India’s recent decision to impose a 50% tariff on certain textile imports has caused significant ripples across the global fabric supply chain. Many international buyers—especially from the U.S., EU, and Russia—are reconsidering their sourcing strategies. The change has led to sudden cost spikes, disrupted shipping schedules, and urgent calls for alternative suppliers. For those who prioritize quality, stability, and scalability, China has reemerged as a top destination.

Yes. The tariff policy is driving a notable portion of global textile orders toward China. With its unparalleled production capacity, vertically integrated supply chain, and extensive export network, China offers a viable solution for importers navigating trade policy turbulence. For companies like Fumao Fabric, this is an opportunity to serve buyers looking for competitive pricing without sacrificing quality or delivery speed.

For many brands, this is not just about finding the cheapest option. It’s about securing a supply partner who can deliver innovation, handle customization, meet sustainability requirements, and navigate complex logistics—while ensuring every shipment passes international quality checks. Let’s explore how this shift is playing out.

Why Are Global Buyers Reconsidering Indian Suppliers?

India’s tariff increase has disrupted traditional sourcing models. For many buyers, it’s not a question of loyalty to suppliers—it’s a matter of survival in competitive markets. The 50% import duty has raised landed costs for buyers importing raw materials or semi-finished fabrics into India. This impacts pricing for exports, especially in competitive markets like the U.S. and EU where cost margins are tight.

How Do Tariffs Affect Total Landed Cost?

Tariffs increase the total landed cost by adding direct expenses to the base price of goods. Learn more about landed cost calculation and its role in import planning. Beyond the numbers, tariffs can weaken supply chain resilience, leading to delayed deliveries and missed seasonal launches. In industries like fast fashion, this delay means loss of relevance in trend cycles, directly impacting sales.

Are There Long-Term Risks in Relying on Tariff-Heavy Markets?

Yes. Buyers dependent on markets prone to sudden tariff hikes risk instability in pricing and contract terms. This uncertainty can derail production schedules and cause stock shortages at retail. Many global brands now create a dual sourcing model, keeping one primary supplier and one secondary supplier in countries with stable trade policies. China remains an attractive choice due to its strong export agreements and robust industrial clusters.

Why China Is Benefiting From India’s Tariff Move

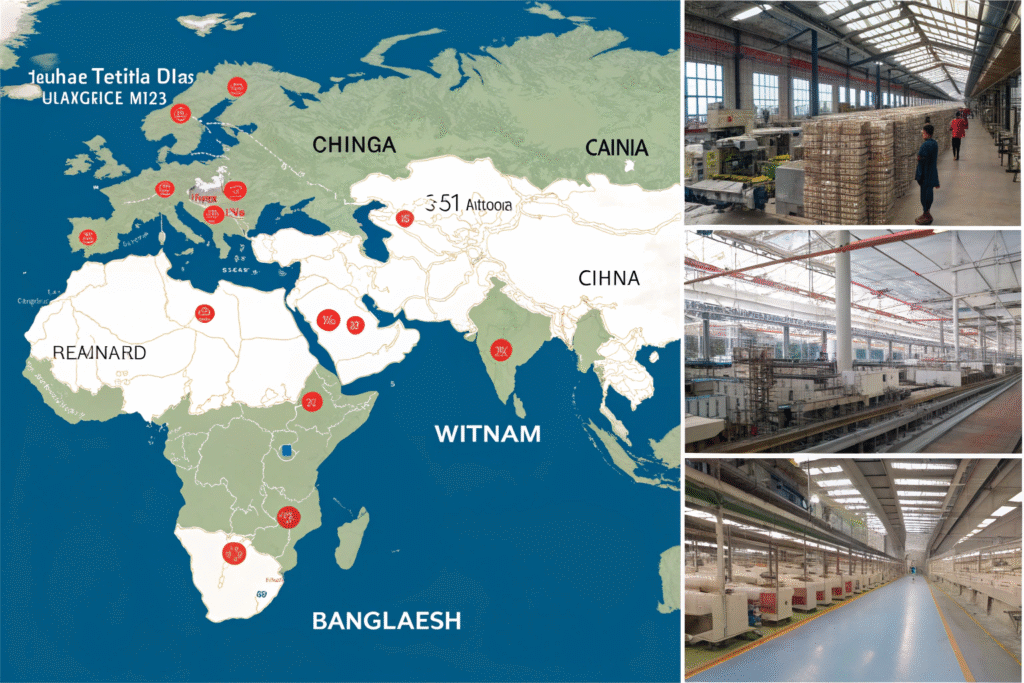

China’s comprehensive supply chain—from raw fiber to finished fabric—provides a competitive advantage unmatched by many other manufacturing countries. Its capacity for end-to-end production allows for faster order fulfillment, even during peak seasons.

How Does Vertical Integration Lower Sourcing Risk?

Vertical integration means controlling every stage—spinning, weaving, dyeing, printing, finishing—within close proximity. This ensures consistent quality control and minimizes the risk of bottlenecks. Read more about vertical integration in manufacturing and its effect on cost predictability. Additionally, lean approaches like lean manufacturing help reduce waste and speed up production cycles.

Which Chinese Textile Segments Are Seeing the Biggest Gains?

Eco-friendly fabrics, functional sportswear textiles, and premium fashion fabrics have seen significant order growth. These products often require advanced finishing and strict compliance certifications like OEKO-TEX and Global Recycled Standard. Buyers are willing to shift orders to suppliers who can guarantee both performance and sustainability at scale.

Are Tariffs Pushing Buyers to Reassess Supply Chain Geography?

Yes. Tariffs are only one factor influencing sourcing geography. Logistics stability, compliance requirements, and supplier capabilities also play major roles in this shift. The Indian tariff has acted as a catalyst for brands to review the balance of their sourcing portfolios.

What Role Does Proximity to Raw Materials Play?

Proximity to raw materials shortens lead times and reduces transportation costs. Discover how raw material sourcing impacts production schedules and supply stability. China’s access to synthetic fibers, cotton imports, and advanced dyeing technologies makes it a self-sufficient hub for most fabric categories.

How Can Buyers Build a Multi-Country Sourcing Strategy?

They can assign different product lines to different countries based on capability and risk factors. For example, organic cotton from India, technical performance fabrics from China, and knitwear from Vietnam. This diversification helps mitigate political risks, currency fluctuations, and capacity shortages.

How Can Buyers Negotiate Better With Chinese Suppliers?

Negotiations in China’s textile sector thrive on trust, transparency, and mutual benefit. Building relationships with suppliers often results in better payment terms, improved service, and faster issue resolution.

What Payment Methods Are Most Secure for International Orders?

Payment security is essential for cross-border transactions. Methods like irrevocable letters of credit (LCs) and trade credit insurance offer protection against default. These arrangements ensure both sides are committed to the terms and reduce financial risk.

How Can Quality Assurance Be Ensured Remotely?

Third-party inspections and in-house QC reports bridge the gap between overseas buyers and Chinese factories. Organizations like SGS and Bureau Veritas provide pre-shipment inspections, factory audits, and lab testing to verify product compliance.

How Are Lead Times Managed in China’s Textile Industry?

Lead times in China are minimized through industrial clustering—where related businesses operate within the same geographic area. This proximity reduces transportation delays and enhances communication.

What Is the Advantage of Textile Clusters?

Clusters allow quick coordination between spinning mills, dye houses, and finishing plants. This means fabrics can move from weaving to finishing within days, not weeks. See how industrial clusters can drive manufacturing efficiency and innovation.

Can AI Tools Improve Production Planning?

Yes. AI-driven demand forecasting enables suppliers to align production schedules with buyer demand, reducing overproduction and stockouts. Predictive analytics can also suggest optimal production windows to avoid congestion during peak export seasons.

Why Are Sustainability Credentials Becoming More Important?

Global brands are weaving sustainability into their procurement strategies as a non-negotiable requirement. This is not just about environmental responsibility—it’s also about aligning with consumer expectations and regulatory frameworks in major markets.

Which Certifications Matter Most in Fabric Sourcing?

Certifications like OEKO-TEX ensure products are free from harmful substances, while Global Recycled Standard verifies the recycled content in fabrics. These certifications can serve as a marketing tool for brands aiming to position themselves as eco-conscious.

How Do Sustainable Practices Influence Buyer Loyalty?

Sustainable practices often lead to repeat business. Buyers working with suppliers who meet environmental standards are more confident in marketing their products to eco-aware customers. This also helps brands qualify for government incentives in certain regions, further strengthening the partnership.

Can Chinese Suppliers Handle Small-Batch Custom Orders?

Yes. China’s textile industry has evolved to accommodate small-batch orders without compromising on quality or lead time. This flexibility is crucial for startups, niche brands, and fashion houses testing new designs.

What Is the Process for Small-Batch Orders?

The process typically involves design confirmation, fabric sourcing, sample development, and limited-run production. Companies offering custom textile printing can deliver specialized designs within days, enabling faster product launches.

How Does This Benefit Startups?

Small-batch production lowers upfront investment risk and allows emerging brands to gauge market response before committing to larger volumes. This approach supports a more agile business model and quicker adaptation to consumer trends.

How Is Technology Transforming Textile Export Logistics?

Technology is revolutionizing textile export logistics by introducing automation, predictive analytics, and integrated tracking systems. These innovations make it possible for buyers to monitor shipments in real-time and predict delivery windows with greater accuracy.

What Role Does Automation Play in Warehousing?

Automation improves speed, accuracy, and scalability. Automated storage and retrieval systems can handle thousands of fabric rolls daily, reducing manual labor costs and human error. Learn more about smart warehousing.

How Does Real-Time Tracking Benefit Buyers?

Real-time tracking platforms allow buyers to anticipate potential delays and adjust downstream production schedules accordingly. Platforms like Flexport integrate logistics data with inventory management systems, offering complete visibility.

Conclusion

India’s 50% tariff decision is reshaping the global textile sourcing map. For many brands, it has underscored the need for diversification and stability in their supplier networks. China’s combination of scale, quality control, speed, and compliance makes it a natural choice for buyers seeking resilience against geopolitical and economic uncertainties.

From eco-friendly innovations to small-batch customization, Chinese suppliers like Fumao Fabric are well-positioned to meet diverse market demands. By leveraging technology, vertical integration, and robust logistics infrastructure, they can deliver solutions that match both premium and budget-conscious segments.

For buyers facing increased costs and unpredictability in other markets, this is the time to forge long-term partnerships with suppliers who can guarantee not just price competitiveness, but also quality assurance and timely delivery.

At Fumao Fabric, we welcome you to explore how we can co-create value for your sourcing strategy. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next fabric order.