Consumers are increasingly aware that what touches their skin can affect their long-term health—especially with regard to endocrine-disrupting chemicals (EDCs) in fabrics. EDCs like phthalates, BPA, formaldehyde, and certain flame retardants can interfere with hormones, affecting reproduction, metabolism, and development.

Testing for endocrine-disrupting chemical residues in textiles involves analytical lab methods such as GC-MS (Gas Chromatography–Mass Spectrometry), LC-MS/MS, and FTIR spectroscopy, often supported by third-party certifications like OEKO-TEX® and GOTS.

If you’re a brand sourcing garments or home textiles from overseas, particularly in categories for babies, underwear, sportswear, or eco-conscious buyers, knowing how to screen for EDCs is not just smart—it’s essential.

What Are the Most Common EDCs Found in Fabric?

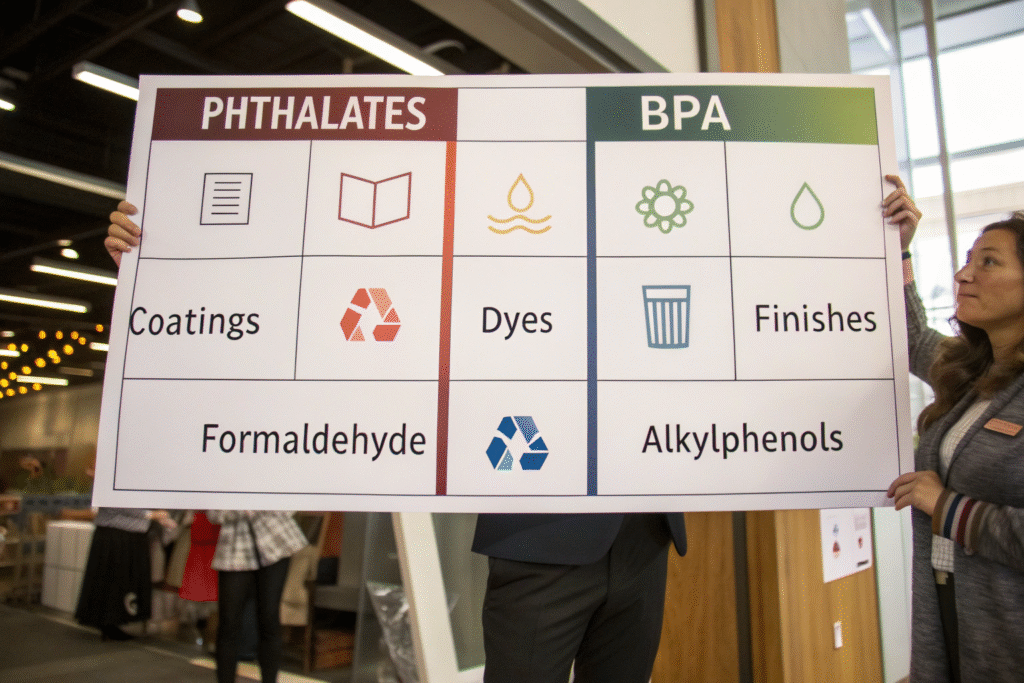

Endocrine-disrupting chemicals can enter fabrics during fiber production, dyeing, printing, finishing, or even post-treatment packaging.

The most commonly detected EDCs in textiles include phthalates, formaldehyde, alkylphenol ethoxylates (APEOs), perfluorinated compounds (PFCs), and BPA.

Where Do These Chemicals Typically Come From?

| EDC Type | Common Fabric Source |

|---|---|

| Phthalates | PVC coatings, plastic prints, faux leather |

| Formaldehyde | Wrinkle-free finishes, dyes, resins |

| APEOs | Detergents, surfactants in dyeing |

| BPA | Polycarbonate coatings, synthetic dyes |

| PFCs | Water- and stain-repellent finishes |

You can read more on chemical inputs at ChemSec’s Textile Guide and Greenpeace Detox Reports.

Are EDCs Regulated by International Standards?

Yes. Key regulatory frameworks include:

- REACH (EU) – Regulates substances of very high concern (SVHCs)

- CPSIA (US) – Limits phthalates and lead in children’s products

- GOTS/OEKO-TEX® – Voluntary standards banning or restricting EDCs

Learn more at ECHA’s substance database and OEKO-TEX® guidelines.

Which Testing Methods Detect EDCs in Fabric Accurately?

Testing for EDCs requires instrumental chemical analysis—not just physical inspection. This is often outsourced to certified laboratories using advanced techniques.

GC-MS, LC-MS/MS, and FTIR are the most commonly used techniques to screen textiles for endocrine-disrupting chemicals at ppm or ppb levels.

What Is the Role of GC-MS in EDC Detection?

GC-MS (Gas Chromatography–Mass Spectrometry) separates and identifies volatile and semi-volatile compounds, like phthalates and flame retardants.

It’s highly accurate and is often used to certify compliance with CPSIA or REACH phthalate bans. Learn more from Agilent’s textile analysis toolkit and Eurofins textile testing.

How Do LC-MS/MS and FTIR Support Broader EDC Screening?

- LC-MS/MS targets non-volatile chemicals like BPA or APEOs.

- FTIR (Fourier-Transform Infrared Spectroscopy) is non-destructive and used for quick surface scans to detect polymer additives and coatings.

Combined methods offer more reliable detection. Check Intertek’s chemical residue testing or SGS EDC analysis for service examples.

What Certifications Indicate Fabric Safety from EDCs?

Certifications simplify the buyer’s task by validating that fabrics meet pre-approved chemical safety standards, including restricted substances lists (RSLs) that exclude EDCs.

OEKO-TEX® Standard 100, GOTS, and Bluesign® are leading certifications proving a fabric is free from harmful levels of endocrine-disrupting chemicals.

How Does OEKO-TEX® Ensure EDC-Free Fabric?

OEKO-TEX® Standard 100 tests against 100+ substances, including:

- Phthalates

- Formaldehyde

- Heavy metals

- PFCs

- Chlorinated phenols

All components of a product—buttons, zippers, threads—must pass. Learn more at OEKO-TEX® official site.

What About GOTS and Bluesign® Certifications?

- GOTS (Global Organic Textile Standard) bans all hazardous chemicals, including known EDCs, and ensures organic sourcing.

- Bluesign® focuses on safe input streams during production, preventing EDCs from entering the fabric process at all.

Certification details and updated RSLs are available via GOTS official site and Bluesign®.

How to Work With Suppliers to Minimize EDC Risks?

To prevent EDC contamination, buyers must go beyond surface-level specs and demand chemical transparency from suppliers.

Working with suppliers who follow chemical management systems like ZDHC (Zero Discharge of Hazardous Chemicals) helps ensure consistent EDC-free outputs.

What Questions Should You Ask Suppliers?

- Can you provide MSDS and test reports for each batch?

- Are your dyeing/finishing units OEKO-TEX® or GOTS certified?

- Do you follow ZDHC chemical management protocols?

- Do you allow third-party testing before shipment?

For templates and checklists, visit ZDHC’s Roadmap to Zero and Fashion Revolution Transparency Index.

Should You Conduct Random Lab Testing?

Yes—especially if you're sourcing babywear, underwear, or medical apparel. Use SGS, Bureau Veritas, or QIMA to test random batches for EDC levels in accordance with EU/US import safety rules.

Conclusion

As consumers and regulators grow more aware of chemical safety, testing fabrics for endocrine-disrupting chemical residues is no longer optional—it’s a business necessity. With methods like GC-MS and certifications like OEKO-TEX®, you can ensure safer, cleaner, and more transparent textile sourcing.

At Fumao Fabric, we provide third-party tested, eco-compliant fabrics, many of which meet OEKO-TEX® Standard 100 and GOTS criteria. We support clients in the US, EU, and Asia with lab-backed safety, material traceability, and fabric development services. For sourcing safe, EDC-free materials, reach out to our Business Director Elaine at elaine@fumaoclothing.com.