When it comes to intelligent temperature control in textiles, Outlast® fabric stands in a class of its own. Originally developed for NASA to protect astronauts from extreme thermal swings in space, this patented phase change material (PCM) technology is now transforming everyday garments—from underwear and socks to mattress covers and tactical gear.

Outlast® fabrics manage heat proactively. Instead of just wicking moisture or insulating, they absorb excess heat, store it, and release it back as needed—ensuring a stable, skin-friendly microclimate in real time. For brands aiming to merge innovation with comfort, sourcing Outlast® materials is both a strategic and technical challenge.

In this article, we’ll explore what makes Outlast® fabric unique, how it differs from other PCM technologies, where to source it, and how to ensure authenticity in your supply chain.

What Is Outlast® and How Does It Regulate Body Temperature?

Outlast® is a patented phase change material technology developed by Outlast Technologies GmbH, utilizing microencapsulated Thermocules®—tiny capsules containing paraffin-based PCM that respond to body heat.

When your body temperature rises, these capsules absorb excess heat and store it. When it cools down, they release that stored warmth back to you, helping to maintain a balanced body climate.

How Is Outlast® Different From Regular PCM Fabrics?

Unlike generic PCM coatings that may wash out quickly or fail to maintain uniform thermal response, Outlast®’s microencapsulation ensures long-term durability—even after 50+ washes. It also offers standardized thermal management values (like heat capacity in J/g) backed by lab testing.

Learn more from Outlast’s official technology page or compare PCM microencapsulation techniques.

What Product Types Can Benefit from Outlast®?

Outlast® can be applied to:

- Underwear and base layers

- Thermal gloves and socks

- Bedding and pillows

- Outdoor activewear

- Footwear linings

- Protective workwear

Discover Outlast in bedding applications or NASA's original textile technologies.

Where Can You Buy Authentic Outlast® Fabric in Bulk?

Unlike open-source PCM coatings, Outlast® fabrics are proprietary and licensed—meaning they can only be purchased from official partners or licensed converters approved by Outlast Technologies GmbH.

At Fumao Fabric, we collaborate with mills that hold legal conversion rights to Outlast® PCM yarns and coatings, offering traceable, verifiable fabric production.

How Do You Verify a Licensed Outlast® Supplier?

Request documentation such as:

- A License Certificate from Outlast Technologies

- Outlast® lab test results (heat capacity, wash tests)

- Product-specific Outlast hangtag eligibility

- Traceable yarn batch numbers or converter IDs

See Outlast’s licensing program or confirm suppliers via Outlast’s partner list.

What MOQ and Fabric Types Does Fumao Offer?

We offer:

- Knit: jersey, rib, interlock (with Outlast® infused yarns)

- Woven: twill, poplin, satin

- Laminated: TPU-backed for outerwear

- MOQ: 300 meters per color, sample ready in 5–7 days

Browse Fumao’s temperature-control fabrics or compare knit structures.

What Are Key Performance Metrics for Outlast® Fabrics?

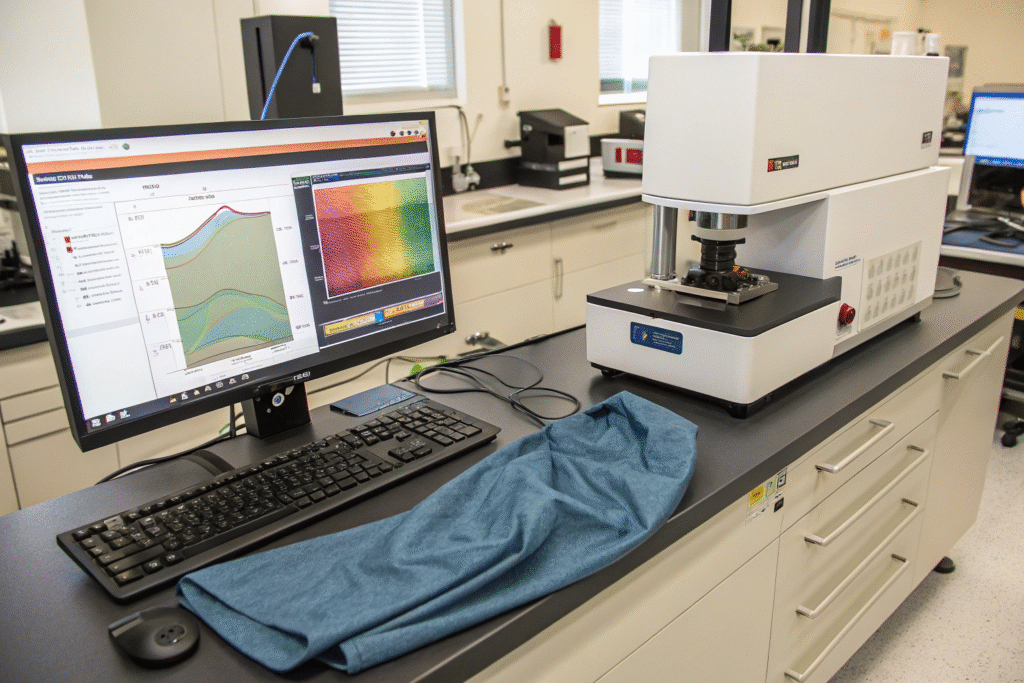

To differentiate Outlast® from imitations, performance must be quantifiable. Legitimate Outlast® fabrics are evaluated using calorimetric testing, infrared thermal imagery, and moisture responsiveness analysis.

The most recognized standard is ASTM D7024 for measuring PCM latent heat capacity. Additional tests include air permeability (ISO 9237) and wash durability (ISO 6330).

What Thermal Performance Values Should You Look For?

| Metric | Target Value Range | Standard |

|---|---|---|

| Heat Capacity | 15–35 J/g (typical) | ASTM D7024 |

| Thermal Conductivity | Low to moderate | ISO 22007-2 |

| Peak PCM Activation Temp | 28°C–32°C | Outlast-specific |

| Wash Durability | 30–50 cycles (verified) | ISO 6330 |

Access DSC testing protocols or see ASTM fabric standards.

Can Outlast® Be Combined with Other Functional Finishes?

Yes. At Fumao, we can combine Outlast® with:

- Antibacterial finishes (silver ion, zinc oxide)

- Moisture-wicking treatments

- Laminations (PU/TPU for waterproofing)

- Reflective or anti-static additives

Explore multifunctional fabric coatings or see hybrid smart textile systems.

How to Integrate Outlast® Into Your Product Line Smoothly?

Integrating Outlast® into your production requires cross-functional collaboration between design, development, and compliance teams. Unlike standard fabrics, Outlast® requires specific product approval before retail use, especially if hangtags or marketing claims are involved.

Fumao offers pre-approved blends and development support for ODM and OEM clients to accelerate onboarding.

What Steps Are Required to Use Outlast® Hangtags?

- Choose an eligible fabric (licensed yarn or coating)

- Submit product prototypes for review by Outlast Technologies

- Pass testing and receive approval

- Order official hangtags for retail

Read Outlast branding policy or explore retail-ready use cases.

Does Fumao Provide ODM/OEM for Outlast® Apparel?

Yes. We support:

- Fabric sourcing (pre-licensed blends)

- Sample development with PCM-specific CAD tech packs

- Compliance coordination with Outlast

- Full-package production for underwear, activewear, medical wear

Contact us via Fumao’s website or explore full-service textile development.

Conclusion

Outlast® temperature adaptive fabrics are a leap forward in comfort and innovation. Rooted in NASA-grade technology and tested for real-world durability, they bring unmatched thermal balance to garments across industries. But sourcing genuine Outlast® material requires diligence, licensing, and trust in your supplier.

At Fumao Fabric, we bridge technology with transparency. Whether you're developing heat-buffering base layers or bedding with thermal precision, we help you source and certify the Outlast® fabrics your customers will feel the difference in.

To explore swatches or start your Outlast® project, contact our Business Director Elaine at elaine@fumaoclothing.com. Let’s deliver thermal comfort powered by space-age science.