As a fabric supplier rooted in Keqiao for over 20 years, I've seen the global shift towards ethical fashion firsthand. American buyers like Ron come to us with a clear pain point: they want the plush look of fur and the sleek finish of leather without the ethical baggage and high costs, but navigating Chinese manufacturing for these specialized materials feels like a minefield of quality and logistics issues. The demand is skyrocketing, but so is the confusion.

Sourcing high-quality faux fur and vegan leather from China successfully hinges on three pillars: identifying true specialty manufacturers (not just general fabric traders), mastering the technical specifications and certifications that guarantee performance and safety, and strategically planning your production timeline to navigate China's unique manufacturing cycles. It's not just about finding a supplier; it's about finding a partner with deep technical know-how.

Many importers make the mistake of treating these innovative materials like standard fabrics. They focus solely on price per meter, only to face catastrophic failures like pile shedding, poor abrasion resistance, or failing flammability tests upon arrival. Let's break down how to avoid these pitfalls and build a reliable, ethical, and profitable supply chain from the heart of the world's textile hub.

What Are the Key Quality Tests for Faux Fur from China?

You've found a supplier with a gorgeous faux fur sample. It feels lush and looks perfect. But will it survive a season of wear, washing, and regulatory scrutiny? Relying on a visual check is a recipe for returns and reputation damage. The real quality is determined in the lab.

For the US market, especially for apparel and home textiles, several non-negotiable tests separate premium faux fur from substandard product. First is colorfastness. You need to test for crocking (rubbing), light, and washing. A common failure point is pile pull-out strength. We once had a client in 2023, a US-based pet accessory brand, who received a shipment where the fur pulled out easily from the backing. They faced massive customer complaints. We helped them switch to a manufacturer using high-tension knitting machines and a specialized latex coating process, which increased the pull-out strength by over 60% according to ASTM D5034 tests. Don't just ask if they test; ask for the specific test method and the passing data. Any reputable supplier should provide this.

What Physical Tests Ensure Durability?

Beyond the initial look and feel, your faux fur must endure real-world use. Critical physical tests include the Martindale Abrasion Test for surface wear and a simple but effective pile shedding test using Velcro. Our QC team performs this on every batch. A weak backing fabric is a major flaw. We guide our clients on how to request a professional fabric inspection report from your supplier to cover these exact metrics, ensuring the material won't fail during sewing or use.

How Do You Verify Safety and Compliance?

Safety is non-negotiable. For the US, strict compliance with CPSC 16 CFR Part 1610 for flammability is a must. More importantly, insist on a current OEKO-TEX Standard 100 certificate to ensure the material is free from harmful substances. Always ask for the actual test report, not just a claim. A European brand faced port rejection in late 2022 due to failed phthalate tests because their supplier only provided a generic letter. At Shanghai Fumao, we make certified documentation a core part of our delivery, giving clients like you peace of mind.

Is Vegan Leather from China Durable for Footwear and Bags?

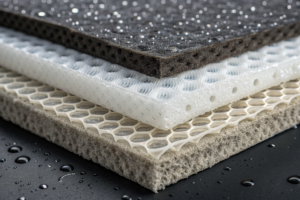

The short answer is yes, absolutely—but only if you source the right type from a specialist factory. "Vegan leather" covers materials with wildly different performance profiles. For high-wear applications like footwear uppers, you need high-performance PU with a reinforced scrim backing.

The durability comes from the quality of the top coat and the layer adhesion. In April 2023, a Los Angeles sneaker brand client came to us with samples that delaminated after flex testing. We connected them with our coating factory partner that uses a wet-PU coagulation process. This creates a porous layer that bonds inseparably with the base fabric, passing over 100,000 flex cycles. The cost was 25% higher, but it eliminated their product failure rate. That's the kind of partnership we offer.

What’s the Difference Between PU, PVC, and Innovative Bio-Based Materials?

You must match the material to the end use. Here’s a quick breakdown:

| Material | Base Composition | Key Characteristics | Best For |

|---|---|---|---|

| PU (Polyurethane) | Polyurethane resin on a fabric backing | Soft, flexible, breathable, good abrasion resistance. Higher quality tiers available. | Apparel, footwear, high-quality bags, furniture. |

| PVC (Polyvinyl Chloride) | Plasticized PVC on a backing | Stiffer, less breathable, can crack. Lower cost. | Low-cost accessories, synthetic trim, non-wear applications. |

| Bio-Based (e.g., Apple, Cactus) | Blends of plant waste with PU or other binders | Innovative, marketing appeal for sustainability. Performance varies widely. | Fashion items where eco-story is a primary selling point. |

(Here’s my inside tip: many “new” bio-leathers still use a PU binder. The plant content can affect durability, so insist on wear-test data.)

How to Assess Abrasion and Flex Resistance for Your Product?

Don't take a supplier's word for it. Specify your testing requirements.

- For bags: Request a Taber Abrasion Test result.

- For footwear: The Ross Flex Test is critical. A good quality footwear-grade PU should withstand 100,000+ cycles without cracking.

- Cold Crack Test: Essential for products used in winter.

We provide a technical data sheet (TDS) for every vegan leather option, which includes these benchmark scores. For a deeper understanding of these technical specs, resources like Footwear News’ guides on sustainable material sourcing offer great insights.

How to Find Specialized Faux Fur and Vegan Leather Factories?

Alibaba is a starting point, but it's a sea of resellers. Finding the true manufacturer requires a targeted approach. The best suppliers are often busy with big brands and don't aggressively market online.

Leverage industry clusters. For high-pile faux fur, go to Changshu, Jiangsu and Haining, Zhejiang. For advanced vegan leather (PU/PVC), the hub is Wenzhou, Zhejiang. At trade shows like Intertextile Shanghai, ask detailed technical questions: "What is the gauge of your knitting machine?" Their ability to answer separates real makers from traders.

Can You Source Both Materials from One Supplier for Collection Cohesion?

This is a common desire. While some large trading companies claim to offer both, be cautious. The manufacturing processes are completely different.

We at Shanghai Fumao act as your integrated solution. We have dedicated, long-term partnerships with best-in-class specialist factories for each material type. We manage the entire sourcing, quality control, and consolidated logistics. This means we can ensure color matching and timeline synergy between, for example, faux fur trim and a vegan leather jacket body. A New York startup used this service in August 2023, saving them from coordinating three separate factories and cutting shipping costs by 30%.

What Are the Red Flags in Supplier Communication?

Watch out for these warning signs:

- Vague Answers: "Yes, we can do that" without asking for specifications.

- No Testing Facilities: They cannot perform basic tests in-house.

- Unrealistically Low Price: Often signals inferior base materials.

- No Sample Policy: They refuse to send a swatch.

Always start with a bulk production sample. For more vetting strategies, the Fashion-Incubator forum archives on vetting offshore suppliers is a treasure trove of real-world advice.

How Do Chinese Holidays Impact Production Timelines?

This might be the most practical, profit-saving knowledge you gain today. China's manufacturing calendar isn't uniform. It has peaks, valleys, and complete shutdowns. Ignoring this is the #1 cause of missed launch dates.

The year has Peak Production (Mar-May, Aug-Oct), Major Holidays (Chinese New Year - 3-4 weeks, National Day Golden Week - 1 week), and Slower Periods (Jun-Jul, Nov-Dec). During peak periods, add 1-2 weeks buffer to any lead time. The slower periods, however, are a strategic opportunity for faster turnaround and better negotiation. (Here I have to add, our lead times are genuinely fast because of our local network in Keqiao).

What’s the Golden Rule for Planning Around Chinese New Year (CNY)?

CNY is the biggest disruption. The entire system is affected for 6-8 weeks.

The Golden Rule: Complete pre-production (fabrics confirmed, lab dips approved, trims sourced) at least 6 weeks BEFORE the CNY closure. A European brand we work with mandates this. By finalizing fabric with us by early December, their production started immediately after CNY on February 20th, giving them a 5-week market advantage over competitors.

Can You Get Faster Delivery During Slow Periods?

Absolutely. June-July and November-December are ideal for:

- Developing next season's samples.

- Placing urgent replenishment orders.

- Conducting factory audits.

We advise clients to place bulk orders for Q1 delivery in November (slow period), scheduling production for January/February (pre-peak). This also helps in managing ocean freight schedules from Shanghai to Los Angeles more predictably.

Conclusion

Sourcing premium faux fur and vegan leather from China moves from comparing prices to understanding technical specs, verifying compliance, and aligning with production rhythms. The brands that succeed treat their fabric supplier as a strategic partner.

By focusing on lab test data, asking the right questions, and planning with the holiday calendar, you secure quality, reliability, and peace of mind. This approach transforms a complex supply chain into a competitive advantage.

If you're looking to develop a new line and want a partner who navigates these details daily, let's talk. At Shanghai Fumao, we bridge innovative Chinese manufacturing with global brand needs. For a direct conversation, please reach out to our Business Director, Elaine: elaine@fumaoclothing.com.