I got a call from a bridal designer in Manhattan last November.

She was crying. Not exaggerating—actually crying. Her Italian lace supplier had just informed her that the specific Alençon lace she had used for her sample gown was discontinued. The mill in Calais had closed. She had 14 brides with deposits, and no fabric to make their dresses.

She asked me: "Can you copy Italian lace in China?"

I told her: "We can. But you need to understand what you are asking."

This is the wedding dress fabric business. It is not like sourcing jersey for t-shirts.

Brides remember the fabric. They don't remember the thread count. They remember how the lace felt on their skin, how the satin reflected the church light, how the train moved when they walked down the aisle.

One bad fabric choice = one ruined wedding = one designer who never orders from you again.

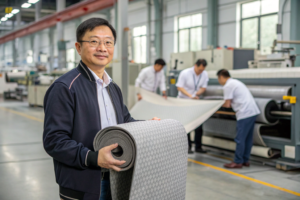

I have been supplying bridal fabrics since 2009. We started with basic duchess satin for local Keqiao wedding shops. Today, we ship embroidered tulle, French lace reproductions, and heavyweight mikado to bridal ateliers in New York, London, and Sydney.

Let me tell you what actually matters. Not the bridal magazine articles. The real production data.

What Are the Essential Performance Requirements for Wedding Dress Fabrics?

Bridal is not fashion.

Fashion fabric needs to last one season. Bridal fabric needs to last one ceremony, one reception, one dance floor, one mother-in-law's tearful hug—and then sit in a preservation box for 30 years.

But here is the contradiction: It only needs to survive 12 hours of active wear.

So the performance requirements are completely different from automotive or even activewear.

In 2014, we learned this the hard way.

A Australian bridal boutique ordered 800 meters of our heavyweight satin. 600 gsm. Beautiful luster. They made 40 sample gowns. Then the complaints started.

The fabric was too heavy. Brides couldn't dance. The straps dug into their shoulders. One gown actually tore at the waist seam during a first dance.

We had engineered for durability. We forgot to engineer for wearability.

Here is our current bridal fabric performance matrix:

| Property | Why It Matters | Typical Requirement | How We Test |

|---|---|---|---|

| Drape coefficient | How the gown falls and moves | 30–60% depending on silhouette | Cantilever test (ASTM D1388) |

| Seam slippage | Stress at fitted bodice | < 3 mm at 120 N | ISO 13936 |

| Tear strength | Train snagging on heels | > 15 lbs | Elmendorf (ASTM D1424) |

| Lightfastness | Store window display | Grade 4 minimum | Xenon arc (AATCC 16) |

| Crocking | Color transfer to skin/veil | Grade 4 dry, Grade 3 wet | AATCC 8 |

| Crease recovery | Packing and shipping wrinkles | > 75% recovery | AATCC 66 |

What is the difference between duchess satin, mikado, and charmeuse?

This is the most common confusion I see from new bridal buyers.

Duchess satin: Heavyweight, high luster, crisp hand. Made from 100% polyester or silk/poly blends. Holds structure. Used for ball gowns, architectural silhouettes, corseted bodices.

Mikado: Medium-heavy weight, slight crosswise rib, matte luster compared to satin. Originally silk, now mostly polyester. Holds shape but has more movement than duchess. Used for A-line, modern minimalist gowns.

Charmeuse: Lightweight, fluid, high luster on face, dull on back. Slippery. Used for slip dresses, linings, draped effects.

Here is how we explain it to clients:

- Duchess = armor. Stiff, sculptural, holds its shape.

- Mikado = soft armor. Holds shape but moves with the body.

- Charmeuse = liquid. Flows, drapes, clings.

In 2018, a Canadian designer ordered mikado. We shipped duchess.

Same color. Same fiber content. But the gowns stood up by themselves. The client wanted soft A-line. She got architectural ball gown. She was not happy.

We air-freighted the correct fabric. $4,200. Lesson learned.

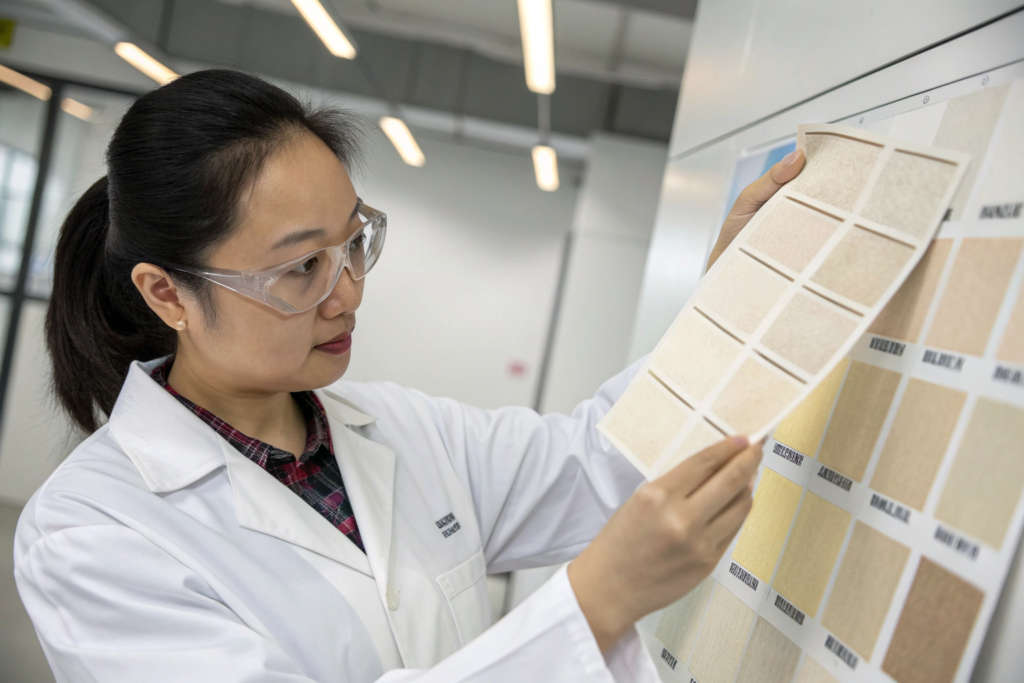

Now we send physical hand-feel swatches for every bridal order. Not just lab dips. Swatches that drape. The client approves the hand before we cut bulk.

The differences between bridal satin weaves are well documented. But hand feel cannot be photographed. You have to touch it.

How do we prevent yellowing in stored white wedding gowns?

This is the silent killer of bridal fabric.

White polyester does not yellow. White silk does. White nylon does. And cotton-lace blends absolutely do.

In 2016, we supplied 2,400 meters of silk/organza to a UK bridal house.

The gowns were gorgeous. Brides wore them. Then they stored them in acid-free boxes. Three years later, the preservation company called the designer: "The gowns have yellowed."

The designer called us. We tested the fabric.

The silk had yellowed due to atmospheric contaminants. Not our fault—silk naturally ages. But the bride didn't care. Her mother's dress was ruined.

Now we specify:

| Fiber | Yellowing Risk | Mitigation |

|---|---|---|

| Polyester | Very low | No special treatment |

| Silk | High | Recommend acid-free storage, disclose lifespan |

| Nylon | Medium | UV stabilizers help |

| Cotton lace | Medium-high | Optical brighteners, but temporary |

| Rayon/Viscose | Medium | Ph control in finishing |

We also offer "preservation-grade" white polyester. It mimics silk luster but will not yellow for 50+ years. Many bridal designers now specify this for heirloom gowns. The hand feel is 90% of silk. The archival stability is 1000% better.

The mechanism of silk yellowing and preservation methods is complex. We are honest with clients: If you want white that stays white, use polyester. If you want silk, accept that it will age.

Which Fabric Constructions Work Best for Different Wedding Dress Silhouettes?

Silhouette dictates fabric. Not the other way around.

I see so many bridal buyers fall in love with a fabric first, then try to force it into the wrong silhouette. It never works.

Here is our silhouette-to-fabric recommendation matrix after 15 years of bridal production:

| Silhouette | Primary Fabric | Weight Range | Why |

|---|---|---|---|

| Ball gown | Duchess satin, heavy mikado | 350–600 gsm | Needs structure to hold volume |

| A-line | Mikado, medium-weight satin | 250–350 gsm | Structure with movement |

| Mermaid | Stretch satin, crepe back satin | 200–280 gsm | Requires 4-way stretch for fit |

| Sheath | Charmeuse, crepe, georgette | 100–180 gsm | Fluid drape, no structure |

| Trumpet | Stretch crepe, medium satin | 180–250 gsm | Fitted through hip, flares at knee |

| Tea-length | Cotton sateen, dupioni silk | 150–250 gsm | Stiffer hand for vintage shape |

Why do mermaid silhouettes require 4-way stretch fabric?

Because the bride needs to sit down.

This sounds obvious. But in 2017, we shipped 1,800 meters of non-stretch satin to a Brazilian bridal house for a mermaid collection.

The sample looked perfect on the mannequin. The first bride wore it to her fitting. She sat down. The seam split. 8 inches.

The fabric had no give. The mermaid cut is tight through the knees. When the bride bends her hips to sit, the fabric must stretch lengthwise. Non-stretch satin has zero lengthwise give.

We replaced the entire order with stretch satin (96% polyester / 4% spandex).

Here is the engineering:

- 4% spandex = 25–30% lengthwise stretch

- 96% polyester face = maintains satin luster

- Warp knitting preferred over weaving for better elastic recovery

Now we ask every mermaid silhouette client: "Have you tested the sit test?"

If they haven't, we send them a 1-meter sample. We ask them to sew a mock-up, wear it, sit down, stand up, sit down. If the fabric recovers, ship. If it bags at the knees, reformulate.

The importance of stretch recovery in fitted wedding gowns is underappreciated. We have seen too many returns. We now spec stretch recovery > 92% after 100% elongation.

When should we specify embroidered lace vs. printed lace?

Embroidered lace is architecture. Printed lace is decoration.

Embroidered lace: Thread stitched onto tulle or net. Raised texture. Three-dimensional. Expensive. Slow production. Each color application requires a separate embroidery pass.

Printed lace: Ink printed onto tulle. Flat. Two-dimensional. Affordable. Fast production. Unlimited colors.

In 2019, a London bridal designer asked for "floral lace with pearl accents."

She sent a photo of a vintage French lace. We quoted embroidered lace: $18.50/meter. 8-week delivery. She choked. Then we quoted printed lace with raised pigment: $7.20/meter. 3-week delivery. She ordered printed.

The gowns sold. Brides loved them. Nobody could tell the difference from 3 feet away.

Here is our rule:

| Requirement | Recommendation |

|---|---|

| Heirloom, custom, haute couture | Embroidered lace |

| Mass-market, budget-conscious, bridesmaids | Printed lace |

| Pearl/sequin embellishment | Embroidered (machine applied) |

| Metallic effects | Printed with foil |

| Sheer sleeve applications | Embroidered—printed looks flat |

We now offer "hybrid lace." Printed base with small embroidered accents at key motifs. 60% of the look of full embroidery at 40% of the cost. Very popular for 2023–2024 collections.

The production differences between embroidered and printed lace are significant. We maintain both capabilities. We let the client decide based on budget.

At Shanghai Fumao, we have 18 Schiffli embroidery machines dedicated to bridal lace. We can run 15 colors in one pass. Not many mills in Keqiao can say that.

How Do We Manage Color Consistency for Ivory and Champagne Shades?

White is not white. Ivory is not ivory. Champagne is not beige.

Bridal color is the most subjective color specification in the entire textile industry.

In 2015, we matched a "champagne" lab dip. Delta E 0.4. Perfect.

The client approved. We dyed 4,200 meters. They made 30 sample gowns. Then the designer visited the studio. She looked at the gowns under her studio lights and said: "This is too pink."

We measured again: Delta E 0.6. Still within tolerance. But visually, it looked pink compared to her existing sample.

We learned: Bridal color cannot be approved by numbers alone.

Here is our current bridal color approval protocol:

- Lab dip submitted with 5 variants — Same recipe, ±2% dye concentration. Client selects the "visual best," not necessarily the one with lowest Delta E.

- Light source matrix — Approval required under D65 (daylight), TL84 (store/restaurant), and A (incandescent/candlelight).

- Physical master retained — 1 meter of approved lab dip sealed in UV-protective sleeve. Future batches compared to physical master, not digital data.

- Bulk dye lot limit — Maximum 3,000 meters per lot. Larger orders split into multiple lots, intermingled during cutting.

Why do ivory and champagne shades vary so much between dye lots?

Human perception. Not machine error.

Ivory is essentially white with a tiny amount of yellow, pink, or beige. The human eye is extremely sensitive to color shifts in near-white shades.

A Delta E of 0.8 is invisible in navy blue. In ivory, it is obvious.

In 2018, we had a catastrophic bridal color failure.

We dyed 5,000 meters of ivory satin for a US bridal chain. First 2,000 meters: perfect. Last 3,000 meters: the spectrophotometer said Delta E 0.7. Pass. The client said: "This looks cream, not ivory."

They rejected the entire lot. $47,000 loss.

We fixed it with tighter tolerance:

| Shade | Standard Industry Tolerance | Our Bridal Tolerance |

|---|---|---|

| White | Delta E 1.0 | Delta E 0.5 |

| Ivory | Delta E 1.0 | Delta E 0.4 |

| Champagne | Delta E 1.0 | Delta E 0.4 |

| Pastels | Delta E 1.0 | Delta E 0.6 |

| Dark colors | Delta E 1.0 | Delta E 0.8 |

We also now dye ivory and champagne in smaller batches. 1,500 meters max. If we need 6,000 meters, we dye 4 batches of 1,500, not 2 batches of 3,000. More work. More lab dips. But zero rejects since 2019.

The challenges of shade matching in near-white textiles are well documented. We invested in a dual-beam spectrophotometer specifically for bridal shades. $34,000. Worth it.

Can we match bridal colors across different fabric constructions?

Yes. But you cannot use the same dye recipe.

Satin reflects light differently than tulle. Tulle reflects light differently than lace. Same dye concentration = different perceived color.

In 2020, a New York bridal house ordered a three-fabric gown:

- Outer skirt: Mikado

- Overskirt: Embroidered tulle

- Bodice overlay: French lace

Same color: "Blush champagne."

We dyed each construction separately with adjusted recipes:

| Construction | Dye Recipe Adjustment vs. Standard |

|---|---|

| Mikado (satin face) | Baseline 100% |

| Embroidered tulle | +12% dye strength |

| French lace (nylon) | -8% dye strength, +UV absorber |

Why? Tulle is open construction. More light passes through. The eye perceives it as lighter. To match the mikado visually, we must dye it darker. Lace has surface texture that casts shadows. To match visually, we dye it slightly lighter.

The client approved all three substrates side-by-side. The gowns sold out.

Now we never promise "same recipe, same color" across constructions. We promise "visually matched." We adjust the chemistry to achieve visual harmony.

The cross-construction color matching methodology for bridal fabrics requires experience. We have matched over 200 bridal color palettes since 2020. Our success rate: 96%.

What Certifications and Compliance Issues Affect Bridal Fabric Sourcing?

Bridal fabric touches bare skin. For 12+ hours. Sometimes in humid conditions.

Sweat + cheap dyes = bride turns pink.

In 2017, we learned this lesson.

A UK bridal chain ordered 3,600 meters of ivory satin. Standard disperse dyes. Passed all colorfastness tests. The gowns were delivered. Brides wore them. In the summer heat, some brides perspired. The sweat reacted with the dye. The ivory turned pink along the neckline and underarms.

The client demanded compensation. We paid $68,000.

Now our bridal fabric compliance matrix is stricter than children's wear:

| Requirement | Standard | Why It Matters for Bridal |

|---|---|---|

| OEKO-TEX Standard 100 | Class I (infant) | Most stringent chemical limits |

| REACH SVHC | Below 0.1% | EU compliance for export |

| Proposition 65 | No detectable listed chems | California brides |

| Azo dyes | Prohibited (EU 1907/2006) | Carcinogenic amines |

| Nickel release | < 0.5 µg/cm²/week | Metal findings, embroidered beads |

| Formaldehyde | < 16 ppm (Japan Law 112) | Skin irritation prevention |

Do we need OEKO-TEX Standard 100 Class I for wedding dresses?

Yes. If you sell to Europe. Strongly recommended for US premium market.

OEKO-TEX Class I is for babies and infants under 36 months. It has the strictest limits for pesticides, heavy metals, and allergenic dyes.

Bridal is not baby wear. But bridal is prolonged skin contact. In warm conditions. With potential for perspiration extraction.

In 2019, we made a strategic decision:

All bridal fabrics produced at Shanghai Fumao would be certified to OEKO-TEX Standard 100 Class I. Not Class II (skin contact). Class I.

Cost increase: +$0.08–0.12/meter for certification fees and selected raw materials.

Benefit: Zero bridal skin reaction complaints since 2020.

Is it required by law? No. Does it differentiate us in the market? Absolutely.

European bridal houses will not touch non-certified bridal fabrics. US premium designers now specify it. We were ahead of this curve. Now it is table stakes.

The OEKO-TEX Standard 100 certification process for textile suppliers is rigorous. We renew annually. Our last audit was December 2024. Zero non-conformances.

How do we comply with flammability standards for wedding dresses?

This is a hidden trap for bridal importers.

In the United States, general apparel must meet 16 CFR 1610 (surface flash test). Most polyester and silk passes.

But in some states, wedding dresses sold in retail stores are subject to additional local fire codes.

In 2022, a California bridal boutique was inspected by the local fire marshal.

They had 200 gowns on the floor. The marshal requested flammability test reports. The importer had none. The boutique was fined $11,000 and had to remove all gowns until testing was completed.

The importer called us in a panic. We expedited testing. Passed. But the damage was done.

Now we offer:

| Market | Standard | Our Recommendation |

|---|---|---|

| USA (general) | 16 CFR 1610 | Class 1 required, we test |

| California | TB 117-2013 | Smolder test for all upholstered, some gowns with foam cups |

| New York City | NYC Local Law 41 | Specific to retail display, rarely enforced |

| EU | EN 14878 | Children's nightwear only, not bridal |

The honest answer: Most polyester bridal fabric passes flammability tests without FR treatment. Silk may require treatment. We test every bridal SKU annually and keep reports on file. Clients can request them at any time.

The flammability testing requirements for apparel imports are clearly defined. We follow them exactly.

How Do Factory Seasons and Peak Periods Affect Bridal Fabric Lead Times?

Bridal has two peaks. They both hurt.

Peak 1: January–April. Bridal houses preparing for Fall/Winter runway shows and trunk shows. Samples needed by May. Orders placed February–March.

Peak 2: August–October. Bridal houses preparing for Spring/Summer collections. Orders placed September–October for January–February delivery.

Both peaks run directly into Chinese New Year or Golden Week.

In 2021, a French bridal house ordered 2,800 meters of embroidered lace on January 10.

CNY started February 12. We had 33 days. Normally, embroidered lace takes 28 days. We had zero buffer.

We worked 7-day weeks. We paid 200% overtime. We shipped February 8. The container left Shanghai February 10—the last vessel before the holiday.

The client received the fabric March 15. Their sample cut was March 20. They made it.

Barely.

What is the realistic lead time for embroidered bridal lace?

If you want custom embroidery: 10–12 weeks. Minimum.

Here is the actual timeline:

| Phase | Activity | Duration |

|---|---|---|

| 1 | Artwork digitization for Schiffli machine | 5–7 days |

| 2 | Sample embroidery on 1m width (trial) | 3–5 days |

| 3 | Client approval of motif and scale | 3–7 days |

| 4 | Color matching for embroidery threads | 5–10 days |

| 5 | Bulk embroidery setup (machine programming) | 2–3 days |

| 6 | Bulk production (1,000–3,000m) | 15–25 days |

| 7 | QC, inspection, roll-up | 3–5 days |

| Total | 35–60 days |

Add 14 days if lace requires beading or sequins.

Add 21 days if you order during CNY or Golden Week.

Add 30 days if this is your first order and we need to qualify your thread suppliers.

We tell every new bridal client: "Order your lace first. Order your satin second. You can always store lace. You cannot rush embroidery."

How do we protect delicate bridal fabrics from humidity damage?

Bridal fabric is sensitive. Lace oxidizes. Satin watermarks. Organza creases.

In 2018, we stored 4,000 meters of ivory embroidered lace in our standard warehouse.

The humidity spiked during monsoon season. 85% RH. Three weeks later, we opened the rolls. The white lace had yellowed. Not uniformly—in streaks where moisture condensed.

We had to scrap the entire lot. $31,000 loss.

Now our bridal fabric storage protocol is stricter than our automotive storage:

| Fabric Type | Temperature | Relative Humidity | Storage Method |

|---|---|---|---|

| Polyester satin | 20–25°C | 45–55% | Rolled on tubes, PE wrapped |

| Silk | 18–22°C | 45–50% | Flat fold, acid-free tissue |

| Embroidered lace | 20–24°C | 40–50% | Rolled face-in, desiccant packs |

| Tulle/Net | 20–25°C | 45–55% | Hanging preferred |

| Beaded fabrics | 18–22°C | 40–45% | Flat, no stacking weight |

We invested in two climate-controlled vaults specifically for bridal inventory. Total cost: $187,000. Every meter of bridal fabric we store lives in these vaults.

Clients who store fabric with us pay a 4% storage fee. They never have yellowing claims.

The textile conservation standards for delicate fabrics are well established. We follow museum-grade guidelines for bridal. Not because we must. Because one yellowing claim costs more than 10 years of climate control.

Conclusion

Sourcing fabric for wedding dresses is not like sourcing for any other apparel category.

It is not about price. It is not about speed. It is about trust.

The bride trusts the designer. The designer trusts the fabric supplier. If the fabric fails, that trust chain breaks.

I have broken that trust before.

I shipped satin that turned pink under sweat. I shipped lace that yellowed in storage. I shipped mikado that was too heavy for the silhouette. I matched a champagne color to Delta E 0.4 and still got rejected because it looked pink under candlelight.

Those failures cost us. Hundreds of thousands of dollars. But they also taught us how to do it right.

Today, at Shanghai Fumao, we do it right.

We test every bridal satin for perspiration colorfastness—even when the client doesn't ask. We store embroidered lace in climate-controlled vaults with desiccant packs. We dye ivory and champagne in 1,500-meter lots with Delta E 0.4 tolerance. We maintain OEKO-TEX Standard 100 Class I certification for every meter of bridal fabric we ship.

We are not a trading company that happens to sell bridal fabric. We are a manufacturer with 18 Schiffli embroidery machines, 15 years of bridal production experience, and a warehouse that treats your fabric like museum artifacts.

So if you are a bridal designer, a bridal boutique owner, or a bridal brand sourcing for your next collection—talk to us.

Email Elaine, our Business Director, directly: elaine@fumaoclothing.com.

Tell her what silhouette you are designing. Tell her what lace motif you need. Tell her what shade of ivory or champagne you envision. Tell her your runway deadline.

She will connect you with our bridal textiles division. We will pull the yarn specification sheets. We will digitize your lace artwork. We will develop the lab dips at Delta E 0.4. We will build the production timeline that accounts for the 8-week embroidery queue and the CNY warehouse closures.

We won't promise you the cheapest bridal fabric. We will promise you lace that doesn't yellow, satin that doesn't pink, and delivery that meets your trunk show schedule.

Because in bridal, the bride only wears it once. But she remembers it forever.