Metamaterials are changing how we think about sound control. Traditional fabrics cannot bend or reroute sound waves, but metamaterial acoustic cloaking fabrics are designed to achieve just that. For buyers and innovators looking to apply this technology in fashion, architecture, or industrial noise control, sourcing these advanced fabrics is both exciting and challenging. The demand is growing, but the market remains niche and highly specialized.

The short answer is that sourcing metamaterial acoustic cloaking fabrics requires identifying prototype developers, partnering with research institutes, and working with metamaterial companies that can adapt the technology into textile form. Leading institutions such as HKRITA in Hong Kong, and specialized suppliers like Applied Metamaterials and NJHQ Acoustics Technology, are paving the way.

The opportunity is clear: these fabrics can redefine sound insulation, wearable technology, and even defense applications. But the path from lab to large-scale supply is complex. In this article, I will share the key sourcing steps, reliable suppliers, and critical considerations to help you move forward.

What Are Metamaterial Acoustic Cloaking Fabrics?

Metamaterial acoustic fabrics are not ordinary textiles. They are engineered with carefully designed structures that guide sound waves around an object, effectively cloaking it from detection. This makes them highly valuable in industries where noise reduction or stealth is critical.

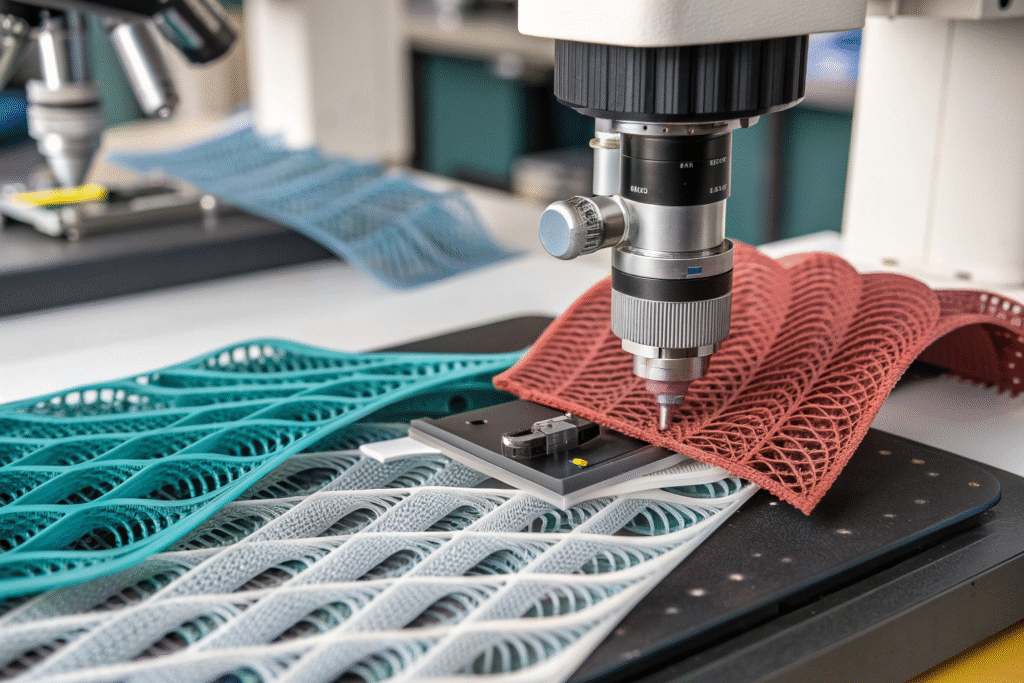

These fabrics use microstructures to control density and elasticity, creating properties that natural fibers cannot achieve. They are still emerging in the textile field, but early research shows strong potential in architecture, aerospace, and smart wearables.

The growing attention to metamaterials comes from their versatility. For buyers, understanding their scientific background is the first step in making informed sourcing decisions. Without this foundation, it is easy to misjudge suppliers or fall for overhyped claims.

Why Are These Fabrics Different from Regular Acoustic Textiles?

Metamaterial fabrics differ from conventional acoustic insulation textiles because they do not just absorb noise—they redirect it. Regular nonwoven materials like felt or cotton padding only reduce sound by damping vibrations. Metamaterial structures, however, use engineered geometry to create anisotropic sound behavior. This makes them lighter, thinner, and more effective for specific frequencies.

Another key point is that metamaterial fabrics are tunable. By adjusting structural parameters, manufacturers can target low-frequency or broadband sound control. Research published by Springer shows that layered or lattice metamaterial fabrics can reduce noise at frequencies traditional textiles cannot block.

Can These Fabrics Be Used in Fashion or Only in Industry?

The immediate applications are in construction, transportation, and defense, but fashion and wearable technology are gaining interest. For example, breathable cloaking fabrics developed by HKRITA combine cotton with acoustic metamaterials, making them light and comfortable. This opens possibilities for jackets, helmets, and accessories that block or reroute unwanted noise.

The transition to fashion requires balancing functionality with comfort. Current prototypes prove that thin, flexible fabrics are possible, but scaling them to mass production will take collaboration between textile manufacturers and research labs. Forward-thinking brands are already exploring this path, especially those targeting the urban noise pollution problem.

Where to Find Suppliers of Acoustic Metamaterial Fabrics?

Sourcing these fabrics is not the same as ordering polyester from Alibaba. The supply base is small, research-driven, and often involves licensing agreements or co-development with institutions.

The most reliable sources today are research institutes, metamaterial design companies, and specialized industrial suppliers. Working directly with them ensures authenticity and performance guarantees.

Early adopters must prepare for higher costs and longer lead times. But being among the first to access these fabrics can give buyers a strong competitive edge.

Which Institutions Are Leading in Fabric-Based Acoustic Metamaterials?

The Hong Kong Research Institute of Textiles and Apparel (HKRITA) is a global leader. Their breathable fabric-based acoustic metamaterial is lightweight, blocks low-frequency noise, and remains wearable. This innovation proves that acoustic cloaking technology can be adapted to textiles for daily use. Buyers can reach HKRITA to discuss partnerships or sample access through their innovation hub.

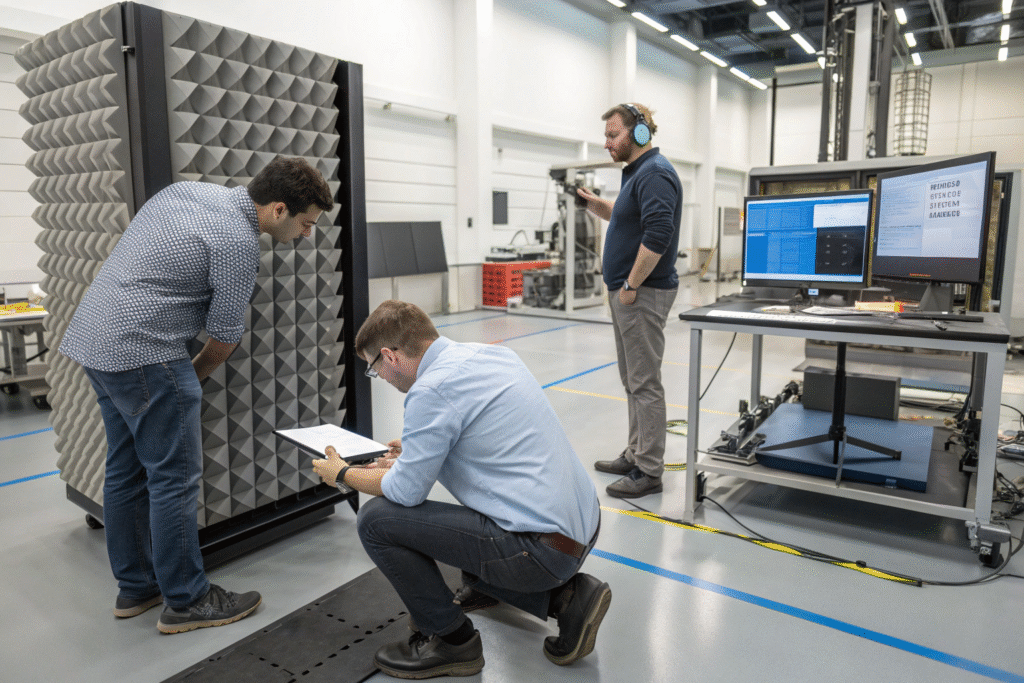

Another research-driven option is working with academic labs in Europe and the U.S., where projects on phononic crystals and transformation acoustics are active. These collaborations usually require clear research funding or joint development agreements.

Which Companies Offer Scalable Acoustic Metamaterial Products?

Two notable commercial players are Applied Metamaterials and NJHQ Acoustics Technology Corp. Applied Metamaterials offers productized noise-control solutions such as Constrained Acoustic Metamaterials (CAM) and Surface Acoustic Metamaterials (SAM). Their expertise in tailoring performance for specific applications makes them valuable for industrial buyers. Learn more directly from Applied Metamaterials.

NJHQ Acoustics Technology, on the other hand, is more focused on infrastructure-scale solutions, supplying acoustic metamaterials for power equipment and transportation. Their large-scale approach ensures stability and production reliability, which can be crucial for high-volume projects. Reference: Haythink Industry Report.

What Are the Key Sourcing Challenges?

Even though the science is solid, the sourcing journey is complex. Buyers must navigate issues like limited supply, high costs, and the gap between prototype and commercial scale.

The challenge lies in aligning your sourcing strategy with realistic applications and production capabilities. Without this, projects risk failure from overpromising or underdelivering.

The right approach is to understand limitations, set clear requirements, and work directly with developers to co-create solutions.

Why Is Large-Scale Production Still Difficult?

Scaling up from laboratory prototypes to mass production is tough. Fabricating precise lattice structures across large textile surfaces requires advanced machinery. Conventional weaving and knitting machines cannot always replicate the required microstructures. This is why most suppliers still produce small batches.

Another barrier is cost. Producing acoustic metamaterial fabrics involves high R&D investment, certification processes, and specialized equipment. This makes pricing higher than traditional fabrics, limiting adoption to industries willing to pay a premium, such as defense or aerospace.

How Can Buyers Overcome Supply Limitations?

The best strategy is co-development. Buyers who invest early in pilot projects can secure supply rights or licensing agreements. Partnering with institutes like HKRITA or companies like Applied Metamaterials allows customization and guarantees access. Another option is blending metamaterials with traditional soundproof fabrics to reduce costs while achieving partial performance benefits.

Buyers should also negotiate flexible timelines, considering longer lead times for experimental textiles. Those who manage expectations realistically will be able to integrate these fabrics successfully.

How to Prepare for Future Opportunities?

The market for metamaterial fabrics is still young, but it is growing. Buyers who prepare now will be in a better position once commercialization accelerates.

The smartest move today is to build relationships with research labs and early suppliers, while exploring hybrid fabric solutions that combine traditional textiles with metamaterial layers.

This proactive approach helps reduce risk while ensuring long-term competitive advantage.

Will These Fabrics Become Mainstream in the Next Decade?

Experts believe acoustic metamaterials will become mainstream as production technologies improve. Fabric-based prototypes already show that wearable applications are possible. As demand for noise reduction in cities and sustainable construction grows, the adoption rate will rise.

The timeline depends on cost reduction and scaling success. Just like recycled polyester or organic cotton, acoustic metamaterials may take 5–10 years to become accessible for mainstream fashion and interiors.

What Should Buyers Do to Stay Ahead?

Buyers should monitor industry publications, attend textile innovation fairs, and establish early partnerships. Joining programs such as the Innovation Hub of HKRITA or following companies like Applied Metamaterials gives first-hand access to new developments. Strategic buyers should also request samples, run tests, and prepare marketing strategies that highlight the unique benefits of metamaterial fabrics.

The goal is not just to wait for the market but to actively shape it. Early adopters can differentiate themselves and win contracts in competitive industries like sportswear, smart textiles, and architectural design.

Conclusion

Metamaterial acoustic cloaking fabrics are a revolutionary category of textiles. Unlike traditional noise-control fabrics, they guide and bend sound, creating new possibilities in wearables, interiors, and large-scale infrastructure. Sourcing them today means working closely with research institutes like HKRITA and specialized suppliers such as Applied Metamaterials and NJHQ Acoustics Technology.

For buyers, the keys are clear requirements, co-development agreements, and patience with scaling challenges. The companies that invest early will gain a long-term competitive edge as this market matures.

If you are looking to source or co-develop metamaterial acoustic fabrics, we invite you to work with us at Shanghai Fumao. We can support your orders with advanced R&D, global logistics, and reliable quality control. For inquiries, please contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next project.