example is an 88/12 Cotton-Nylon twill treated with a Pyrovatex-type finish. It's a workhorse for many manufacturing facilities. However, its ATPV (Arc Thermal Performance Value) will degrade over time. You must have a strict garment lifecycle and retesting protocol based on the manufacturer's instructions.

What are the advantages of inherent FR fibers?

Inherent FR fibers are born with flame resistance. The property is engineered into the polymer chain of the fiber itself at the molecular level. It cannot be washed out or worn off.

- Mechanism: These fibers are inherently less flammable. When exposed to extreme heat, they carbonize and char, forming a thick, protective barrier that insulates. They resist melting and dripping—a critical feature, as molten synthetic material can cause severe secondary burns.

- The Fiber Arsenal:

- Aramids (Nomex®, Kevlar®): The gold standard. Meta-aramid (Nomex®) offers excellent thermal and flame resistance; para-aramid (Kevlar®) adds extreme tensile strength.

- Modacrylic: A cost-effective inherent fiber often blended with others to boost FR performance and improve moisture management.

- FR Viscose/Rayon: Provides the moisture-wicking comfort of cotton with built-in FR properties.

- PBI (Polybenzimidazole): The ultimate performer for extreme heat, used in firefighter turnout gear and race suits.

- The Investment: These fabrics carry a significantly higher initial cost. However, for high-risk, repeated-exposure environments (oil & gas, electrical utilities, firefighting), they offer permanent protection and a better total cost of ownership over the garment's lifespan. The protection is reliable for the life of the garment.

Blends are common. A typical high-performance arc-rated fabric might be 60% Nomex®, 35% FR Rayon, 5% Antistatic Fiber. This blend balances protection, comfort, and ancillary safety features.

What standards and certifications are mandatory?

In FR, "certified" is the only word that matters. Uncertified claims are noise. Compliance is a legal and moral imperative, not a marketing feature. Standards are not arbitrary; they are codified, test-based definitions of performance against specific, lethal hazards. Your sourcing must be driven by the standard that governs your workplace.

The fabric, the thread, the zippers, and the final garment assembly must all comply. This is a system, not just a material.

What do NFPA 2112 and NFPA 70E cover?

These are the North American pillars of safety. You must know which hazard you are guarding against.

- NFPA 2112: Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Short-Duration Thermal Exposures from Fire. This is the flash fire standard. It simulates a sudden, engulfing fire (like a vapor cloud ignition). Key tests include:

- Thermal Protective Performance (TPP): Measures the time until second-degree burn through fabric.

- Vertical Flame Test (ASTM D6413): Measures afterflame time, afterglow, and char length. Must self-extinguish in <2 seconds.

- Heat and Thermal Shrinkage: Fabric cannot shrink more than 10% in any direction, preventing it from tightening on the wearer and causing steam burns.

- NFPA 70E: Standard for Electrical Safety in the Workplace. This is the arc flash standard. It references ASTM F1506 for the fabric. The holy grail metric here is:

- Arc Thermal Performance Value (ATPV) or Energy Breakopen Threshold (EBT): Expressed in cal/cm². This is the incident energy level the fabric can withstand before there's a 50% probability of causing a second-degree burn. This number directly determines the PPE Category (CAT 1, CAT 2, CAT 3, CAT 4) of the garment.

Crucially, NFPA 2112 certification does not imply arc rating. A fabric can protect against a flash fire but fail catastrophically in an electric arc event. For electrical work, the ATPV/EBT on the garment's label is your lifeline.

How do EU (EN) and international standards differ?

The European framework is harmonized under a different system.

- EN ISO 11612: Protective clothing — Clothing to protect against heat and flame. This is a broader, multi-hazard standard. Instead of a single pass/fail, it uses a alphanumeric code to rate performance against specific threats:

- A1/A2: Flame spread (similar to vertical flame test).

- B1/B2/B3: Convective heat (similar to TPP).

- C1/C2/C3: Radiant heat.

- D1/D2/D3: Molten aluminum splash.

- E1/E2/E3: Molten iron splash.

- F1/F2/F3: Contact heat.

A garment's label will list the codes it meets (e.g., A1, B1, C1). For the EU market, CE marking as Personal Protective Equipment (PPE) Category II or III is legally required, backed by an EU-type examination certificate. Understanding this complex landscape of global PPE certification is essential for exporters.

What are the key applications and industry uses?

FR fabric is not a monolith. Its weight, blend, and construction are meticulously engineered to defeat a primary threat. Using a fabric designed for welding spatter in an arc flash environment is a technical failure. The application dictates the armor.

Beyond the base FR property, secondary features like antistatic protection, moisture management, and durability are critically tailored to the work environment.

Which fabrics are used for arc flash and electrical safety?

For utilities, data centers, and any facility with energized equipment, Arc-Rated (AR) inherent fabrics are non-negotiable. The threat is instantaneous, intense heat from an electrical fault.

- Fiber Strategy: Blends dominate. A typical blend like Nomex® III (95% meta-aramid, 5% para-aramid) or a mix of meta-aramid, FR rayon, and antistatic fiber provides the necessary char structure, comfort, and prevents static discharge that could ignite an explosion.

- Beyond ATPV: Look for ATPV/EBT stability after laundering (per ASTM F1506). The garment must maintain its rating for its usable life. Also, consider color fastness—faded garments may not perform as tested.

- The System: Protection comes from complete body coverage—shirt, pants, coverall, arc-rated hood, and face shield. Gaps are failure points.

We recently co-developed a fabric for a North American utility that needed a CAT 4 (40+ cal/cm²) hood fabric that was breathable. By using a specific weave of aramid and a proprietary vent design, we achieved the ATPV while reducing heat stress—a major advancement.

What are the requirements for welding and firefighting apparel?

These are the two most severe FR use-cases.

- Welding: The hazards are radiant heat, molten metal spatter (both iron and aluminum), and sparks. Fabrics must be heavyweight, densely woven, and inherently FR. While heavy 100% cotton or wool can provide some protection (they char rather than melt), modern standards push for treated leather (for aprons) and inherent fabrics like aramid felts. The fabric must resist "breakopen"—where spatter burns through. The American Welding Society (AWS) provides guidelines, but often specific corporate or site standards are stricter.

- Firefighting (Turnout Gear): This is a multi-layered Composite system, each layer with a dedicated function:

- Outer Shell: PBI/Kevlar® or Aramid blends for maximum thermal and abrasion resistance.

- Moisture Barrier: Keeps water, chemicals, and blood-borne pathogens out while allowing sweat vapor to escape (e.g., Crosstech®, Gore-Tex®).

- Thermal Liner: A thick, quilted, aramid or FR rayon batting that provides crucial insulating airspace.

For these professions, the entire garment system is certified as a unit (e.g., to NFPA 1971). You cannot mix and match components from different certified systems.

How to source and specify FR fabrics correctly?

Sourcing FR is a technical procurement exercise, not a typical textile buy. Your supplier must be a verified expert, and your process must be evidentiary. The consequences of error extend far beyond financial loss.

Due diligence here is a formal, documented protocol. It separates credible partners from dangerous pretenders.

What questions must you ask your FR fabric supplier?

Interrogate their expertise. Your checklist should include:

- "Can you provide the third-party test report (from SGS, UL, BTTG) for this specific fabric batch against the full standard (e.g., ASTM F1506-2023)?" (Not just a generic spec sheet).

- "What is the fiber traceability? Can you provide mill certificates for the inherent FR fibers (e.g., Nomex® brand certification)?"

- "If treated, what is the chemical used, and what is the documented service life/laundering limit before retesting is required?"

- "Do you have evidence of batch-to-batch consistency in ATPV/TPP testing?" (Ask to see data from the last 5 lots).

- "Can you support garment manufacturer compliance by providing all necessary fabric documentation for their Technical File (for CE marking)?"

A supplier's hesitation or inability to provide this is a clear disqualifier. For deep dives, consult resources like the ISEA (International Safety Equipment Association) technical guides.

Why is independent third-party testing non-negotiable?

Your final verification step must be objective. Never ship bulk garments based solely on the supplier's in-house data.

- The Audit Test: Upon receipt of bulk fabric or finished garments, send randomized samples to an accredited third-party lab (SGS, Intertek, TÜV). Pay for them to conduct a full audit against the claimed standard.

- What It Validates: It confirms the fabric in your possession performs identically to the sample originally certified. It catches production drift, dye lot variations, or finishing inconsistencies that could lower performance.

- Your Legal Shield: The resulting report is your defensible proof of "due diligence" and compliance. It is essential for workplace safety audits and liability protection.

This step, costing a few hundred dollars, is the cheapest insurance you will ever buy. It transforms a claim into a verified fact.

Conclusion

Flame Retardant fabrics represent a critical engineering discipline where material science meets enforceable safety law. The foundational choice between treated and inherent technologies dictates the very nature of the protection—its permanence, its durability under stress, and its total cost of ownership. This choice must then be channeled through the rigid pipeline of geographic standards—NFPA for flash fire and arc flash in the Americas, EN ISO's multi-hazard coding system in Europe—which provide the only legitimate benchmarks for performance. Finally, sourcing becomes an exercise in forensic verification: demanding traceability, insisting on independent audit testing, and partnering only with suppliers who treat compliance as a documented science, not a sales feature.

Mastering this process is an operational and ethical imperative. It transforms a procurement task into an act of risk management and duty of care, ensuring that the last line of defense between a worker and a thermal hazard is not just a piece of cloth, but a certified, reliable shield.

If your responsibility includes specifying or sourcing life-saving FR fabrics, you need a partner whose processes are as rigorous as your standards. At Shanghai Fumao, our Technical Textiles Division operates at this level. We supply certified inherent and treated FR fabrics with full traceability and third-party documentation, supporting compliance from fiber to finished garment. For a technical consultation on your specific hazard protection needs, contact our Business Director, Elaine: elaine@fumaoclothing.com.