Sourcing implantable textiles that comply with ISO 10993 is no small task. Medical-grade fabrics are not only expected to perform flawlessly inside the human body but also to meet rigorous safety, durability, and regulatory requirements. The stakes are high—whether you are designing vascular grafts, hernia meshes, or other implantable devices, your choice of fabric directly impacts patient safety, product approval, and market trust.

When sourcing these materials, you need to balance performance, compliance, and supplier reliability. From understanding the certification process to identifying trustworthy manufacturing partners, there are specific steps to follow. In this guide, I’ll share insights from years in textile manufacturing to help you navigate the sourcing process with confidence.

As a fabric manufacturer with decades of experience in high-performance materials, I’ve seen how the medical textile sector requires a different mindset—one that blends precision engineering, cleanroom discipline, and regulatory awareness. Let’s dive deeper into the core factors.

Understanding ISO 10993 Standards for Medical Textiles

ISO 10993 is the gold standard for evaluating the biocompatibility of materials intended for medical use, especially those that come into direct or indirect contact with the human body. For implantable textiles, compliance ensures that the fabric does not release harmful substances, cause toxic reactions, or provoke immune responses over long-term exposure.

What Tests Are Required Under ISO 10993?

ISO 10993 consists of a series of biological evaluation tests. For implantable textiles, these often include cytotoxicity, sensitization, irritation, systemic toxicity, and implantation studies. Each test addresses a different safety concern. For example, cytotoxicity testing determines if the fabric’s extractables harm cells, while implantation tests assess tissue compatibility over months or years.

Long-term implants may also require genotoxicity or carcinogenicity assessments, which are more time-intensive and expensive. Selecting a supplier with an in-house or partnered ISO/IEC 17025-accredited laboratory can speed up this process significantly.

How Does Certification Impact Product Approval?

Without ISO 10993 compliance, most regulatory bodies—including the FDA in the U.S. and EMA in Europe—will not approve implantable devices. Certification data becomes a cornerstone of your device’s technical file. Not only does it ensure safety, but it also serves as a marketing advantage, showing buyers and hospitals that you’ve invested in the highest safety standards.

Selecting the Right Biocompatible Textile Materials

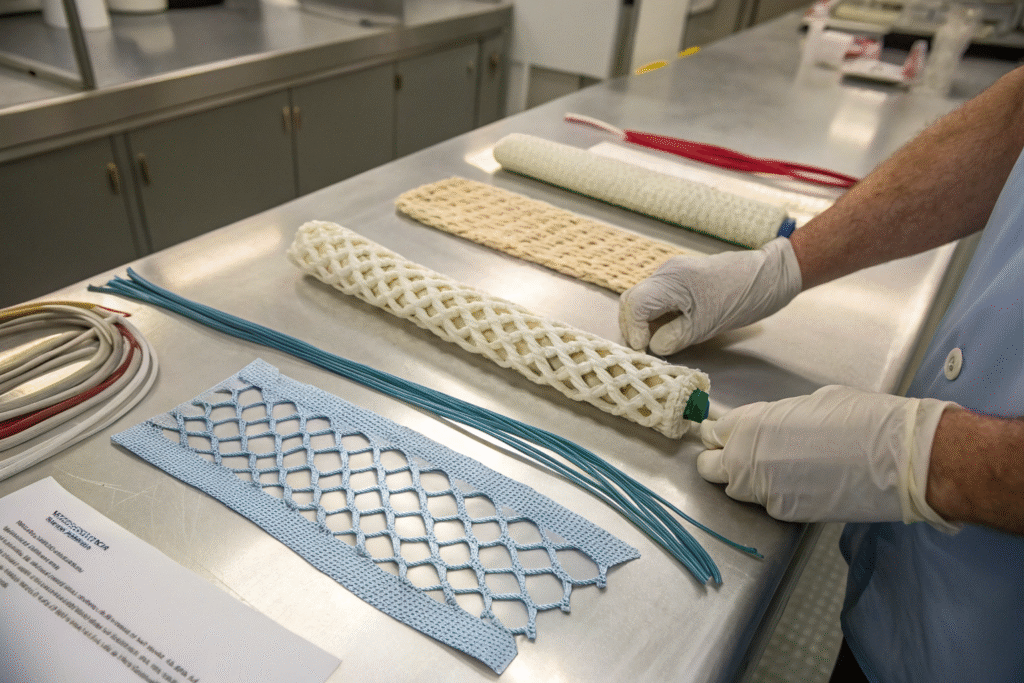

Not all fabrics are suitable for implantation. Beyond comfort and flexibility, the fiber composition, weave structure, and finishing treatments must be designed for stability inside the human body. This means no harmful degradation, predictable mechanical performance, and resistance to biological fluids.

Which Fibers Are Suitable for Implantable Textiles?

Common choices include polyester (PET), ePTFE (expanded polytetrafluoroethylene), and polypropylene for structural support, and silk fibroin or collagen-based fibers for bioresorbable applications. Each has unique benefits. For example, ePTFE is chemically inert and widely used for vascular grafts, while knitted polyester offers strength and flexibility for ligament reconstruction.

Natural fibers like silk are used in certain bioresorbable scaffolds, but must be purified to remove sericin to reduce immune reactions. The material choice will depend on whether the implant is temporary (resorbable) or permanent (non-resorbable).

What Role Does Fabric Construction Play?

Weave density, porosity, and surface texture affect tissue integration. A warp-knitted mesh may encourage cell growth for hernia repairs, while a tight woven structure can reduce bacterial infiltration. Surface modifications—such as plasma treatment—can enhance cell adhesion. Resources like the Journal of Biomedical Materials Research provide deep insights into how construction impacts performance.

Vetting and Partnering with Certified Suppliers

Choosing the right supplier is as critical as choosing the fabric itself. A capable supplier not only manufactures the textile but also manages documentation, traceability, and quality assurance.

)

)

What Certifications Should a Supplier Hold?

In addition to ISO 10993 testing capabilities, look for ISO 13485 certification for medical device quality management. This ensures the supplier’s processes meet global standards for medical products. A supplier with FDA registration is even better if you plan to sell in the U.S.

If you’re sourcing from overseas, confirm that they comply with Good Manufacturing Practices (GMP) and can provide lot traceability for every shipment.

How to Ensure Quality and Consistency?

Arrange for third-party audits and request batch testing reports. Partnering with a supplier who offers real-time QC tracking—for example, QR codes linked to test data—can greatly enhance transparency. Platforms like SGS offer independent verification services to strengthen buyer confidence.

Managing Logistics and Compliance for Global Distribution

Even after sourcing and manufacturing, implantable textiles must be shipped under strict environmental controls to prevent contamination and degradation. Documentation is as important as physical handling.

How to Ship Implantable Textiles Safely?

Use sterile barrier systems and maintain controlled humidity during transit. Temperature monitoring devices like ELPRO sensors can ensure environmental stability. For high-value shipments, tamper-evident seals are essential.

If crossing borders, confirm with your freight forwarder that they are experienced in medical device transport and can handle customs documentation under HS codes specific to medical textiles.

How to Handle Regulatory Paperwork Across Markets?

Different countries require different formats for biocompatibility documentation. The EU MDR (Medical Device Regulation) demands a detailed biological evaluation report, while the FDA uses a 510(k) or PMA process. Working with MedTech Europe or similar trade associations can help navigate market-specific requirements.

Conclusion

Sourcing ISO 10993 biocompatible implantable textiles requires a deep understanding of regulatory requirements, material science, and supply chain discipline. From selecting the right fiber and construction to choosing a supplier with the correct certifications, every step matters in ensuring patient safety and gaining regulatory approval.

If you are ready to develop your own line of medical-grade textiles with a trusted manufacturing partner, contact Shanghai Fumao today. Our Business Director, Elaine, is available at elaine@fumaoclothing.com to discuss your project requirements and provide customized solutions.