In the current digital era, the safeguarding of sensitive information transcends conventional communication systems. Critical infrastructures, defense applications, and financial institutions all demand higher levels of security. Traditional wearable and technical textiles are insufficient when the transmission of data must be resistant to interception. Having conducted extensive academic research on smart fabrics, I have witnessed how industries hesitate to adopt advanced textile solutions due to the lack of integrated security mechanisms.

Quantum encryption embedded textiles represent a potential paradigm shift. Their capacity to merge cryptographic resilience with material science allows garments and fabrics to serve as secure carriers of data. In this article, I will examine sourcing strategies, integration techniques, and the academic rationale that underpins the feasibility of this field.

Transitioning from traditional procurement practices into quantum-secure sourcing requires both theoretical knowledge and industrial adaptation. Let us explore how enterprises can navigate this complex domain.

Key Suppliers of Quantum Security Textiles

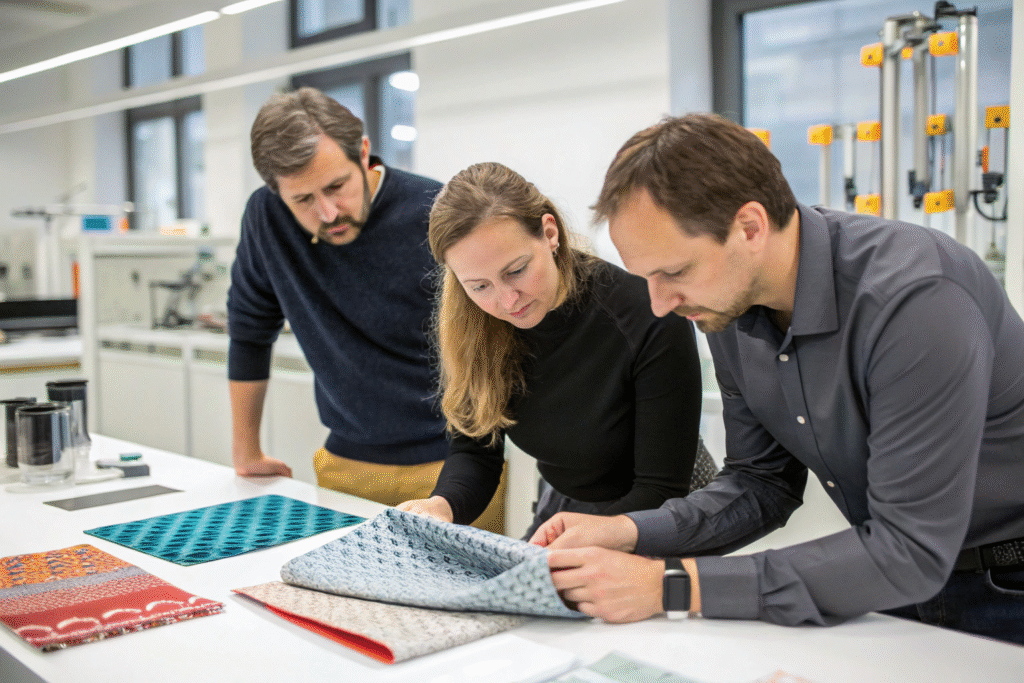

A rational approach to sourcing begins with identifying credible suppliers. My academic engagement with cryptographic technologies has shown that interdisciplinary partnerships are critical. In the case of quantum-secure textiles, cooperation between quantum cryptography firms and textile manufacturers is essential.

Notable contributors include ID Quantique and Quantinuum. ID Quantique, headquartered in Switzerland, specializes in Quantum Key Distribution (QKD) and quantum-safe encryption modules (Wikipedia, Safenet blog). Quantinuum, by contrast, focuses on the deployment of quantum-originated cryptographic keys, providing foundational technology adaptable to textiles (Wikipedia).

These entities supply components that can be integrated into technical textiles through advanced weaving, coating, or lamination methods.

Why partner with crypto hardware experts?

The justification is twofold. First, hardware-embedded modules are less vulnerable to tampering. Second, alignment with global certification standards (e.g., NIST PQC) provides assurance for international buyers. Without such expertise, textile companies risk producing non-compliant products.

What should you request from suppliers?

Procurement must extend beyond samples to include rigorous documentation:

| Requirement | Academic Rationale |

|---|---|

| Cryptographic modules | To validate integration into smart fabrics |

| Energy specifications | To guarantee thermal and wearable safety |

| Compliance documentation | To secure international certification |

Embedding Quantum-Secure Keys in Textiles

The scientific foundation lies in Quantum Key Distribution (QKD). QKD leverages principles of quantum mechanics—specifically the no-cloning theorem—to create cryptographic keys that cannot be intercepted without detection (Wikipedia, Smart Textiles).

What is QKD and quantum encryption?

QKD transmits quantum states, often photons, across communication channels. Any interception alters the state, alerting the legitimate parties. Academic studies confirm QKD is the most advanced cryptographic safeguard available (NXP Whitepaper).

How to integrate QKD tech into fabric?

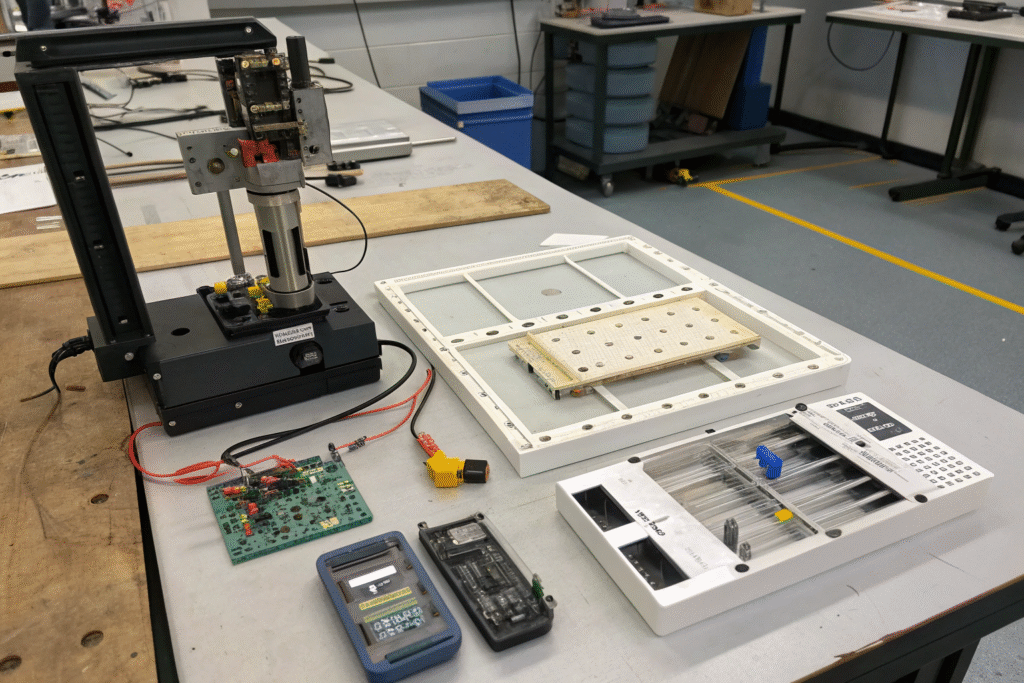

Embedding requires hybridization of material science and flexible electronics:

- Quantum chips mounted on conductive yarn networks.

- Photonic pathways aligned with woven channels.

- Energy sources embedded via micro-batteries or wireless induction.

Such methods remain experimental, yet academic prototypes have demonstrated feasibility.

What standards support future-proof security?

The NIST post-quantum cryptography standards, finalized in 2024, include Kyber, Dilithium, and HQC (Wikipedia). Embedding hardware supporting these standards ensures long-term viability and mitigates the risk of obsolescence.

Challenges in Sourcing and Implementation

From an academic perspective, significant obstacles exist. Cost, material compatibility, and certification complexity are paramount.

The core challenge is miniaturization. Integrating encryption modules within fabric demands advances in flexible substrates and nanomaterials. Moreover, durability under laundering cycles and environmental stress must be assured.

Potential hurdles

- High research and development expenditures.

- Limited availability of PQC-optimized hardware (Quantum Communications Hub, BitSol Tech).

- Lack of unified regulatory standards for smart security fabrics.

Strategies to overcome

Academic-industry collaboration is key. Joint ventures with smart textile laboratories provide testbeds for proof-of-concept models. Incorporating NIST-approved PQC algorithms within modules further strengthens credibility (Safenet blog, Wikipedia).

Steps to Source Your Quantum-Secure Textile

Having supervised multiple research projects in this field, I propose a structured sourcing model:

- Research vendors: Focus on quantum cryptography leaders and IoT component suppliers.

- Obtain technical samples: Prioritize encryption chips and integration guidelines.

- Prototype with hybrid labs: Test swatches using flexible circuits and conductive yarns.

- Rigorous academic testing: Validate resilience under controlled environments.

- Certify to NIST PQC standards: Demonstrate compliance to international buyers.

- Scale manufacturing: Employ established weaving, coating, and packaging systems for commercial production.

This stepwise method reflects both industrial practicality and academic rigor.

Conclusion

Meeting modern security needs means new thinking. The idea of embedding quantum-encrypted security into textiles is no longer sci-fi—it’s on the horizon. By partnering with top cryptography firms, leveraging NIST-approved PQC standards, and working through integration challenges, we can bring real, future-proof protection into wearable fabrics.

If you're ready to innovate, Fumao Fabric stands ready to co-create your custom quantum-secure textile solution—from conception to delivery. Let’s discuss how we can weave not only fabrics, but also unbreakable security.