If you're sourcing apparel, this question is crucial. You see a leading activewear brand demanding CMIA from their sportswear suppliers, but your classic menswear shirt factory hasn't even mentioned it. Confusion sets in. Is this a niche requirement for "eco" lines, or is it about to become as universal as a social audit? From my two decades supplying fabric to every category—from high-fashion silks to industrial workwear—I can tell you the answer is nuanced. No, CMIA certification is not universally required for all apparel categories today. However, viewing it as a simple yes/no question is a strategic mistake. The real question is: for which categories is it becoming a de facto requirement, and for which is it a powerful differentiator? The demand is spreading from specific, high-impact categories outward, driven by brand risk, consumer pressure, and the sheer logic of supply chain management.

Think of it like seatbelts in cars. Initially, they were for race car drivers. Then, they became standard in luxury models. Now, they're legally required in every passenger vehicle. CMIA is on a similar trajectory in apparel. It started with categories where environmental impact is most visible or controversial (like outdoor gear or fast fashion). It's now moving into the mainstream. The "requirement" depends entirely on who you're selling to, what you're making, and where you're selling it. For a factory making basic socks for a discount retailer, the pressure might be low. For that same factory making socks for a European brand with a public "Net Zero" pledge, CMIA could be the deal-breaker.

So, let's move beyond the binary. The critical task is to map the landscape. Understanding which product categories are in the "required," "strongly preferred," and "emerging" zones for CMIA will save you from costly missteps and unlock premium opportunities. This isn't about chasing every trend; it's about strategically aligning your production or sourcing with the market's evolving definition of responsible manufacturing.

For Which Apparel Categories Is CMIA Becoming a De Facto Requirement?

The push for CMIA certification is strongest where the link between product, environmental impact, and brand identity is most direct. These categories are in the "red zone," where leading brands are making it mandatory for their core suppliers.

1. Sportswear & Activewear: This is ground zero. Brands like Nike, Adidas, Lululemon, and their competitors are locked in a battle over sustainability innovation. The materials (polyester, nylon, elastane) are energy-intensive to produce. The performance features (moisture-wicking, UV protection) often involve chemical treatments. For these brands, CMIA provides the hard data to back their claims of "lower impact" products. In 2023, we saw a major sports brand require CMIA or equivalent for any factory producing their core polyester fleece lines. For a supplier, lacking certification here means being excluded from the most lucrative contracts.

2. Outdoor & Technical Apparel: The ethos of this category is tied to nature preservation. Brands like Patagonia, The North Face, and Arc'teryx have built their marketing on environmental stewardship. Their customers actively demand transparency. CMIA certification offers a rigorous, third-party-verified framework to demonstrate reduced carbon footprint in the manufacturing of waterproof membranes, insulated jackets, and hiking apparel. It's often required alongside other certifications like Bluesign.

3. Childrenswear: This is driven by heightened consumer safety concerns and regulatory scrutiny (like CPSIA in the US). Parents are exceptionally sensitive to chemicals and environmental ethics. Major children's brands and retailers are using CMIA as a proxy for overall factory management rigor. A factory that controls its carbon and chemical inputs is seen as inherently more reliable for producing safe, high-quality children's products. We supply GOTS-certified organic cotton to several childrenswear factories in Asia, and for them, adding CMIA has become a non-negotiable step to secure long-term orders from EU brands.

4. "Sustainable" or "Conscious" Collections from Major Fast-Fashion & Mid-Market Brands: This is a critical expansion. While a brand's entire supply chain may not be certified yet, their dedicated eco-lines almost always are. When Zara, H&M, or Uniqlo launches a "Join Life" or "Conscious" collection, they mandate specific environmental credentials from the manufacturing partners for those specific garments. CMIA is increasingly on that shortlist. For a factory, getting certified might initially grant access only to these special lines, but it's a foot in the door with a massive buyer.

In these categories, CMIA is transitioning from a "nice-to-have" to a cost of doing business with tier-1 brands. The requirement is often explicitly stated in the supplier code of conduct or the request for quotation (RFQ).

Why Are These Specific Categories Leading the Charge?

The drivers are a mix of consumer pressure, brand risk, and material impact.

- Sportswear/Outdoor: Consumers are "activists"; brand identity is ecological.

- Childrenswear: Consumer risk aversion is extreme; regulatory oversight is high.

- Fast-Fashion Eco-Lines: Brand response to criticism; a tool for reputational repair.

The common thread is that the end-consumer in these segments is either highly engaged or highly concerned, forcing brands to seek verified proof points down the supply chain.

What Does This Mean for a Factory Specializing in These Categories?

If your factory predominantly produces for these categories, pursuing CMIA is no longer a strategic option—it's a strategic imperative for survival and growth. It is the ticket to the negotiating table. The investment should be framed not as a compliance cost, but as the entry fee for the premium market segment. The conversation shifts from "Can we afford it?" to "Can we afford to be left out?"

In Which Categories Is CMIA a Strong Competitive Advantage (But Not Yet Required)?

This is the "yellow zone"—categories where the leaders are adopting CMIA, the forward-thinking brands are asking for it, and the mainstream is starting to look. Here, certification isn't a gatekeeper, but it is a powerful tool to win better business, command higher prices, and build lasting partnerships.

1. Denim: Denim manufacturing is notoriously resource-intensive, requiring vast amounts of water, energy, and chemicals for dyeing, washing, and finishing. Brands are under immense pressure to clean up denim's act. While not every denim brand requires CMIA yet, the most innovative ones (like those promoting laser finishing and ozone washes) are using it to quantify their improvements. A denim factory with CMIA can convincingly market its "lower-impact jeans" to brands, providing a tangible edge over competitors. We work with a mill in Keqiao that supplies low-water indigo dyeing fabrics, and their CMIA-certified finishing partners are consistently winning the most interesting (and profitable) development projects.

2. Luxury & High-End Fashion: The luxury sector is increasingly conflating quality with responsibility. While artistry and heritage are primary, customers now expect ethical and environmental integrity. CMIA offers a structured, credible way for a luxury brand's atelier or exclusive supplier to demonstrate environmental stewardship without greenwashing. For a factory producing high-end silk blouses or wool coats, CMIA certification becomes part of the story of exquisite, conscious craftsmanship. It's a value-add that supports the premium price point.

3. Corporate Workwear & Uniforms: Large corporations issuing tenders for employee uniforms are adding ESG (Environmental, Social, and Governance) criteria to their scoring. A uniform supplier with CMIA certification can score highly on the environmental pillar, potentially beating a lower-priced but uncertified competitor. This is especially true for companies with their own public sustainability targets.

4. Fashion Knitwear (Sweaters, Cardigans): The production of wool and synthetic knitwear involves significant energy use in spinning and knitting. Brands focusing on "slow fashion" or "responsible knitwear" are seeking partners who can validate their lower impact. Certification here helps a factory move beyond being a simple CMT (Cut, Make, Trim) unit to becoming a development partner for sustainable knitwear programs.

In these categories, you have a choice. But the choice is between competing on the old battlefield of price and speed versus competing on the new battlefield of value, transparency, and future-proofing. Early adoption in the yellow zone establishes you as a leader.

How Can a Factory in These Categories Leverage CMIA Proactively?

Don't wait for a brand to ask. Integrate CMIA into your sales and marketing narrative.

- Case Studies: Create a brief document showing how certification led to a 10% reduction in energy use per sweater.

- Sample Tags: Include a line on your sample hangtags: "Developed in a CMIA-Certified Facility."

- Direct Outreach: Target the sustainability managers at brands in your category, not just the buyers. Offer to share your carbon footprint data per product type.

This positions you as a solution to their problem, not just a supplier fulfilling an order.

What's the Business Case for Certification in This "Advantage" Zone?

The ROI is in margin enhancement and client retention. You may not win a contract solely on CMIA, but it can be the tie-breaker that wins you a 5-15% price premium and a three-year contract instead of a seasonal one. It makes your business "sticky" because replacing a certified, transparent partner is harder for a brand than swapping out a generic supplier.

Are There Any Categories Where CMIA Is Currently Less Relevant?

Yes, the "green zone" exists, but it's shrinking. These are typically categories characterized by extreme price sensitivity, minimal brand consumer engagement, or very short product life cycles where environmental concerns are not yet a primary purchase driver.

1. Ultra-Fast Fashion & Deep Discount Commodities: The business model here revolves around speed and ultra-low cost. The margin structures are so thin that the upfront cost and operational discipline of CMIA are often seen as prohibitive. The end-consumer is buying primarily on price and trend, with little inquiry into manufacturing origins. For now, the commercial pressure for certification is minimal.

2. Simple, Non-Branded Basics (White Label): Think of the plain t-shirts, socks, or underwear sold in bulk packs without a strong brand story. The buyer (a distributor or retailer) is often sourcing purely on FOB price. However, this is changing as large retailers like Walmart or Tesco set their own Scope 3 emission targets. Even white-label suppliers may soon feel pressure.

3. Certain Technical Textiles with Highly Regulated Primary Functions: For example, military uniforms or specialized industrial workwear where performance specs (flame resistance, ballistic protection) are the absolute, legally mandated priority. The environmental footprint, while important, may currently be secondary in procurement criteria. However, even here, government procurement is starting to include sustainability clauses.

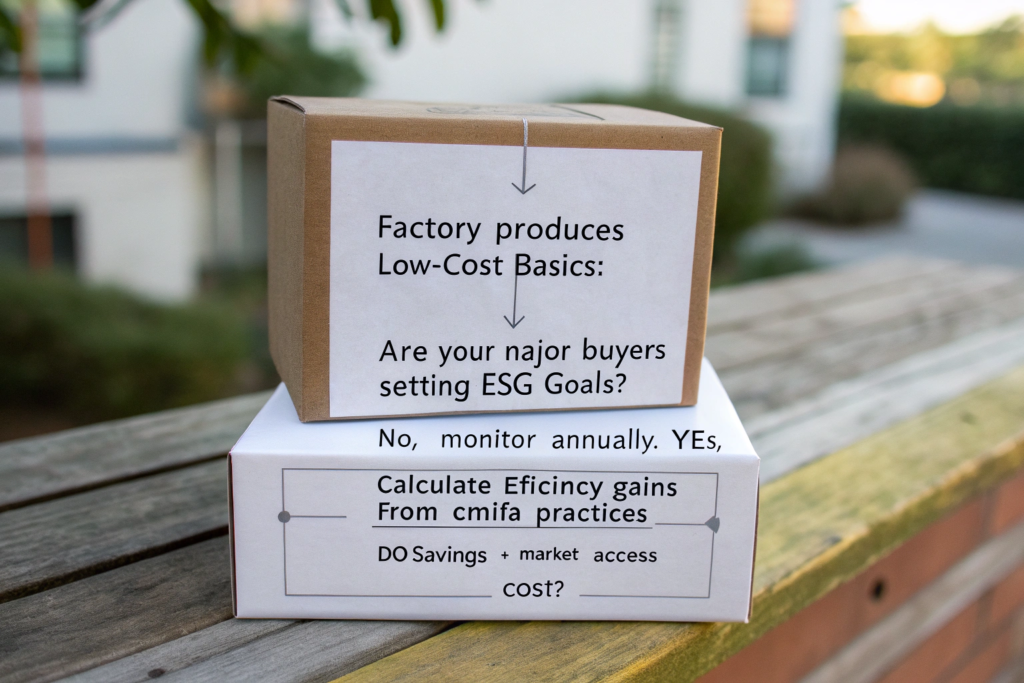

Important Caveat: "Less relevant" does not mean "irrelevant forever." A factory in this green zone should still monitor the situation. If your major client gets acquired by a larger group with sustainability policies, or if new legislation like the EU's Carbon Border Adjustment Mechanism (CBAM) comes into full effect, the relevance can change overnight. The smart move is to at least understand the basics and the potential costs, even if active pursuit isn't justified today.

Should a Factory in These Categories Ignore CMIA Entirely?

No. They should understand and monitor. The factory owner should be aware of what the certification entails and its approximate cost. They should ask their largest buyers about their 3-5 year sustainability roadmaps. This isn't about investing now, but about avoiding being blindsided. A strategic review once a year is prudent.

Could There Be Hidden Benefits Even Here?

Potentially. Even in a low-margin business, the process efficiency gains from a CMIA-like approach (waste reduction, energy saving) can directly improve the bottom line. A factory might implement some core practices—like tracking material yield—without seeking full certification, purely for internal cost control. This builds a foundation for the future.

How Should a Factory Decide If CMIA Is Right for Its Product Mix?

This is the strategic decision-making process. It's not a guessing game; it's an analysis based on your clients, your aspirations, and your operational readiness.

Step 1: Client & Market Analysis (Look Outward)

- Current Clients: Survey your top 5 clients. Do they have public sustainability goals? Have they ever asked about your carbon footprint or environmental management? What categories do they sell?

- Target Clients: Who do you want to work with in 3 years? Research their supplier policies. Download the sustainability reports of your dream brands. You'll quickly see if CMIA or similar frameworks are mentioned.

- Category Trajectory: Based on the zones above, where does your core expertise lie? Is it in a red, yellow, or green zone?

Step 2: Internal Capability & Cost-Benefit Analysis (Look Inward)

- Data Readiness: Do you have 12 months of utility bills? Can you track fabric consumption by order? If not, this is your first gap.

- Cost Estimation: Get quotes from 2-3 consultants for a gap analysis and certification project for a factory of your size.

- Benefit Projection: Estimate potential benefits. Can you attract 1-2 new clients willing to pay a 5% premium? Can you reduce energy and fabric costs by 3-5%? Model the 3-year financial impact.

Step 3: The Strategic Choice

Map your position. For example:

- "We make activewear for growing EU brands." → Path: Pursue CMIA ASAP. It's a market requirement.

- "We make high-quality woven shirts for mid-tier US brands." → Path: Develop a 2-year plan. Start with data collection, aim for certification as a client-retention tool.

- "We make unbranded polyester bags." → Path: Monitor and improve efficiency internally. Certification is a future possibility.

A Real Case from Our Network: A Shanghai Fumao client, a mid-sized factory in Jiangsu producing both basic polo shirts (green zone) and performance cycling jerseys (red zone), faced this dilemma in 2022. They chose to pursue CMIA but focused their certification story and marketing efforts exclusively on their performance wear division. This targeted approach allowed them to win a major new cycling apparel client in Germany, while their polo shirt business continued unchanged. The investment paid for itself within 18 months through the new business alone.

What If My Factory Makes Multiple Product Categories?

This is common. The strategy should be category-led, not factory-wide in messaging. You can get the factory certified as a whole, but when you talk to clients, tailor the message. To a basics buyer, emphasize your quality and efficiency (outcomes of the system). To a sportswear buyer, lead with the CMIA certification itself. The operational benefits (like lower waste) will improve profitability across all categories, even the uncertified ones.

How Can Fabric Suppliers Like Shanghai Fumao Assist in This Decision?

We sit at a unique crossroads. We see which of our fabric categories are being specified for CMIA-backed projects. We can provide insights into which brands and product categories are driving demand for certified supply chains. Furthermore, by providing you with certified materials (like GRS recycled fabrics) and comprehensive technical data sheets, we reduce the complexity of your own certification process. Partnering with informed suppliers is a key part of your risk assessment and strategic planning.

Conclusion

The question of whether CMIA certification is required for all apparel categories has a clear answer: not yet, but the trend is unequivocal. The requirement is cascading from high-impact, high-visibility categories (sportswear, outdoor, childrenswear) into the mainstream (denim, luxury, workwear). For factories, the decision is no longer about if but about when and how to engage with this standard.

Ignoring this shift is a significant business risk. Treating CMIA as a checkbox for a niche market is a missed opportunity. The most successful factories will be those that conduct a clear-eyed analysis of their product mix and client portfolio, then develop a strategic roadmap. For some, this means immediate investment to secure their position in the premium market. For others, it means building internal capabilities now to enable a swift response when their market inevitably turns.

Ultimately, CMIA is more than a certificate; it's a marker of a modern, efficient, and transparent manufacturing operation. The disciplines it instills—data-driven management, waste reduction, and supply chain transparency—are good business practices regardless of category. By embracing this standard where it matters most, you're not just complying with a trend; you're future-proofing your business and building a foundation for resilient, profitable growth in an increasingly conscientious global marketplace.

To navigate this landscape effectively, align with partners who understand both the technical and commercial dimensions. At Shanghai Fumao, we are committed to supporting manufacturers through this transition with traceable, sustainable fabric solutions and insights into evolving brand expectations. If you're evaluating the role of CMIA in your factory's future and want to discuss how your material choices intersect with certification strategies, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build a strategic path forward for your product categories.