You're developing both a men's workwear line and a women's lingerie collection. Your supplier sends over CMIA certificates that look identical. A question hits you: should the safety standards for a rugged men's shirt be the same as for delicate women's undergarments? I've watched brands make dangerous assumptions here. One client nearly shipped chemically unsafe children's sleepwear because they used the same "general apparel" certificate template for all products. The truth is, while the CMIA framework is consistent, the specific requirements and risk profiles differ dramatically between men's and women's wear categories.

The core Chinese national standard GB 18401 applies to all textiles, but its application varies based on the product's end use. The certification isn't about gender; it's about product category and skin contact level. A men's suit lining and a women's bikini top both need certification, but the testing rigor, acceptable limits, and even the referenced standards can change. Assuming "one certificate fits all" is the fastest way to compliance failure and product recalls.

Let's clarify the confusion. This guide will dissect exactly where and how certification requirements diverge between typical men's and women's wear items. We'll explore how fiber composition, skin contact intimacy, and special functional needs create different testing priorities. Most importantly, we'll give you a practical framework to ensure every product in your range, regardless of gender category, meets its exact compliance requirements—protecting your customers and your brand.

The Foundation: How GB 18401 Classifies Textiles By Use, Not Gender

The cornerstone of CMIA certification for apparel is GB 18401-2010 (National General Safety Technical Code for Textile Products). This standard cleverly avoids gender labels entirely. Instead, it classifies all textile products into three categories based on how they interact with human skin:

- Class A ( Products for Infants and Young Children): For children under 36 months. This has the strictest limits.

- Class B (Products in Direct Contact with Skin): Clothing where fabric touches skin for extended periods.

- Class C ( Products Not in Direct Contact with Skin): Outerwear where fabric does not typically touch skin (e.g., coats, suits).

This classification system reveals the answer to our core question: CMIA certification differs based on the product's type, not the wearer's gender. A woman's winter coat (Class C) and a man's winter coat (Class C) have identical requirements. However, a man's brief (Class B) and a woman's bra (Class B) share the same class but may face different practical testing emphases due to material and construction differences.

The critical step is correctly classifying each SKU in your line. Misclassification is a common audit failure. For example, marketing a sheer blouse as "outerwear" (Class C) when it's clearly worn against the skin (Class B) is a violation, even if the physical garment is the same for men or women.

Where Requirements Typically Converge: Outerwear and Base Layers

For many apparel categories, gender is irrelevant to the standard. These items fall into the same GB Class and thus have identical CMIA test limits:

- Class C (Non-direct Skin Contact): Blazers, overcoats, padded jackets, most suit trousers (worn over undergarments), some structured dresses.

- Class B (Direct Skin Contact): Basic t-shirts, polo shirts, underwear, socks, nightwear, most dresses and skirts, athletic jerseys.

Here, the certificate for a 100% cotton men's t-shirt and a 100% cotton women's t-shirt, both Class B, should be virtually identical if the fabric composition and weight are the same. The testing lab is certifying the fabric's safety properties, not the garment's pattern. This is why working with a fabric-focused partner like Shanghai Fumao is efficient—we certify the fabric roll to a specific class, and that certification covers all garments cut from it, regardless of final shape or intended gender market.

The Critical Grey Area: How Design and Marketing Influence Classification

Sometimes, the garment itself forces a classification, regardless of marketing intent. A common pitfall is "unisex" or "gender-neutral" apparel. The standard doesn't recognize this term. You must classify based on realistic wear.

- A Unisex Oversized Hoodie: If marketed and typically worn as outerwear over other clothes, it's Class C.

- A Unisex Fitted T-Shirt: Worn directly against the skin, it's Class B.

If you are unsure, always choose the stricter class (B over C). It's safer legally and ethically. In 2022, a brand selling unisex linen shirts classified them as Class C, arguing the loose fit meant less skin contact. A regulator disagreed after a consumer complaint, resulting in fines. The brand now certifies all their linen shirts as Class B—a simpler, safer protocol.

Where Testing Diverges: Material, Dye, and Finish Considerations

While the GB class sets the baseline limits, the actual testing focus and risk points can vary significantly between typical men's and women's wear due to prevailing material choices, dyeing depths, and functional finishes.

1. Fiber Composition Trends:

- Men's Wear: Often features heavier cottons, wools, polyester blends, and technical fabrics for performance or durability. Testing may prioritize colorfastness to rubbing and perspiration for dark shirting fabrics, and formaldehyde in "easy-care" wrinkle-resistant finishes on trousers.

- Women's Wear: Frequently uses lighter, more delicate fabrics: silks, fine cottons, rayon/viscose, lace, and elastic blends for stretch. Testing here prioritizes pH balance (delicate skins), colorfastness to water (for lighter shades), and the safety of metallic or complex dyes used in prints.

2. Dye Depth and Color Fastness:

Dark, rich colors (common in men's formalwear and basics) require more dye, increasing the risk of heavy metal residues or poor colorfastness. Lingerie and women's summer wear often use lighter dyes but may have complex prints where testing for allergenic disperse dyes in synthetic garments becomes critical.

3. Functional Finishes:

- Men's: Anti-odor, moisture-wicking, and durable water repellent (DWR) finishes are common. These introduce chemical compounds that require specific screening.

- Women's: "Silky touch" softeners, anti-static finishes, and shape-retention treatments on stretch fabrics are frequent. Each finish adds a chemical layer that must be assessed for safety.

A real example from our work: A client produced men's hiking pants (nylon-cotton blend with DWR) and women's yoga leggings (nylon-spandex blend with moisture-wicking). Both were Class B. The men's pants certificate focused on formaldehyde (from DWR) and heavy metals (from dark green dye). The women's leggings certificate focused on pH (for skin comfort) and banned amines (from the specific dyes used on synthetic fibers). The core standard was the same, but the test reports highlighted different potential hazards.

The Special Case of Lingerie, Swimwear, and Activewear

These categories, which are predominantly women's but increasingly unisex, often face the highest scrutiny due to intimate wear and strenuous conditions.

- Lingerie & Swimwear: Tight-fitting, often with elastics (spandex/Lycra) and synthetic linings. Requires rigorous testing for phthalates in elastic components and formaldehyde in crease-resistant fabrics. Colorfastness to perspiration and chlorinated water (for swimwear) is paramount.

- Performance Activewear: For both genders, but women's styles often involve more direct compression. Testing must cover nanoparticle silver (for anti-odor), chemical UV blockers, and the safety of bonding adhesives used in seamless construction.

For these items, a basic Class B certificate is the starting point. Discerning brands should demand additional, specific tests. At Shanghai Fumao, when we develop performance fabrics, our CNAS lab runs extended protocols that cover these niche risks, providing a more comprehensive safety profile that brands can leverage in marketing.

How to Specify and Verify Correct Certification for Your Line

You are responsible for ensuring each product is correctly certified. Here is your actionable quality control protocol:

Step 1: Create a Product Compliance Matrix.

Before production, make a simple spreadsheet for your collection:

| Product SKU | Description | Target GB Class | Key Materials | Special Finishes | Required Tests Beyond Baseline |

|---|---|---|---|---|---|

| MW-101 | Men's Work Shirt | Class B | 100% Cotton Poplin | Wrinkle-Resistant | Formaldehyde, Colorfastness (Rubbing/Perspiration) |

| WW-205 | Women's Silk Blouse | Class B | 100% Silk Charmeuse | - | pH, Colorfastness (Water) |

| WU-301 | Unisex Hoodie (Worn over tee) | Class C | 80/20 Cotton-Poly Fleece | Brushed Back | - |

Step 2: Embed Requirements in Tech Packs.

In your technical pack for each style, include a clear section:

COMPLIANCE: Fabric must comply with GB 18401-2010, Class [B/C]. Supplier must provide valid CMIA certificate from CNAS-accredited lab for the production batch, with product description matching this garment's primary fabric.

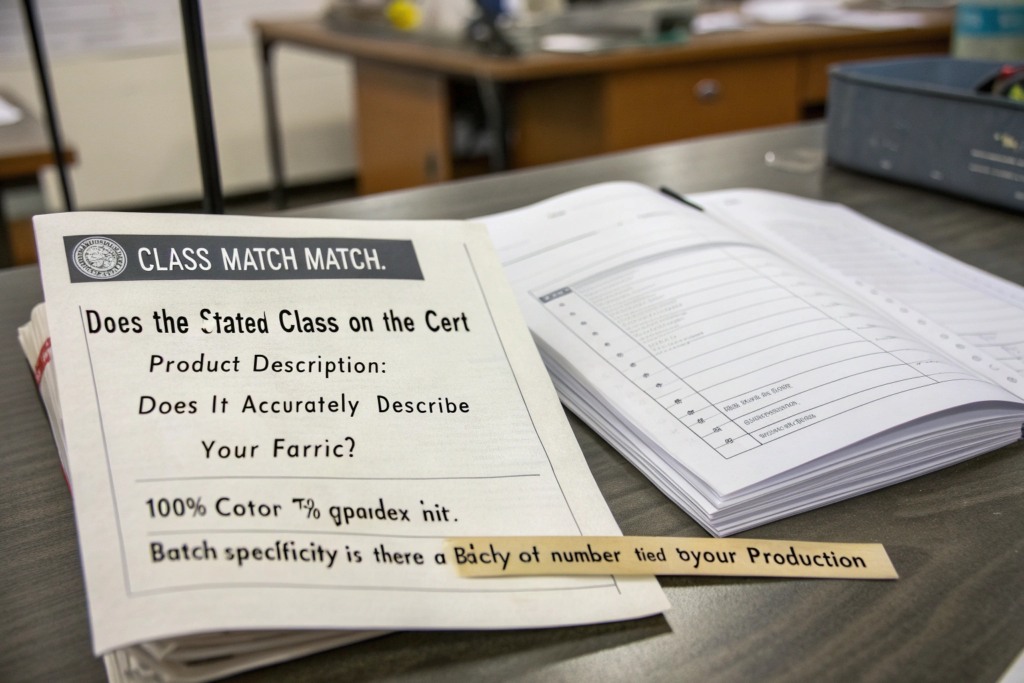

Step 3: Verify the Received Certificate.

When the factory sends the certificate, check:

- Class Match: Does the stated class on the cert match your matrix?

- Product Description: Does it accurately describe your fabric? "100% Cotton Knit" is not valid for a "95% Cotton 5% Spandex Knit."

- Batch Specificity: Is there a batch/lot number tied to your production?

- Test Items: Do the tested parameters cover your special concerns (e.g., pH for silk, formaldehyde for treated cotton)?

Step 4: Conduct Spot Testing for High-Risk Categories.

For lingerie, swimwear, or infant wear (even if not your primary line), invest in independent third-party spot checks on finished goods. This validates the factory's provided certificates.

Navigating Unisex and Gender-Fluid Collections

For truly fluid collections, adopt the strictest applicable standard across all marketing contexts.

- Strategy: Certify the fabric to the strictest class you intend it for. If a linen is used for both a boxy overshirt (Class C) and a fitted dress (Class B), certify the fabric roll as Class B. This ensures universal safety.

- Communication: On your website, explain your safety philosophy: "All our fabrics meet or exceed direct skin-contact safety standards (GB 18401 Class B), regardless of style, for your peace of mind." This turns a compliance complexity into a brand trust message.

The Role of a Knowledgeable Supplier

A premium supplier understands these nuances without being reminded. When you ask Shanghai Fumao for a fabric, we don't just ask "What color?" We ask about its intended application: "Will this be for men's shirting, women's dresses, or children's wear?" This informs our internal testing protocol from the start. We might recommend a different dyeing process or finishing treatment to ensure the final fabric not only looks right but also easily passes the correct certification class for your end use. This proactive guidance is what separates a fabric vendor from a true development partner.

Common Pitfalls and How to Avoid Them

Mistakes in this area are costly but preventable. Here are the most frequent errors we see:

Pitfall 1: Assuming "Adult Apparel" is One Category.

- Error: Using a single generic certificate for an entire range.

- Solution: Classify each style individually based on skin contact. A sweater and underwear cannot share a cert.

Pitfall 2: Overlooking Accessories and Trims.

- Error: Certifying only the main fabric. Buttons, zippers, drawcords, and lace appliqués are part of the product.

- Solution: Require evidence that all components comply. For example, nickel-free claims for metal parts need supporting test reports. This is part of a thorough quality assurance checklist for imported garments.

Pitfall 3: Ignoring Care Label Impact.

- Error: A "dry clean only" label does not automatically move a garment to Class C. If it's worn on skin (like a silk blouse), it's still Class B.

- Solution: Classify based on use, not care instructions.

Pitfall 4: Not Planning for Blended Fabrics.

- Error: A 60% Cotton / 40% Polyester blend is tested as one material, but the risks (e.g., azo dyes from polyester) differ from 100% cotton.

- Solution: Ensure your supplier's lab understands blends and tests for the relevant risks of all fiber types present.

A client learned this last lesson painfully. They produced a women's dress from a cotton-poly blend with a vibrant print. The factory provided a CMIA certificate. However, the test only covered the base safety standards. When the dresses were spot-checked in Germany, they failed for a specific allergenic disperse dye common in polyester printing—a test not required under the basic GB 18401 for that class but mandated by German consumer protection standards. The result was a rejected shipment. Now, they specify "Fabric and print must comply with GB 18401 Class B and EU REACH Annex XVII regarding restricted substances" in their POs.

Conclusion

CMIA certification is not gender-biased, but it is intensely specific. The difference between men's and women's wear certification lies not in the rulebook, but in the application of the rules based on materiality, design, and wearability. A safety-first brand moves beyond the question of "Do we have a certificate?" to "Do we have the correct, verifiable certificate for this specific product's risk profile?"

Your strategy should be one of precision: correctly classify every item, specify requirements clearly, verify documents meticulously, and always err on the side of stricter safety. This disciplined approach is what protects your customers from harm and your brand from reputational and legal catastrophe.

In a market where consumers are increasingly scrutinizing the ethics and safety behind their labels, this precision becomes a competitive advantage. It allows you to communicate with confidence about your product integrity, across every item in your collection.

If navigating this landscape of classes, materials, and verifications seems complex, partner with experts who live in the details. At Shanghai Fumao, our vertical control from fiber to finished fabric allows us to guide you to the right material choices and deliver the precise, compliant certification you need for every garment, for every customer. Let us help you build a collection that is not only stylish but also unquestionably safe. Contact our Business Director, Elaine, to begin: elaine@fumaoclothing.com.