If you're an apparel buyer or brand sourcing from China, this question isn't just about checking a box. It's about risk management. You've likely heard horror stories: shipments rejected at customs, brands fined for false claims, or entire product lines pulled from shelves because "organic" content couldn't be verified. So when you ask if Fumao Clothing is OCS certified, what you're really asking is: "Can I trust you with my brand's reputation and compliance?" The short, unequivocal answer is yes. We are not just a certified manufacturer; we are an integrated OCS supply chain partner with certification spanning our core operations, backed by a system built for transparency and audit-proof traceability.

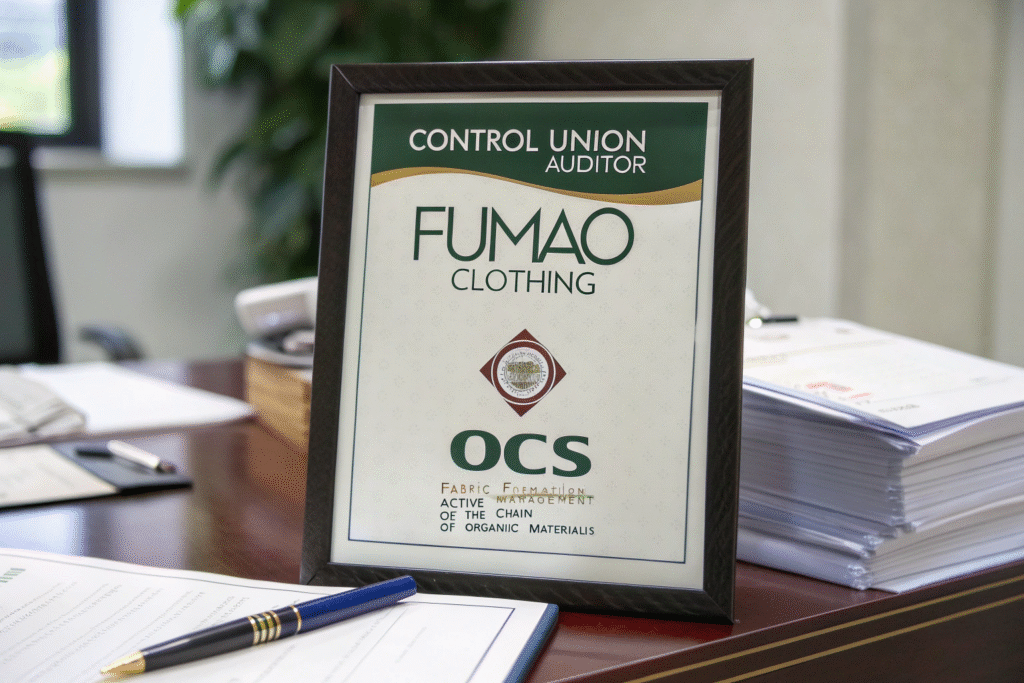

As the business owner here at Shanghai Fumao, I treat our OCS (Organic Content Standard) certification with the same seriousness as our financial audits. It's our operational license to serve discerning global brands. Our certification, issued by the renowned body Control Union (Certificate Number CU-109623), specifically covers the manufacturing and trading of organic textile products. This isn't a generic company certificate—it precisely lists our certified activities, including the management of knitting, weaving (through our controlled partner mills), and the critical chain of custody tracking that is the hallmark of authentic organic production.

Let me be direct: In today's market, a supplier claiming to handle organic cotton without a verifiable, scope-specific OCS certification is a major red flag. Our certification is your first layer of security. But the real value lies in how we implement it daily to protect your orders from contamination, fraud, and compliance failures. Let's break down exactly what our certification means for you.

Our Certification Scope: What "Certified Manufacturer" Really Means.

The devil is in the details—especially in certification. Many trading companies hold a generic "trader" certificate, which only allows them to buy and sell certified goods they did not physically transform. This adds a risky, opaque link to your supply chain. Fumao Clothing's certification is fundamentally different. We are certified as a manufacturer under the OCS standard. This means our certification scope, as verified by Control Union auditors, includes the key processes of fabric formation and the active management of the chain of custody for organic materials.

This is critical for you because it holds us directly accountable for what happens to the organic cotton during production. We don't just pass through a pre-made fabric; we actively manage and transform the certified yarn into finished fabric under the strict OCS protocol. Our system is designed to maintain the integrity of your organic content from the moment the yarn enters our control until the final fabric roll is shipped.

What specific processes are covered under your OCS certificate?

Our OCS certificate explicitly covers:

- Knitting & Weaving Management: While our owned factory specializes in knitting, our certification encompasses the weaving processes performed at our long-term, audited partner mills. We manage them as an integrated unit under our OCS system.

- Chain of Custody Management: The entire tracking, documentation, and mass balance system for organic materials.

- Trading: The legitimate sale and documentation transfer of certified goods.

This scope was verified in our most recent surveillance audit in November 2023. The auditor spent a full day tracing a single batch of OCS yarn through our receiving logs, our partner weaving mill's production records, and back to our finishing and inspection reports. This end-to-end verification is what defines a true certified manufacturer. You can compare this to the basic requirements outlined in a guide to understanding OCS certification scope for importers.

How does your certification protect my order from contamination?

The certification mandates the procedures that prevent contamination. Because we are audited on these specific processes, we have implemented a "Clean Flow" protocol. Certified organic yarn is stored in a designated, labeled warehouse zone. Production on knitting machines or looms is scheduled in dedicated blocks. Most importantly, we enforce a mandatory machine cleaning and verification procedure before any OCS run begins, documented with checklists and photos.

In March 2024, we ran a large order for OCS organic cotton jersey for a French children's wear brand. Before starting, the knitting line was cleaned, and we ran a test with sacrificial conventional yarn to check for any residual fibers. Only after this verification did we load the OCS yarn. This procedure, required by our certification, ensured a 0% contamination rate, confirmed by the client's own third-party lab test. This operational rigor is the practical result of holding a manufacturing certificate.

Proof in Practice: Our Transaction Certificate System.

Certification is only as good as the paperwork it generates. For you, the Transaction Certificate (TC) is the ultimate deliverable—it's the legal, auditable birth certificate for your organic fabric. Every single OCS order that leaves Shanghai Fumao is accompanied by a unique TC that tells its complete story. This document is generated from our digital tracking system and provides the unbroken chain from our certified yarn supplier to us, and finally to your specified consignee.

We don't see TCs as an afterthought; they are a core output of our production. Our ERP system is configured to link physical batch numbers to documentary outputs automatically. This minimizes human error and ensures that the data on the TC—weights, percentages, supplier IDs—perfectly matches the physical shipment. When you receive fabric from us, you receive proof.

Can I see a sample Transaction Certificate before ordering?

Absolutely, and you should demand this from any potential supplier. We proactively provide anonymized sample TCs to serious inquiries. A genuine TC will show:

- Our company info and OCS license number.

- The consignee (your company or agent).

- A detailed product description (e.g., "100% Organic Cotton Single Jersey Knit Fabric").

- Exact quantity in kilograms and/or meters.

- The reference number of the input TC from our yarn supplier, creating the chain.

A sample demonstrates our familiarity with the system and confidence in our processes. In contrast, a supplier hesitating to provide a sample TC often lacks real experience with certified production. Reviewing this document is a key step in any pre-shipment verification checklist for ethical sourcing.

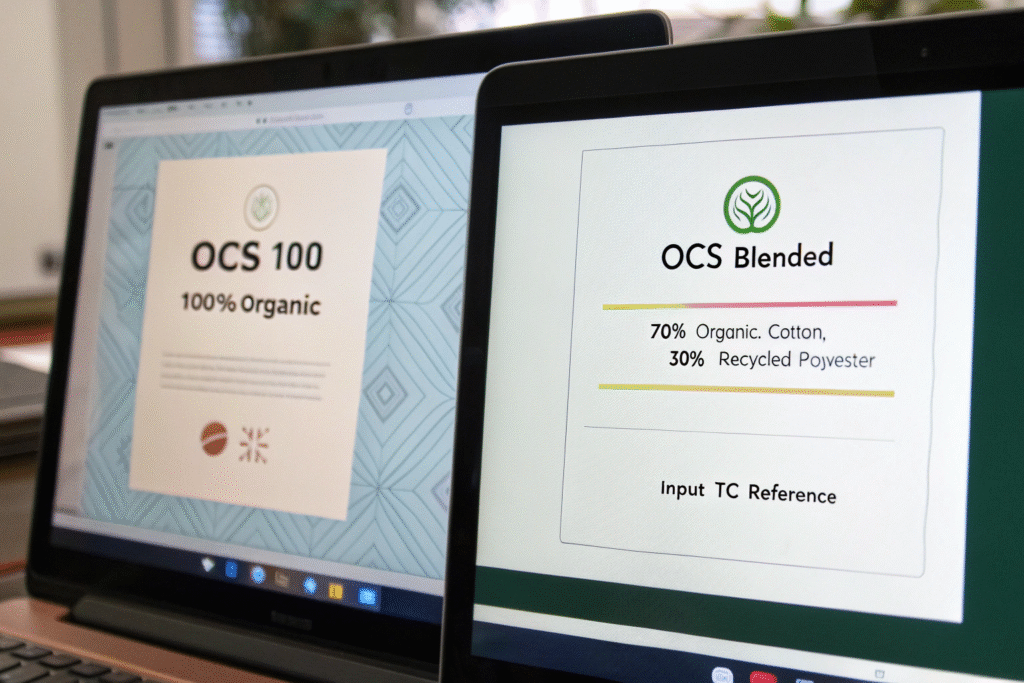

How do you handle OCS Blended vs. OCS 100 certifications?

We are certified and fully equipped to handle both categories with precision.

- OCS 100: For products with 95-100% organic content. We track the entire product mass.

- OCS Blended: For products with 5-94% organic content. We track only the certified organic portion through mass balance.

The choice impacts your labeling, cost, and marketing. For example, in Q1 2024, a Californian activewear brand worked with us on a 70% organic cotton / 30% recycled polyester blend (OCS Blended). Our system tracked the 70% organic cotton from its certified source, while the recycled polyester was documented separately. The final TC clearly stated the organic percentage, ensuring compliant labeling. Understanding this distinction is crucial for developing a cost-effective sustainable apparel line.

| Scenario | OCS Category | Fumao's System Action |

|---|---|---|

| 100% Organic Cotton Fleece | OCS 100 | Tracks 100% of the fabric weight from certified organic yarn. |

| 55% Organic Cotton / 45% Tencel™ Jersey | OCS Blended | Tracks only the 55% organic cotton portion. Tencel is documented separately. |

| Blended Yarn (e.g., Organic Cotton + Conventional Cotton) | OCS Blended | Tracks the organic cotton percentage within the blended yarn itself. |

Beyond the Certificate: Our Integrated OCS Control System.

The certificate on the wall is the result, not the process. Our real investment is in the integrated control system that makes certification meaningful. This system combines physical segregation, digital tracking, and trained personnel. It's how we ensure that the OCS fabric you receive isn't just paper-certified but process-guaranteed.

Our Quality Control team has a dedicated OCS coordinator. This person's sole responsibility is to oversee compliance for every certified order—from verifying incoming TCs against yarn shipments to authorizing the final TC issuance. This specialized focus eliminates the "this is someone else's job" problem that plagues less committed factories.

What kind of internal audits do you perform?

We conduct monthly internal audits that mirror the external certification audit. Our QC team checks:

- Mass Balance Reconciliation: Comparing yarn input (from TCs) against fabric output and recorded waste.

- Storage & Segregation: Physical inspection of warehouse zones and production line setups.

- Documentation Review: Ensuring all TCs, inventory logs, and cleaning records are complete and accurate.

For instance, in December 2023, an internal audit flagged a minor discrepancy in the waste log for an OCS terry cloth batch. We immediately paused shipping, investigated (finding a data entry error), corrected it, and documented the corrective action. This internal vigilance is what prevents major non-conformities during our annual external audit. It’s a level of discipline that brands should look for, as discussed in forums on managing supply chain transparency in fashion.

How do you partner with dyeing/finishing mills under OCS?

This is a critical point. Many fabric "manufacturers" lose control at the dyeing stage. Our model is different. We use a select number of cooperative dyeing and finishing mills that are included under our OCS certification scope. They are audited by Control Union as part of our operation, not as separate entities.

We provide them with certified organic fabric, and they operate under our strict processing protocols. Their output is tracked back into our system. This means the entire journey—from yarn to greige fabric to dyed/finished fabric—remains within one certified, controlled pipeline. This vertical integration is a game-changer for authenticity and is a core reason why brands working with Shanghai Fumao experience fewer compliance issues. (Here's a real advantage: this control shaves 1-2 weeks off the lead time for certified orders, as we avoid inter-factory coordination delays.)

Verifying Our Credentials: A Checklist for Smart Buyers.

Trust, but verify. We encourage our potential clients to be thorough. Here is exactly how you can check our credentials and what you should look for in any OCS supplier.

First, request our official OCS scope certificate. You can contact us directly or verify our status with Control Union using our company name and certificate number. Second, ask for sample documentation—a sample TC and perhaps an excerpt from our mass balance log for a past order. Third, request a virtual tour of our OCS storage and production setup. Seeing is believing.

What are the red flags in an OCS supplier?

- Certificate Scope is Only "Trading": This means they don't control manufacturing.

- Inability to Provide a Sample TC Quickly: Indicates lack of practical experience.

- Vague Answers on Physical Segregation: If they can't describe their "Clean Flow" process in detail, they likely don't have one.

- No Mention of Partner Mill Management: For processes they outsource like weaving or dyeing.

A green flag is a supplier who, like us, actively educates you on the system. We recently spent an hour on a video call with a startup from Portland, walking them through every line of a sample TC and explaining how it would be generated for their specific order. That transparency builds the foundation for a secure partnership.

Ready to Partner with a Certified Manufacturer?

Choosing Shanghai Fumao means choosing a partner whose OCS certification is woven into its operational fabric. It’s the foundation of our service to brands that cannot afford compromises on authenticity or compliance.

Conclusion

Yes, Fumao Clothing is a certified OCS organic cotton manufacturer, with a scope that covers the critical transformation and chain of custody management processes. But more importantly, we are a partner that has built a robust, transparent system around this certification to de-risk your organic sourcing. Our certification is not just a badge; it's a verifiable promise of integrity, backed by documented procedures, integrated partner control, and a commitment to providing you with irrefutable proof of content.

In a market flooded with unverified claims, this certification and our implementation of it are what separate true partners from mere vendors. It ensures that the premium you pay for organic cotton delivers real value—in brand trust, consumer confidence, and supply chain security.

If you are looking for a reliable, transparent, and certified source for authentic organic cotton fabrics, let's connect. Shanghai Fumao is ready to provide not just the certificate, but the complete, audit-ready story behind your fabric. Contact our Business Director, Elaine, to start your certified organic journey. Email her at elaine@fumaoclothing.com for a copy of our credentials and a consultation.