Outdoor furniture lives under harsh conditions. Sunlight, moisture, and heat can quickly fade and weaken fabric if it’s not made to withstand the elements. For businesses designing or producing cushions, umbrellas, or garden loungers, choosing the right UV-resistant fabric is not a luxury—it’s a necessity.

UV-resistant fabrics protect outdoor furniture from fading and degradation by blocking or absorbing ultraviolet rays, offering durability, color retention, and longer product life. But not all fabrics are created equal. You need to consider fiber type, treatments, test certifications, and supply chain dependability to get it right.

At Fumao, we help global clients—from U.S. patio brands to European hotel groups—source and develop high-performance UV fabrics built for exterior environments. In this article, I’ll show you exactly how to evaluate, source, and partner for the best results.

What Fabric Types Offer the Best UV Resistance?

Not every fabric is suited for outdoor use. Materials that work indoors—like cotton or rayon—can fade or weaken quickly under UV light. Outdoor-grade fabrics are specially engineered to resist degradation from the sun.

Solution-dyed acrylic, olefin, and UV-treated polyester are the top fabric types used in outdoor furniture for their colorfastness and resistance to fading.

Why Is Solution-Dyed Acrylic Preferred?

Solution-dyed acrylic is considered the gold standard for outdoor durability. Brands like Sunbrella® pioneered this fiber, where the dye is added to the polymer before it becomes a yarn—locking in the color.

This process offers superior fade resistance, water repellency, and mildew control. Ideal for cushions, umbrellas, and marine-grade applications.

How Does Olefin Compare?

Olefin (polypropylene) is a strong, lightweight fiber with natural UV resistance. It’s often more affordable than acrylic, with great stain and moisture resistance. Though not as soft, it’s ideal for budget-conscious projects.

You can learn more about olefin’s outdoor capabilities here.

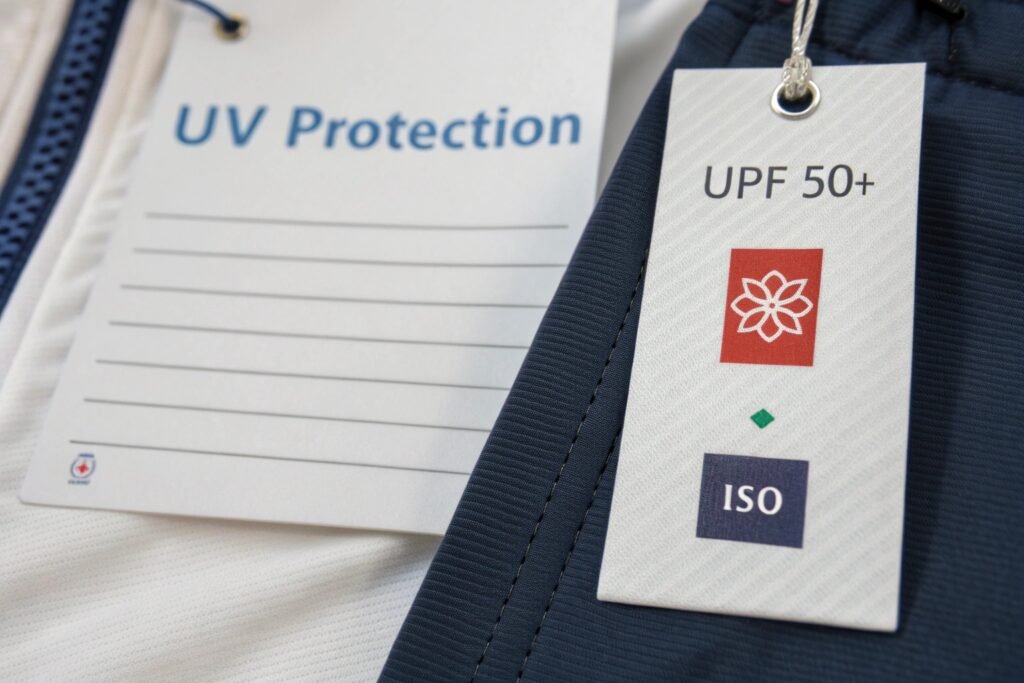

What UV Standards and Certifications Should You Check?

To ensure you're truly sourcing UV-resistant fabric, don’t rely on marketing labels alone. Reputable suppliers will provide lab test data and certifications based on international standards.

Look for fabrics tested under ISO 105-B02 or AATCC TM16, with verified UV resistance ratings indicating colorfastness and fiber stability.

What Is ISO 105-B02?

This is the most widely used international test for color fastness to artificial light (UV exposure). It grades fabric fade resistance on a scale of 1 (poor) to 8 (excellent). For outdoor furniture, aim for a grade 6 or higher.

Learn more about the ISO test methodology and why it's crucial for exterior textiles.

How Do U.S. Buyers Verify AATCC Compliance?

The AATCC TM16 test is commonly used in the U.S. to simulate sun exposure. Look for results showing fabric color retention after 40–80 hours of simulated sunlight.

This AATCC overview provides guidance on what buyers should look for in reports from testing labs or suppliers.

Where Can You Find Reliable UV Fabric Manufacturers?

With the right supplier, you can access tested UV-resistant materials in small or bulk volumes with design flexibility. But it’s important to find manufacturers with verified test equipment and consistent quality control.

China’s textile clusters in Keqiao and Guangdong offer competitive, certified UV fabric production at scale—with options for coating, lamination, and outdoor finishing.

What Makes a Manufacturer Trustworthy?

Look for UV fabric suppliers who offer:

| Feature | Details |

|---|---|

| UV Testing Lab | In-house ISO/AATCC simulation units |

| Outdoor Fabric Catalog | Solution-dyed, coated, laminated stocks |

| Sample Customization | MOQ from 100–300 meters per color |

| Certificates | ISO 105, OEKO-TEX, REACH compliant |

You can explore supplier directories like Foursource or request catalogs directly from outdoor fabric companies listed on Textile World.

How Can Fumao Help?

At Fumao, we offer UV-resistant polyester and acrylic blends with 98% client pass rates. Our QR-linked test reports, CNAS lab results, and custom printability give clients the flexibility and compliance they need.

Visit Fumao Fabric to request UV-certified swatches or start a small run.

What Performance Specs Should You Look For?

You don’t just want UV protection—you need a fabric that performs on all fronts: abrasion, water resistance, and style. Here’s how to assess a fabric’s real-world outdoor fitness.

Ideal UV-resistant fabrics should score high in colorfastness, have a protective coating, and offer mechanical strength for high-use furniture.

What Are the Key Technical Benchmarks?

| Spec | Ideal Value |

|---|---|

| UV Colorfastness (ISO 105) | Grade 6 or above |

| Water Repellency | 80–100 spray test rating |

| Abrasion Resistance | 15,000+ Martindale cycles |

| Mildew Resistance | Treated or solution-dyed |

| Weight | 200–400gsm (varies by end use) |

You can learn about these textile specs at SGS Textile Testing Services.

Is Coated Fabric Always Better?

Not always. Solution-dyed acrylic offers built-in UV resistance without coatings. Coated polyester is more affordable but may crack or peel after long sun exposure.

Ask your supplier for outdoor simulation test results over 500 hours to verify true durability. Here's a helpful resource on coated vs. solution-dyed fabrics.

Conclusion

UV-resistant fabrics are essential to outdoor furniture durability and customer satisfaction. From solution-dyed acrylic to treated polyester, the right choice protects your designs from fading, mildew, and mechanical wear. With verified lab testing, trusted manufacturing partners, and the right specs in mind, your sourcing can align both quality and cost. At Fumao, we back every UV fabric roll with transparent testing, flexible sampling, and deep knowledge of outdoor performance. Ready to bring long-lasting style to the outdoors? Let's build it together.