As global fashion and fabric buyers push for low-carbon materials, verifying a fabric’s true carbon footprint is no longer a marketing option—it’s a procurement necessity. Greenwashing is rampant, and serious brands demand data-backed transparency in every square meter they source.

To verify carbon footprint data for sustainable fabrics, buyers must check for certified LCAs, third-party emission audits, recognized labels like GHG Protocol or ISO 14067, and traceable data sources from suppliers.

At Fumao Fabric, we’ve helped clients in the U.S., Germany, and Australia assess the real carbon performance of organic cotton, recycled polyester, and bio-based blends—across weaving, dyeing, finishing, and transport.

What Is the Industry Standard for Carbon Footprint Verification?

Carbon footprint standards define how emissions from a fabric are calculated across its life cycle. Not all declarations are equal—some only cover raw material, while others include processing, transport, and end-of-life.

The most trusted standards include ISO 14067, the GHG Protocol Product Standard, and PAS 2050, all of which offer rigorous frameworks for calculating textile emissions in kg CO₂e per meter.

What Is ISO 14067 and Why Is It Important?

ISO 14067 specifies the principles and requirements for quantifying and reporting the carbon footprint of products. For textiles, this covers fiber production, weaving, dyeing, finishing, and logistics.

We work with certified carbon consultants to create ISO 14067-compliant Product Carbon Footprint (PCF) reports for our eco-fabrics.

How Does the GHG Protocol Apply to Fabrics?

The GHG Protocol Product Standard defines emissions in three scopes: Scope 1 (direct emissions), Scope 2 (energy usage), and Scope 3 (supply chain). It’s often used by brands conducting full apparel LCA and carbon offsetting.

We’ve provided GHG-based Scope 3 data for clients creating low-carbon capsule collections in Europe and Asia.

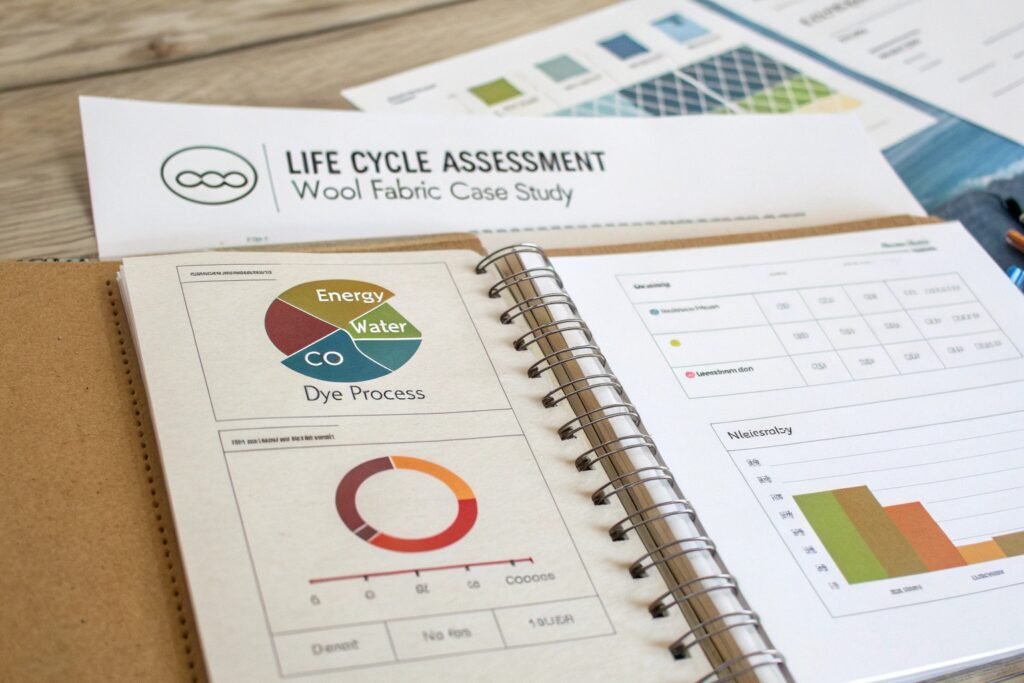

How to Read an LCA for a Sustainable Fabric?

A Life Cycle Assessment (LCA) is the most holistic way to evaluate a fabric’s environmental impact. It tracks emissions and resources from cradle to grave—or cradle to gate.

An accurate LCA reveals carbon hotspots across the value chain: fiber growing, transportation, weaving, dyeing, finishing, packaging, and even disposal or recycling.

What Are Key Indicators in Fabric LCAs?

Look for metrics like:

- Global Warming Potential (GWP) in kg CO₂e per kg or m²

- Energy use per process stage

- Water footprint

- Dye chemistry emissions

- Transportation impact

Platforms like SimaPro or OpenLCA are often used to run textile-specific LCAs, which our clients use to compare Tencel™, rPET, and conventional cotton fabrics.

Can Fabric Suppliers Generate LCAs Themselves?

Only if they partner with accredited bodies or software providers. At Fumao, we collaborate with third-party environmental engineers to generate LCAs for our recycled and organic lines. The final reports come with QR-code traceability and verification stamps—avoiding greenwashing risk for downstream buyers.

What Third-Party Certifications Prove Carbon Transparency?

Certifications make it easier for brands to trust a fabric’s environmental claims. While LCAs are technical, verified sustainability labels communicate transparency in a buyer-friendly way.

Carbon-conscious fabric buyers rely on standards like Climate Neutral Certified, GRS, OEKO-TEX® Made in Green, and Cradle to Cradle™ to ensure their sourcing aligns with verified emissions data.

What Does Climate Neutral Certified Guarantee?

The Climate Neutral Certification confirms that a product’s emissions have been measured, reduced, and offset according to GHG Protocol rules. Though more common in apparel than raw fabrics, we help clients tag full-supply-chain emissions for brand-level neutrality.

We also support clients using carbon labels integrated with Product Environmental Footprint (PEF) profiles for the EU market.

Is GRS Enough to Confirm Low Carbon Footprint?

No. GRS (Global Recycled Standard) confirms recycled content and social/environmental practices, but not carbon numbers. However, combining GRS with LCA results creates a stronger claim.

We offer both GRS and OEKO-TEX®-certified fabrics, with optional carbon footprint add-ons calculated by certified assessors.

How to Request and Compare CO₂ Data From Suppliers?

Getting verified carbon data from suppliers isn’t always straightforward—but it’s essential for responsible sourcing. Ask the right questions and demand the right paperwork.

To verify carbon footprint from suppliers, request cradle-to-gate LCA reports, emission scope breakdowns, and third-party verification. Compare across materials and choose partners with traceable reporting systems.

What Should I Ask My Fabric Supplier to Provide?

Start with this checklist:

- Full LCA (PDF or Excel)

- CO₂e/kg values by process stage

- Verification body or software used

- Scope 1/2/3 disclosure (if available)

- QR-coded traceability labels or blockchain ID

Tools like Higg MSI are also popular among apparel brands looking to estimate upstream fabric impact.

How Does Fumao Help Clients Validate Emissions?

We offer pre-verified reports for key SKUs, or co-develop carbon impact calculators with clients based on their specific use case (e.g. U.S. DDP delivery vs EU FOB shipping). Our textile engineers also assist buyers in comparing material alternatives based on real emission values—not marketing brochures.

Conclusion

Carbon footprint claims in textile sourcing must be verified—not assumed. As sustainable regulations tighten across global markets, brands and buyers need clarity, not just claims. Verified LCAs, GHG-aligned reporting, and traceable certifications are the new norm.

At Fumao Fabric, we combine deep textile manufacturing roots with carbon audit transparency—empowering you to make better material decisions. Whether you're building a carbon-neutral fashion brand or reworking your sourcing strategy, our team can help you cut emissions from fabric to freight.