As global consumers become more sensitive to thermal comfort—whether in smart sportswear, bedding, or industrial uniforms—temperature-regulating fabrics are moving from niche to mainstream. But sourcing these advanced textiles, particularly those using phase change materials (PCMs), requires deeper technical understanding and supply chain navigation.

Phase change fabrics absorb, store, and release heat based on the wearer’s body temperature or environmental fluctuations. To source them successfully, buyers must focus on the PCM integration method, textile structure, and supplier’s R&D and testing capabilities.

At Fumao Fabric, we work with global clients to develop PCM-integrated fabrics for outdoor wear, pajamas, automotive interiors, and even medical applications. This guide will help you understand the science, sourcing strategies, and testing protocols necessary for your next thermoregulating product launch.

What Are Phase Change Materials and How Do They Work?

Phase change materials are compounds that absorb and release thermal energy as they transition between solid and liquid states. The most common types used in textiles are paraffin wax-based PCMs, which change phase near skin temperature (~28–33°C).

When the ambient or body heat rises, PCMs absorb excess heat to prevent overheating. When it cools, they release that stored energy to maintain comfort.

What Are Microencapsulated PCMs?

PCMs are encapsulated in micron-sized polymer shells and then infused into fibers, finishes, or coatings. This process ensures durability through washing and movement. These capsules store latent heat and allow thermal buffering without altering fabric texture.

Commonly used PCM brands include Outlast®, developed for NASA, and Thermocules™, used in bedding and military wear.

How Are PCMs Integrated into Fabrics?

- Fiber extrusion: PCM is blended directly into synthetic fibers during spinning

- Finishing/coating: PCM microcapsules are bonded to fabric surface

- Lamination: PCM layer is laminated between fabric plies (common in bedding or boots)

Each method impacts durability, cost, and performance—coated textiles are cheaper but wear faster than spun-in versions.

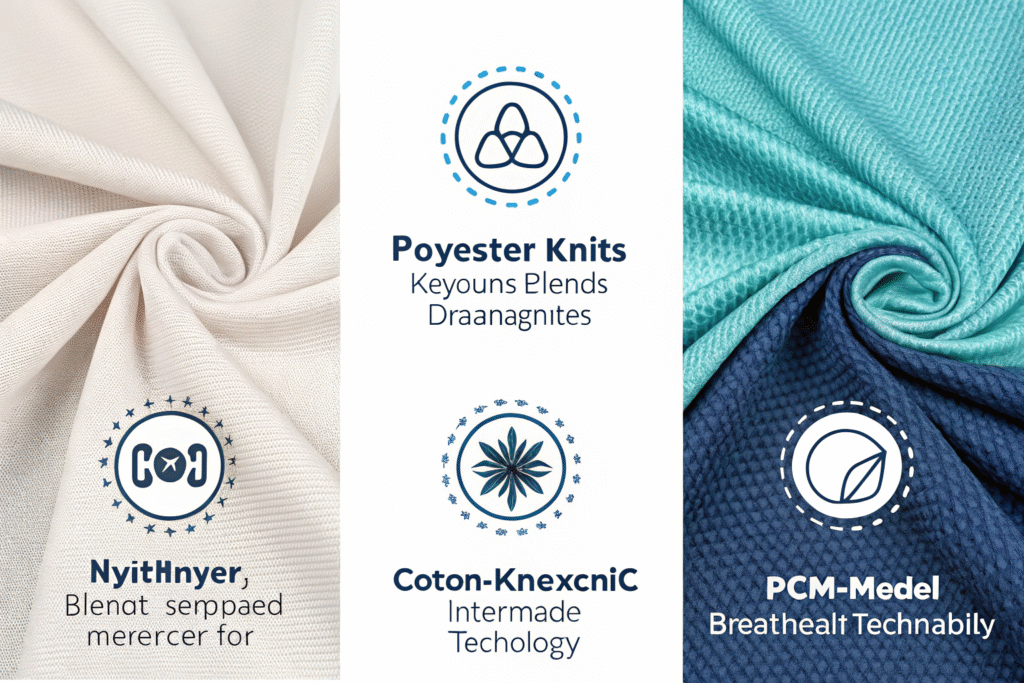

Which Fabric Bases Are Best for PCM Application?

Not every textile structure is suited for PCM integration. The ideal base fabrics must offer good thermal conductivity, high surface area, and stability during coating or extrusion.

The most effective PCM carriers are polyester knits, cotton interlock, nylon blends, and lightweight double knits used in performance wear and sleepwear.

Why Are Synthetic Blends Preferred?

Polyester, nylon, and spandex blends provide strong bonding surface, low moisture retention, and high resilience. These characteristics ensure PCM finishes adhere well and don’t degrade with washing.

For high-performance uses—like outdoor sports or tactical gear—we recommend warp-knit polyester with moisture-wicking and PCM coating, tested under ISO 11092 for thermal resistance.

What About Natural Fibers?

Cotton, bamboo, and modal can be used, especially in loungewear, sheets, and babywear. However, coating durability is slightly lower unless stabilized with binders.

We’ve successfully coated GOTS-certified organic cotton interlock with Thermocule™ capsules for clients in Germany and Japan seeking a soft-touch, sustainable thermal fabric.

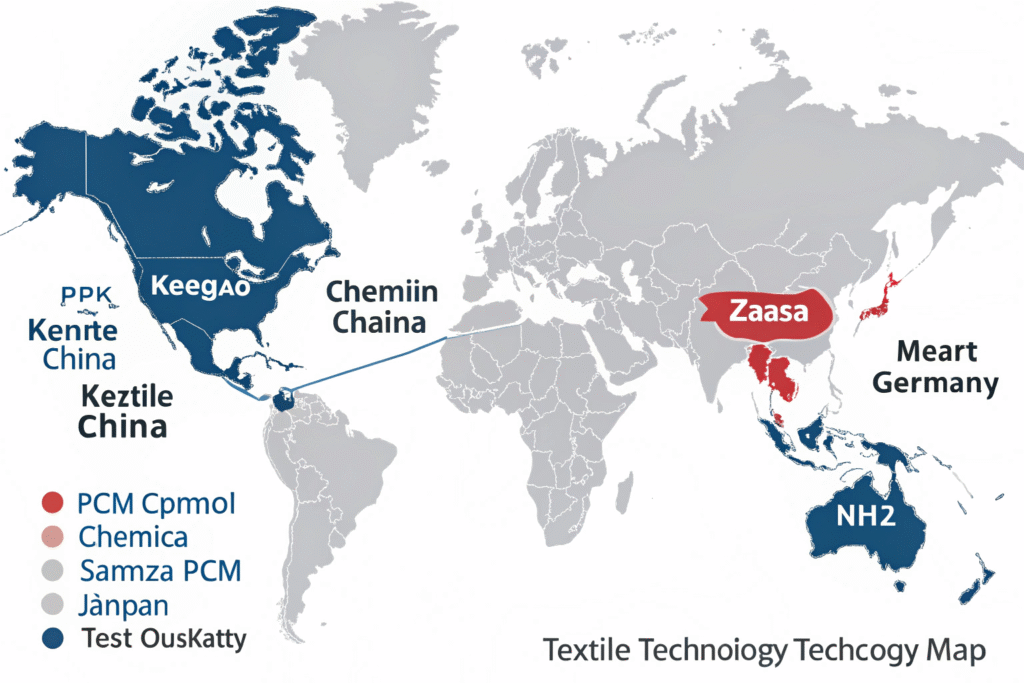

Where Can You Source Reliable PCM-Integrated Fabrics?

Sourcing PCM fabrics involves working with advanced mills or chemical partners who have expertise in textile finishing and smart fabric development. The top regions include:

- Keqiao, China – Affordable PCM coating, rapid sampling, large-scale capacity

- Osaka, Japan – High-end spun-in PCM yarns for bedding and base layers

- Chemnitz, Germany – Technical textiles for automotive and defense sectors

Among them, Keqiao offers the best cost-to-performance ratio for apparel-grade PCM fabrics, with proven production volumes and lab support.

Which Certifications or Tests Should You Ask For?

To ensure performance and reliability, your supplier should provide:

- DSC Testing: Differential Scanning Calorimetry proves thermal absorption range

- AATCC 135: Wash durability post-laundering

- ISO 11092: Thermal and vapor resistance (Ret value)

- CPSIA, OEKO-TEX: Safety for children or skin-contact garments

At Fumao Fabric, we provide test data from CNAS-accredited labs and support on-roll batch traceability using QR-coded lot history.

What MOQ and Lead Times Should You Expect?

Standard MOQ for PCM-coated fabrics starts at 500 meters per color, with lead times of 15–22 days depending on coating density and fabric type. Strike-offs for new clients can be delivered in 3–5 working days.

We’ve helped buyers from North America and the EU reduce development time by bundling tech pack consultation, performance testing, and shipping logistics into one sourcing cycle.

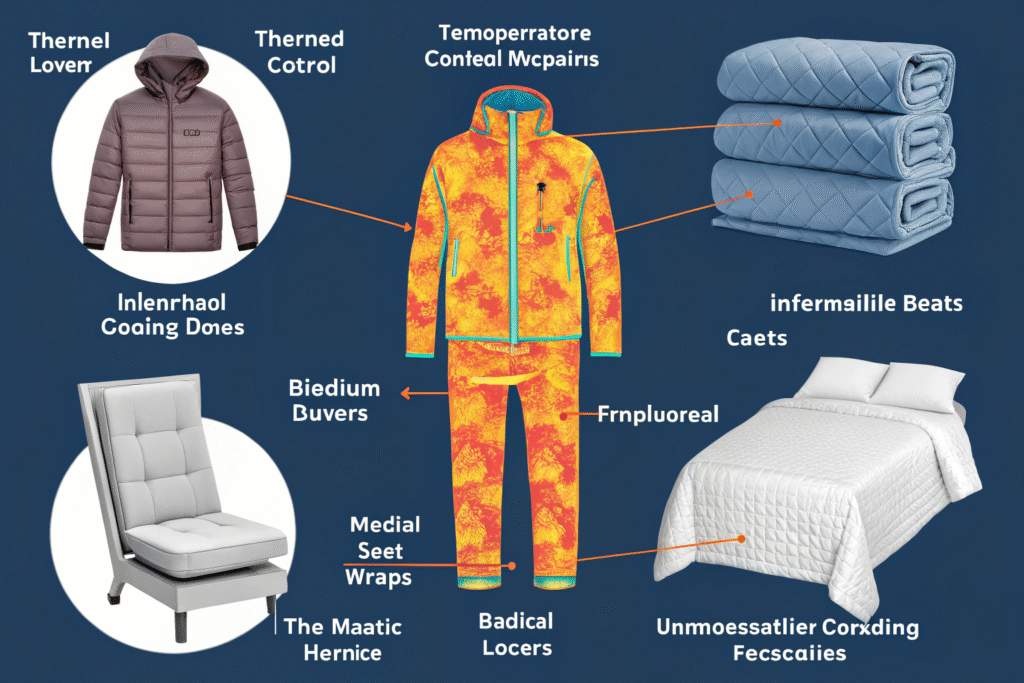

What Are the Key Applications and Market Trends?

PCMs are no longer limited to astronaut suits or lab experiments. In recent years, they’ve entered multiple market verticals thanks to performance enhancement and consumer demand for comfort with function.

Key growth segments for PCM textiles include smart fashion, thermal loungewear, temperature-neutral bedding, and medical textiles for injury recovery or menopause care.

Which Consumer Products Use PCM Today?

- Pajamas with Outlast®: Used by brands like Lands' End

- Athletic wear with climate adaptive zones: Nike and Uniqlo HEATTECH

- Mattress toppers and pillowcases for sweat control

- Footwear and insoles in tactical or hiking shoes

In our recent production, we developed polyester pique PCM fabric for a Korean babywear brand and knit sandwich laminate with PCM layer for a Danish mattress company.

What Are Buyers Prioritizing in 2025?

According to global B2B sourcing trends, buyers want:

- Washable and durable PCMs (40+ washes)

- Vegan-certified thermal fabrics

- No added formaldehyde or PFAS chemicals

- Temperature swing range of ±3–5°C

We see growing inquiries from sleepwear startups, elder care brands, and pet apparel designers, all seeking breathable, regulating fabrics without heavy insulation.

Conclusion

Temperature-regulating fabrics with phase change materials are redefining comfort across fashion, bedding, and technical sectors. But sourcing them requires more than just a fabric swatch—it involves supplier testing, process transparency, and application insight.

At Fumao Fabric, we offer integrated PCM fabric solutions backed by lab testing, small MOQ support, and fast prototyping. Whether you're building thermal pajamas, activewear, or future-ready uniforms, we can help you source and develop the right PCM textile. Contact our Business Director Elaine at elaine@fumaoclothing.com and let’s bring comfort science to your fabric lineup—one degree at a time.